If you compare the functionality of fireplaces and furnaces, it becomes clear that they do not replace completely different and each other. But from the structural point of view, it is very similar: both devices have a firebox, coal or firewood is used as fuel, and combustion products should be output through chimney.

And therefore, the idea to combine both possibilities is fully justified.

Furnaces combined with fireplace - varieties

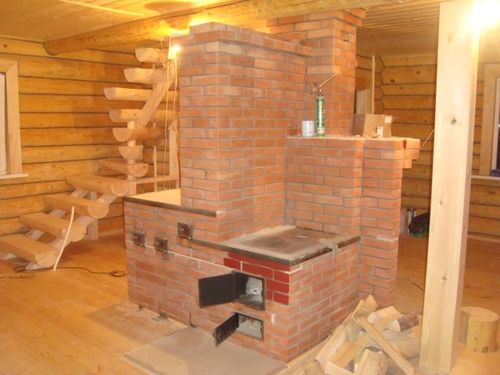

- The easiest way to find the desired is to choose a suitable model among ready-made steel or cast iron machines. Models produced very diverse and designed for heating quite large areas. Look like a refined bourgeitarian version with a transparent fuel chamber door. There are, by the way, very decorative. You can find devices equipped with a cooking surface. This kind of ovens combined with the fireplace is presented in the photo.

- A more complex option that requires work with your own hands is the purchase of a finished coaching chamber, which is then plated and connected to the brick or steel chimney. Installation in this case is greatly simplified: the camera is already lined, and the grate grille is installed. The coherence order is simple and facilities of complex chimney channels does not provide.

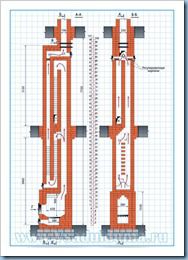

- The furnace combined with the fireplace + with his own hands is a structure that is independently erected from the brick from the foundation to the cap on the chimney. The order is complex, since such a design requires the arrangement of two modules - a furnace and firecraft and two serving chimneys. Without proper experience, experiment is not worth it.

Construction of foundation

Even with the most compact sizes, a fireplace combined with a kitchen oven is a capital construction and weighs the appropriate. Its construction should be provided in the project, since the foundation is laid under it together with the foundation of the building.

- To do this, the selected area rotates the same depths that the main foundation and dimensions of 5-10 cm are larger than the structure.

- On the bottom, the brown and crushed stone are placed, the layer is poured cement-sandy solution - 2-3 pieces of sand on 1 part of cement, and boot and crushed stone again.

- The layers are repeated as long as the foundation height does not reach the level of 5-7 cm below the future floor. Then the base is aligned with the cement layer and leave to dry for 3-7 days.

- Before masonry, the foundation is hydroizing a layer of rubberoid.

Masonry furnace

Brick ovens combined with fireplace put on chimney mix. It can be purchased in the store, or make it yourself, if you can find a good fatty clay.

- 1-3 rows are "zero", that is, they are laid out entirely of the brick and carefully levels under the level. In this way, a smooth base is obtained.

- In the second row, the door is installed for pondered - fix in the seam on metal pins, in 2 and 3 continue its installation, and over 3 mounted a grain furnace for the fireplace.

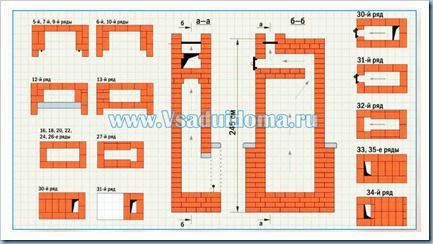

- In 4, the installation of the door ends, and the grate for the furnace firebox is mounted over 4 rows. In order not to be mistaken, it is necessary to accurately follow the order - the scheme on which the laying of each row is presented. In the photo you can see the sample.

- If the finished fireplace is used, the order will be different. Most often, it is started to construct on the basis of the base, the ashpan, the pool, and in parallel tolay the brick-ready-made fireplace cassette. This method is much easier.

- From 5 to 12, the door for the fireplace firebox is mounted - it is more in size, as it serves to demonstration targets.

- From 6 to 8, the door is installed for the furnace flipper and form the chamber itself. In 9 - overlaps the brick. 9-10 row, as a rule, includes the formation of chimney channels.

- How to combine oven for cooking and fireplace? To do this, on 11 row above the furnace furnace, a cooking surface is mounted.

- In 13-15 row, the formation of channels continues. From 16 to 18 lay down the arch of the hob. In 19, set valves regulating air intake.

- With 22 rows, the chimney builds, the air ducts are narrowed. In 26, set the overall valve on both furnaces.

