Any building will serve for a long time if the builders laid a qualitative basis -. And his strength, in turn, is directly dependent on the properties of the used building materials.

Most individual buildings are erected on monolithic structures.

In private construction, several types of foundations are used:

- - for brick and blocks two-storey houses;

- - for houses of frame type and wooden;

- - For the construction of massive buildings and other buildings, built on weak soils.

Since two factors are influenced by the choice of the foundation type - the mass of the above-ground part and the state of the soil, it can be said that they are determining when the brand of concrete is selected.

In general, it can be guided by the following rule: a concrete brand for the foundation of the house designed in the form of a monolithic tape is taken lower than on the pile.

The influence of the state of the soil on the choice of brand of concrete mix

Without having a conclusion about the characteristics of the soil at the construction site, it is impossible to correctly determine which concrete is needed for the foundation of the house ().

Without having a conclusion about the characteristics of the soil at the construction site, it is impossible to correctly determine which concrete is needed for the foundation of the house ().

If you only focus on the weight of the aboveground part of the building, you can draw the following conclusion:

- M150 is a completely appropriate brand of concrete for the foundation of the house of foam concrete (single-storey);

- M200 - withstand one-two-storey () building with light floors;

- M300 and M250 - are able to carry a large load from multi-storey cottages;

- M350 and above - reasonably apply only during the construction of high-rise buildings.

However, all these statements are valid only when the house is built on a rocky or sandy soil. If the developer faces clays or sublinks, the situation changes dramatically.

What brand concrete for the foundation of the house to apply so that it does not squeeze it up? Monolithic tape for light frame house We will have to erect from the mixture M250. And if the walls are planned to be made brick, then the concrete must be chosen at least M300.

Great influence on the durability of the underground part of the building are groundwater. With their high level, it is desirable to apply high grades with good waterproof concrete.

How to calculate the volume of concrete mix

The brands of concrete under the foundation of the house do not affect its consumption. The amount of the mixture is calculated, based on the geometric dimensions of the structure.

There are several simple formulas with which you can easily calculate how much finished concrete will be needed for fill.

Ribbon foundation

Calculation of the needs of concrete in this case is reduced to counting the volume of the tape ().

Calculation of the needs of concrete in this case is reduced to counting the volume of the tape ().

Denote the foundation parameter as follows:

- a - building length;

- b - the width of the building internal perimeter;

- d - the width of the tape;

- h is the height of the tape.

So, the volume of monolith V \u003d 2D x H (a + b)

In the presence of inner bearing walls, the volume of these areas of the foundation is also calculated in the same way. The results are summed up.

Slab

Volume monolithic plate Calculated by multiplying three quantities:

Volume monolithic plate Calculated by multiplying three quantities:

- length;

- widths;

- heights.

Columnar

The volume of the round column can be calculated by the formula:

The volume of the round column can be calculated by the formula:

V \u003d (3.14d 2/4) x H, where

D - the diameter of the pillar;

H is his height.

The volume of rectangular or square supports is defined as follows:

V \u003d a x b x h where

a - width of the cross section of the support;

b - the length of the section;

H is the pillar height.

In all cases, the resulting volume should be increased by 10% (that is, multiplying the coefficient of 1,1). So you are insurfrant of yourself in case of unforeseen circumstances.

How to cook concrete of the desired brand

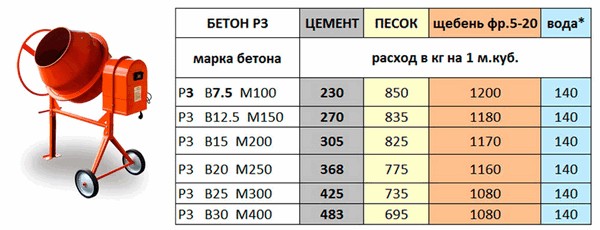

Private developers do not always buy ready mixes factory production. It is more convenient for them to prepare concrete directly at the construction site: it is cheaper and more corresponds to the pace of individual construction ().

Private developers do not always buy ready mixes factory production. It is more convenient for them to prepare concrete directly at the construction site: it is cheaper and more corresponds to the pace of individual construction ().

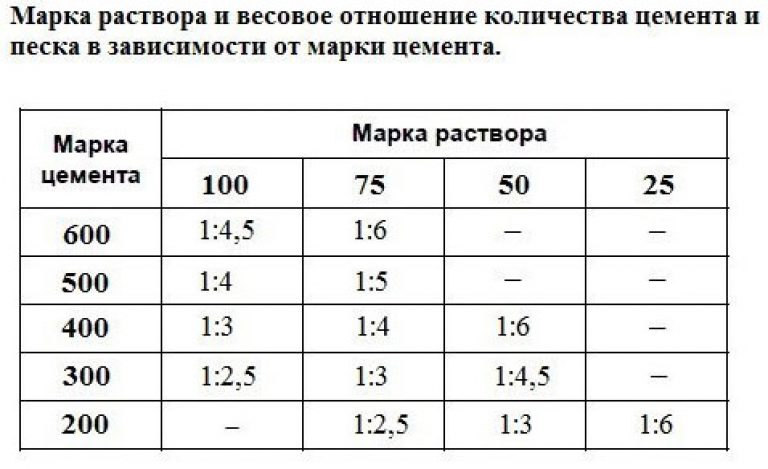

So, you decided on the brand of concrete under the foundation of the house. Now you need to choose the necessary proportions of the components concrete mix. All concrete, regardless of the brand, are prepared on the basis of cement brands M400 or M500.

For example, consider the preparation of concrete M250.

If you decide to use cement M400, then the proportions of the mixture will be as follows:

- cement - 1 kg;

- sand - 2.1 kg;

- crushed stone - 3.9 kg;

- water - 0.56 kg.

The total yield of one serving of concrete will be 7.56 kg.

It is worth replacing the cement M400 on the M500, and the proportions will change:

- sand will need more - 2.6 kg;

- the amount of rubble will increase - up to 4.5 kg;

- more will have to pour and water - 0.64 kg.

At the exit you will receive 8.74 kg of concrete mix. The difference in the price of the cement of the above brands is small - it is 10-20 rubles in a fifty-thousand bag. Do not be lazy, calculate the cost of raw materials in the other case. So you will understand what option will cost cheaper.

But before you need to calculate how the amount of source materials you need. It is simple: the volume of the foundation is multiplied by the proportion of concrete, and the resulting result is divided into the total weight of one portion of the mixture. Now you will learn to multiply the amount of each component on the resulting number of servings.

The density of concrete mixes is different. If you need for the calculations for the foundation of the one-storey house, the brand of concrete M250, its density is 2348 kg / cube. m. And the cubic meter M350 weighs 2502 kg.

Although builders often operate with averaged concrete density equal to 2400 kg / cube. m.

The results of all calculations are rounded into the biggest. In this way, the magnitude of the concrete shrinkage is compensated for - independently calculate it unreal. When buying a finished concrete, you can use the shrinkage coefficient specified by the manufacturer.

