Grounding the housings and other parts of industrial and household electrical installations that are not usually energized, allows you to remove the electric current into the soil. This is provided for by the rules safe operation Consumer electrical installations and applies to the flanges of supporting insulators, shields and control cabinets, drivers of disconnectors, housing of measuring transformers, welding machines and other equipment. Installation of the grounding system involves the installation of grounding pins and attaching grounding conductor to them attached to electrical equipment enclosures.

Grounding the welding machine representing a stationary installation is performed in order to ensure its safe operation. Basic grounding requirements in the following:

- All inactive parts of electric welding installations and one secondary output are ground.

- Welding equipment must be equipped with a special contact in (the form of a bolt or hairpins) designed to attach grounding.

- The grounding bolt must be with a contact pad, indicated by a special ground sign.

- Sequential grounding of multiple installations is prohibited: For each, a separate connection point must be provided.

Portable welding automatic installations and semi-automatic networks connected to the network alternating current Over 42 V (and more than 110 per permanent), also equipped with grounding contacts. In the event that the grounding (reinforcement) cannot be used or the ground installation is difficult, electrical equipment must have a Uzo (protective shutdown device).

Grounding can be used for lightning protection device.

For objects powered by a lower transformer with plug-free neutral And the voltage on the secondary winding of the 380/220 B, the re-ground is arranged at entering. At the same time, the resistance of the grounding circuit, according to Pue, should not be a large 10 ohm. In order to provide such parameters, it is necessary to use grounding machines with a large contact area and good conductivity. Their surface must be cleaned from oil and paint. Suitable for this:

- metal pipelines (except those associated with combustible liquids and gases);

- metal cable shells;

- casing;

- foundation elements.

Mounting circuit The grounding circuit in this case should provide for double connecting them to the grounding line. Welding is used to attach grounding machines to grounding conductors. At the same time, the welding seam should be twice the wider rectangular shape of the conductor (in section) and six times round. If the welding cannot be used - clamps are used, which, as well as welding seams, are protected from corrosion of the bitumen layer. Before imposing a clamp, the surface of the natural earthinger in this place should be cleaned.

In explosive rooms natural grounding Can only be used as an additional. The main thing should be an artificial ground, made in accordance with PUE.

The inner ground circuit is attached to the anchor bolts directly to the wall. In places of their intersection with cables or pipelines provide protection from pipes. In rooms with a high level of dampness and acidity, the inner contour of the ground is fixed on supports at a distance of 100 mm from the walls.

Various grounds

In the absence of natural earthingers, the outdoor ground loop is mounted to which the corresponding conclusions and terminals of electrical equipment are attached.

Artificial grounding can be implemented from vertical or horizontal earthing. For vertical, pipes from steel or corners, which connect to each other, resulting in a circuit. Connecting elements are horizontal earthing: It is used for this metal strip thickness of at least 4 mm or a round cross section of the armature with a diameter of 10 mm.

Horizontal earthingers can be made in the form of metal bands laid on the bottom of the kittlers prepared for the construction of the foundation. The strips are located in such a way that their largest surface is oriented towards the Earth. The cross section of the strips is 30 × 4 mm, a round steel fittings with a diameter of 12 mm can be used.

It is not allowed to use aluminum to create a bellged ground, since this metal is quickly destroyed in the soil from the electrocorrosion.

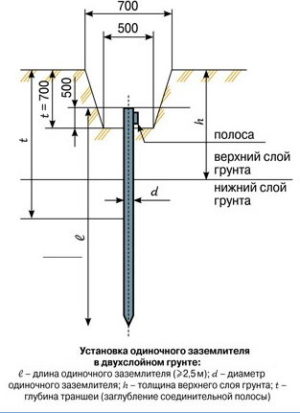

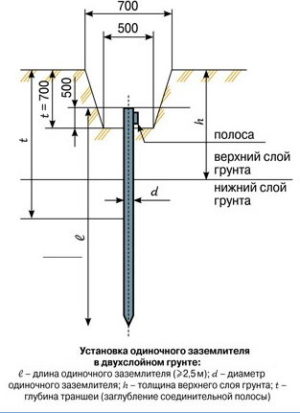

Where the installation of horizontal grounding is impossible (for example, due to the lack of a land plot free from asphalt and other communications), the technology of deep grounding is applied. At the same time at one point in the ground different ways Metal rods are introduced: the end of each of the following is connected to the previous one, forming a ground with a large contact area.

