When building your own house with zero, preference is given to warm, comfortable and reliable projects. Until recently, buildings from bricks, foam concrete and other reliable materials that guaranteed long-term operation and complete safety were greatly popularity. Wooden buildings, so popular in European countries, were considered not reliable, not aesthetic and cheap.

What is the house on a wooden structure? House on wooden design more profitable than the traditional house. Referring to the price difference between the house on a wooden structure and a traditional house, there is no big difference. Prices are approximately the same. But as the situation has changed, the cost of the traditional house falls by about 50%, at home on a wooden structure are approximately the same as the brick or concrete.

Also offer prices for wooden housesposted on the forum. We send you our common price proposal for the types of construction and technical description of the types. We do not do projects because we have an architect with which we work for many years.

At the moment, wooden struggle gradually displaces other types due to their environmental purity and relative cheapness of projects. In addition, frame houses are particularly popular, which at their cost becomes affordable and real alternative to close urban apartments. In the areas near the city there are beautiful and practical houses, which are not inferior to apartments and brick neighbors by their qualities. For an acceptable cost in the shortest possible time, comfortable housing is erected with a significant increase in area and for the same amount.

Price wooden house An area of \u200b\u200b171 square meters. M: - 780 euros - sandwich type, "red" - 620 euros - solid wood, "red". Our prices are calculated for square. M and contain: -All items from wood - windows and windows with thermal insulation - insulation - polystyrene - grid, rippines - costumes - inner wood - if necessary - electrical installations - transport - assembly.

Do wooden houses have a big fire danger?

Prices are not included: - Sanitary and heating installations - flowering. We have the ability to perform "turnkey". In this case, only the fund is not included in the price. Note that we work on any project of the client. The current technology is very advanced and, as a rule, according to people who proceed, if the rules are met, there is no danger of fire.

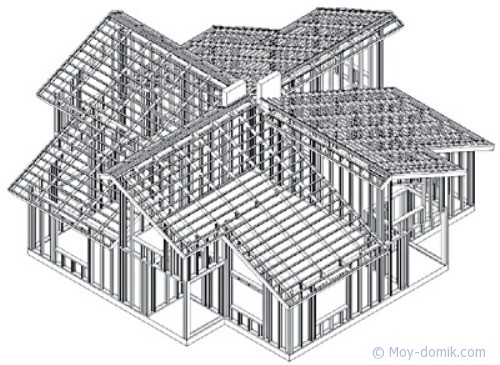

In many nearby countries technologies frame construction We got great distribution and recognition for a long time. To understand the principles of frame construction and make sure its functionality and practicality, it is necessary to identify all the pros and cons of technology and compare it with the rest of the construction of houses. First of all, it is necessary to understand what is frame house And what materials will be needed for installation.

How long do these houses have wood structure?

It is said that the biggest reason for the outbreak of the fire is non-professional electrical installation. Houses on a well-structured wooden structure have a duration of more than 100 years.

Is there any danger that the mold, mushrooms and insects will be applied on a wooden

Builders say that there are no such risks, since wood is treated with environmental substances of a wide range of action for these possible pests.What advantages have a house on a wooden design?

Views of people at home with wooden structure

Energy efficiency Low assembly time optimal humidity. . I built my house on a wooden design. Yes, the biggest problem is a problem with work. Foundation: take care of leaks and water supply. Pump pump, do not scratch! The builder will show you the work he did, and supported the connection with his former customers. Great caution when installing - you can do it with subcontractors.What is the frame house and its species depending on the materials?

The concept of "frame house" is worth perceive literally. The building will indeed consist of an internal frame that will be shifted from the inner and outer side with special materials. For the outer and inner skin, both sheet materials (CSP, OSB and plywood) are used (CSP, OSB and Plywood) and the molding (block house, lining or imitation of timber). The insides of the walls are filled with any insulation - glass gamble, mineral wool, polystyrene foam or foam. The main load of the building is distributed on the frame, which can be both wooden and metallic, although the first option is used much more often.

Finishing: highlights 50% of the budget. This eliminates friends and relatives who helped me, only artisans called and paid. If you put them, ultrasound will not pass through the walls. In the structure and on the foundation I had "craftsmen", then on plasterboard, installation. I am the owner of the house of this type, that is, a wooden structure with a thickness of 12 mm, isolated from the outside with a polystyrene by 10 cm, and on the inside of mineral wool 20 cm plus drywall.

I live in winter, where she lasts 4 months. Houses are made of wood and hundreds of years continue. They are cheaper, better isolated and warmer. It can cost after 6 months, and the problem with mold does not exist. Heating is on gas, and therefore in winter the air is dry, a humidifier is required. In the summer there is air conditioning, which highlights a certain humidity of the preamble lakes Toronto. In Sweden, the same thing is done in wooden housesAnd winter is serious and there. Recommended for those who want to do the house.