Pay attention to water quality. In the liquid there should be no oil or biological impurities. So the standing swamp as a water source for the preparation of concrete is not suitable. It is best for the knead to use conventional drinking water.

How to determine the brand of concrete without the help of the laboratory

How to check which brand of concrete for the foundation of a private house did you get? To check the quality of the concrete mix, there is a special device - sclerometer.

How to check which brand of concrete for the foundation of a private house did you get? To check the quality of the concrete mix, there is a special device - sclerometer.

But you are unlikely to bring it back to buy it, as it is 11-35 thousand rubles. You can make samples and send them to the laboratory, but this pleasure also has a feeling of pocket.

It remains to use home methods. To begin with, look at the concrete mix. The higher its quality, the blue shade. If there is a yellowish tint in cement milk, it can be concluded that in concrete contains clay impurities or slagodes. The thick milk, the higher the brand of concrete.

Now try to explore the pre-manufactured concrete cube. Prepare a hammer weighing 400-800 g and chisel. Cut the chisel to the surface of the cube and hit the hammer over it. The impact force must be medium.

If you managed to drive the edge of the chisel to a depth of 1 cm and more - you received the concrete M 75, by 0.5 cm - M150. A small dent says that concrete brand for the foundation wooden house It is quite suitable - it is within M200-250. If only a small note remained after hitting - you managed to prepare a high-quality brand M350 concrete.

Conclusion

Worth the question of which concrete is needed for the foundation of a one-story house, a private developer must have accurate information about the soils on its site, the total weight of the construction, snow and wind loads in this climatic belt.

Worth the question of which concrete is needed for the foundation of a one-story house, a private developer must have accurate information about the soils on its site, the total weight of the construction, snow and wind loads in this climatic belt.

But in any case, experts advise adhere to the golden middle: not to use high brands and low brands (above M350) and low (below M200). The first is because there will be unnecessarily high costs for the construction of the foundation, the second - based on reasons of the reliability and durability of the construction.

Concretes of brands below M200 can be used only for the construction of inappropriate structures - fences, sites for the installation of household equipment, arbors or small cells.

Video about what concrete is needed for the foundation.

From the brand of concrete, its strength characteristics depend on the foundation, or rather, which maximum load is able to withstand. If you use a concrete solution of a lower brand than necessary, the base is deformed and collapsed under the weight of the rebuilt house. Concrete class and mixing quality affect the reliability and life of the entire building. To determine the brand it is better to apply to experienced specialists to avoid problems in the future.

To find out which concrete is needed for the foundation of the house, it is necessary to take into account the following factors:

- load - the weight of the entire structure, the number of floors;

- soil type;

- climate;

- terms of Use;

- type of base design (tape, pile and so on).

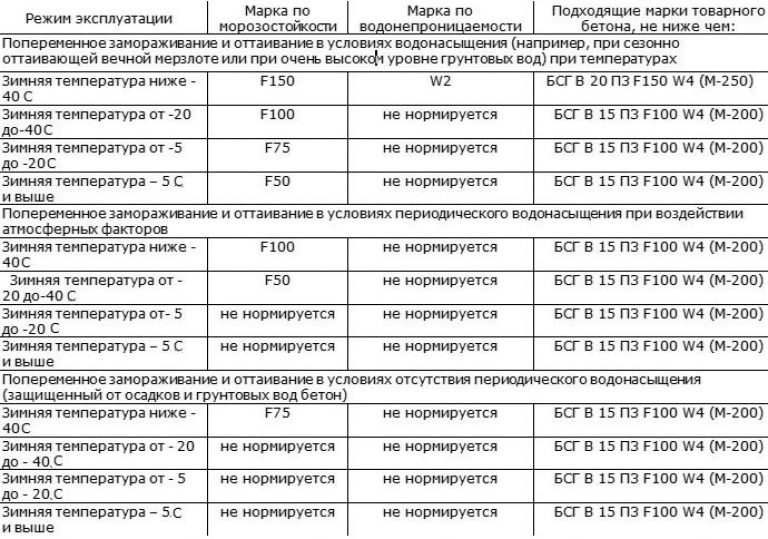

Strength is one of the most important characteristics to be paid attention to first. But no less important is the degree of its moisture resistance and frost resistance. All of these properties vary depending on the proportions of the components and add different additives that accelerate or slow down solidification or grapplation.

The type of soil has a significant impact on the choice of brand. In the construction of low-rise private houses on sand and rocky soils, you can use smaller classes of concrete. For clay soils, higher brands are needed (from M250), since during the freezing such soil expands much expanding, hearing occurs. Because of this, the deformation and destruction of the foundation of the private house can occur. In addition to the use of high brand concrete solutionThe base is elevated below the level of primerization of the soil.

It is also necessary to pay attention to the brand of concrete on waterproof. Marked with the letter W and the number after it, for example, W2. The greater the number is indicated in the brand, the less moisture it absorbs. The degree of moisture permeability of the material depends on the proportion of components and the cement brand. For the construction of private houses on places with high levels of groundwater, brands are recommended from W6.

It is divided concrete and in the classes of frost resistance. This characteristic indicates how much freezing and thawing can withstand the material. It is especially important to take into account the Class of Frost resistance when choosing a concrete for the construction of a private house in a harsh climate. Marked with the letter F and numbers - F35, F100 and so on. The greater the number, the greater the amount of freezing and thawing tolerates concrete. If the base is high qualityly insulated, then the F75 brand can be selected. If the foundation is in more severe conditions, for example, at a high level of groundwater and strong frostsIt is recommended to use the F100 class.

What is a brand for the strength of concrete, and what are they?

By the class of concrete, it is determined which largest load it can carry. This indicator is marked with the letter in and the number after it. For example, B25 means that the material is withstanding pressure up to 25 MPa. There is also a marking of the letter M, indicated in kg / cm2. M100 is a concrete, withstanding up to 100 kg / cm2. The range of brands for the construction of a foundation of a residential building and other buildings begins from M100 and comes to M500.

To translate the brand to the class, the following formula is used: B \u003d M * 0.787 / 10. The class of concrete varies depending on its composition. The more cement, the higher the strength and brand.

For foundations, M100, M150, M200, M250, M300, M400 and M500 are used for foundations. M100 and M150 are selected when building build-up buildings, small garages, fences, private houses (no more than one floor) from foam, aerated concrete or wood. Also as an initial layer under the fill of a higher-class solution. The M200 brand concrete is used in the construction of the grounds of small buildings from aerated concrete, foam concrete, slag blocks with light floors. M250 and M300 is suitable for the construction of the foundations of two-storey houses and buildings of greater floors, fillings monolithic structures. The concrete of this brand can withstand significant loads. Most often it is he who is chosen when building private houses.

M350, M400 and M500 are applied to multi-storey buildings. For construction standards, it is not recommended to use a concrete solution below M250.

The base of the concrete solution is influenced by the type of base, so, for example, a concrete is more stronger for the house with the basement, than for the usual building. A brand for a ribbon foundation can be low, and for pile needs a class above. With a high level of groundwater, M350 or more is selected for the pile base.

