The concept of "classiness" of a suburban real estate object in the realities of the modern market suburban construction has become very conditional. However, the criteria for defining the middle class in today's Russia are also very vague. The project of a miniature cottage overlooking the bay in the Kurortny district, made by an architect "named", will be considered elite, and frame house a large area, created by the labor of a hired team, will still be an economical country house. Nevertheless, the customer today is offered a large selection of projects of country houses in a wide price range, the boundaries of which in each case are determined by the constructive type of building, the building materials used and the area of \u200b\u200bhome ownership. None of these factors are decisive, but taken together, they allow us to conditionally classify customer preferences when choosing projects country house.

Popular projects of economical houses

Currently, the most popular projects of economical houses with an area of \u200b\u200b140-200 sq. m., houses of average footage, from 250 to 500 sq. m., much less demand. Demand, in general, is the only difference between economy-class houses and the conventional average, but in both cases it is economical construction. The desire for savings also explains the popularity of ready-made projects, which are much cheaper than individual developments. Some customers skip the design and construction stages altogether, purchasing a finished house for final finishing. Which option is more profitable depends in each case on the specific conditions and circumstances. But, of course, finding a suitable project is much more realistic than an already built house. In addition, design offices are well aware of the customer's preferences: quality and reliability at minimal cost. At the same time, projects of economy-class houses cannot be called primitive - there is a great variety of design solutions due to changes in various elements of the house.

Moreover, the demand for the project is evidenced by the number of options arising on its basis. The main design principle in the "economy" format is a rational and laconic layout with a sufficient level of comfort, and during the dialogue between the designer and the customer, it is always possible to improve the project of a country house, taking into account the interests of the client.

For reasons of economy, most of the ordered projects provide for two floors in the house, and the second floor is usually made attic. The construction of the attic allows not only to maximize the full potential of the vertical structures of the building, but also to give it additional architectural aesthetics. For the attic, it is especially important to correctly calculate the size of the windows, their number and the optimal installation height. Vertical windows create a kind of "attic" twilight in the attic, so it is better to use inclined window structures. However, all such nuances must be foreseen at the design stage - this, in fact, expresses its purpose.

Our expert opinion

With regard to the orientation of houses, there is a principle: it is advisable to turn to the north auxiliary premises, for example, an attached garage, stairs, bathrooms, anteroom, storage rooms. To the south, accordingly, it is better to orient the veranda, common room, dining room. This approach is convenient in terms of keeping warm in the house, and in terms of lighting. To make it convenient to check projects according to this principle, draw for yourself a simple diagram with a plot where the cardinal points are indicated, indicate the direction of entrance to the house and arrival at the site. Keep this diagram handy when you look at projects.

Before choosing a project, try to decide on the spatial scheme of the house that you would like to implement:

- located on one floor. Such a house is convenient for communication, monitoring children. For such a house, a relatively large plot is needed. The cost per square meter is relatively high.

- ground floor and attic - a comfortable classic layout. The most economical option in terms of cost per square meter.

- on two full floors. The attic is fully used (the walls of the second floor are raised to such a height that allows the operation of the entire area, including under the roof slopes) or the house has a second floor. The classic, the most common scheme, is fully justified economically.

- on three floors. Such a layout is sometimes forced when the land plots are cramped. The disadvantage is long vertical communications: you can't run away from the first floor to the third one again.

Vladimir Tarasov, architect, general director LLC "Architectural and Design Studio" ALFAPLAN "

Economy materials

In projects small houses economy class can be provided for almost any wall materials. They are also built of bricks, but the requirements of economy are forcing the customer to abandon houses of large weight, requiring an appropriate foundation. Houses made of timber, foam concrete and aerated concrete, and even more so frame structures have less stress on the base. Expensive strip foundation replaced by pile, including screw piles.