How is the horizontal ground

Ground installation technology is simple. It is used to perform the works of Bulgarian with a circle for metal, welding, sledgehammer and a metal brush for stripping the places of welding. The whole process consists of the following items.

- Treat necessary materials. You will need:

- the strip of the same material is 40 × 4 mm or a round wire (reinforcement) with a diameter of 10 mm;

- hot-zinc corners of 2.5 m (cross section of 50 × 50 × 5 mm - 3-4 pieces).

- We compile a project in which there is enough space for the location of the vertical electrodes at a distance exceeding their own length (that is, more than 2.5 m).

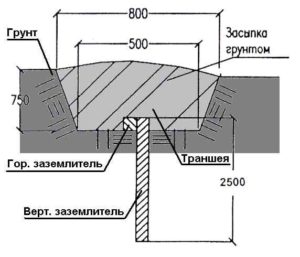

- There is a trench of a width of about 400 mm depth of 700-800 mm.

- In the outlined places, the corners with sharpened tops are clogged with a sledgehammer, leaving on the surface of 200 mm.

- Welding the ground loop is performed: the metal strip is welded to the tops sticking over the ground.

- Grounding welding with wire or tire laid to a camshaft or control cabinet.

- Welding the grounding strip with corners and connecting wire is covered bituminous mastic To protect against corrosion.

- All elements are sprinkled by the Earth, which is then rambling.

- Measured ground resistance.

- If the result exceeds 4 ohms, it is necessary to add another vertical element that is connected by welding with the rest of the design.

Installation of vertical deep grounding

In addition to saving space, the deep ground has another advantage: due to contact with the lower, dense and saturated groundwater layers of the soil, good conductivity is achieved.

Mounting grounding with their own hands is carried out in various ways. The choice depends on the properties of the soil in this area:

- for loose rocks, pressing, screwing and driving electrodes consisting of separate rods is applied;

- in dense and frozen soils, electrodes are immersed by drilling or vibrating driving;

- in rocky rocks, the electrodes deepen into a specially drilled well.

Electrodes, depending on the soil, are used different. They are square, corner and round. The cross section is chosen for soft soils in the range of 12-14 mm (if the depth of the driving is enough to 6 m), for dense soils and a significant depth of the driving (over 10 m), the cross-section of the electrodes should be 16 to 20 mm. Special vibrators are used for deep driving, in other cases, it is enough to use a jackhammer or a powerful perforator.

If nothing is known about the properties of the soil, when installing deep grounding, they act as follows.

- The electrodes of the required length are harvested.

- We clog the first segment of the grounding and measure grounding resistance.

- To the upper end of the scored segment, the next element is welded and scored it.

- The measurements are again carried out so far until the required ground resistance value is obtained.

- To the upper end of the in-depth electrode, the tire or wire is welded, the other end of which is created in the distribution cabinet or shield.

What is an artificial earthing?

In most cases, the role of an artificial earther is a conductor, made of steel and placed in a soil in a horizontal or vertical plane. In some cases, use a whole group of similar conductors, which are connected to each other. In this case, the entrance is complex. If the electrodes form the contour, then it will already be a grounding contour.

What differ from each other vertical and horizontal earthingers?

In fact, these concepts are sufficiently conditional, since, for example, in the second case, it is absolutely optional that the grounding position in the ground was strictly horizontal. However, it is very important that the conductors that make eating or grounding contour are at the required depth. This is necessary in order to earthworks They did not receive any mechanical damage.

Due to the fact that the surface of the Earth in various areas is not flat enough, horizontal earthingers must follow the surface relief, if possible, repeating it.

Similarly, vertical electrodes can be installed not quite vertically, and under a minor inclination, which, however, will not have a significant effect on their work.

What depth is the horizontal earthing?

Horizontal earthingers are best laying at a depth of about 0.5 m. If the land is arable, then the depth is best increased to about 1 m. They should be used in cases where the top layer of the soil is able to provide the required conductivity electric current.