- On a 26-27 row, overlapping is performed, and with 27 lay out the chimney to the desired height.

On the video, the construction of a fireplace combined with a stove and a cooking surface is considered in more detail.

Cottage for each Russian is a favorite holiday destination. According to the most fresh sociological polls, an increasing number of country sites turns from places to work in the resting place. Growing and harvesting ceases to be a priority occupation for experienced dacities. In young people, the cottage is associated exclusively with the place of pleasant time. Country sites today are visited in winter and in summer period. Accordingly, it will take not only to warm the house well, but to constantly maintain heat in it. With a similar purpose, it is worth thinking about the construction of the caminet for giving from.

It is worthwing to know that the construction of furnace structures is a difficult occupation, but if desired, it can be comprehended. Let's start such a necessary process as your own hands.

List required tools and materials:

- basalt wool;

- acrylic paint;

- m-250 brick and facing brick;

- construction Scotch;

- building level;

- sand, gravel, cement;

- masonry mesh;

- asbestos pipe 1 mm;

- chimney;

- armature rod.

How the oven-fireplace works, and where it is better to place it

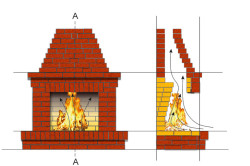

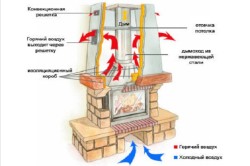

The diagram of the movement of air masses and flue gases in the fireplace of the fireplace and the smoke collector.

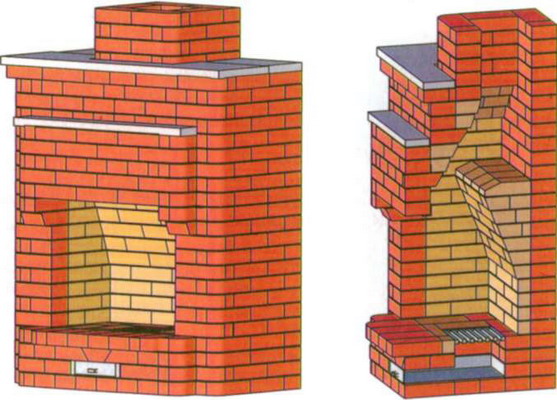

The furnace-fireplace is a structure that combines elements inherent in the bread furnace. It is able to keep warmly well. Fireplace - the presence of an open firebox that allows you to quickly warm the room. If you consider in the design of a similar furnace a small plate, it is possible enough to cook in it.

A feature of the grain furnace device is that it has two chims and two fireboxes. Consequently, there is an opportunity to coat a separate fireplace and separate the oven. In such a design, smoke channels will have a large amount of smoke-rotation. With the help of similar channels in the furnace, heat will remain warm. In addition, there will be a smaller amount of fuel in order to perform heating. From the point of view of saving it is a big plus.

It is worth considering such an ecological criterion as healthy heat. This term implies the most favorable thermal air microclimate for a person. It is possible to use for heating the most different fuel: peat, firewood, stone coal and so on.

Speaking about where it is better to place a gift fireplace that will be built with your hands from heat-resistant brick, it is worth knowing that this construction is solid. The most reasonable thing to think over to its construction before the direct construction of cottages. It will give the opportunity to determine the place for its foundation without any alterations.

However, there is an embedding of the focus in a fully prepared country house. In this case, you will have to disassemble a part of the roof and floor.

There are some tips on the installation process.

- The fireplace has a fairly large weight. Even the smallest fireplace has a weight of more than 600 kg. Therefore, it is important to take care that the foundation for the fireplace device is reliable.

- For a brick furnace, a large number of space is required - much greater than for the construction of the fireplace itself.

- In the finished building it is best to build a brick furnace Kuznetsov separately. This will avoid alterations.

Brick Caminox Device

In case it is planned to build a furnace-fireplace for giving with your own hands, you should begin with the construction of the foundation. The depth of the foundation will be approximately 1 m. At the bottom of the pit, which will be dug, it is necessary to make a waterproofing gasket. To do this, use the runneroid, which is in two layers.

In order to build the masonry, you need to make a clay solution. Clay is soaked for 3 days, after which he mixes with sand. At the same time, the brick is pre-soaked in order not to take moisture from the solution.

Build the oven Kuznetsova Namobum is impossible. The required order is performed depending on which design it will be selected for the manufacture of bricks (angular, built-in, wondered). The order contains a description of each row with maximum accuracy.

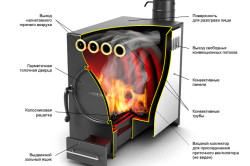

Metal devices Caminox

Building a bread oven for giving does not necessarily be done from the brick. It is possible to come up with an equivalent replacement. One option can be the installation of a metal bread furnace.

