With limited construction budget pile screw foundation (SVF) is a rational choice of the maternity owner. If there is time and strength, you can make a screw foundation with your own hands for this you need to immerse the piles to the reservoir with the bearing ability. The technology does not depend on the weather, the cottage or garden lodge is guaranteed to be built in the same season, since it is not necessary to wait for the set of strength of concrete elements of the base.

In comparison with all the well-known technologies, the screw foundation is the most economical basis for any ground structures. The advantages of SVF are:

- construction in difficult conditions - hilly, swampy terrain, coastal area, dense development, the presence of trees on the site, passing third-party communications;

- the minimum budget is almost complete lack of concrete, earthworks, formwork, waiting for a set of strength by concrete structures, rental of special equipment;

- the variability of construction technologies - a screw foundation is suitable for log cabins, brick, panel buildings, panel, half-timbered frame buildings, grounding circuits of the house, fences, maf;

- maximum strokes - 3-storey buildings with attic on individual construction are allowed;

- high resource - with normal anti-corrosion processing screw piles It is 75 - 100 years.

Please note that the ground is a separate design, and not connecting the grounding wire to the pile field of the foundation. Piles for the grounding circuit should not have protective coatings of non-conductive current.

The only disadvantage of CRS is unsuitable for projects with a base / basement floor. Manual installation of screw piles, not only admissible, but also recommended by experts. With the immersion of these structures, the special equipment is more difficult to control the tightening force when the bearing reservoirs is reached.

Step-by-step technology of foundation on screw piles

Thanks to a fairly simple design, if required tools, equipment (welding machine, gas cutter) Screw foundation can be made at home. Installation is made by technology:

- check screw;

- design;

- markup;

- production of guide wells;

- immersion SVS;

- trimming in the level of pipes towering over the ground;

- pouring concrete;

- installation of the gloves;

- staying the pile field painted;

- enter communications.

To plan the time of work, it is enough to measure the step of the screw blades. With each turn, the pile will dive with this depth, allowing you to calculate the time of each cycle. For example, in step 5 cm, 40 laps will need to screw the CCS to a depth of 2 m. Professional brigade mounts 15-25 SBS per shift, creating a field for a cottage with an area of \u200b\u200b100 m².

Calculation of the pile-screw foundation

The technology is quite developed in all regions of the Russian Federation, to calculate the SVF, it is possible to use the joint venture from 2011 per number 24. 13330 for pile grounds. The main calculations are:

- the carrying capacity of the reservoir at the depth of immersion of the pile blades, the bearing capacity of one pile is calculated from this parameter;

- number is a step of CSS in direct areas, positioning in places of walls of walls, minting of piles under separate designs (boiler / furnace, porch / internal staircase, emergency generator / pumping equipment.

In order not to order expensive geological surveys of the site, in 75% of cases, a trial screw is used, which allows you to calculate the data necessary for the project:

- the depth of the bearing formation (necessarily below the level of freezing of the region);

- the composition of the soil (finding in different layers of large stones, gravel, limestone);

- the level of the corning (very conditional).

The main characteristics of piles are indicated by manufacturers. For example, the sizes of the CCS are chosen, based on the type of design for which the base is necessary:

- pier / pier - pipe 89 - 108 mm, wall 3 - 4 mm, screw 20 - 25 cm;

- base strengthening - pipe 89 - 108 mm, wall 3 - 4 mm, blade 20 - 25 cm;

- retain wall - 54 - 89 Pipe (2 - 3 mm wall), screw 15 - 20 cm;

- Maf, gazebos, fences - 54 - 76 mm pipe with wall 2 - 3 mm, the blade of the screw 15 - 20 cm;

- combination with ribbon MZLF - pipe 108 - 168 mm, wall 4 - 8 mm, blade 25 - 40 cm;

- block, brick cottage - wall 6 - 10 mm, body diameter 168 - 270 mm, 40 - 80 cm blade;

- panel, half-timbered, shield, frame, cutting house - 89 - 114 mm pipe C 3 - 5 mm wall, 20 - 30 cm blade.

Thus, after counting the prefabricated loads (operational + wind + structural + snow), the figure is divided into the supporting ability of piles to count the required amount of CSS.

Preparation and markup of the site

Due to the lack of planning and earthwork work, the layout of the building stains is maximally simplified. It is enough to put on the ground axis of the walls, partitions and additional heavy equipment (boiler, staircase, pump, etc.). To do this, a slightly far corner of the house is made to install pegs, which stretch cords. Instead, it is possible to use a more complex design of two stakes with a horizontal jumper, which allows you to install two cords on the outdoor sizes of piles.