As a rule, similar entries are installed with the help of special devices, so manual work here is practically not involved. It should be noted that the upper soil layers are often able to resist electrical current more compared with deeper.

If you lay down the horizontal earthing too close to the surface of the Earth, then in this case the spreading current by the soil will be not too evenly, and at a more significant depth such an effect is achieved without extra cost and effort.

Horizontally laid conductor resistance is significantly higher compared to a similar conductor installed in a vertical position. It is for this reason that most often when carrying out electric installation works are used by vertical conductors.

It is best for this purpose to use deep vertical electrodes, as they are able to get to the well-conductive electric current of the soil layers.

How to choose the dimensions of artificial entrancers?

Grounding electrodes installed in the soil, as well as conclusions from them and any jumpers, must have the following minimum permissible dimensions:

Round steel - diameter 10 mm;

Round galvanized steel - diameter of 6 mm;

The angular steel is the thickness of the shelf 4 mm;

General section for earthingers with a lightning protection attached to them - 160 mm2;

Strip steel - 4 mm, if the cross section is 48 mm2 (in the manufacture of grounding highway, the cross section should be at least 100 mm2, and for grounding with lightning protection - 160 mm2);

Removed pipes - the thickness of the walls of pipes is 3.5 mm.

Based on what the minimum sizes are calculated?

The above minimum sizes for the electrodes in the artificial grounding system are taken mainly to use them in temporary installations, where the corrosion conditions can be neglected, as they will not have a decisive role.

If you need to build a grounding system for a permanent installation, then in this case the ground cross section needs to be chosen in such a way that the reserve for the corrosion destruction of materials is also. It is best to resist the negative impact of corrosion processes Round Steel. The fact is that the rust metal depends directly on the metal surface, which will directly touch the ground. Due to the fact that the round area is the smallest, it is much slower than destroying.

In order for the entry reliably to function quite a long time, for example, 40-50 years, it is necessary to take the material much more thickness than the specified minimum value. For example, if the pound conditions are fairly favorable, that is, not too wet, the diameter of the grounding must be greater than 2-3 mm. If the soil is wet, the diameter should be more minimal than the value twice.

How to install an artificial entrance in the soil?

From the grounding part of the electrical installation, the horizontal rays of the grounding device should diverge in opposite directions. If these rays are not two, but more, then it is best to have them at an angle to each other.

This is done with the goal that the large area of \u200b\u200bthe Earth can be used rationally. If you install the grounds next to each other, they will be shielded by each other, therefore, their effectiveness will be largely reduced. For the same reason, at a considerable distance, vertical entries are installed from each other. Vertical earthingers are best set to a distance equal to at least the length of the earthing itself.

Due to the fact that the potentials on the surface of the earth can host it too evenly, they will be created around the earthing dangerous stress. In order to align different potentials, the earthing is made in the form of a grid, which must be made of horizontal elements. In the soil they need to be laid along and across the places of electrical installation. Also, they should be connected to each other with welding. As a rule, the size of one cell of the resulting mesh is from 6 x 6 to 10 x 10 m.

In addition, in some cases, the potentials are aligned with the earthing, which is made in the form of concentric rings. They must be placed in the soil and connect with an enthusiast device.

The surface voltage can be reduced due to the mesh earthing, only in this case it is still a high probability that outside of this mesh the possibility of electric shock will be saved. In this regard, you need to put additional entries, the depth of the bookmarks of which should gradually increase. Such additional designs also need to be connected to the main grounds.

How to additionally secure grounding section?

The grounding area and metal consumption can be reduced due to the construction of a special insulating barrier, which is installed around the ground perimeter. It should be noted that the fence must be made from the dielectric. This approach allows you to prevent the expansion of the electric current on the earth's surface. In addition, the fence from the dielectric allows to level the potential outside the grounding.

What is the best way to make a barrier?

To build this design, any material that does not transmit electric current can also be used, it should also be quite strong from a mechanical point of view, and its electrical strength should be at least 1 mV / m. For this purpose, insulators are best suitable, which are manufactured on a bitumen basis. For example, they include brizol produced from production waste. Its electrical strength is usually at least 20 mV / m.

What difficulties may occur when making a grounding?

