Traditionally, Russian baths build from logs, however, both brick baths are very popular, as this is also an environmentally friendly material that has many advantages over wood. The only thing that is important not only competently build the design, but also to produce insulation and waterproofing work.

General

Brick, as you know, durable and durable material, which tolerates temperature differences and increased humidity. In addition, there are a number of other features of the brick bath.

Dignity

Among the advantages of such a structure, the following points can be distinguished:

- From the brick, you can perform architectural elements of any configuration and shape.

- Paired bricks are much longer than wooden. When complying with technology in construction, their service life is more than 150 years.

- A brick structure fire safety is significantly higher than that of a chopped bath.

- Building structures from facing bricks Do not need finish.

disadvantages

Of course, along with the advantages, there are some drawbacks:

- Construction price brick bath It is always more expensive.

- The brick has a big heat capacity, so it takes more time on heating such a bath. The problem is solved by good thermal insulation.

- Brick is inclined to be cheat, as it has less steadyness than wood. However, this deficiency can also be corrected using ventilation and vaporizolation.

Choosing a place

When choosing a room for a bath, first of all it is necessary to draw attention to the fact that the place is dry. If there is a river or lake nearby, the construction site should be at a distance of at least 30 m from it. Otherwise, during the spring spilling, the flooding or simply high humidity is not excluded.

In addition, it is necessary to take into account firefire requirements. Distances to neighboring buildings should be at least 12 m.

If the bath will be heated not to firewood, but a gas or electric boiler, then this distance can be reduced to 5 m.kom, the bath can be attached to any residential building, it will save building materials and simplify the lodding of communications.

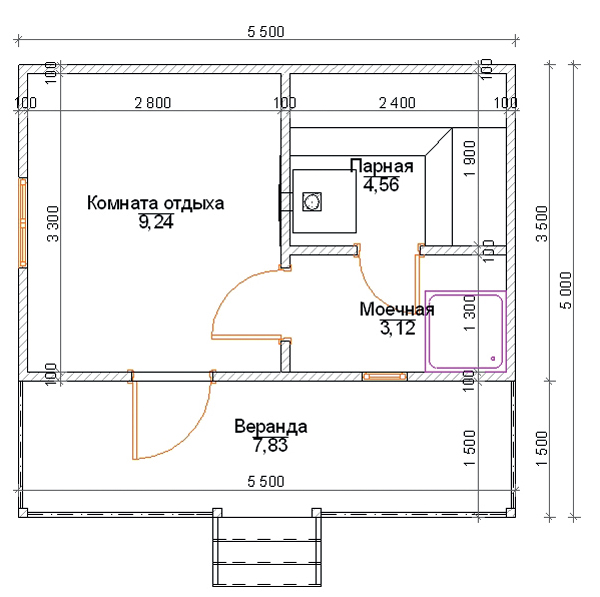

Project

Before building a brick bath, you need to prepare a project. If you are engaged in construction for the first time, it is better to take ready project On the Internet, or seek help from specialists. The preparation of the plan is a very responsible moment, since it depends on the cost of construction, quality, strength of construction, its durability, etc.

The most comfortable . It should be shuffled into the ground no less than a meter, the foundation is still deeper on the clay soils.

- First of all, it is necessary to cut down the pit and fall asleep with a layer of sand with a thickness of 15-20 cm.

- Then it must be poured with water and tamper.

- Next on the sand is laid out the mixture from cement-sandy solution And rubble with a thickness of 10 cm. Then again sand, and therefore several layers should be alternated.

- After that, you need to install formwork and armature carcasswhich is poured by cement mortar.

- After the concrete freezes, it is necessary to paro insulation consisting of several layers. In addition, to protect against rain you need to build a breakdown with a width of one meter, which is performed from clay and gravel.

- The comprehensive drainage system and drainage system is then mounted.

Of course, such a foundation requires certain costs, but for a brick bath, this is the best option.

Walling

Material

For the construction of the box, it is best to use facing and silicate brick. Even before the construction of the bath, you need to calculate the required amount of material.

The calculation of purely mathematical - the planned height and width of the walls must be divided into multiplicated height and width of the brick. It is necessary to add another 5 percent to the resulting bricks, in case of a damaged material.

Tip!

The outer walls are better to put on one and a half or even two bricks, the inner partitions in the pair can be made in one brick.