Frame house Mounted directly on the plot from specially selected piece blocks - materials. Eated in accordance with the framework technologies of the house is resistant to deformations, have high rigidity and long service life. External construction of the structure of sheet materials helps to strengthen common design and achieve all recommended parameters.

Among the technologies of frame construction distinguish two species that are classified depending on the method of the building of the building:

In both cases, the cost of home installation will be approximately the same, but in the first version it is necessary to pay extra for each type of work - the trim, insulation and finishing, while in the second cost will increase due to the quality of the material.

Advantages and disadvantages

Of course, when choosing a project, an individual comfortable and durable house will be erected, many factors are taken into account. I want to build not only inexpensively cost, but also served for a long time with minimal costs. That is why when choosing a material and a project, it is worth paying special attention to considering the advantages and disadvantages of construction technology and its incarnation.

Arguments in favor of frame construction:

- Frame technology It is considered the most economical to build individual houses;

- The small weight of the house helps reduce the cost of the foundation;

- Fast installation allows you to put a structure to operation after a few months;

- Wooden frame structures have a high energy saving coefficient and help significantly reduce heating costs. In addition, in winter conditions, the house quickly warms up, and the low thermal conductivity of the structure allows you to make walls with a thickness of 15 cm;

- Simple and comfortable houses have a high heat shield, resistant to deformations and have high rigidity. They also do not settle, which allows producing interior decoration Immediately after installing the structure;

- The surface of the material of the casing can be used without additional processing, which makes it possible to significantly reduce the costs of the finish. From the inside the frame house is trimmed with plasterboard, which also reduces the cost of internal repair.

Despite all the advantages and long-term construction period, framework technologies, like other types of construction, still have their drawbacks. Therefore, it is necessary to familiarize yourself with them before the start of design, to fully ensure that framework technology satisfies the wishes.

Disadvantages of frame construction:

- For mounting frame house Wanted highly skilled workers who will strictly comply with technology, assembly rules and use a special tool;

- An increase in the project will incur additional costs. Basically, frame construction is used for small houses with a maximum height of three floors and a long no more than 20 meters;

- Wooden frame requires additional impregnation and treatment with antiseptics and protection against fire.

After the choice is still made in favor of frame construction, it is necessary to determine the material for the manufacture of the foundation of the house.

Options for maccas

Despite the fact that European houses are almost completely erected from wood, it is worth considering and a metal version of the frame, which has significant advantages. As a metal base, thermal fighters, which has a high fire resistance, is not subject to corrosion and influence of fungi, significantly reduces the weight of the structure and serves more than 100 years. The wooden frame has a service life of up to 60 years and is influenced by all of the above factors.

It is worth paying attention to the fact that the construction of any kind of frame is fraught with consequences. Bad assembly will significantly reduce the life of housing, and unreliable seams of seams will reduce the thermal conductivity of the structure. Therefore, it is better not to save and entrust the construction of professionals.

Production of a foundation for a frame house

As you know, the foundation is the basis of the structure and affects its service life. Construction technology frame houses It provides for the use of three types of foundation - tape, columnar and tile. Choosing the foundation you need to pay attention to two main factors:

- Weight construction;

- The structure of the soil.

For the landing or or etched soil, a tile foundation will be the ideal option. It helps evenly distribute the load on the ground, in contrast to the column and belt Fundament. To improve such a reason, it is necessary to remove the upper layer of the soil, thereby reducing the likelihood of its compression, and then dug the pit, create a sandy pillow and put the stove.

For another soil, both tape and foundation columnalwhich is able to withstand the load of the frame home and ensure its durability. It is very important after analyzing the foundation correctly calculate the weight of the design and, based on it, select the desired type.

Types of roofing

In frame construction The same types of roof are used as in brick and wooden houses. Depending on the roofing project and the features of the attic room of the roof can be attic, duplex or multisciprough. Especially popular for residential buildings use duplex and children's roofs. These designs do not represent difficulties in the installation and are covered with any material. The roof must match the climate and confront the winds and precipitation well.

When choosing roofing material For frame houses, it is necessary to take into account the architectural features of the project, the slope of the design, the life of the material and the financing of the project. To improve the roof, such a coating is perfect:

- Metalo tile. It is used to finish a roof with a tilt of 25-45 °. Service life with due care is 35 years;

- Bituminous slate or ondulin is used for a roof with a slope of 35-40 ° and serves at least 50 years;

- Asbic cement slate when painting serves to 40 years, without additional processing up to 30. It is used to finish the roof with a slope of 25-45 °;

- Roofing steel is used for roofs from 18-30 ° slope. The service life of the material is up to 30 years.