Pile's immersion

Step-by-step instructions for screwing SBS, regardless of the type of blades, tip, level of groundwater, other factors, looks like this:

- making a pit - the guide wells are created to a depth of 0.5 - 0.7 m manual or by the motoroburn, they allow you to accurately position the piles, make it easier to go to the ground, the diameter of the leader-wells should be slightly less than the size of the SVS blade;

- pile's immersion - scrap is breeded inside the body of the pipe, the tubular levers are put on it, two employees move them in a circle, creating a torque, the third controls the vertical of the trunk with a bubble level, with a sharp increase in the tightening force (necessarily below the freezing mark) work;

There is a mechanical immersion technology of SBS without attracting special equipment, a slightly increasing construction budget:

- on the upper end of the SBS, the torque enhancement device (reducer) is put on;

- it is based on the installation of the electric drill (power from 1.5 kW);

- the design is installed in a vertical position over the guide well;

- drill is connected to the power grid.

The device of the torque amplifier is a gearbox with a 1/60 gear ratio. Instead of levers, an electric tool is used, the operation can perform two workers.

Alignment of SBS in the horizontal plane

The pile field must be tied with painter in the form of concrete, metal or wooden beams located on the gloves. For this, the pipes protruding from the ground must be put back. Alignment technology has the form:

- a single level mark - a level is used, a theodolite or laser plane builder, level;

- trimming - the body of the pipe is cut off by the EMS on the markup.

On this, the device of the pile field is considered complete when using monolithic or metallic woodwork. If frame, cutting, panel or panel house is erected, it is necessary to mount the gloves to which the timber can be relying, the calibrated log. The headset has several modifications:

- square - 10 x 10 - 30 x 30 cm plate welded to the patch;

- reinforced - the size is similar to the previous case, the plate is welded to the pipe, the inner size of which is equal to the outer diameter of the pile, there are 4 ribs (brazers);

- U-shaped - the inner size between the shelves 17 cm for laying a bar of 15 x 15 cm.

This element is put on the body of the CCS, attached to it with welding (less than bolts). Holes in the plate allow you to fix wooden beams Scarlet for obtaining a single spatial design.

Pouring concrete

The pile, even with a hermetically welded head, is covered with moisture from the inside. To prevent this phenomenon, special protection is used - filling the pile body concrete after immersion on the design depth. Usually use several technologies:

- dry mix - packed sand-concrete m 300, which, when contact with condensate, is independently cementing inside the product;

- commodity concrete is a classic fill through a funnel, the technology has a significant disadvantage - the presence of emptiness, cavity inside the mixture;

- peskobeton - brands M 300 - M 400, due to the absence of a large filler, void in concrete is practically no;

In addition, concrete injections allow you to increase the spatial stiffness of the structure, which is relevant for thin-walled piles.

Piy Roullovka strapping

In direct areas, the recommended height of the soles scraping from the Earth is 0.5 - 0.7 m. It is the optimal size for the location of the ventilation products in the cab. Without it, the floors of the lower floor will be the source of heat loss, in the absence of natural ventilation, the power frame will quickly come into disrepair. For each type of woodwork, there are installation features.

Monolithic Rosshark

The technology is the most difficult, costs more than other options, however, is the only possible for brick cottages on a complex relief, in the coastal strip and on the swamps. Device of a monolithic frame technology:

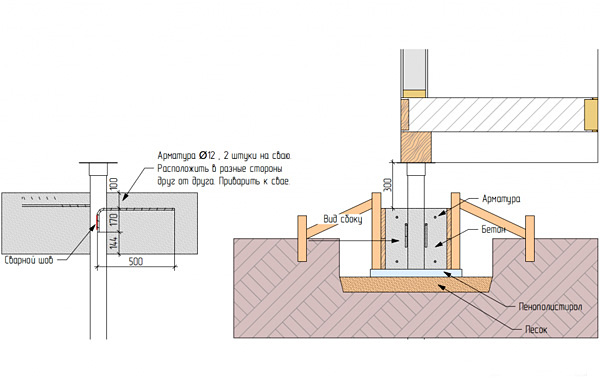

- the formwork assembly - the lower shields are put on the pipes, supported by jumpers fixed on two quiesses, side shields are attached to the bottom, connect between themselves with spacers and screeds;

- reinforcement - two belts from the periodic cross sections (12 - 16 mm rifle) are binding to horizontal and vertical 6 mm jumpers or clamps;

- bundle with pile - in the pipes are being burned or holes, in which additional fittings are launched, joined knitted wire to armoances of the structure;

- pouring - formwork is filled concrete mixture Prior to the design level, compacted by rods of reinforcement or deep vibrators.