Required tool

To build a bath with your own bricks, you need to prepare the following tools:

- Trowel;

- Shovel;

- Plumb;

- Rule (one and a half or two meters long);

- Level;

- Roulette;

- Kirk hammer;

- Corolnic

Types of masonry

When building a bath, the masonry can be performed in one of several ways:

- With air gaps up to 6 cm wide;

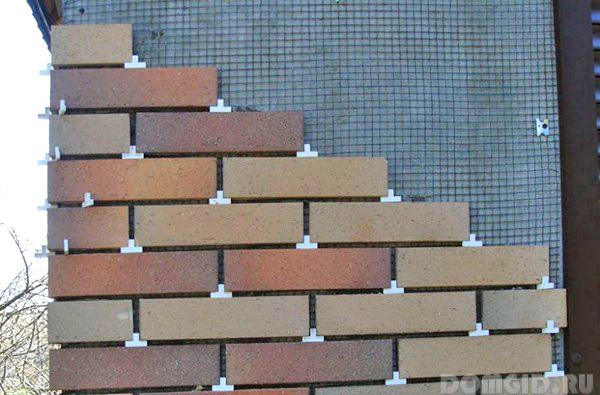

- The ring-shaped masonry, when thermal insulation is covered between the internal and outer rows.

- Without internal voids. In this case, from the inside it is necessary to use good.

The most economical is the second option, since the masonry thickness is significantly less, and the heat engineering indicators are very good. The only one, it is necessary to pay attention to the accuracy of the seams and thorough dressing.

Masonry technology

The brick part of the foundation and the base located below the waterproofing must be made of full-scale brick, and above waterproofing can already be used hollow. When laying subsequent rows, bricks can be used with chips.

Instructions for the construction of walls look like this:

- First of all, it is necessary to make a solution in a ratio of 1: 2.

- Then the solution is applied to the foundation protected from moisture.

- Before switching to the walls of the walls, you must lay out several bricks in the corners.

- Depending on the chosen type of masonry and the dressing scheme, there is a laying of the walls themselves.

- After the masonry is completed, it is necessary to drive the pins into the walls and fasten the bars on them. Overlapping beams are installed in special nests directly on bricks, but they must be wrapped in rubkeroid. The ends of the beams should be left open, and the gaps between the walls and beams are filled with thermal insulating material.

Tip!

The masonry of the series should be performed, focusing on the moor cord, which must be stretched on each row and fix it with nails.

Crossing the roof and insulation of the ceiling

Creating a roof for a bath does not differ from the construction of the roof in other buildings:

- Initially, you need to install anchors on the walls of Maurylalat.

- Then the rafter system is attached to Mauerlat.

- Over rafter system A wooden lamp is installed and the roofing material is fixed.

All this design is mounted according to the project, therefore there should be no difficulties. When the roof is ready, it is necessary. As a rule, for these purposes, a pinned or sharply plane of larch, cedar, needle or aspen is used.

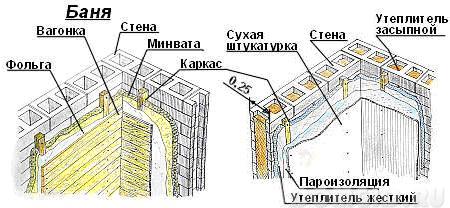

In the photo - heat insulation of walls

Warming and waterproofing

The bath must be insulated. To do this, the empty space between the walls of the masonry should be filled with a mixture of sawdust, lung and slag and lime-fluffs in a 2: 2: 1 ratio. The mixture should be poured by layers and over each layer pour the solution of the sample of the creamy-like consistency.

There is one more insulation option - tile.

It is performed as follows:

- Wooden plugs are mounted in the brick set, which rakes are stuffed.

- The space between the rails is insulating plate Material either mineral wool.

- Then the vapor barrier layer is performed, for this you can use foil polyethylene.

- Next to the raids attached the casing material.

It is possible to insulate the foundation using mineral wool. At the same time, the soil under the floor should be covered with a thick layer of slag or clay, so that from under the lag did not go crude cold. If the floor in the bath is solid, you can put mats and mineral wool on it and perform waterproofing on top.

Tip!

So that the bath had a traditional Russian style, it can be seen siding.

No less attention should be paid to the ceiling warming in the bath, since it does not significantly depends the preservation of heat in the steam room. Mineral wool is also the most popular material.