The selection of the roof should be carried out taking into account the arrangement of the attic room. If it is planned to be residential, then additional insulation and careful development of roofing framework will be required.

Procedure for the construction of a skeleton house

A clear observance of the order will ensure the correctness of the work and will help take into account all the details. This algorithm gives a guarantee that the house will be mounted in all construction standards and serves a long time.

To begin with, it is worth choosing an optimal place. For construction, it is required to choose the optimal soil and the level of groundwater location, take into account all climatic features Places and location of communication systems. After that, you can mark the markup and bookmark of a suitable foundation. When installing a wooden frame in the foundation, two crowns are stacked from the processed timber for which mounted wooden frame. When building a metal frame, this operation is not produced.

Then the framework of the frame and its outdoor casing. During the installation of the trim, windows and doors are installed. Due to the fact that the house is not deformed and does not sit down the installation of windows can be carried out directly during construction. At this stage, insulation is carried out if the finished shields were not used during the construction, which at the moment of the inner sheat simply closes with plasterboard.

Well, when the entire frame is assembled and trimmed, the inner partitions are collected, floors and ceilings are placed, communications are held. Lastly, the roof is mounted and an internal and external finish is made.

Frame construction It is not only the most popular and inexpensive, but also fully provides home durability, functionality and comfort. Subsequent operation costs are minimized due to insulation and high heat thermal conductivity. A huge advantage is the rapid construction and commissioning of the building, as well as the durability of the high environmental friendliness of materials that help create cozy and useful housing for the minimum term.

Video about the construction of a skeleton house

If you want to build a house as quickly as possible and relatively cheap, then you should prefer frame technologies. The sander has its advantages, thanks to which these buildings are very popular. However, you should not neglect the disadvantages that any structures have. The technology of frame construction is quite simple, so you can easily build a house yourself. To choose the right to choose the technology on which your frame house will be erected, it is necessary to study the features of each of them.

Advantages and disadvantages

First of all, it is worth listed, what pluses and cons have frame buildings. The construction technology of the frame house allows you to get facilities that have the following advantages:

- Frame buildings are quite warm and this, despite the small thickness of the walls. The whole thing is that the main part of the wall construction is covered with thermal insulation material, and special methods of connecting nodes and parts allow you to avoid the formation of cold bridges.

- The cost of exploitation is small. Due to the high tightness of the house and the good thermal insulation qualities of the walls on heating such a building, some means goes away, because heat in the room is preserved for a long time. Moreover, the walls of the framework are rather durable and durable, so do not need special care during the operation of the house.

- The technology of frame house-building is so simple that you can easily build a house yourself. At the same time, heavy construction equipment you will not need.

- The technology of the construction of the frame house is relatively inexpensive, so by purchasing typical projects, you can significantly save on construction. Additional savings you will receive on the construction of a foundation, which can be made lightweight due to the small specific weight of the material of the walls.

- A frame house can have any configuration and architectural style. You can build one- or two-storey house, Building with attic, garage, balcony, terrace or veranda. In any case, this house will cost cheaper than the structure of similar planning from brick or concrete. Applying a different facade finish, you will get completely different structures in style.

- You will spend 2-3 months on the independent construction of the house on the frame technology. If the construction of the construction to instruct the team of qualified workers, then construction will take even less time (a few weeks). Since the construction does not give a shrinkage, fulfill the finish at home and you can approach it immediately after the construction.

- You can lead at any time of the year (even in winter), because in the process of the construction process there are no "wet" processes. The only thing to do to cold weather is to equip the foundation.

- In the frame house, it is much easier to perform a hidden gasket of engineering communications.

- Frame buildings can be used as seasonal accommodation homes. The thing is that the design of walls with ease will withstand the winter period without heating. The walls will not behave, they will not be swarming, they will not redeem.

Very often you can find the opinions of specialists about the fact that frame houses, the construction technologies of which we describe in our article have many drawbacks. However, it really really judge by:

- Often you can hear the opinion that the main lack of a stemman is the impossibility of redevelopment after the construction. However, this statement is valid only for frame-shield houses. The frame house, erected by framework, can be re-posted, because light partitions are not supporting structures.

- The view that the skeleton building can be built no above one floor - delusion. Really, shielded houses It is not recommended to do two-storey, but the attic floor you can afford. If you need a two-storey house, select the framework of the construction technology.

- The myth that the frame house has a short service life (not more than 75 years), you can easily debunk. At the end of this period, the house needs to be repaired. However, the thing is that even a house from any other material needs to be repaired and replacing some parts, for example, roofing. Since the frame of such a house is reliably protected from any weather influences, the construction can serve until 100 years.

- Previously, it was believed that the sump was not very warm, but the framework technology is improved over the years, new thermal insulation materials, efficient winders and vapor barrier membranes appear, so now in the thermal insulation qualities of such a house should not be doubted.