For the preparation of a concrete solution you need to use only pure sand. Either crushed stone, either gravel with a fraction 2-4 cm, or gravel fraction is selected, as a broken brick cannot be used, since because of it, the strength characteristics of concrete are significantly reduced. The cement is selected grades 400 or 500. The most common proportion of components for a concrete solution is 1: 3: 4 (cement / sand / crushed stone). Everything is thoroughly mixed up to a homogeneous consistency, there should be no lumps.

The more dense solution, the stronger the foundation will be. Due to voids, the quality and strength of the entire concrete structure is reduced. Therefore, after the fill, the mixture is treated with vibration installation. It will evenly distribute the solution over the entire surface, it wins and remove the air.

Monolith should be poured in one approach. If you do this in several stages, the first party will already have time to grab. After the fill, the second in the concrete will appear "Cold seam". According to the principle of action, this defect is similar to cracks. As a result, the base will not be monolithic, but consist of several parts. Due to the load, such a foundation can collapse.

During the fill of the concrete solution, temperature conditions must be respected. Optimal temperature It is considered + 16 ° C. If the construction is carried out in the winter season, contamination components are added to the solution. If without them, the foundation must be insulated and warmed, for example, thermal guns or current. Thanks to this, water will not freeze.

In the summer, the water is evaporated too quickly from the top of the solution. As a result, the concrete dries unevenly, cracks appear. To avoid this, it is constantly watered with water and is covered with a non-transparent material. Or add plasticizers even at the stage of breeding the mixture.

Even with properly kneading and dosage of components of a concrete solution, it is impossible to ensure that it will have a stated stamp stronger. During hardening, all must be observed the necessary conditions - Temperature, humidity and so on. The largest strength of concrete is gaining in 28 days (with optimal temperature and humidity mode).

For buildings that will be built from aerated concrete, monolithic bases should be erected. Since aerated concrete has a weak bend. Even with a small bent of soil in aerated concrete blocks, cracks appear. If the foundation is monolithic, then the load from the aerated concrete and other elements will be distributed evenly over the entire surface.

The value of the concrete solution is completely dependent on the brand of concrete for a ribbon foundation or other structures. What it is higher, the more it was spent for its manufacture of cement. To determine the required volume of concrete mortar, it is better to refer to the specialists. Since in the event of a lack of a mixture, the foundation will be filled not at a time, which will lead to a deterioration of its quality, and if excess, then the overpayment for extra concrete.

According to SNiP concrete for the manufacture of foundations should be a brand not lower M250.

Maintenance brand of commercial concrete and their scope:

- M-100 - It is used in the construction of various inextended and non-carrying structures, for example, when pouring sidewalks, pedestrian walkways and parking sites, in the manufacture of the scene.

- M-150. - In the fortress, slightly differs from the above-described brand of concrete, therefore, the scope of application of concrete M 150 is almost similar.

- M-200 - Used in the production of floor slabs, for the manufacture of various reinforced concrete belts, road coating at low loads.

- M-250 - Accordingly, there are insignificant differences from the above-described concrete brand, therefore the area of \u200b\u200bapplication of concrete M 250 is almost similar.

- M-300 - Applied when casting staircases, paving slabs, roads subject to strong loads, during the production of slabs of overlapping, various wells and pipes, as well as other responsible structures.

- M-350 - As well as concrete MARK M 300, it is used in the construction of responsible structures: in the construction of staircases, borders (grooves), during the construction of highways capable of withstanding heavy loads.

- M-400. - It is used in the construction of buildings foundations, as a carrier layer in the construction of high-strength floors in garages, basements, various workshops and production workshops, as well as many other service premises, where the strength of the floor is more important than other qualities.

- M-450 - It is considered one of the strongest brands of construction concrete. Used in the construction of responsible structures that can withstand heavy loads. It is used in the construction of high-strength carrier slabs of overlapping, when building foundations of buildings and other responsible structures.

- M-500 - Being the most stronger and reliable among popular brands, I found my use when erecting draft designs, where extreme reliability and durability is needed. The concrete of this brand is perfectly protected from all sorts of destruction, and continues to stand tightly even in the most severe operating conditions, when other less strong concretes are already surrendered.

Brand concrete - Key criteria for determining the quality of concrete. All other parameters - frost resistance, mobility and waterproofability - are directly dependent on the brand. In most cases, the higher the brand, the greater the percentage of cement in the composition of the concrete mixture.

| test Concrete samples |

Experts allocate brand concrete for compressive strength - Load Load (kgf / cm2), which can withstand the concrete sample cast in the form of a cylinder or a cubicle with a size of 15x15x15 cm, which was set aside for 28 days of hardening under optimal conditions. There is also a concept concrete brands on tensile strengthThis characteristic is specified in the event that this indicator is key in this design.

Cement Stamps for Frost Resistance and Waterproof Specified much less often, since these properties in conventional construction are not key. Waterproof is determined by one-sided hydrostatic pressure (kgf / cm2), in which the sample does not pass liquid. The frost resistance brand is determined during the test of samples with multiple freezing and thawing.

Mark is denoted by the Latin letter "M". Today, concrete is presented in the market in the m50 interval to M1000.

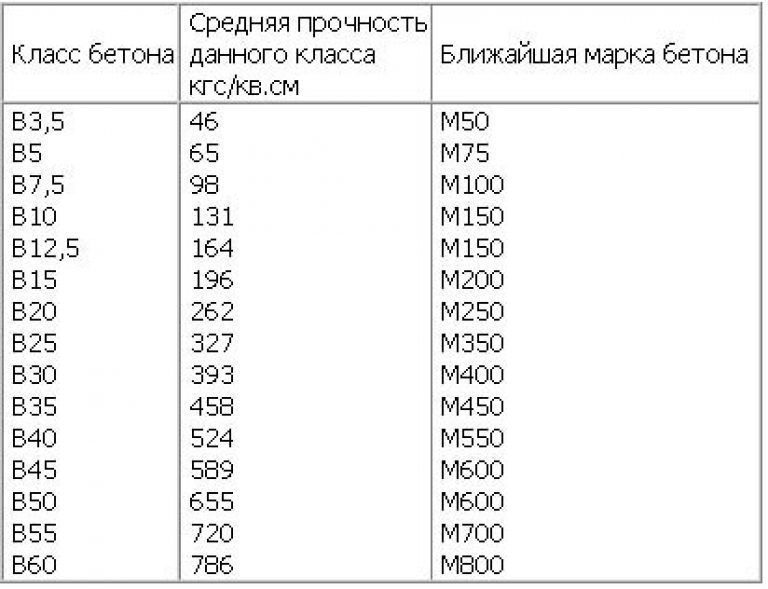

Along with the concept of concrete brand in modern construction The term is widely applied class concrete. The difference between these concepts is that if the brand is averaged indicator, then the class assumes guaranteed compliance with the specified level of strength. In the design documentation in accordance with ST SES 1406, it is the class of concrete required for use. The class of concrete is indicated by the Latin letter "B", on the market you can meet concretes from B1 to B60.