The prototype of this species is the design, which in the people called the bourgear. At the beginning of the 20th century, this species was established exclusively in urban apartments. To date, the installation of the bread furnace is produced in country houses. Such a design is capable of easily fit into any interior.

There are the following methods for installing a similar chimney design:

In the event that the installation of metal fireplaces in the country, which can be mounted with their own hands, should pay attention to the installation of the chimney. This device must be fireproof. Installation can be made in two ways:

- outside the room;

- indoors.

Chimney indoors

Chimney, which is located inside the house, has the best deal. Due to the fact that it is built strictly vertically, it is less damaged by the contamination of soot, which can be formed in the combustion process.

In such chimneys, fewer condensate will be formed. Such a pipe can create inconvenience in high-rise buildings. The pipe will have to take place of the upper floors.

Performing chimney outside the house

In the event that Kuznetsov furnace is delivered with their own hands from the outside of the house, it will be quite convenient to make a street chimney. In this case, not all people can come to taste metal pipethat is stretched over the entire wall of the house. In such chimney, a larger amount of moisture will be formed - condensate. This leads to regular crafts. In addition, it will be somewhat faster than cooling, because it passes along the outer wall.

Despite some flaws, most people prefer the installation of a street tube.

This is due to the fact that they have no desire to disassemble the roof device.

Step-by-step manual for installing a fireplace in the country

First of all need a drawing.

Preparation of material. number required material It will depend on what area will need to be missed. It will take the M-250 brick and facing brick, as well as acrylic facade paint and basalt wool, which has a thickness of 5 cm.

Next poured the foundation. Pouring occurs with a concrete, which is made for fundamental work on the proportion of 1: 3: 1 (1 part of the sand, 3 parts of gravel, 1 part of cement). Reinforced by a masonry mesh, after which piles are necessarily laughed, which are made of asbestos pipe, having a length of 1 m.

The total number of piles, which will be needed for a similar fireplace should be no less than 5. In each pile, it will be necessary to put the reinforcing bar, after which everyone is pouring concrete. The foundation should work below the floor level at least 3 rows of masonry.

As a mixture for completing the masonry, it is necessary to use a stove with a packaged 25 kg. This mixture is possible to purchase in almost any construction supermarket.

3 rows need to be performed in order to bring the masonry "in zero". So the songnists are expressed when the perfect surface is displayed along the horizon using the starting rows. Multiple masonry rows will need to make the perfectly smooth base of the furnace.

The process of bookmarking the base of the woodwood and fireplace. The foundation is preparing to be used by the future wobbler and a fireplace chamber. Before you start the laying, you must take care of the approximate layout (without a solution) so that you can navigate in the future masonry device. After the order is decomposed, you need to start working with a solution. It will be necessary to lay out 3 rows of foundation.

The front side will be a camera under fireplace, and the rear is the base under the woodwood. Very well, if the heat of the furnace will dry the lamps before they are laid in the furnace.

So that the metal corners applied in the masonry for fixing the hanging elements are not thrown into the eyes, you should hide them into the inner part of the masonry.

Next to the woodwood will be an ordinary heating fireplace for which an ordinary drawing will need. At first, I was thinking and the ashpan, then the chimney, screed and the heat chamber.

Installation of the fireplace cassette. Before installing the cassette, it will be necessary to align all the testimony of the construction level. The weight of the cassette is approximately 90 kg, therefore, its installation is a rather complicated and responsible process. For the closure of the fireplace, rows are rising.

The edges of the fireplace are punctured by construction scotch. It will give the opportunity to get rid of building flams and scratches that could be allowed. Masonry rows rise to the upper edge. The inner wall is excreted from ceramic red brick, all other walls from facing.

Using the use of the cutting circle of ceramics, the brick should be formed by the brick, so that the decorativeness of the masonry can hide all the iron elements of the cassette that perform.

Do not trim the solution immediately after the masonry of the rows. He must slightly grab.

Ceiling cuts out. The opening should be at least 75 cm on each side of the rafter.

Pipe is done. Basalt wool is recorded on the outer walls of the masonry. All bricks on the outer face should be sickling with a construction scotch. Next, you should proceed to the masonry.

The pipe is laid out to the roof slide at a distance of 50 cm. At the top of the hatch is installed. A slot is done in the flooring and the crate, after which the pipe is laid out to the roof slide. The pipe itself is folded by basalt cotton.