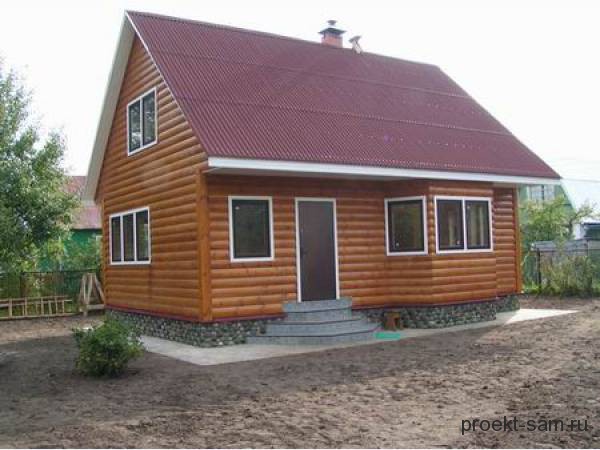

Significant market share finished projects make up frame and panel-frame houses, which are produced on production lines in the factory, after which they are transported to the construction site. Work on the construction of a house can be performed by a couple of workers without the use of special equipment. But the benefit here is not only economical construction: compared to other technologies, walls frame house have the smallest thickness, which allows you to increase the usable space of the premises. By the way, frame technology has in its arsenal a method of building from light metal structures. The economy of such a frame allows it to compete with a wooden one in price, and it is often used for the construction of the attic floor mentioned above. Based on a framework that performs the functions rafter system, insulation is being laid and roofing... The structures of maximum factory readiness are assembled without the use of a crane, and its low metal consumption allows erecting a superstructure without a significant increase in the load on bearing structures houses. "Achilles' heel" frame construction - the problem of air permeability, since the space between the racks is densely filled with insulation to exclude cold bridges and reduce the cost of heating the house. Again, the project in this case should provide for an effective combination of thermal insulation, impermeability of the outer shell of the house and its ventilation.

An important point in the design of budget houses is the thoughtfulness of the design and the optimization of material consumption. With a house size of 6 x 6 meters, it becomes possible to use construction Materials almost no residue in the floors. For the same purposes, the height of the ceilings in the room should be chosen taking into account the length of the racks. In the presence of a second floor, a multi-pitched roof allows you to use its space as efficiently as possible, in contrast to houses with a gable roof.

Finishing an economical country house

The design of the house may not take into account its decoration, but this too good way save. For example, one of the most affordable facade materials for low-rise economy-class housing is vinyl siding. In addition to its good performance properties, this material imitates the texture of brick, stone or wood. Of course, this imitation is rather arbitrary - a discrepancy is visible from a close distance, but the external appearance of the building turns out to be quite aesthetic. Not so long ago, an alternative to polyvinyl chloride panels appeared on the market - siding made of galvanized steel with a polymer coating. Fiber cement siding made from cement, water, sand and fiberglass is slightly more expensive. In general, the environmental friendliness of the material today is paid attention to in any price segment of construction. In budget houses, as a rule, artificial facing materials are used, which are much cheaper than natural ones. Moreover, for the manufacture of artificial finishing materials either natural ingredients or neutral ingredients are used. For example, artificial stone is made from sand and cement, adding various dyes and fillers. Fiberglass is absolutely environmentally friendly, another option for imitating natural stone finishes. During the manufacturing process, the molten mass is poured into appropriate shapes that repeat the relief different types natural stone.

The advantage of artificial materials is also expressed in the ease and simplicity of installation. The back side of cladding panels and tiles is flat, so they can be easily attached to any surface. And fiberglass panels are fastened using self-tapping screws or sealants, which gives a gain in time and cost in comparison even with artificial stone. True, their price is higher, but this is already a matter of choice.

Text: Eduard Dominov

Consultant:

LLC "Architectural and Design Studio" ALFAPLAN "

Country building # 3 (79), 2013

Economy class house projects are a budget option for a high-quality, durable and beautiful home. In addition, such projects can be used by construction companies for the construction of cottage villages.

Economy-class cottage villages

What to build an inexpensive house from

Based on your preferences and financial capabilities, you can choose perfect material for building your own home.

- One of the most popular materials is wood, which can be used to build a reliable, warm and environmentally friendly structure.

- An economy class brick house project is the best choice for people who value the safety and durability of their home.

- Aerated concrete houses perfectly combine acceptable cost and high quality.

- Projects frame houses economy class allows you to get a solid and reliable home in the shortest possible time without unnecessary spending.

Inexpensive brick house project

Economy class house projects - advantages

Many construction companies offer their clients projects of inexpensive houses that have a number of advantages:

- short construction time;

- the ability to choose a suitable project and material;

- a full range of construction services;

- internal and exterior decoration building;

- provision of all necessary documentation;

- saving money;

- engineering support of a finished standard project;

- the opportunity to start building a house immediately after the approval of the project.