In all information materials, price lists, etc. Concrete is indicated with a digital and letter index. When designing products, concrete is prescribed certain characteristics of concrete: MAP, C-, mobility P-, frost resistance F- and water resistance W-

Today, the concepts of brand and class of concrete are used in parallel. Translation of the brand to the class of concrete can be made through the table below.

The ratio between the class and brands of concrete for strength

(normative coefficient of variation V \u003d 13.5%)

| Class concrete | Average strength This class, (kgf / cm2) |

Nearest Mark. Concrete |

| B3.5 | 46 | M50 |

| AT 5 | 65 | M75 |

| B7.5 | 98 | M100 |

| AT 10 O'CLOCK | 131 | M150 |

| B12.5 | 164 | M150 |

| B15 | 196 | M200 |

| IN 20 | 262 | M250 |

| B22.5 | 302 | M300 |

| B25 | 327 | M350 |

| B30. | 393 | M400 |

| B35 | 458 | M450 |

| B40. | 524 | M550 |

| B45. | 589 | M600 |

| B50 | 655 | M600 |

| B55 | 720 | M700. |

| B60 | 786 | M800. |

The brand and class of concrete is determined not only by the components belonging to the composition, but also the ratio of these components. For example, in accordance with the recommendations of the composition and proportions of concrete, the cement 400 grade 400 can be used for the manufacture of concrete M100 B7.5, and can be brands 500, in the latter case cement consumption will be lower. For each construction object, the composition of the concrete is developed individually. Most often, cement grades 400 or 500 are used for the manufacture of commercial concrete at factories.

cement brand M400 (cement, sand, crushed stone)

| Brand concrete | Mass composition C: P: Sh (kg) |

Volume composition on 10 l cement, P: Shk (L) |

Number of concrete Of 10 l cement (L) |

| M100 | 1: 4,6: 7,0 | 41: 61 | 78 |

| M150 | 1: 3,5: 5,7 | 32: 50 | 64 |

| M200 | 1: 2,8: 4,8 | 25: 42 | 54 |

| M250 | 1: 2,1: 3,9 | 19: 34 | 43 |

| M300 | 1: 1,9: 3,7 | 17: 32 | 41 |

| M400 | 1: 1,2: 2,7 | 11: 24 | 31 |

| M450 | 1: 1,1: 2,5 | 10: 22 | 29 |

Table of proportions of concrete components when used

M500 brand cement (cement, sand, crushed stone)

| Brand concrete | Mass composition C: P: Sh (kg) |

Volume composition on 10 l cement, P: Shk (L) |

Number of concrete Of 10 l cement (L) |

| M100 | 1: 5,8: 8,1 | 53: 71 | 90 |

| M150 | 1: 4,5: 6,6 | 40: 58 | 73 |

| M200 | 1: 3,5: 5,6 | 32: 49 | 62 |

| M250 | 1: 2,6: 4,5 | 24: 39 | 50 |

| M300 | 1: 2,4: 4,3 | 22: 37 | 47 |

| M400 | 1: 1,6: 3,2 | 14: 28 | 36 |

| M450 | 1: 1,4: 2,9 | 12: 25 | 32 |

Concrete is a modern construction materialFor strength, competing with natural stone. Its high performance properties provided him with popularity in the production of all types of construction work, including when the foundation is built. If light designs can use that capital structures require a high-quality belt or pile foundation, the characteristics of which directly depend on the selection of the brand of concrete, skillful kneading and carefully selected composition.

In this article we will look at what concrete is used for the foundation.

Composition of the mix

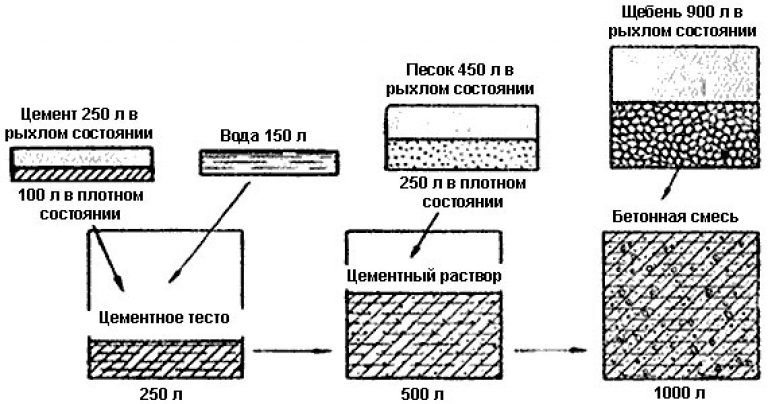

In a concrete mix, you can highlight two main components:

- Fractional filler (sand, crushed stone or gravel) is a "power" element that perceives all loads. The volume fraction in the composition is up to 80%.

- A binding substance resulting from the contact of the cement mixture and water. The volume fraction in the composition is up to 30%.

The ratio of listed substances in may be different, depending on the humidity of the filler, the presence of additives. The foundation is the carrier part of the building, therefore, to ensure resistance to settlement loads, it is necessary to properly choose the composition of the concrete mix. Concrete perfectly works on compression, which allows the foundation to successfully withstand the pressure of the ground construction. The reinforcement frame applied in the foundation provides strength in the transverse direction in the primer of the soil.

The selection of concrete for the foundation depends on the construction of the built building. There are various requirements for the foundation, which causes the use of concrete brands in the practice of a wide list.

To answer the question of which brand of concrete for the foundation of the private house will suit, consider the main types.

M100 brand concrete

Refers to light concrete, is distinguished by low cement content. The main application finds on the preparatory steps of construction work, when pouring concrete training. M100 is sufficient to cheat, but its strength characteristics limit the use of non-vacant buildings, such as fences, frame houses, shed.

M150 concrete brand

In terms of its characteristics, this is not very different from M100. Basic use - preparatory construction works. From concrete M150, it is possible to pour only the easiest ribbon foundations of one-storey light houses from a tree or hollow blocks, garages and sheds. This brand of concrete for the foundation of the private house is permissible only if the rocky soil will act as a reliable base. It is impossible to deepen the foundation due to the danger of groundwater, otherwise it is necessary to use waterproofing (liquid rubber).

M200 brand concrete

This concrete is already stronger and often used when erecting low-rise (up to two floors) of buildings and structures with wooden or metal floors. Magni M200 concrete is allowed to manufacture magbene, such as piles or slabs of overlapping. The main area of \u200b\u200bapplication in residential construction is the fill of the foundation under frame-shield houses. The soil is allowed only sandy, and the groundwater should not rise to the height of the freezing, and their seasonal oscillations should be taken into account.

M250 and M300 brand concrete

Cement content - average. The M250 is a concrete brand for the foundation of the house (for fill) to three floors. Magna M300 - a more durable concrete, it is used in the foundations of cottages with a height of up to five floors. According to construction standards, M300 brand concrete is allowed to use for manufacture monolithic overlaps. Finds use when pouring pools. Concrete data stamps can be used when the foundation is arranged on sandy soils, as well as on a ground of gravel or rubble with a relatively high level of groundwater.