All types of masonry for brick house walls and any other construction technologies are allowed on the monolithic frame.

Wooden Rosshark

Construction technology wooden houses It facilitates the task of the developer to which it is necessary to tie the pile field with long elements to provide spatial stiffness at home. Lower crowns Siruba (calibrated log), the cutting of the "sander" are ready as the woodwork.

Manufacturing technology has the form:

- installation of flat headings - are needed to increase the area of \u200b\u200bthe support surface;

- laying beams - timber, logs are joined in Poledev, are attached to the gloves of self-drawers, bolts or nails.

This is the fastest framework, however, the technology is unsuitable for brick masonry, projects of big storey. The height of the building cannot exceed one floor with an attic.

Metal Rosshark

If the height of the log cabin, the "skewer" exceeds the standard floor, wood woodwork may not withstand collectible loads. Pouring monolithic beams for wooden buildings is economically unprofitable, we can use woodwork from metal. Technology has the form:

- laying pieces of chapeller shelves down, the wall up on the pipes of the CCS either a heap on the lower shelf in exactly the same way;

- docking elements of woodwork, tack in several places;

- chinking double seam of each joint.

Metal woodwok is suitable for single-storey brick buildings only with a decrease in the pile field step to 1 - 1.5 m. This is due to a large structural mass of the material - for example, the channel begins to bend under its weight already in 3 m spans.

Enter engineering systems in the building on screw piles

Most often, the CRS pipe slightly protrudes over the surface of the Earth. This makes it difficult for communications in the underground 0.5 - 1 m of height. Therefore, it is wiser to carry out the introduction of life support systems at the stage of the foundation. Later for this you have to open the draft floor, produce excavation In a closed space. For normal operation of the building must be summarized:

- plumbing - in the freezing underground pipes, it is necessary to warm up, both in the ground to the marking of the frozen, and above its surface with polystyrene shells or minvata (2 - 3 layers) and the heating cable, respectively;

- sewage - Stocks come to the outer sewer circuit with warm, so sufficient winding of the air pipes with one layer of basalt wool, underground pipelines of the polystyrene foam shell at a depth of 1-1.5 m;

- grounding at home - CACs of the minimum diameter can be used in the form of a 2 M of a triangular circuit, lined with thick wire or tires from a metal strip, can not have piles protective coating non-transmitting current;

- power supply cable - sometimes underground entry, be sure to protect the casing.

After wiring engineering systems, you can set a download. If the project is laid brick wallsThe false base is manufactured at the stage of finishing the facade. Because in this case the probability of damping facing materials is a random stone or solution.

Screw Packaging

There is no full-fledged base in pile bases, to protect against purge, penetration in the underground of precipitation is manufactured by a bog. For the construction of a false base, you can use several technologies:

- a frame system - on the piles the timber is mounted or a galvanized profile, we will wear the grille with the basement siding, professional flooring, panels;

- masonry - ceramic, clay brick, buttone.

The clogging is complemented by a glassland for the removal of storm, flood drain. Facing materials of these structures should be hydroizing. For this you need:

- install the frame of the frame;

- fasten it vertically rubkeroid on it;

- run it under the horizontally located scene;

- making the installation of siding and paving slabs.

Natural ventilation underground is carried out due to the produced in the false base, the total area of \u200b\u200bwhich should be 1/400 from the surface of the Zabirki. It is not necessary to insulate the design, since there is no heating inside underground.

Screwdriver resource

To increase the operational resource of the CCS, anti-corrosion treatment of each product is required according to GOST R 9.905, 9.908, 5272. Manufacturers use the following anticorbore technologies:

- cold galvanizing - it takes almost completely at the immersion of piles due to the abrasives contained in the earth;

- hot galvanized - keeps a little longer, does not provide an informed 75 year resource;

- powder staining - serves 30 - 50 years after installation, destroyed by walking currents in the ground;

- painting with bitumen compositions - protects against groundwater, regardless of the height of the corner, provides 50 - 70 years of service

- soil Vl 05 + Cold Cold Location (enamel IR 02) + Fiberglass - resource 300 - 400 years in extreme conditions, electrochemical corrosion is absent;

- enamel IR02 or Zinga Metall + polyurethane or epoxy two-component enamel - were created to protect the nepheterns (air, underground), have 50 - 100 year resources;

- soil Vl 05 + Polyurethane enamel Hempel, Masco - Standard level of protection of the bottom of icebreakers, submarines, tanks of fuel and lubricants, 30 - 70 Summer resource.