In large country houses there is plenty of place for fireplaces of any design. But in the country houses with a small area it is necessary to install the heating devices, correlate with the size of the building. We can offer several options and tell about fireplaces about furnaces, how to carry out the construction of small combined designs for the cottage.

In a small oven, the fireplace includes two combined heating devices combined with each other. Its design has three advantages: simplicity, compact dimensions and good heat engineering characteristics. Due to which it is precisely those who are choosing amateur gardeners to install in their country houses. Construction of this device will solve several tasks: heating the room and create conditions for cooking.

Furnace Fireplace in the countryCompact furnace fireplace

For the fire furnace to begin construction, the following materials and devices will need:

- ordinary red brick-200 pieces;

- refractory brick-35 pieces;

- steel corner 45 x 45 x 4 mm - 1.5 meters;

- sheet steel - 1.8 square meters;

- grate grid - 1 piece;

- paddy door - 1 piece;

- fire door - 1 piece;

- smoke valve - 1 piece;

- clear door - 1 piece;

- cast iron stove with one burner - 1 piece.

Also necessary will be accurate drawings.

Dignity

It is best to build a fireplace in a partition between the rooms, it turns out that this device will slow down two rooms at once. In addition to all its advantages, the furnace can be equipped with their own hands with a kitchen stove for cooking.

Design

It consists of a brick base and a smoke collector, which is cut from a metal sheet. In the design of the fireplace, there is no grateproof grille, so it is necessary to put the metal lattice stand in the center and lay the fuel to it. So, it will better get root. This video shows the construction and step-by-step drawings.

Masonry

The construction of furnaces and fireplaces begins with the foundation. In our case, you need to arrange the foundation with your own hands from large butt stones by laying it to a depth of up to 1 meter. Down the foundation you need to lay a layer of sand and thoroughly compact it with a tamper. On top of the sand lay the layers of the boob stone, fixing each of them per solution. On top of the foundation, arrange two - three-layer isolation from a toly. Construction in houses brick stoves And fireplaces are kept strictly in the ranks. Features brick masonry The fire furnace is as follows:

In the 1st row, you must lay out the platform under the place of combustion of fuel, laying bricks on the edge.

2nd + 7th rows Lay with whole bricks.

On the 2nd row to install a pensive door and consolidate it with the third round of bricks.

In the 5th row, install a grate grid for the fuel.

In the 6-7rd rows, install the furnace door and secure it with a knitting wire.

In the 8th row, perform the overlap of the flue hole; Install the cast-iron plate with one burner.

To create a reference basis for bricks of the ninth row, hand over a couple of centimeters

In the 14th row to arrange the basis for the cooking chamber from the plated bricks with the use of strips of steel and stainless corners.

In the 15-16th row, where the third smoke is carried out, bind the firecloor of the fireplace to the withdrawal brick wall of the furnace by means of a fireplace. The junction between the heating shield and the smoke collector should be made hermetic. Asbestos used asbestos cord, fiberglass or clay. It is recommended to add chopped asbestos to clay as a reinforcing material. Modern masters do not, use other reinforcing materials.

In the 24th row in the chimney, install the oven.

After the construction of this furnace device, it is necessary to remember the consecutive installation of the fireplace and furnace valves. If you incite a fireplace, and at this time the oven does not work, then open both valves. Only at the opening of two valves will be there a traction. And so that warm air does not flow through the stoves through the channels, the furnace doors are well closed and pondered. In addition, it should be not forgotten that the fabric chimple of the fireplace during its firebox, and having touched him, you will get serious burns. For its finishing, it is recommended to use only heat-resistant paints and varnishes.

Furnace "Swedie" with fireplace

Furnace with fireplace "Swedie"

Furnace with fireplace "Swedie" Furnace "Swedie" with a fireplace is ideal for giving. It is reliable, will last long, it will not be trouble in operation. It includes a fireplace, a full-fledged cooking panel and an oven. We have this furnace in interroom simpleness so that the furnace and cooking stoves are in the room where it is supposed to prepare food. The fireplace will be in the living room, and the other room will warm the side of the furnace, without any devices. It turns out that this furnace heats three rooms.

For fastening the fireplace lattice, metal rods should be laid. They are placed in the second row of the "Swedish" masonry. In the racks of the grille there are metal tubes that dress on the rods. It is arranged in order to remove the grille and regularly clean the fuel from the combustion products. The design of the furnace is arranged in such a way that the rear wall in the fireplace leans to the hodge of the furnace. To achieve this effect, we begin in the fifth row to put a brick with a nasky, and the bottom edges of the brick are grinding and we are silent, otherwise the wall surface will not be smooth. When the masonry is finished and sucked, the grinding of the rear wall begins. For this, abrasive material is used, for example, emery can also be used brick. Such a construction with your own hands, of course, it is necessary to maintain the drawings using the coaches.