Often grounders made from profile steel are not able to satisfy those requirements that make grounding structures. Suppose, in dry terrain, it is rather problematic to ensure that this type of the entrance has the necessary conductivity of the electric current. In rocky rocks, the installation of this type of entrancers is difficult, and in the aggressive medium it is very difficult to protect them from corrosion and at the same time achieve the necessary level of electrical conductivity. For such cases, special designs of artificial entrancers have been developed.

What makes the grounding in areas with arid soils?

For arid areas, the next construction is most often used. The earthing is a container made of reinforced concrete. It is placed below the surface of the Earth. Water such a container is filled through a special removable hatch.

This design is equipped with a water distribution system. It is a segment steel pipesin which there are holes for water drain, are evenly located along the entire length of the pipe. Pipes are covered with a layer of material capable of absorbing moisture, such as concrete or cement. The moisture filtering rate with which water will leak through concrete and go into the soil directly depends on the brand of concrete. Properly chosen concrete will reduce the costs of efforts aimed at regular moisturizing. The output from reinforced concrete container is connected to steel rods.

What are the distinctive features of the foreign design of the grounding of the modern sample?

The main purpose of this design is to reduce the metal and facilitate the premises of this device into the ground. The entrancener in this case is equipped with a thin-walled metal tube (the thickness of its walls is 1-2 mm). At the same time, a semi-rider was installed in it made of plastic material. However, its rigidity is sufficient to serve as a support for an elastic tube with not too thick walls. This property allows the earthing to bypass the obstacles that are found on its path. In order to maximize the service life of this earthing, the tube is made of stainless steel.

At the end, this tube has a cone-shaped steel tip made of conventional steel. It is intended to so that the tube can be easier to score into the ground. If there is no tip, then the tube can be simply enclosed in the vice.

The diameter of this tube is usually 15 cm. At the same time, the diameter of the core, which is closed into such a tube, usually more of it. The tube is sometimes filled with a non-semi-rigid core, but by fluid material solidifying after filling. Most often, epoxy resin, polyurethane or elastomer are used for this purpose.

However, it should not be used for this purpose too plastic materials, as they are not able to create sufficient strength for the walls of the tube, because it will have to score on a relatively large depth - approximately 2.3 m. In order to score such a construction into the soil, use a special removable Anvil. In its design, there is a shoulder, which rests on the end of the tube, as well as the protrusion, which is connected not only with the inner diameter of the tube itself, but also a plastic core.

In order to provide electrical safety in the house or in the enterprise, it is necessary to establish a grounding contour. Earth, is an excellent conductor, which is charged negatively, and if the housing of powerful electrical devices is connected to this conductor, by means of vertical grounding, you can not be afraid of electric shock, even in the case of a phase voltage leakage.

To carry out the installation of vertical grounding, which would meet all the rules and standards, you need to get acquainted with the basic principles. proper Installation of this method of electrical protection.

Materials for vertical grounding

As practice has shown, the best vertical earthinger is a steel round rod that is installed in the ground directly near the protected object. In addition to the steel rod, the copper wire is allowed as a ground. But given the high cost of this material, it is not so often used as a grounding conductor. One rod is not enough to ensure reliable protection against electric shock, so the rods placed at some distance from each other are connected by electrical welding.

In order to combine the rods between each other, it is necessary to purchase fittings, which is welded to each round of round steel, and is entered into the house for connecting to electrical devices and devices.

The price of the steel rod is small, and in the presence of an electric welding machine, all work can be performed independently. The cost of consumables during such work will also be too large, so the grounding, which is made with the use of steel rods and reinforcement, will not require significant financial investments.

Calculation of parameters

Before proceeding to perform installation work, it is necessary to implement right calculations Ground parameters. The area of \u200b\u200bcontact of the vertical entry with the breed directly depends on the resistance of the soil.

If carried out in the northern regions of the country where the soil is freezing to a significant depth, the area of \u200b\u200bcontact with the ground must be more significant than in the south, where the ground does not freeze at a depth of more than 0.5 meters.

When the soil is freezing, its resistance increases sharply, which negatively affects the efficiency of the grounding circuit. Therefore, to ensure the proper level of electrical protection in the conditions of permafrost, assembly technologies differ from generally accepted.