Even when buying a SVS with the factory anti-corrosion layer, it is necessary to cover piles for the reliability of the specified compositions.

Appointment of screw piles

The first pile structures with screw tips in the Russian Federation began to be applied solely for the needs of the army in the middle of the XIX century. They could be used for temporary structures or in difficult operating conditions. The stated resource was 100-180 years old than modern manufacturers could not boast. Currently, CSS and other modifications of piles are used for:

- construction of the house on the swamp, the slope, in dense development, the forest zone, on the soils with a high CE, low bearing capacity;

- budget construction of fences, maf, arbors, surplus buildings;

- strengthening tape, slab bases;

- manufacturing engineering systems, such as home ground, water intake well.

The height of the CCS is practically not limited - when the lower element is immersed with the screw blades to the ground level to the pipe, you can welcome the next piece or somewhat for the guaranteed achievement of the reservoirs with the carrying properties. For installation, there are enough three people or one wizard with a powerful electric drive with a gearbox.

This step-by-step instruction Suitable for mounting screw piles under the building, erected by any technology from different wall materials. Recommendations will avoid mistakes, increase the operational resource of the dwelling.

Tip! If you need contractors, there is a very convenient service for their selection. Just send in the form below a detailed description of the works that you need to perform and offers to you in the post office with prices from building brigades and firms. You can see the reviews about each of them and photos with examples of work. This is free and does not oblige anything.

The topic of this article is to calculate the cost of screw piles. We will try to illuminate all the main stages - from the assessment of the mass of the structure to the cost of individual work on the construction. Important moment : The real cost of materials and works in your region may differ significantly from the author's given.

The house begins with the foundation. Our goal is to assess the costs of it.

Stages of calculation

Let's start with the compilation of the list of stages of our calculation.

- It is necessary to at least roughly estimate the mass of the structure for which we plan to create a foundation. It is tied to the material: It is clear that the wall of 2.5 bricks and the wall of SIP panels have a very different weight of the route meter.

- Taking into account the mass of the house, we need to choose the diameter and the number of piles.

- If all work on screwing the piles is planned to perform with your own hands, the calculations will end up; However, it is also necessary to find out the cost of installing screw piles. In addition, any additional work may be required.

Calculation of the Load for the Foundation

How to find out how much the future house weighs? The obvious solution is the meaning of the medium density of the material of the walls, multiplying it into a common cube and make amendments to the weight of overlaps, roofing, inner utensils, snow on the roof, etc.

Important moment: Even if the load on the foundation is calculated very accurately, it is recommended to leave a margin on the supporting load at least 30% - the inhomogeneity of the soil, the inevitable corrosion of piles and other unaccounted amendments.

We present the reference density of some popular building materials.

- Brick masonry (red funny brick) - 1800 kg / m3.

- Reinforced concrete - 2500.

- Foam concrete - 300-1400 depending on the brand.

- Bar pine - 500.

- Polystyotilol - 45-150.

Calculate the total mass of overlaps, internal partitions, roofs and household items are quite problematic. A simple rule will help here: for a balanced design, the walls of the walls are approximately equal to the burden on the foundation from all other designs, snow, etc. An exception - frame structures And at home from SIP panels: it is better to multiply the calculated mass of the walls by 3.

As an example, let's calculate the mass of the house of 8 * 8 meters in two floors. Wall material - a timber thickness of 25 centimeters; The height of the ceilings is 3 meters.

- The total volume of the outer walls is equal to (8 + 8 + 8 + 8) * 6 * 0.25 \u003d 48m3.

- Their mass at a density of 500 kg / m3 is 48 * 0.5 \u003d 24 tons.

- The total mass of all other elements of the house will take an equal mass of the walls. Thus, the structure will weigh 48 tons.

- Taking into account the 30 percent stock of the strength, the foundation we will calculate, based on the peak load in 48 * 1,3 \u003d 62.4 tons.

Calculation of the number of piles

To obtain the required amount of supports, you only need to separate the extensive load on the carrying ability of one pile. The instruction is simple, but for implementing our plan lacks some reference data.

We give them:

- Piles with a pipe diameter of 76 millimeters are designed for the device of light terraces, fences and playgrounds. They are designed for load up to 350 kilograms.

- Products with a pipe diameter of 89 mm and blades with a cross section of 250 mm can already become a base for light-storey residential buildings. Their carrying capacity is estimated at 1,500 kg.