Unlike the previous furnace device, the "Swedish" valves of the fireplace and the furnace do not depend on each other. Therefore, if you flip the fireplace, then you do not need to open the furnace valve. Two valves should be opened only with the simultaneous operation of the furnace and fireplace. The unimpeded passage of gases through the pipe is provided with the amount of its section 13 x 26 centimeters. In the area where gas is combined from both furnace devices, you need to lay out the separation wall.

How to build a fireplace oven? It seems that we answered your question. These devices can be tried to fold with your own hands.

One of the unconditional advantages of a private cottage house and - the ability to create a real home focus on the cottage. What how to build is to choose you.

Despite the fact that more functional and practical boilers, plates and heaters, no stoves, or fireplaces are not lost on the change of the furnaces and the camp. Moreover, the technology of taming fire is also not on the spot, and the cooking engineers all the time improving proven developments.

Yes, not always even a new fireplace or the furnace will be able to remove with modern devices. In terms of often, they can serve as an addition to the existing life support system and be for the safety net. So let's figure it out in the main features of furnaces, fireplaces and their varieties in which the oven and fireplace are combined.

Requirements to cottage house in which the construction is planned:

Best time To select and plan the system - the building design stage. And it is not necessary to erect the same furnace during construction, you can only leave a place for her. It is important to take into account the features of the structures:

The furnaces are the most massive and require a reinforced foundation. In addition, if the oven is complete and can be used not only for cooking, but also for heating at home, it is necessary to leave a lot of space. In the ready-made house will be chaled to disassemble large areas of intergenerational overlaps to organize the chimney.

The fireplace is easier in terms of buildings in the finished house. It is easier for the furnace, but still it may require the enhancement of the foundation. The design of firebirds and chimneys is easier than chimneys, require less space and mounted faster.

As for the aspect of improvement, the finally becomes more and more popular with chimneys, covered with bricks. Modern designs of iron or steel furnaces, and especially expensive global manufacturers to mock easier and faster. Often they have a smaller weight and sometimes reach the efficiency (efficiency) of 85%.

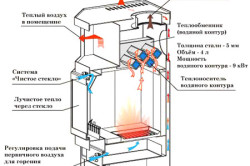

The furnace-fireplace is a combination of heating furnace and a fireplace that combines the benefits of both heat devices. The possibilities of the fireplace allow you to quickly heat the room at the expense of radiant energy, and the design features of the furnace make it possible to save heat for a long time. This is achieved by the fact that the fireplace is equipped with a glass door or two fireboxs in one case. The advantages of the fireplace furnace are especially well manifested in the premises, where the owners are irregular.

Another subclass is a cast iron or steel oven, sometimes lined with ceramics.

This is the maximum autonomous systemSince often sold ready (even with chimney). In essence, this is the same "bourgeitogo", but thoughtful and technically, and aesthetically. Facilities, fireplaces put forward minimal requirements for the object and can be installed almost everywhere.

The crisis forced many to reconsider their priorities. In many ways, it affected the life of ordinary homeowners.

Energy-efficient light bulbs, household appliances class "A" and "A +", ventilation with recovery.

It would seem that there is no place for the "outdated" furnaces and fireplace on this list. But this is only at first glance. Each of the systems will pay for itself in its own way.

The furnaces are perhaps the most important component of the autonomy of the house.

Housing heating, cooking, water heating - all this can be solved with the help of an ordinary oven.

Yes, while there are gas in the pipes, and in the wires current, such autonomy seems funny and far-fetched, straight stone age. But all more people They put wind power plants, which if they pay off, after a few decades. And the wells are digging in case of sound problems. And they make toilets in the yard, if there will be problems with sewer or septic.

Is there any need for the presence of an oven?

Fireplace, if we talk about the standard design, is also able to heat the house, but only the room in which is located. Sometimes the fireplace is supplied with aircraft system, allowing warm air to other rooms or floors. Of course, the system only works during firewood burning.

The efficiency of the classical fireplace is up to 15%, the rest of the heat in the literal sense of the word flies into the pipe. That is, in terms of heating, it is not a smooth furnace and performance, and by frequency of fuel loading, and to control the combustion process.

Fireplaces with metal closed fireboxes and air ducts are technically successful and can be used to heating throughout the house. Heated air is supplied to different rooms on a special system of air ducts. The combustion process in such fireplaces can be monitored by varying the volume of air supplied to the furnace. In addition, such furnaces, unlike standard fireplaces, are not "warm air vacuum cleaners."