If an attic compartment is not provided in the bath, then the ceiling can be insulated with a mixture of clay and sawdust. After that, you need to perform vapor and waterproofing. It is best for these purposes to use a foil material that is easily attached to the beams.

Laying vaporizolation should be so that the edges of the material of centimeters on 10 lay on the walls. After that, you can start finishing.

Output

We reviewed the main points of construction of a brick bath. Of course, in the process of work will have to face many other nuances, but having a minimum experience in construction, it will not work with them to cope.

Additional information on this topic can be obtained from the video in this article.

Brick - years proven material. In the construction of the bath, he established himself from a positive side and this is determined not only reliability. Brick is not published in terms of decoration, and a bath, built of stone, can be frozen outside with any decorative material. Popular brick band projects can be viewed in the photo below and in the special section of our site.

An option with the original finish is a wet facade. Interior decoration made in the style of minimalism: tambour, lounge and through it the entrance to the washing office and steam room.

Another original version of the brick bath. By outdoor finishThat this material was used in construction, does not say anything at all.

Brick two-story building: ![]()

Spacious and functional bath. The first floor is decorated in accordance with the rules, the second provides for a spacious hall and two bedrooms.

Brick sauna, decorated with decorative stone.

Individual external layout. The terrace is made in the form of the letter G.

In addition to the functional premises, this project provides for the attic floor, which at first glance is not determined outside.

The layout is quite original. Spacious lounge, fireplace room and of course washing with steam room.

Two-storey brick bath With a small veranda at the entrance and a spacious second tier.

On the first floor there is everything you need for the adoption of procedures and a pleasant pastime.

The second floor is a spacious billiard room, which is possible to re-equip under bedrooms for guests.

Country householders have long been able to fully use all the benefits of civilization: water is connected to the cottages, they are heated with modern boilers, they have a water heating system and sewage. Nevertheless, giving tribute to traditions, but rather not wanting to refuse to receive anything that is not comparable to visiting the steam room, they hardly continue to build a bath. Even if the bath is not constructed simultaneously with the house, with time the appropriate project is selected and construction begins.

Materials for building baths, advantages and disadvantages of brick bath

The traditional material for the construction of a bath house is wood, it can be log cabin or a timber. But the desire to equip the bath is domesticated, and even to build at all bath complex, caused the use of materials more practical and modern. Today it is often possible to meet a brick or foam concrete car, materials allowing to build in the house not only the steam room, but also:

- shower

- pregnant

- little pool.

- adjust an open terrace.

Brick selection as building material justified for:

- his durability

- high Fire Safety

- operating opportunities without special facade care.

From negative points should be remembered:

- on the need for the construction of thicker walls and their thermal insulation with the subsequent trim

- the need for finishing works

- on the need to build a ribbon or pile with painting foundation.

Nevertheless, the construction brick walls It significantly expands the design features and allows you to diversify the projects of a brick bath projects, especially in terms of their finishes: the walls can be lined with ceramics, to use the core tile on the floors.

As for the thermal conductivity of the brick, it is significantly higher than the one that wood has 0.56 W / (M * C) against 0.09 W / (M * C), therefore, to ensure heat resistant, the large wall thickness will be required and the installation of an additional heat insulation system will be required. . In addition, time to warm up the brick wall will need significantly more. For example, the walls of the baths, built of logs, warm up in a couple of days, coal over the winter, the brick house will give the cold and dampness accumulated in the walls over several weeks.

What wall design is better to choose

Construction uses several wall design options. The construction of a brick bath will require a reasonable choice of one of the options.

- The most inappropriate option is solid laying. It will be necessary to build very thick walls, which will lead to significant costs for building materials. In addition, a lot of time will be required to warm this room. This option is acceptable only if the construction of the bathhouse is assumed exclusively in the summer.

- Bole will be acceptable to perform the walls of the well-masonry, allowing you to set the insulation layer inside the wall.

- An equally rational way is the construction of a thin brick wall with high-quality insulation of it outside.

- Optimal, according to experts, the option is a small masonry thickness and installation of a thermal insulation system inside a bath house.

However, the wall thickness is smaller than 250 mm thick, i.e. One brick is not recommended. And the reason here is not in the thermal insulation properties of the brick, but in the need to create reliable bearing structures Which will allow the installation of overlapping and roofing.