- Pile 108/300 mm is designed for two-three-storey structures from SIP panels. Calculated load for it - 2100 kg.

- Size 133/350 mm will give an opportunity with a sufficiently strong painter to build walls of bricks, foam and aerated concrete, a 40 cm bar and thicker. Maximum load for it - 2900 kg.

It is clear that the larger the diameter of the pile - the higher its price; In addition, install it manually is much more difficult. Our obvious choice is a product of 108/300 millimeters. The length is determined on the basis of geological studies: the pile blades should be based on the dense layers of the soil.

In our case, 62.4 / 2.1 \u003d 30 piles will be required.

Clarification: The real carrier capacity of one screw pile 108/300 mm on dense soils is estimated at 4-10 tons. Impaired values \u200b\u200bare usually driven by manufacturers from reinsurance reasons from lawsuits and to increase profits.

Calculation of value

Prices

What is the cost of a screw pile for home? How much will work on its installation? Let's give an excerpt from St. Petersburg Price List construction company (in order to avoid accusations in hidden advertising, we will bypass without specific names).

Product

- The pile 108/300 with a welded tip at a length of 1650 mm costs 1550 rubles, with a length of 3000 mm - 2050 rubles.

- The three-meter pile of the same diameter, but with a cast tip and galvanized up to 3200 rubles.

- A headpoint that allows you to tie supports by painting from a bar or steel channel, costs 300 rubles.

- The welded tip and size 133/350 with a length of 1650 mm will provide the cost of one pile equal to 1900 rubles.

- The same product, but with a length of 3000 mm it will cost 2350 rubles.

Work

The cost of work on the screw piles depends on their length, soil density and a number of other factors. We give indicative estimates for popular sizes.

The cost estimate is not always objective. When using heavy technician, the costs of time and forces are little dependent on the pile diameter.

Rates for additional work on the device are given already taking into account the value of the materials:

- The strapping of the supports channel 160 * 80 * 5 mm will cost 900 rubles per stranded meter.

- Vent. profile pipe With dimensions of 60 * 30 * 3 mm will reduce costs up to 500 rubles per temporon meter.

It is useful: Of course, with such a width, Proftrub will not be replaced by Ruralt. It only provides strictly vertical location Piles with any drawdowns and soil movies. An additional measure to ensure the rigidity of the foundation can be the installation of slopes: a triangle is a rigid figure, and any horizontal displacements will be impossible.

- The blocking of the 150 * 150 mm bar will cost 700 rubles / meter.

- With an increase in the cross section of the timber to 200 * 200 mm, the cost of the frame meter is grown up to 900 rubles.

- Drilling of the well in a solid foundation (it is mandatory if the pile does not plunge at least 1.5 meters) costs from 300 rubles per each. The exact cost is determined again by the type of soil: on limestone and granite time spent time will be very different.

- The trial twisting required to estimate the density and the structure of the soil is cost in 2000 rubles.

- Rent a generator where the existing electrical network It can not provide power in five kilowatts, will additionally cost 2500 rubles per day.

It is worth introducing clarity: different companies have the cost of mounting screw piles can be assessed not only by different tariffs, but also by characterized criteria.

For example, many companies use different rates for manual and mechanized installation; The strapping frame can be evaluated separately from the cost of materials and draw up, for example, 600 rubles per pile for timber and 800 - for a chapeller.

In most of the price list, the installation cost is calculated without taking into account the pouring body of pile concrete. However, this operation more than positively affects the strength of the foundation, and, most importantly, its longevity: a concrete pillar will keep paintwork even with end-to-end corrosion of the pipe.

Clarification: Galvanized pipe, it would seem invulnerable for dampness and rust. However, it is necessary to take into account the inevitable violation of the zinc layer when screwing. Each damage to the protective anti-corrosion layer is a pass-through hole in the pipe.

Counts

So, let's spend a trial calculation for the case under consideration.

- For our purposes, the supports of 108/300/3000 millimeters are guaranteed. Shorter 1650-millimeters are used only on very dense soils. For dry and not too dense soil, it is possible to prefer a cheaper option - piles without galvanized with welded tips.

- The cost of one product without installation according to the price list given by us is 2050 rubles. In 300 rubles it will cost the head, in 1850 - installation. Total - 2050 + 300 + 1850 \u003d 4200 p.

- The total cost of piles will be 30 * 4200 \u003d 126000r. Two more thousands - the cost of trial drilling.

- Suppose that the bar does not enter the price of the strapping by painting. Thus, when calculating costs, it is possible to take into account only the cost of the work: it will be 600 rubles per pile, or 18,000 rubles.