It is important to consider that different systems are presented on the market, but the installation costs up to 12-15 thousand are rarely qualitatively. In addition, pay attention to the door opening method - horizontal cost cheaper, but quickly fight during operation.

The furnace-fireplace is perfectly suitable for heating, and for cooking. In this case, both process will be as comfortable as possible. The main difference of Caminofen from a conventional masonry fireplace is in principle. The traditional fireplace with an open firebox heats the room mainly due to the radiant energy of the open flame, while the fireophen heats up mostly air in contact with its walls (efficiency of at least 70-80%.) Heating can be controlled by the same fresh air supply to the furnace. And for cooking the system has familiar burners, similar to electric. Here, however, it is almost impossible to control their temperature.

Also on the topic -

Laying the fireplace

If you build a fireplace with your own hands, it's not everyone, then to check - the task is not only sat, but also believe in the word - necessary.

Foundation of the fireplace

Light fireplaces are installed directly to the floor, and for large (weighing more than 700 kg), it is mandatory to build an independent foundation of a depth of at least 0.5-0.7 m.

In the fireplace construction there are two main options for the foundation.

For the filling foundation, a liquid concrete or concrete with a filler is used, for example, with a crushed stone, finely with bricks, etc. If a very large and heavy fireplace is assumed, such a foundation can be reinforced by reinforcing lattices.

Brick foundation is suitable for light fireplaces. It is laid out on the edge brick. For a ligament solution, only high-strength cement (not lower than M300 marks) are taken. The number of rows laid out of the brick is 4-6. Top of the bay concrete foundation usually do at the floor level or lowered below the floor by 10-15 cm to go to the height of the floor on clay solution. For the fill of the foundation is mandatory formwork.

To protect the foundation from moisture, many simply cover the walls and the bottom of the formwork on the rubberoid, after which they process all the joints by bitumen. So that the moisture does not penetrate the place of attachment, they are also better to squeeze. The lower part of the foundation is poured a thin layer of clay.

If a large fireplace is installed on the second floor, the foundation is still built. The exception is done only if the floor is wooden. In this case, the floor is simply put a layer (more than 15 mm thick) solid refractory) material that is covered with iron sheet. The first layer of bricks is laid on a clay-cement solution.

When the foundation is ready, you need to wait five to six days so that it is completely dry.

Chimney

Pipe walls make enough thick: it helps reduce heat loss. If the fireplace has interior Wall, Pipe is laid out in one brick, if the outer one is one and a half or two bricks. Optimal cross section chimney - From 1/10 to 1/15 of the combustion hole. Minimum pipe parameters -14 x 25 cm.

Of course, it is dangerous to describe a heavy brick tube on a light fireplace. If you need a high hound tube, it is best to use metal or ceramic pipes. Outside the building they insulate them. For greater reliability, they can, for example, put a brick, pouring between it and the pipe clamzit.

The quality of thrust directly depends on the height of the pipe. The best is considered height 5 ~ 7 m-above the flap The smoke pipe has the form of a narrowing pyramid and in its upper part goes into the chimney. The front wall of the smoke box is usually raised to docile it tightly with chimney, and the vertical rear goes into the chimney directly.

The chimney is provided with a damper (fit or rotary, cast iron or metal).

With it, the fireplace is closed after going, and also regulate the force of thrust. It is best to have a flap to be 20-30 cm (although it can really be 80-100 cm) above the flue opening, at a distance of about 2 m from the floor. The damper plays a special role if the chimney is low (up to 5 m), because through a short tube cold air from the street quickly fills the room. It is believed that if the pipe is above 7 m, the smoke valve can not be installed, but the experienced liveniks advise it to use it anyway.

An example of masonry fireplaces

On specialized sites and in the books on a chimney, you can find phased laying descriptions. For clarity, and may, for practical applications, we present one of these descriptions.

The system is offered in two sprinkle variants: with a spark-winner (recommended) and without it. The traction in the fireplace is regulated by the valve. CPD is 10-15%

You can lay out the first three rows or the contour of the series, and fill the inner part with a filling from rubble and sand. Fourth line lay out from fireproof bricks. Here m-shaped mortgage pins are installed - for fastening the fireplace lattice.

Drawing 1. Fireplace masonry coach without a brawler

Drawing 2. Masonry scheme (ordinary) of the last rows of the fireplace with a sparking

In order to build a fireplace given on the drawing scheme, you will need the following materials:

| Chimney brick | 370 pieces |

| Refractory brick | 62 pieces |

| Chimney | 12 bags \\ 300kg |

| Fireproof chimney | 2 bags \\ 50 kg |

| Sandob concrete mixture | S mesh / 150kg |

| Latch 240 w 130 mm | 1 PC. |

| Fireplace grille | 1 PC. |

| Reinforced concrete stove for shelves and portal | 4 things. |

Stove laying with their own hands

For example, we will analyze the project of a large heat capacity furnace. Its distinctive feature is the possibility of one-time firebox during the day.