As for the cost of the structure, then the bath from the brick with its own hands, performed in accordance with the fourth option will be cheaper, because Installation of insulation indoors and its decorative finish will be combined, while the second and third options suggest a separate installation of the insulation layer, which will not save from the need for a sheaving and decorating the inner surfaces of the walls. Moreover, the technology of the construction of brick walls with internal insulation will have a value less than the construction of a church.

The only losant moment will be the need for the construction of a stronger foundation. If the question arose what kind of bath brick to use, then the answer is unequivocal - only red, distinguished by a long service life and heat-resistance.

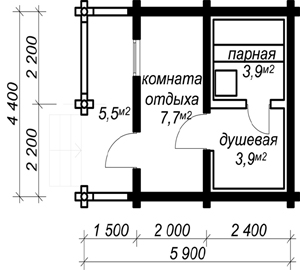

Brick Bath Projects

There are many of the most diverse options for planning a bathroom and its finishes, finding suitable on functionality and cost will not be particular difficulties.

You can stop the choice at a minimalistic version, you can build a real complex, including a bath, sauna, shower, swimming pool, recreation room and cosmetic procedures.

The only thing, but very important condition - the project should be performed by a specialist, the bath is a room with high risk The emergence of fire.

The procedure for performing construction work

foundation

The depth of the foundation laying should correspond to the depth to which the soil freezes in the winter period. For the construction of the foundation used funny brickAt least before the lower level of waterproofing, then you can use hollow. Planning the design dimensions should be remembered that the size of the walls must be multiple 150 mm if bricks are used in size 24x12x65 or 100 mm - for bricks 24x12x88.

When building a bath also often build ribbon foundation.

Erecting brick walls

The masonry of the walls start with the corners, laying out several at the adjacent angles - connect the cord, orient the wall laying on it. The laying of the cord-mooring will make it possible to make a straight wall, rows horizontal, with the same seam thickness.

The solution for masonry bricks should be prepared by observing the norms, and when the masonry is performed, it is necessary to make it necessary to get the seams to the desired degree, depending on the puffing masonry, the tile or spoonful rows are laid out. It is also required to observe the reliability of dressings.

For masonry of the first row, you can use only high-quality solid brick. The masonry should be started with the outer layer bricks. Bitted brick can be used for spoonful rows from the inside of the wall. It is not recommended to put out the combat of simpleness, walls, supporting areas and angles. Before laying bricks should be wedged with water, especially at high air temperature.

The thickness of the internal bearing walls should be at least 25 cm, the partitions can be laid in the Pollipich or a quarter. If the length of the partition laid out in a quarter brick will have more than one and a half meters, then it will be necessary to perform masonry reinforcement every three rows.

The location of the doors and windows is made in the usual way using wooden bars or 120th corner, installation wooden structures It is better to produce during wall masonry.

How to plaster the walls

For plaster works, a solution consisting of 2 parts of sand and 1 cement is used. To give a special strength, the application of plaster on a metal grid, which is stretched on the nails slaughtered into masonry seams. Sews on the front surface that will be plastered with a solution to a depth of 10-15 mm, if the wall is not subject to trim, then the seams are filled with a closure with the surface of the wall. If an excess solution is applied - it should be immediately removed using cells. To make the seams on the surface of aesthetic species, they first produce the extension first vertical, then horizontal seams.

Installation of steam and thermal insulation of walls

Since the brick is a material that is prone to absorb moisture, then allow the contact of the brick wall with the soil cannot be completely. Therefore, the arrangement of the waterproofing system is a mandatory point. Recommended surface treatment of all walls bituminous mastic Or rubberoid.

For the installation of the insulation, lighthouses forming the gap of about 2-4 cm or wooden rails are attached to the walls, the plugs are laid in the seams in the seams. Next on the rails are stuffed with insulation plates made from arbolite, mineral wool, light concrete or other insulation materials.

As finishing material for inland walls Baths are usually used lining. It is also possible to sow the wall, while you will have to drive into it wooden traffic jams to which will be used to fasten the planks or metal profile. The space remaining between the brickwork and the lining space is filled with tile insulation, pergamin, mining, packles. If horizontally boards are used as a finishing material for walls, the insulation of the brick bath can be performed by clay.

Which roof to choose for a bathroom

The roof of the bath should be primarily functional - its task is the maximum pair and thermal insulation of the room. By design, the roof can be double or single-sided, depending on the architectural solution of the bathhouse. Especially complicated design does not make sense - an excessive number of turrets, bends, complex elements on a small and not high constructions will look inappropriate. In addition, the process of performing work will complicate significantly.