M350 brand concrete

One of the most popular concrete brands in construction. Much significantly exceeds M300 not only by strength, but also in frost resistance. Different with a long declared service life.

Suitable for the construction of multi-storey buildings, used when erecting consoles, overlaps and other responsible structures. When erecting the foundation, the M350 concrete brand is permissible to apply for a single-storey residential building of the brick. Suitable for difficult clay soils and places where high groundwater levels. Suglinki and clay soil are the most common. Freezing, clay increases in the amount, which can lead to the deformation of the foundation in the case of an incorrectly selected brand of concrete.

M400 brand concrete

This brand is extremely high strength characteristics due to the large cement content and a specially selected filler.

This concrete brand is used for the foundation of the private house. Also allowed scope is the construction of multi-storey buildings (up to 20 floors in height).

Which brand concrete is needed for foundation?

Concrete is a lower brand cheaper, however, when the foundation is raised, it is better to provide a certain margin of safety, especially for those cases when it is planned to make a basement with residential. Which brand concrete is needed for foundation? Concrete brands M350, M400 is distinguished by increased density, and therefore moisture will be worse through it worse, and the base will be superior. Sometimes, in the construction of irrelevant structures on a bad ground, it makes sense to calculate that it is more profitable: to use a higher brand of concrete or to do with concrete cheaper, but to process the foundation of waterproofing to protect against groundwater.

The easiest way to determine which brand of concrete is needed for the foundation of the house, which brand to choose is to pre-order design and estimate documentation to the constructor. It defines the suitable brands of concrete for each type of work, including the foundation, and additional properties that the solution must satisfy, such as:

- density,

- waterproof (protection against groundwater),

- frost resistance (the higher, the more suitable for the harsh climate),

- fluidity

- fire resistance.

However, the brand of concrete for the foundation of a private house may be selected independently. To do this, it is necessary to take into account the following features of the construction of the structure:

- the weight of the structure, the floors, the presence or absence of the basement,

- geological surveys of the plot: the type of soil and the depth of groundwater is determined,

- foundation type: tape, pile or any other.

Each of the above factors affects what a concrete is needed for the foundation, the choice of brand of concrete, taking into account its special characteristics, etc.

On concrete monolithic foundation There are multidirectional forces around the perimeter. The foundation should be deepened in the Earth so that it turns out to be lower than the level of freezing. Specific values \u200b\u200bof the drainage depth are widely vary, depending on the soil and climatic conditions. In general, for average latitudes, the level of frozen is 0.9-1.5 m. The depth of the embedding is recommended to choose with some reserve. Support on the ground base, not susceptible to freezing, saves ribbon foundation From the deformations of frosty powders.

For a ribbon foundation, lower concrete stamps will rise, but the pile, on the contrary, requires higher and more durable. Pile foundations Used by erection of capital multi-storey buildings. Ribbon foundations are equipped for

Selection of concrete mortar and kneading

Despite similar designations, the brand of concrete and the cement brand is completely different concepts. The number in the cement mark means the strength of the cement mortar.

Since the foundation design implies its reinforcement in order to ensure transverse strength, it is optimal to choose a cruggy or gravel of the average fraction. Best ensures the grip of the bright granite gravel.

The water is not presented to the water, the ordinary water supply will be suitable. Cement-water ratio is 2: 1.

The preferred method is the use of concrete mixer, but manual mechanical mixing of the solution is possible. This requires a volumetric container into which sand, gravel or crushed stone and cement are added in a certain ratio. Mixing dry components well, you can gradually pour water, constantly stirring until the formation of a homogeneous mass. It is important not to overdo the amount of water.

Calculation of the desired amount of concrete

The wrong calculation threatens the lack of material or the formation of surplus, which is also undesirable.

Separate plate volumes, ribbon base bands, pillars, which are then summarized. The desired value is multiplied by the coefficient of concrete shrinkage, the value of which is taken from the passport. Since the armature also occupies some volume in the formwork, then the volume of concrete on the coefficient 1.05 should be divided into account. The resulting value is rounded into the biggest.

What concrete is needed for foundation

Instructions for choosing:

- carefully calculate the weight of the structure;

- allocate the safety margin due to possible errors or unforeseen circumstances;

- determine at what depth are groundwater;

- determine the interaction of the soil and the future foundation.

Ribbon foundation can be safely attributed to the category of the most popular - it is preferred in the overwhelming majority in the construction of its own housing outside the city. The scheme of such a base, the algorithm of its calculation, the drawings of reinforcement and the technology of the fill - all these issues are worked out in practice to the smallest detail, and therefore many of the site of the plots very often prefer to take on its construction on their own.

But nothing will cost competent calculations of the sizes of the foundation tape, neatly dug in trenches and firmly chopped formwork, reliable waterproofing and perfectly thoughted armature carcassIf it does not apply to the fill that does not correspond to the conditions for future operation or poorly prepared concrete. Therefore, we offer a reader who is interested in the topic of a belt foundation, make a small excursion to the theory and practice of the preparation of the solution necessary for such purposes. It is useful to know when planning the order of finished concrete, and for self-preparation of the solution at the place of construction.

So, what brand of concrete is needed for a ribbon foundation, and how it can be made by its own.

First of all, that in general this is concrete. Under this term, it is customary to understand the stone of artificial origin, which is obtained as a result of the mixture filled into the shape, consisting of properly selected components, among which include:

- the binder (most often the cement acts in this role);

- Fillers (usually sand, gravel or crushed stone, but some concrete assume use of other materials).

- water speaking and as a diluent, and as a necessary component for chemical reaction Education and maturation of concrete stone.

If you read the construction literature, you can make sure that the classification of concrete is very branched, and includes many of their varieties of the most different destination. However, it is not possible to delve into it in this case - we are interested only in those types that are suitable for the construction of foundations. And this means that from all the variety, only heavy solutions based on Portland cement and on dense aggregates.

If you figure out, the almost complete picture of the operational qualities of concrete gives the four main indicators of the solution: this is a vintage strength or class (may be indicated by the symbol M or C), frost resistance (F), water resistance (W) and mobility or disappointment (P). Some indicators are decisive for the construction of the foundation, others, say, indirect, but to get acquainted with everyone.

Concrete Strengths and Classes

This is perhaps the main indicator that needs to be considered when choosing a specific solution.

The brand indicates which load on compression is able to withstand completely ripened concrete, expressed in kgf / cm².

Total concrete brands on strength - quite a few, from M50 to M800. However, in the sphere of private construction, and specifically, when the foundations, developers, as a rule, have to face stamps from M100 to M300, less often - M400.

In reference books and in building technological instructions, very often instead of the concepts of varying strength, the concrete class is operated. These values \u200b\u200b- to a certain extent interrelated, and differ rather "coordinate system".

The class is denoted by the letter in and a numeric indicator, which corresponds to the load (expressed in megapascals), which, with a probability of 95%, will withstand an experimental sample - a cube with grains of 150 mm.