Table 2: Characteristics of the cooking stove

| Characteristics of the furnace | |

| Fuel section | 890 × 1150 mm |

| First floor shield | 770 × 1020 mm |

| Second floor shield | 770 x 950 mm |

| The height of the furnace | 7150 mm |

| Heat pumping surface | 20 m 2. |

| Medium heat transfer during furnace per day Total daily heat transfer The number of dried dryers | 5500 kcal / h 59 kg / day |

| Heat transfer time after one firebox | 24 hours |

Construction

For the construction of the stoves given on the drawing for cottages you will need building materials:

| List of materials | |

| Red brick full-length (selective) | 1900 pcs. |

| Brick refractory | 170 pcs. |

| Clay red | 2.1 m 3. |

| Door of the cooler 350 x 350 mm | 1 PC. |

| Door podding 135 x 120 mm | 1 PC. |

| Clear doors 135 x 120 mm | 5 pieces. |

| Furnishing valves 130 x 260 mm | 2 pcs. |

| Final sheet 500 x 700 mm | 1 PC. |

| Grass grille 400 x 400 mm | 1 PC. |

Scheme 1 and 2 - Drawing-co-order for masonry stoves in the country

This furnace is a two-story, channel, one-time, with one fuel in the first floor. A single massive design is located within two floors. Build it on independent foundationrevealed to the floor level of the first floor. In the plan, the cross section of the fuel section of the furnace has a size of 0.89 x 115 m, and heating pads - 770 x 1020 mm for the first floor and 770 x 950 mm for the second.

The total height is somewhat conditional and given to the height of the ceilings of both floors of 3.4 m.

It can easily be changed in any direction by changing the number of rows in the masonry from 26 to 46 and from 60 to 82.

The dimensions of the pop-up are designed for a single loading of approximately 50 kg of dry lanes 50 and a thickness of up to 10 cm. And put the lamps in the firebox. From the fuel gases rise on the first upward chimney up. At an altitude of about 3.2 m from the floor level, the part of the gases is separated into the smoke-speed of the heating panel of the first floor, and the other - rises to the top of the furnace and enters the smoke of the second floor.

In the lowering channels of smoke-rotation of heating plates of both floors and in the last lifting channel of the first floor there are special heat exchange nozzles (issues) - protruding from the masonry inside the bricks canal. They increase the heat-absorbing surface in smoke revolutions and the heating rate of the furnace masonry.

The last lifting smoke channels of both floors (ranks from the 60th to 88th) have a section of 120 x 190 mm and end in the upper part of the oven shared chamber - rows of the 89th and 90th. In this chamber, adjustment bricks are installed, with the help of which the corresponding amounts of flue gases are distributed in the smoke rotations of each floor.

These adjustment bricks rely on special protrusions with a width of 1.5-2 cm, made when laying out the channels in the 88th row. The flue gas distribution adjustment is made once at the first test furnaces, moving bricks and achieving uniform warming up the furnace masonry on the lower and upper floors. After the final installation of adjusting bricks, the side windows of the chamber are tightly closed and shrinking the clay.

Also read on the topic (easier option):

Fireplace - furnace (combined option) do it yourself

The placement of the furnace-a fireplace is determined by the location of the stationary chimney or the place of its possible installation.

Conducting construction work

If the overlaps do not need to be strengthened, the system is installed on the platform laid out with refractory brick, tiles or metal sheet with a thickness of 1.2 cm. The site should be over the boundaries of the device from all sides by 50 cm. The distance to the wall of combustible materials should be at least 1 m, from non-combustible - up to 20 cm. Before the furnace, you need to leave the free space about 1.25 m2, and to furniture and other objects of the situation - 1.5 m. However, all requirements must be specified in the accompanying documentation.

Connecting a fireplace stove to chimney

If the room has a smoke canal, laid inside the wall, the distance between it and the fireplace should be minimal. Determining where the stamps will be installed, the place of connecting the device to chimney will be installed on the wall. Then pierce the chimney or wall masonry, the hole in the form and size of the foot ring is expanding, the ring is installed and close the crops with refractory plaster or wet clay. After that, combine the chimney pipe of the chimney oven. If there is no last, there is a new chimney from metal, or bricks (similar to fireplace). For work use high-quality full-length red brick.