Typical project wooden house economy class

Construction of a frame house

One of the most popular options is the construction of country houses based on frame technologies... However, in this case, it is necessary to take into account some points:

1. The calculation of all structures and supporting elements is carried out taking into account snow and wind loads, as well as the weight of the house itself. In the case of insufficient cross-section of the beams and frame racks, the service life of the house can be noticeably reduced.

2. The level of heat in the house depends on the quality of the insulation used during construction, as well as the absence of so-called "cold bridges". The insulation layer should be at least 150 mm (even thicker in cold regions).

3. It is recommended to completely cover the inside of the house wall with a vapor barrier film, which will protect the fiber insulation from moisture and thereby preserve its properties. From the outside, the insulation must be closed with a diffuse membrane, which is able to perfectly protect against wind and moisture, while freely releasing excess steam outside. Otherwise, for the normal ventilation of the rooms, you will have to arrange supply and exhaust ventilation, which will result in additional costs for heating the home in the future.

Economy class frame house

Considering all the above nuances, it is advisable to think over your decision again before making the final choice in favor.

Construction of an insulated house from a bar

The best option in terms of price / quality ratio among timber houses can be considered structures made of unplaned timber of natural moisture with external insulation, which is carried out in accordance with the "ventilated facade" technology.

In addition, thermal insulation using the "ventilated facade" technology is able to protect the load-bearing walls of a building from adverse effects. environment, which will significantly increase the life of your home.

Projects of cheap houses made of wood can be used for exterior decoration practically any materials: ceramic brick, block house, vinyl siding, imitation of a bar. For interior decoration imitation of timber, lining, wallpaper, drywall for painting are suitable.

Saving money in this case is achieved due to the inexpensive material of the bearing walls, the possibility of erecting a light foundation, a simple structure of a "ventilated facade", savings on heating and a heating boiler.

Economy class house project from a bar

Construction of houses from foam blocks

When it comes to the construction of houses from stone, first of all, projects of houses from foam blocks are meant. Savings in the construction process can be achieved due to the rejection of additional insulation of the enclosing walls (despite the fact that their thickness is not too large). It is necessary to carefully verify the quality of the blocks themselves. High-quality blocks allow laying on glue instead of mortar, so the thickness of the masonry joints can be reduced to 2mm.

When building houses from blocks, it is necessary to take into account the light absorption of moisture by the material, which can be solved with one little trick: increasing the vapor permeability of the material closer to the outer surface of the wall. In this situation, you can use all kinds of paints, putties and plasters suitable for exterior and interior decoration.

The project of an inexpensive economy-class house made of foam blocks

Building a brick house

Today, building an inexpensive brick house is a feasible task. In most cases, load-bearing walls are made using masonry bricks, insulation is carried out using the "ventilated facade" technology, and facing - with artificial stone or ceramic tiles.

Economy class brick house project

Economy class garden houses

Garden houses deserve special attention, which for reasonable money combine strength, beauty and environmental friendliness.

Economy class garden house project

Naturally, the operation of garden houses is associated with some nuances. If the structure was erected from non-planed timber, then there is a need for additional measures for sheathing surfaces with siding or clapboard. In order to avoid such work, you can immediately use a specially treated timber that can significantly increase the visual appeal of the house.

Inexpensive small garden house from a bar

Today panel board frame houses - the most popular projects of economical houses.

Letters from readers with various questions regarding construction come to the editorial office of the magazine. Grigory Yasenev turned to the editorial office with a request to advise him on the most economical material for building a house. Experts Valery Mostovich and Evgeny Shesterov tell our readers how to make a house economical.

Private house: What does the concept " economical house»?

Valery Mostovich, architect: First of all, it should be small in size.

For example, we recently made an area of \u200b\u200b6 by 6 m. Planning it is quite suitable for a family of three. On the ground floor there is a living room, a kitchen, a dining room, a bathroom; upstairs there are two bedrooms.

The second property of an economical home is compactness. The smaller the area of \u200b\u200bthe outer walls, the cheaper the house is to heat. It's the same with electricity and water supply.