Thus, if the brand speaks of a averaged value of strength, then the class is already about the actual one. An example is a solution of one and the same component composition corresponding to a certain brand, but frozen and shaking strength in various conditions may, according to the test results, show a different class of strength.

However, in the conditions of independent private construction, the knowledge of such sublications is unlikely to be needed. It is important to deal with concrete stamps and in how they are roughly related to classes. And it will help in this - the following table.

Table 1. The ratio of brands and concrete classes

| Concrete strength for compression, kg / cm2 | Concrete class | The nearest brand of concrete for strength |

|---|---|---|

| 65.5 | AT 5 | M 75. |

| 98.2 | B 7.5. | M 100. |

| 131.0 | B 10. | M 150. |

| 163.7 | B 12.5. | M 150. |

| 196.5 | B 15. | M 200. |

| 261.9 | B 20. | M 250. |

| 294.4 | B 22.5. | M 300. |

| 327.4 | B 25. | M 350. |

| 392.9 | B 30. | M 400. |

| 458.4 | B 35. | M 450. |

Having at hand such a "crib" is easy to navigate in both systems for assessing the strength of concrete.

Frost resistance concrete

A frost resistance mark is denoted by the letter symbol "F" and a number that speaks about the number of freezing cycles and thawing material samples without any significant changes in its physicomechanical and operational characteristics.

The method of definition of frost resistance is installed GOST 10060.0-95. The same standard provides for the classification of materials for such an indicator - marking varies ranging from F25 to F1000.

When evaluating frost resistance, unnecessary extremes often admit:

- The number of freezing cycles does not mean the number of years, that is, winter alternations with the summer. During one cold season of such freeze-thawing cycles, there may be several, and sometimes even a few dozen - remember the winter with an abundance of thaws.

- Class of frost resistance, for example, F50 - this does not at all mean that after 50 cycles, the concrete comes in complete disrepair.

In principle, such an assessment of frost resistance concerns concrete, which is saturated with water. For example, a dry-colored structure from, say, concrete with a stamp of frost resistance F50 or F100, for the period of its many years of operation, it is capable of withstanding thousands of frost cycles-thawing, while remaining completely unharmed. That is, if the foundation is to ensure proper quality of waterproofing (and this is one of the key requirements for ensuring the durability of your own home), then the brand of frost resistance will not be a critical indicator. Moreover, when complying with the technology of concrete preparation, this indicator, even if desired, cannot be understood - to make a smaller F100.

- It is the pavement of the tracks and the fill of the scenes: the class of frost resistance is desirable here not lower than F300

- The second case is cement tile The roof, when the release of which the responsible manufacturers achieve frost resistance of the F600 ÷ F800.

Practice shows that for foundations (naturally, with their waterproofing), the F150 indicator is quite enough, and for the walls - and less, about F50 ÷ F100

Class of waterproof concrete

This indicator is denoted by the letter W and a number (from W2 to W12). The numeric indicator indicates about the maximum pressure, expressed in megapascals, in which the prototype (cylinder height is 150 mm) does not pass through itself.

From the point of view of practical application in the conditions of individual construction (in particular, when erecting a belt foundation), the significance of this indicator is small. By analogy with the class of frost resistance, if you follow the requirements of the technology of preparing a qualitative concrete solution of the desired brand (class) of strength, the optimal parameters of water resistance will be achieved by themselves.

Table 2. Approximate compliance of concrete indicators with standard optimal combinations of components and compliance with solutions

Class (nearest brand) concrete concrete Frost resistance Waterproof B-7.5 (M100) F50 W2. B-12.5 (M150) F50 W2. B-15 (M200) F100 W4. B-20 (M250) F100 W4. B-22.5 (M300) F200 W6. B-25 (M350) F200 W8. B-30 (M400) F300 W10. Even if the owners seem that the ground in the construction site is oversaturated with moisture, it is still much cheaper, faster and more reliable will perform high-quality waterproofing than to order expensive concrete with an increased brand of waterproof (W12 or even higher).

Performance indicators of solutions

But this parameter is extremely important to ensure the quality of work on the construction of the foundation. Especially - in conditions of ordinary construction siteWhen the means of mechanization on laying concrete into formwork may not be available. In fact, this indicator hides how much the solution is plastic, it is pouring, distribution with the full filling of all cavities, alignment at a given level.

There are several criteria for evaluating workability, but in everyday construction practice, the mobility indicator is most often used, denoted by an alphabone symbol of P and a digital value. Where does that come from?

The measure of the mobility of the solution shows how much it can spread under the influence of its own weight. The test of this parameter is carried out with simple experiments - firmly filled with a special form in the form of a truncated cone (the base diameter is 200 mm, the diameter of the upper hole is 100 mm, the height is 300 mm. Filling is carried out in three receptions - equal in height layers, with mandatory multiple Shtyking (piercing the solution to the base of the base with a metal rod). Then the surplus is removed from above, and the shape is neatly, the forward movement is removed (it should be spent from 3 to 7 seconds). The form is set next to a molded cone that sends under the cone. Own weight.

The forms of the sedimentation of the cone from the initial horizontal level (from the vertex of the form) will lead to the desired indicator of the mobility of the solution.

Table 3. Indicators of mobility of concrete and features of using solutions

The magnitude of the settlement of cone Mobility indicator Note 0 Not regulated Hard concrete is a special scope of application. - from 1 to 4 cm P1 Large-resistant, half-west concrete. Hold on a vertically located bayonet shovel. In private construction practice - practically not used. - from 5 to 9 cm P2. A solution of medium mobility - smoothly slides from the bayonet shovel. It can be used when filling the foundation, but with a rather rare armature rod location and with mandatory deep vibration. - from 10 to 15 cm P3. Mobile mortar - flows from the vertically located bayonet shovel. It can be considered probably optimal for filling a belt foundation with any frequency of the arming of reinforcing rods. Requires the mandatory use of the vibrator. - from 16 to 20 cm P4. Concrete solution of high mobility, practically fluid. Great for working with concrete-pump installations. A good option For a belt foundation. The use of vibratinglading is desirable. - Over 20 cm P5 Fully fluid solution. To a greater extent for fill monolithic walls and overlaps. For a ribbon foundation, it will be nevertheless too mobile, and for such purposes it is usually not applicable. What is concrete Order for a belt foundation?

So, the main criteria for evaluating concrete solutions applied to individual construction were considered. It remains to find out: what composition will be optimal for the fill of the tape basement.

Table 4. Areas of application of commodity concrete various brands

Class (brand) concrete for strength Commodity brand concrete Application concrete B7.5 (M100) BSG 7.5 p3 F50 W2 Preparation under the foundation B10 (M150) BSG in 10 p3 F50 W2 Preparation for the foundation, fill of the tape base for non-refined structures B12.5 (M150) BSG 12.5 p3 F100 W2 Preparation under the foundation, filling of the belt foundation for non-refined structures (light household buildings) B15 (M200) BSG 15 p3 F100 W4 Monolithic foundations of ribbon and slab, tie, screeching. B20 (M250) BSG 20 p3 F150 W4 Monolithic foundations - ribbons and stoves, riglels, insulated Swedish plates, ties of warm floors B22.5 (M300) BSG in 22.5 p3 F150 W6 Monolithic foundations of any types, monolithic reinforced concrete bearing structures, Thin high strength ties of warm floors. B25 (M350) BSG 25 p3 F200 W8 All the above applications - in particularly complex operating conditions B30 (M400) BSG in 30 p3 F200 W8 Monolithic foundations and bearing structures under heavy multi-storey buildings, among other things, in complex areas of construction.