- Total all costs for the foundation will be 126,000 + 2000 + 18000 \u003d 146,000 rubles.

Output

Dear reader, we showed only the calculation scheme. Repeat again: the prices listed may be irrelevant to your region.

Successes in construction!

This article was written in 2010 and since then only a little edited. Over the past years, the foundation on screw piles has acquired literally nationwide recognition. Already several machine-building factories produce cast tips for screw piles, but the demand is so large that in the season sometimes you have to get up to shipment.

Low percentage of advertising, high reliability, excellent conditions for ventilation wooden overlaps - And this is not all the advantages of pile-screw foundations.

In industrial construction, screw piles are used from the 19th century. In individual construction, the active use of screw piles falls on the last fifteen years. Therefore, a wary attitude towards this "novelty" is natural (this is written in 2010 and it seems no longer relevant). Mostly everyone is worried about three questions: the service life of the foundation on the screw piles, its reliability and ways to outdoor decoration. In this article we will discuss these problems.

Screw the pile (screw anchor) is steel pipe With a pointed tip and a spiral blade, which allows you to spin the pile in the ground, like a self-sufficiency:

But this is not the main thing. The blade of the screw pile performs the same function as broadening the lower part foundationMade using TISE technology: reduces the pressure of loaded pile to the ground and prevents it out of the forces of frosty powder. Therefore, the screw tip (auger) is the main element of pile, which determines its reliability as a support.

Thanks to the blade, the spiral pile provides a fixed point of support. This is very important for a Canadian house with a relatively low weight, since the soils in the suburbs are mostly bubbly. And frosty powder forces are able to push the usual pile of soil.

Under standard conditions, the pile is screwed into the dense (carrier) layer of the soil below the depth of the freezing (1.5 meters in the Moscow region).

In individual construction, screw piles are used with a barrel diameter of 108 mm and a blade diameter of 300 mm.

The carrying capacity of such pile depends on the soil and amounts to the results of field tests:

The carrying capacity of the F of the screw pile linearly depends on the moment of twisting:

where M (kg * m) is a torque, k (1 / m) - an experimentally defined coefficient whose value depends on the soil and lies within 6-12.

The specified property allows you to determine the resistant to the pile resistance to how reliably in terms of the bearing ability, this pile is installed.

Piles with a blade of 300 mm can be screwed up using levers. The simplest set of devices: scrap and two pieces of pipes 3 meters long. In cramped conditions, a special device will be required. To create the required torque of about 300-500 kg * m, 4 people are enough.

The main disadvantage of the manual method is that it is often impossible to ensure the accurate installation of piles. It depends not so much from the skill of the installers, as from the coincidence (geaselovia at a particular point). We resort to manual screwing only in two cases: either there is no entrance for the equipment, or piles are so small that the delivery of the equipment is too overclocked.

Builders for screwing piles use various devices and techniques. The most accurate, high-quality and reliable installation of piles provides hydrobur based on the excavator thanks to a more complex and flexible control of the multi-wing arrow.

An experienced excavator driver has the ability to check the pile carrying capacity by pressing on it with the weight of the excavator (about the need for field tests of piles for carrying ability to read below):

The widespread use of excavators with hydrobur for the installation of screw piles is constrained by a high price for renting an excavator and its delivery, because special transport is required to transport an excavator:

Self-propelled yamobura (hydraulic drive on the crane arrows) are more common and available. The crane operate is somewhat more complicated, but experienced specialists cope with the task of confident:

After screwing the piles are cut down in terms of level. The pile trunk is poured by concrete. This protects the trunk from the internal corrosion. Top on the pile dresses the headband for fastening a wooden strapping bar. Sometimes instead of the tips use a metal chaserler. Under the Canadian House in most cases, the piles of the Swamp is not needed.

For the Canadian home, the foundation on the screw piles is the perfect solution, but its device is not always possible. Stony soils, or strength soils of fluid consistency, deep peatlands - possible contraindications To the use of screw piles in the Moscow region. But such cases are rare. In our practice, and this is a lot of hundreds of established foundations, only in several cases had to abandon the screws of the piles. For example, one building site was on the site of the former swamp. To the bottom (to the carrier of the soil), then did not get. With stony soils, we still manage to be able to largely due to a cast tip, but about it a little.

The advantages of the foundation on the screw piles a lot. The most pleasant is the relative cheapness (cheaper than a high-quality ribbon fine-breed concrete foundation) and high installation speed (on average it takes one or two days on the whole cycle of work).