If the earth is completely laughed, then it is necessary to make drilling to a significant depth, install metal electrodes and pour a hole previously removed soil.

From the rock in which grounding is necessary, the area of \u200b\u200bcontact of the soil with soil and resistivity Substances.

The greatest value of resistance in the rocky and stony ground. The length of the vertical earthing, in this case, will be maximum in order to ensure the normal passage of electric current in the breed. In such conditions, the installation of vertical grounding is the only way to carry out electrical protection of the object. The most optimal option for installing electrical protection in such conditions is the use of a special vibrator, which allows you to easily easily install the rod in the rocky or stony ground.

If the grounding is installed in chernozem and peat, then to ensure normal grounding, it is enough to immerse the electrode to a depth of 1.5 meters.

The diameter of the vertical earthing must be at least 16 mm. Usually as vertical rods for grounding, used metal fittings diameter 18 - 20 mm.

Installation of equipment

After the type of soil is defined, where the grounding is planned, you can start setting the rods.

Before installing the rods to the ground, it is necessary to remove the top layer of the soil to a depth of at least 0.5 meters. Usually such a trench is done around the perimeter of the entire building. The distance between the vertical grounds should be no more than 5 meters. The number of vertical earthingers is easy to calculate if the total length of the trench is divided into "5". For example, with a total trench length of 50 meters, the number of vertical entries will be 10 pieces.

In order to carry out the penetration of rods into the ground to the necessary depth, you can drive them with a sledgehammer. If the soil is soft, and the length of the rods does not exceed 3 meters, then the installation manually will not take much time and forces. For the convenience of further installation, it is necessary to install vertical rods into the trench in such a way that they rise from the bottom at a height of 10 - 20 cm.

If the soil is stony enough, you can apply a jackhammer with a special nozzle to install vertical rods.

The original installation method is used in the event that there is a tractor-excavator type "Cockerel". The hydraulic drive of the bucket control allows with sufficient strengthening to affect the vertically supplied rod so that the latter is completely fully entered into the rocky soil.

After installing all vertical entries, they are connected to each other horizontally located pieces of fittings.

The diameter of horizontally located rods should be at least 10 cm, otherwise the resistance is not achieved at the required level.

You can connect the rods with each other with a steel ribbon. The tape width must be at least 48 mm, and the thickness of the metal is at least 4 mm. Welding must be performed qualitatively that the process of corrosion is not formed in the metal compound places, which can be significantly reinforced with currents passing through the weld.

In order to ensure the unimpeded expiration of the electric current on the conductor, it is necessary to provide all over the perimeter of the electric circuit, the resistance of vertical entries equal to 4 ohms. If it is not possible to achieve this ideal resistance indicator, permissible deviation of this value to 10 ohms, without deteriorating the protective properties of the vertical grounding.

If immediately after installing electrical protection, it is put into operation, the places where the vertical rods are located, it is necessary to pour a significant amount of water. Thus, it is possible to restore the structure of the soil, which will most effectively transfer electric potential from metal rods land.

Independent installation

Vertical ground electrodes can be installed independently. When installing, you need to know the composition of the soil to determine the approximate depth of the installation of the operating electrodes. To set the grounding, you will need to purchase a welding machine and the required number of electrodes to cook vertical and horizontal earthing.

For the compound of metals, it is not recommended to use various clamps and other threaded connections. Over time, such places can significantly worsen the conductivity of the site. electrical chainthat will negatively affect the efficiency of the grounding circuit. If the ground does not freeze in winter time At a depth of more than 0.5 meters, and is not rock or stony, you can use a round rod with a length of no more than 1.5 meters.

Under adverse conditions for the installation of grounding, the depth of the rods should be at least 3 meters, and the distance between them can be reduced to 4 meters. It is not recommended to further reduce the distance between the electrodes, otherwise the overall impedance of the grounding unit can increase significantly, due to the shielding effect.

If there is no desire to engage in grounding independently, you can contact specialized firms, which in the shortest possible time will install vertical grounding on the area adjacent to the house. Despite the fact that such services will cost money, time saving can be significant. And if this resource is very important, it is better to entrust the work of professionals.