The pipe of the metal chimney is attached to the wall with the help of casing, dowels and screws, which are usually included. At the base of the chimney, a pocket with a cleaning door should be provided. Cleaning is made at least once every three months (with permanent operation).

What should be paid attention to:

- The foundation of masonry oven is important to lay out with special care

- The furnace must be with a closing fuel.

- In order to admire the flame, you can install a transparent door - now they are on sale, there are quite heat-resistant.

- It is important to pay attention also to the masonry from the inside - the slits, the jackets, the influx of the solution are unacceptable, as they lead to a decrease in thrust and rapid deposition of ash.

- At all stages of construction, it is necessary to control the verticality and horizontal masonry of the furnace or fireplace, the quality of installation of cast iron elements.

- Modern finished "burning bourgear" is perfect for a country style. In addition, it can be prepared on it.

- The location of the chimney through the wall must be forced!

: When to transplant seedlings in an open ...

Both oven and fireplace have their own special advantages. The first faster heats the room and more economically spend fuel, the second allow you to enjoy the beauty of a living flame and its warmth. Most of the premises do not allow you to install two heating instruments at once. Therefore, the most frequent question in all sorts of forums is how to combine oven and fireplace. There are two possible options, we will try to consider each of them in more detail.

Installation of finished equipment

The easiest option to combine these two types of heating devices is the acquisition and installation of already finished products or if there is a need to fold the furnace combined with the fireplace. This is possible if at an early stage of construction under it, a place was left. There are several design solutions how to combine fireplace and oven.- Combining two coil chambers in one case. This method is more acceptable, and enjoys in high demand. Such a design can also be used in traditional embodiments of furnace equipment, for example, in a Russian oven. Interesting is the option in which the furnace furnace goes into one room, and the fireplace to another.

- Installation of a glass door. Tempered glass, closing the flue chamber, simultaneously makes it possible to work both in the furnace mode and fireplace. From the quality of the heat door of this type, the timing of its operation is dependent. Bad tempered glass can over time to lose its heat-resistant qualities and come into disrepair.

There are several advantages of such a solution. The installation of products occurs at a predetermined place, the connection to the chimney takes place as quickly as possible. Costs in this case are minimal.

There are many options, how to combine fireplace and oven, most of which require coordination with project documentation and project harmonization with relevant instances.

Union of the fireplace and oven

The complexity lies in the fact that the diameter of the channel section in one and other form of equipment is different, therefore, for the execution of such works, at least the installation of two smoke systems will be required. It is much easier to combine the fireplace and the stove if they are metallic. One embodiment of such a compound is the ability to finish the equipment with a refractory brick. The furnace and the fireplace are embedded in such a design.Nuances associated with the union of the fireplace and stove in one design

- Contact advice. Without the competent Council of the Pechsk, it is better not to be re-equipped. He should also be entrusted to fulfill all the necessary work.

- Find out the rules and acts regulating the installation and operation of such equipment. For example, you can get information that the modern analog of "bourgeitors" can be installed in almost any room without restrictions. The convenience of this option is that some manufacturers not only combined fireplace and oven, but also made sure that such equipment is sold fully prepared, to operate. The composition of such models includes chimney, so you can install it almost anywhere at home.

- Invite the master. Only the competent livesh should cope with the conversion or creation of a new combined furnace.

The ability to combine the fireplace and the furnace, in addition to aesthetic value, has economic benefits. The efficiency of efficiency grows up to 80-85%.

Fireplace and oven - What is the difference?

Is there a difference between how the room is heated with a fireplace and an oven? At first glance, it seems that if it is, it is insignificant. In fact, beauty as it is noticed in the same proverb, requires victims, and in this case their roles are the heat loss, which are associated with the burning in the fireplace.The fact is that the heating of the room mainly occurs due to heat that comes out from the furnace chamber. A large percentage of hot air simply goes to the street. The device of the furnace allows you to accumulate it warm and with it to warm the walls, which are the source of the heating of the room. If you manage to combine the level of warming up the room, which has a common oven with the beauty of natural caine, can be reduced the heat loss coefficient. Therefore, folded the furnace combined with a fireplace or to establish ready-made combined equipment is cost-effective. There are some more advantages of such a design:

- Possibility of cooking. Some models provide a place under the oven wardrobe, and they have a cooking surface. The only significant disadvantage is that the heating mode can only be monitored by reducing the fuel, which is not always convenient.

- The use of combined equipment as the main source of heat. In this case, a water circuit is installed in the bracket chamber.

Combining the brick oven and the fireplace can be correct not only because of the aesthetic value, but also due to economic benefits. Such a solution also increases the effectiveness of the warming of the house and makes it possible to use a fireplace as the main source of heating.