The harder the relief of the plot, the more significant these advantages of the screw piles. Foundations on screw piles are very popular when construction on slopes with a large height difference (cottage on Nicolina Mount can be viewed). Another cottage from the sip panels on a rather steep slope (April 2013):

Unlike "floating" foundations (ribbon fine-brewed or stove), the foundation on screw piles can at any time increase For the construction of an extension to the house. This is very important because most people think about the extension to the house after a couple of years of operation.

Excellent ventilation underground provides long service life of zero wooden overlap. When belt Fundament This ventilation is hampered by internal jumpers.

Convenient access outside facilitates repair and other work in the underground. In the case of a ribbon foundation, it will have to do hatches in zero overlap.

Screw piles are perfectly screwed in winter, which allows you to build a Canadian house "from scratch" in the winter during seasonal discounts on building materials and work:

Of disadvantages (disposable) Screw foundation We note the relatively low stability of the individual screw pile with respect to the side load. With a weak soil or when the soil is bursting around the pile (most often a preliminary basement), you can even sense the shaking of individual piles. Over time, the soil around the pile is compacted, and the pupil acquires the necessary lateral stability.

Scarlet out wooden bar Or a channel forces the piles of the foundation to work together, which gives the necessary side stability of the screw foundation as a whole:

If the upper ground is weak, if the piles are highly cut above the ground level, if the building is similar to the tower (high height at a small base area), it may be necessary to increase the stiffness of the pile foundation with additional connections (steel corner, a rectangular pipe, etc.):

On a plot with a big bias, if piles are cut high (norm 0.5 meters) and (or) a clearly weak upper ground (for example, a bulk soil, black soil or a peatman), then the strapping is better to order at once. Screw-in-law experts can with great accuracy to predict the need for strengthening. But it happens that the problem is revealed after the house is built. There is nothing terrible in this, since the strengthening (welding) of the screw piles by metal products is a matter of several hours.

Life time

The history of screw pile covers almost two centuries. The main use of screw piles is such responsible structures, like lighthouses, bridges, pier, masts of lighting, LPP supports, cellular rigs.

The oldest structure (pier on the screw piles) stood in seawater of almost a half century and was dismantled due to reducing the water level in the ocean. Screw tips of the first piles are stored in museums.

In Russia, screw piles were mainly used by the military, which are crucial for the squeezed duration of the foundation-dismantling for quick deployment or change of positions.

Russian experience in using screw piles as a support of an individual house does not exceed fifteen years. During this period, there are no complaints regarding the corrosion resistance of piles. There are complaints about the quality of piles made by treasure, to the quality of the anti-corrosion coating and the qualifications (in good faith) of workers. No foundation failed due to corrosion of metal. Single cases of drawdown are noted, which is a consequence of the violation of the technology, according to which the pile blade should be included in the dense carrying ground. Cases of separation of pile blades are recorded when screwing out due to poor-quality welding. Alloy tips remove this problem.

It is argued that, with proper manufacturing, proper anti-corrosion coating and competent installation, the Whisper will last at least 100 years. It is clear that it is impossible to confirm or refute this statement now. Two-year history of screw pile and the absence in the low-rise construction sector for 15 years of disturbing signals about the rapid outlet of the screw piles due to corrosion indirectly confirm the long service life of the screw foundation.

For comparison, the facts of failure of the "eternal" reinforced concrete foundations Already in the first years of exploitation in individual construction there are many. A common case - reinforced concrete tape after the first winter due to the poor quality of concrete came to full dissent:

Therefore, the service life of 150 years for the belt concrete and 30-50 years for the columnar concrete foundation - This is ideal. In individual construction, there is a clear tendency to reduce the cost of foundation due to such potentially hazardous decisions as a decrease in the area of \u200b\u200bthe cross section of the ribbon, pillars and woodworks, reducing the density of reinforcement, etc.

It is difficult to say that it will be with a ribbon small-breeding foundation or a "floating plate after 30-50 years. Long-term exploitation, as in the case of screw pile, no. The territorial construction norms of the Moscow Region adopted in 1998 "Design and a device for small-breeding foundations of low-rise residential buildings in the Moscow region (TSN MF-97 MO) (TSN 50-303-99)" was recognized in 2008 with invalid strength.

Monitor the state of the screw piles is simple enough. The zone of increased risk of corrosion is at the surface of the soil. The periodic audit of the state of piles does not represent technical complexity.

Restoration of helical pile is fundamentally possible. One of the options - installation of steel coupling on top pile trunk. The reconstruction of the foundation is possible: unlike the stone houses, the frame-panel house can be raised by jacks without the risk of destruction of the structure.