- The only thing that is true is that noise protection at the skeleton house is slightly lower than that of brick or stone buildings.

Varieties of technology

We will list the most common technologies for the construction of frame houses:

- Dock technology;

- frame buildings in canadian technology (houses from sip-panels and construction on the platform system);

- houses in german technology (factory sets for the shield structure);

- phagging technology;

- framework construction.

If you decide to build a house frame, construction technology may differ slightly, so you should consider in detail the features of each framework.

Doc Technology

Technology Doc is the construction of a house with a double volume frame (dock). Design and construction of such houses is justified in the conditions of regions with a harsh climate. The main distinguishing features of the structures rated by this technology are the following points:

- Additional heat and comfort in the premises of the house are achieved due to the fact that in the design of the walls there are completely lacks of cold bridges. Due to this, the service life of the house increases significantly.

- In the design of the walls there are additional measures to protect against condensate accumulation and reduction of thermal insulation qualities during operation. In particular, a special ventilation gap is used for this.

- In house-building on this technology, only high-quality materials are used.

- Frame houses on technology DOP are built only using chamber drying lumber.

- The construction adheres to European quality standards.

This achieves the special energy efficiency of the enclosing structures, as well as their strength. The main condition is the displacement of the frame racks relative to each other. After laying a basalt insulation, wooden frame racks overlap the heat-insulating material, thereby eliminating the formation of cold bridges.

Canadian Technologies - System "Platform"

![]()

Such a frame house can be assembled at the construction site or components for it can be made in factory conditions. Since the walls of the house are mounted from shields, buildings belong to the category of frame-shield houses.

Important: Shields are a design of an OSP, plywood and other sheet wood materials with thermal insulation bench inside.

They are installed on the mounted platform from lag and oriented chipboard. Shields are installed as a groove on a special platform comb. From above, all shield elements are connected to the upper strapping. Also, shields are additionally bonded. Shakes are carefully isolated by mounting foam.

As you can see, the panel mounting feature provides that each of them is simultaneously a carrier element, so the redevelopment of such a house is impossible. After mounting the walls of the house, the roof is erected, engineering communications are paved, the walls are finished.

Canadian Technologies - Sippar

- two outer layers are leaf wood material (OSP or moisture resistant plywood). Most often an oriented chip plate with a thickness of 1.2 cm;

- the thermal insulation material layer may be of different thickness, which depends on the climatic conditions of the construction region. Usually, polystyrene foam is used for these purposes.

In the ends of the SIP panel there are a groove to facilitate fixation to the brusade, which will perform the framework of the framework. The same bar is installed not only in a vertical position, but also as the upper and lower horizontal strapping of the walls.

Important: Sip panels are used not only for the formation of wall structures, but also as floor of the first floor, as well as ceiling slabs of overlaps.

German technologies

The construction of houses in German technology is different from the above methods in that the panel panels are used to build a house, which are manufactured in factory conditions. Moreover, windows and doors are already installed in them, the communication is laid, the insulation is laid, and the primary wall decoration has been completed. Overlappings are also collected in the factory.

Due to the considerable weight of one panel for its transportation and installation, you will need a lifting technique. All this contributes to the rise in price of the construction of the house. However, the principle of compounding the shields in the design of the walls is the same as in the technologies described above.

Among the disadvantages of this technology, it is worth lifying the following:

- the quality of assembly and insulation of shields in the factory conditions cannot be monitored;

- for installation and delivery you will need a construction lifting technique;

- the strength and reliability of the house is lower than that of the buildings erected by frame-framework technology.

Facrifical houses

Such buildings are built by frame-framework technology. For the manufacture of the frame of this house, a glued beam is used with a cross section of at least 15x15 cm. Then the space between the frame racks is filled with the selected material. It can be a stone, brick, leaf material with insulation inside, glass, concrete, saman, etc. So the house is going to construction site. In addition to vertical and horizontal frame racks, diagonal bonds and transverse bars are necessarily used.

The main distinguishing feature is that the frame is not hiding in the design of the walls, and the deposit is set. Moreover, it is usually painted in a contrasting color and stands out against the background of bright walls. For such houses, large glazing areas are characteristic.

Framework

This way of erection of the house is ideal for independent construction in mind the simplicity and availability of technology. For the construction of a house, you will not need construction equipment, all work is carried out on the construction site manually. The layout and design of the frame-frame house can be the most different.

The essence of the technology is that the framework of the house from the bar is first built on the construction site. Then outside it is trimmed with wood sheets. After the assembly and installation of the roof of the wall of the house are insulated from the inside and are sewn with PCP or plywood. In the design of such walls, windbarrier is necessarily used, hydro and vapor barrier membrane.