More durable brands in individual construction are not found.We will pay special attention - it is yet that the finished commercial concrete, which are ordered in the relevant firms with delivery to the construction site. At the same time, the dimming of the mixture should be made no later than 90 minutes after the primary shutdown of components with water - during transportation in special concrete mixers, and no more than 45 minutes - if the solution is transported in the dump truck, that is, without constant mixing. It means that it is necessary to evaluate the principal possibility of such delivery in advance, to provide access to the place of fillionate the foundation.

When ordering the finished concrete mix (BSG), it is necessary to take into account some more nuances. Unfortunately, the emergence of a considerable number of small firms practicing production construction solutionsIt does not mean that they all work with compliance with standards or established technical conditions. Alas, the realities are such that it is not possible to trust everything - it is necessary to familiarize yourself in advance with the reputation of the nearby organizations of such a profile. Very often, it is necessary to face the fact that, according to the results of the maturation of the concrete, its final actual strength differs significantly from the declared solution, and it is very difficult to check it at the purchase stage. It is quite clear to the desire of manufacturers to "save on cement", but not due to the quality of the quality!

Which exit?

- The first is to trust only yourself, and cook concrete yourself, with strict observance of all necessary proportions (We will come to this question slightly later).

- The second - for insurance when ordering a commercial concrete intentionally to overestimate on one or two steps its strength class and all other corresponding characteristics. In the same way, by the way, they come if the construction will have to be conducted on a plot with a pronounced bunch of soil.

Therefore, one more table can be brought, based on the practice of construction under normal conditions "Russian depths". The indicators given in it do not have any theoretical justifications - these are only generalized average data on the use of ready-made commercial concrete concrete for filling tape bases.

Type of one-story house Soils with good bearing ability, weakly Bunny soils Light wooden boards or frame houses BSG in 15 p3 F100 W4 (M-200) BSG 20 p3 F150 W4 (M-250) Brous houses, log cabins BSG 20 p3 F150 W4 (M-250) Houses from gas silicate blocks, ceramzite concrete, opilk concrete (arbolit) and other similar materials BSG 22.5 p3 F150 W6 (M-300) BSG 25 p3 F200 W8 \u200b\u200b(M-350) Brick houses, stone or monolithic reinforced concrete BSG 25 p3 F200 W8 \u200b\u200b(M-350) BSG in 30 p3 F200 W8 \u200b\u200b(M-400) Note to Table 5. In the case when the building is planned to build more than one floor, it is recommended to order BSG on the brand above. But in any case - not higher than B30 (M400).

Cooking concrete for a belt foundation yourself

If there is no possibility to use the services of manufacturers of commodity concrete, or completely lacks confidence in local "shabashniks", you can assign this very time-consuming function on "own shoulders".

It is necessary to be prepared for the fact that the work is to have a considerable and almost uninterrupted, since the fill of the ribbon foundation is recommended for one shift. It became necessary to prepare everything in advance necessary components To prepare the desired brand of concrete, provide for the procedure for the correct dosage (by volume or by mass). It is possible to think about whether the working hands will have enough for carrying out practically continuous loading and unloading of concrete mixer.

So, for the independent preparation of a concrete solution for the foundation, the previously mentioned components are required - cement, sand, crushed stone or gravel, water. It does not rule out the use of special additives that improve certain qualities of the finished solution. But about additives is a special conversation, and we will talk about them in a separate Racking of our portal. In the meantime - basic components of concrete.

Basic components of concrete solution

Cement

Cement in the composition of concrete acts as the binder component. Most often, portland cement (PC) is used for these purposes, obtained by a thin variety of spinning grains of special clay (clinker) and limestone, with dosage added (from 1.3 to 3%) gypsum.

The cement manufactured by the industry is divided into brands - from 300 to 600. By itself, the Mark speaks about how approximately the compression strength of the solution prepared from cement and sand (in the proportion of 1: 3), with an optimal water-cement ratio and full maturation (28 day). For the preparation of concrete solutions going on the filling of belt foundations, the Cement PC-400 is most often used, as the most accessible and quite universal for such purposes. Cement of PC-500 can be used - it's only in changing the original proportions, but simply PC-400 is usually easier to purchase because of its widespread accessibility, and the price value - quality speaks in his favor.

From the cement marking, you can learn some other information.

- So, the symbol d says about the presence of modifying additives: "To" - additives are missing, other number is the percentage of additives from the mass of cement;

- The symbol "B" is a fast-hardening cement;

- - "pl" - plasticized cement;

- - "GF" - cement with hydrophobic qualities.

You should always pay attention to the date of cement production. Even in normal conditions of storage, cement for the first three months is capable of losing up to 20% of its valuable strength, for six months this loss will already be 30%, and up to 40% - during the year. Output - or use only fresh cement, in accordance with the proportions of the solution, or to make appropriate adjustments by the amount of deposited cement (in proportion to the loss of strength) and increase the time for the preparation of the solution (practically four). Much better, definitely, try to do with fresh cement.

Sand

Sand is used as a compulsory fine-phrase aggregate in concrete. The optimal option is a career, with a module of size from 2 to 3.25 mm, but with voidness of no more than 30%, that is, with the content of all fractions.

In private construction, the preparation of concrete brand to M300 is allowed to use sand. With a fine fraction (less than 1.6 mm) not more than 20% of the total volume., And with the content of impurities (clay) to 3% by weight. The content of dust-shaped sand fractions (less than 0.6 mm) should also not exceed 3%.

Sand for the right water-cement ratio is better to use dry. The average density of sand is about 1500 kg / m³.

Gravel or crushed stone

Crushed stone or gravel is used as a large-scale concrete aggregate. The difference between these materials mainly lies in that crushed stone is a derivative of the forced crushing of rocks, and its faces usually have an acute form. Gravel is a product of natural destruction (weathered or water erosion) of rocks, and its elements often have rounded outlines and smooth rounding faces.

Crushed stone and gravel may also differ in the fraction size - usually this indicator may vary in the range from 5 to 70 mm (four fractions are divided: 5 ÷ 10 mm, 10 ÷ 20 mm; 20 ÷ 40 mm and 40 ÷ 70 mm). According to existing standards for high-quality concrete preparation, it should include crushed stone or gravel at least two different fractions - with a maximum of up to 40 mm, or three at maximum up to 70 mm.