In December 2010, our company demolished an old house In the Kaluga region. In the accurate under the outer wall of the house at a depth of about 15-20 cm discovered details of old scales. Judging by the age of the house, the piece of iron lay in the ground at least 70 years. Metal condition surprised. In such conditions, the steel pupil will last and 200 years without any anti-corrosion protection.

Load bearing capacity

The carrying capacity of piles with a diameter of 108 mm, with a blade with a diameter of 300 mm, on average, on our experience in the Moscow region is about 4 tons (often much more: 6-9 tons). This is not determined by non-calculation, but field tests. The weight of a two-storey house of 150 m2 from SIP panels about 25 tons. And the foundation of such a house on SNIP 2.02.03-85 "Pile foundations" is calculated on the load of about 70 tons (taking into account the normative operational and snow load and the reliability coefficient for the load). Thus, according to SNiP for the foundation device, 17 piles are enough. Screw piles twist with a step of 2-3 meters for the framework of a wooden bar. Under a two-storey house of 150 m2, about 25 piles are screwed. Therefore, a helical foundation for the Canadian house in most cases is obtained by "superphan" on the bearing capacity.

Important! Calculation and design of screw foundations is carried out in accordance with the SP 50-102-2003 "Design and Device of Pile Foundations". One of the mandatory conditions is to carry out engineering and geological surveys to a depth of at least 5 m below the designed depth of the attachment of the lower ends of the piles. It is long and expensive for an individual house. Therefore, with a rare exception, everyone violates this requirement.

This practice in the individual construction sector has become the norm not only for pile foundations, but also for tapes, etc. This is not madness. Individual house - This is not a skyscraper. Loads for the foundation are relatively small. Many thousands of years, humanity is building dwellings, and about the behavior of the foundations on different soils Experts have long been known. The accumulated experience protects against errors. If you do not find specialists, then good way - It looks at the neighbor's houses.

Some kind of soil information is always available. Someone drowned a well, someone dug a well, etc. Much valuable information gives the process of screwing. In the suburbs mostly bubbly clay soils - sandy and loam. They are great for the screw foundation. Without information about the soil to build the foundation risky.

Sometimes engineering and geological surveys are held for the entire country or cottage settlement. If you are lucky with a construction or project company, then according to engineering and geological surveys, you calculate the foundation for the carrying capacity regarding the main combinations of loads and impacts. For an individual house, this is already good. Only there is one problem - the formula of the joint venture 50-102-2003 to calculate the carrying capacity of the screw pile by the soil parameters gives a highly understated value. Moreover, the rules require dividing it to the reliability factor for a load of 1.4! As a result, the calculated amount of piles exceeds several times really demanded. Builders are beneficial. Designer This fact does not care. The more stock, the calmerness of the builder and the designer. For the customer it is unacceptable for financial considerations. At this case, the SP 50-102-2003 provides for the conduct of field tests. The foundation team of LLC "Hotmell", when there are doubts about the soil, performs the test of piles weighing an excavator (5-7 tons):

Many customers a limited budget does not allow you to pay engineering and geological surveys, field tests and the corresponding SNiP calculations and design. Therefore, all screw foundations for individual houses are installed today with a formal impaired SNiP. In such a situation than a more experienced, the construction organization, the less risk.

According to the experience of the movie, which built many times more sip-houses than any other company, the percentage of advertising on screw foundations is negligible. In the entire 10-year history, the championship of the problem arose only in isolated cases. And during this time, specialized teams of the HOTMAL installed more than 1,500 screw foundations. That is, we are talking about the tenths of the percentage. And in all cases, shortcomings are eliminated. This is not only the merit of engineers of the movie, but also a useful feature of screw foundations.

If necessary, we can not only increase the screw foundation, but also to completely replace it under the already assembled house.

Advertising on the device of reinforced concrete foundations only due to the poor quality of concrete is an order of magnitude greater. And the consequences of errors in the construction of reinforced concrete foundations are most often disrepair.

Therefore, the foundation on screw piles is a reliable foundation, especially if you trust it with an experienced and responsible specialists. It is best if the foundation establishes a company that will build your home. High material responsibility disciplines.

The transfer of this stage of construction to third-party persons offering a favorable price is a big risk. Low price Forcing the Contractor to risk and save on everything, including on the salary of its workers. Practiced manual screwing of piles by migrant workers, etc. For the same reason, such contractors have no physical ability to compensate for you even partially possible damage. It is no secret that such "organizations" risk consciously, because they do not plan anything in the event of problems. Examples of thousands.