Third, an economical home is simple. The basement or basement floor will raise its price by 30 percent. And the foundation in this case will not be cheap: it needs to be buried to a depth of freezing (for example, for the Northwest it is deeper than 1.60 m). Waterproofing plastic windows described If there is excessive moisture in the soil, reinforced waterproofing will have to be done. This requires additional costs.

The standard dimensions of aerated concrete blocks are 60 × 30 × 40 cm, it is easier to work with them - you can save on wages for workers.

And, of course, the value of a house is largely determined by the material.

Today the cheapest and most heat-efficient of all wall materials is aerated concrete.

In terms of thermal insulation properties, it is preferable to traditional brick. In addition, the brick itself is more expensive, and its laying requires a higher qualification of bricklayers. Aerated concrete blocks are larger ( standard sizes - 60 × 30 × 40 cm), they are easier to work with.

Private house: What are the basic "rules" for handling aerated concrete?

Evgeny Shesterov, designer: Different manufacturers produce aerated concrete of various sizes and properties. The main advantage of porous aerated concrete is its high thermal efficiency. And vice versa: the fewer pores in aerated concrete, the stronger it is, but such a material requires additional external thermal insulation. If the walls are thin and cold, it makes no sense to insulate from the inside: the thermal insulation layer will get wet from condensation and deteriorate. That is, by choosing a more porous material, you can save money. If aerated concrete meets the regional requirements for heat-shielding properties, the outside can simply be covered with decorative plaster or facade paint.

However, the more porous the concrete, the lower its bearing capacity. Heavy structures should not be laid on such a wall. First, a reinforced concrete distribution "belt" is made around the perimeter of the walls, and already on it you can put reinforced concrete beams, metal beams, and even slabs. This does not greatly increase the cost of construction.

The problem can be solved by building a one-story house of a larger area with a light roof.

However eyeliner engineering networks will cost more than two-story houseand heating costs will rise - more heating devices will be needed.

Project E-0841-0. A good example of an economical house: total area 85 m 2, foam concrete walls, monolithic foundation from reinforced concrete.

Private house: Does the use of aerated concrete impose any restrictions on the architectural appearance of the house?

Valery Mostovich: As an architect, this material suits me. It makes it possible to make compact volumes and immediately indicates a certain direction in architecture. Buildings turn out to be more strict and simple in terms of three-dimensional solutions, but not boring. For example, in an attic house, a high complex roof with kinks, partially covering the aerated concrete facade, can become the main plastic element of the house.

It is impossible to create small rounded elements from aerated concrete: turrets, round bay windows, like brick. You can combine brick and aerated concrete, but the difference in thermal conductivity of materials can create difficulties, and the brick part will either have to be additionally insulated or made much thicker. But from aerated concrete, you can make triangular bay windows, arrange the walls at different angles. He saws well (however, sawing on a construction site increases the cost of work).

Private house: What other building materials can be called economical?

Evgeny Shesterov: All of the above can be attributed to foam concrete. Moreover, it is lighter and better in heat engineering properties. It can be used for partitions (it is very effective in terms of sound insulation) and as an element of insulation for monolithic reinforced concrete, frame or brick walls... And for supporting and enclosing structures it is better to use denser aerated concrete.

Valery Mostovich: Traditionally, the category of economical buildings includes panel houses, but they are not suitable for year-round living in our climate. Wood is still used as a frame, but it is quite expensive. The frame is filled with mineral insulation and sheathed: outside - with siding, inside - with plasterboard.

A panel house can be cheaper than aerated concrete house if you buy a small prefabricated house from ready-made elements according to a standard project. They will bring it to you, put it on the foundation, equip it. But he will be completely uninteresting in architecture and is unlikely to become your personal individual house, in which you have invested not only money, but also your soul.

In projects implemented by various construction firms, Valery Mostovich acts as GAP (chief architect of the project), and Evgeny Shesterov - as chief engineer of the project.

Evgeny Shesterov, Constructor-developer (on right)

In his student years, he participated in construction teams, and later took an active part in the construction of the first houses designed by him. In 1983 he completed his postgraduate studies at LISS, defended his dissertation on urban planning. Candidate of Science (Engineering). Special attention is paid to the economy of houses and the ability of the material to withstand adverse climatic conditions. Teaches at the Department of Urban Construction.