At the same time, the maximum grain size of rubble or gravel should not exceed two thirds of the distance between the longitudinal reinforcement rods. In addition, the maximum size should not be greater than 1/3 (and better - even 1/5) from any minimum size filled building construction. Since we are talking about a belt foundation, then, for example, with a tape width of 200 mm, the size of the rubble fraction or gravel should not be above 40 mm.

In fact, when pouring tape foundations for small buildings, private developers often use a large aggregate of one fraction - 20 mm. This, in principle, it happens quite enough, and work on small concrete mixers with a larger rubble or gravel, and when filling the narrow tapes with a rather frequent location of reinforcing rods, it is very difficult.

Crusp or gravel should also be clean - even small clay contaminants are capable of sharply, up to 30%, reduce the final actual strength of the finished concrete solution. So if the material is purchased with obvious signs of strong pollution with clay or soil, before starting work, it is necessary to wash the water with directional jets from hoses in advance.

Water

It would seem - and here that is complex: leu yourself water into a mixed solution, until you get the desired consistency ...

It turns out, everything is not so simple.

- First of all, certain requirements for its purity are also presented to water chemical composition. All of them are listed in detail in the TU established by GOST 23732-79 - this is the absence of traces of petroleum products, acids, phenols, sugars, regulatory oxidation, maximum salt content, etc. True, in most cases, pure water and well water is quite suitable for the knead.

- The second and, perhaps, the main thing is the optimal ratio of water and cement. Excess moisture never goes to favor the resulting "cement stone". It is enough to look for an example on the next diagram.

The crooked lines in the diagram indicate changes in the grade strength of the obtained concrete from cement (in proportion to the sand 1: 3) of the corresponding brand. Take, for example, Cement PC-400. With a water-cement ratio of 0.4, total maturation reaches an indicator of over M400. But with an increase in the amount of water there is a sharp decline, and with a ratio of 1.0, concrete strength is already evaluated in total in M100, that is, the loss in this indicator is four times !!!

This, however, is easy to explain. Unused in a chemical reaction with cement water has only two ways:

- Or it gradually evaporates, leaving behind large pores, sharply reduce the strength quality of the material.

- Or it remains in an unrelated form in the pores - and this is even worse, as at the occurrence of frosts, this moisture will begin its destructive action.

So, when mixing concrete, it is necessary to strictly observe the optimal water-cement ratio. For reference - average values \u200b\u200bfor different brands of concrete and used for their manufacture of cement are given in Table:

Planned to the manufacture of brand (class) concrete Portland cement PC 400. Portland cement PC 500. M100 (B7.5) 1.03 not applicable M150 (B12.5) 0.85 not applicable M200 (B15) 0.69 0.79 M250 (B20) 0.57 0.65 M300 (B22.5) 0.53 0.61 "Recipes" of concrete for filling tape foundations and the procedure for conducting the knees

Dosage components for making concrete

So, it remains to consider what proportions must be observed for the preparation of a particular brand of concrete.

If desired, it would be possible to bring the entire method of calculation and theoretical substantiation of the ratio of the initial ingredients - by weight and by volume. But, probably, the reader is more interested in the practical side. Well, the preparation of this type of concrete, suitable for filling tape foundations - before the question spent in everyday practice, which can be simply given the proportions tables.

Table 7. Dosage of components for the preparation of concrete on the basis of cement of PC-400

M100 (B7.5) 1: 4.6: 7.0 10: 41: 61 7.8: 1 M150 (B10 ÷ B12.5) 1: 3.5: 5.7 10: 32: 50 6.4: 1 M200 (B15) 1: 2.8: 4.8 10: 25: 42 5.4: 1 M250 (B20) 1: 2.1: 3.9 10: 19: 34 4.3: 1 M300 (B22,5) 1: 1.9: 3,7 10: 17: 32 4.1: 1 M400 (B30) 1: 1.2: 2.7 10: 11: 24 3.1: 1 Table 8 Dosage of components for the preparation of concrete on the basis of cement of PC-500

Brand (class) of the strength of the manufactured concrete Mass ratio (Cement: Sand: Crushed) Volution in volume (cement: Sand: Crushed stone) The volumetric ratio of finished concrete to cement M100 (B7.5) 1: 5.8: 8.1 10: 53: 71 9.0: 1 M150 (B10 ÷ B12.5) 1: 4.5: 6.6 10: 40: 58 7.3: 1 M200 (B15) 1: 23.5: 5.6 10: 32: 49 6.2: 1 M250 (B20) 1: 2.6: 4.5 10: 24: 39 5.0: 1 M300 (B22,5) 1: 2.4: 4.3 10: 22: 37 4.7: 1 M400 (B30) 1: 1.6: 3.2 10: 14: 28 3.6: 1 The amount of water is easy to determine for each specific case on the recommendations located above the table of the water-cement ratio.

Mixing ingredients in concrete mixer

The main task is to create an enveloping layer of their cement "test" for all aggregates, regardless of their fraction. Manually such an operation should be done almost impossible - the use of mechanical mixers allows you to raise the strength of the solutions obtained to 40% compared with the mixing of the shovel in the container.

When preparing a solution in concrete mixer, the following order of operations are adhered to:

- At the very beginning of work, the capacity of concrete mixers is necessary, so to speak, "lubricate". For this, a fluid solution from cement of sand and water is stirred for several minutes - it is then merged - it can be used to use it on a running construction.

- Then in the working concrete mixer of a large volume (0.5 m³ and more) is sequentially added:

- 15 ÷ 20% of the planned amount of water;

- the amount of sand and cement required by dosage;

- After mixing this load, a large-scale aggregator (crushed stone, gravel) and the remaining amount of water is added.

- If a small concrete mixer is used, then it is better to do so:

- the necessary proportion of sand on dry is mixed with about a half rubble;

- then added, also on dry, cement;

- After thorough mixing to dry - add water, and at the very end to finally split all possible lumps - the remaining part of the rubble (gravel).

- It should never be assumed that the longer you interfere with, the better the solution. In everything, there must be a measure, as it may turn out with the accuracy "to the opposite": the longer cycle, the more water simply evaporates, and the plasticity of the concrete will decrease.

The minimum stirring duration is usually estimated per minute - one and a half. (Interestingly, the German standards have their own opinions on this expense - the duration of mixing is generally estimated at 30 seconds).

Video: An example of making concrete M300 in concrete mixer

Appendix: Fast and accurate calculation of components for self-preparation of concrete for filling tape base

Below is a calculator that will allow you to quickly calculate the required amount of ingredients to prepare the desired amount of concrete.

The calculator allows you to calculate in two ways:

- The first is the definition of the amount of ingredients for the preparation of a specific volume of the solution - it can be useful, say, to plan the boot of concrete mixer of a known one-time performance.

- The second option - allows you to determine the total amount of concrete for filling the entire belt foundation. In this case, it will be more likely to go about the volume of the ingredients that need to be purchased or prepared on the workstation for self-preparation of the solution.

The calculator calculates the two most frequently used solutions grades - M200 and M300, which are made from cement PC-400.

The calculations appear "People's" unit of measurement - bucket. This refers to a bucket with a capacity of 10 liters.