The roofs constructed on the baths can have an airless design or attic. When choosing an option, you should consider whether the bath will be used in winter time. The roof with the attic is significantly warmer, it helps to reduce heat transfer through the ceiling. In addition, the attic can be used to store bath accessories, brooms, etc. If the roof is high enough - you can equip the room for relaxation.

For a bath, which will be used in summer it is quite suitable for a nonsense design. On the flat roof You can place water tanks or equip sushill for fruit. More simpler and cheap at a cost of single-pate roofs.

After making a decision on the form and design of the roof, you should consider the option of its insulation. There are several insulation methods: laying insulation under rafyles, between them or above them. Most often resort to laying thermal insulation between rafyles. To do this, first lay a layer of vaporizolizing material, the bottom of the rafter is fed plywood or board, providing for emptiness. It is them that they are filled with any of the thermal insulators, for example - basalt wool. When laying thermal insulation, the density should be monitored - otherwise the so-called may appear. Bridges cold. The material is better to sharpen in two layers, having plans in a checker order.

Decorative Facade Bath

If the bathhouse is cooked from cheap, but practical materials that have a not quite attractive form, then it is often a decision that you need to lay a brick. Beautifully executed brickwork The facade will give the structure an attractive and aesthetic appearance.

Since the brick is the material is sufficiently heavy and significantly increases the load on the foundation, then the brick tile is more rational as a facing material - the weight it is small, but all the technological characteristics of the material it supports. Facing with brick or tile is also often subjected to the dilapidated structures that have lost their appeal.

There is an opinion that best Material For - a tree that is used for these purposes has already been several hundred years. But in our time, his monopoly is absolutely unjustified, because there is a lot of no less worthy alternatives. And one of them is a brick, using which you can implement almost any original project Bath. Of course, this undertaking will be successful only if you familiarize yourself with the pros and cons of the material in advance, as well as credit the instructions for the construction of a bath with a photo - this is exactly what we suggest to do further.

Advantages and disadvantages of a brick bath

To have a complete picture of the features of a bath of a brick, it is important to know the principal advantages and disadvantages of this building material. Let's start with advantages:

- increased fire resistance - brick significantly surpasses the traditional materials for the bath in terms of fire safety;

- durability - the service life of the brick bath can sometimes be higher than 50 years;

- ecology - brick is made from different types of natural raw materials, so the material is absolutely safe for humans;

Brick - eco-friendly material, so suitable for building a bath

- wide architectural features - brick allows you to build not only standard "boxes", but also the baths of complex configurations.

Minuses of brick baths:

- increased heat capacity - on heating the brick pair you need much more time than heating a wooden structure;

- high hygroscopicity - brick quickly absorbs moisture, so if you do not perform hydro and vapor barrier, the building will be cooled;

- high cost - brick is by no means cheap material, so the construction of the bath from it will cost quite expensive.

Let us turn to the consideration of the technology of building a brick bath, conventionally dividing this process into three group stages.

Step 1: Bookmark Foundation

The first thing you need to take care of a high-quality deep foundation, which can withstand a heavy brick design:

- Marking up the future base and keep the peg on its perimeter to designate the working borders.

- Drop the pit - its depth should not be less than 1 m.

Council. If the site is located on clay soil, the base depth must be 1.5 m or more.

- Arrange on the bottom of the pillow from sand and rubble: first pour 15 cm of sand, moisten with a layer with water and thoroughly sink, then put a layer of rubble on top of a layer - not more than 15-20 cm, and then put one step and rubble again. After that, perform the final dummy of the received "cake".

- Mount wooden formworkAnd then install on the base fixing frame from reinforcement rods.

- Prepare cement mortar And carefully pour them the foundation, moving the layers by rule.

Foundation for baths

After soaring the cement, build the base - there will be enough two or three brick rows. Next, steamed the foundation. To do so put on cement base Two layers of rubberoid. The last step is to arrange holes for water pipes, and.

Stage 2: Construction of walls and roofs

There is a lot of ways to lay brick walls, but if you do construction work For the first time, pay attention to two more or less simple options:

- Single masonry: one brick is installed across, one - along. Such a masonry system is called chain. It requires a certain skill, but the difficulty of execution is fully justified by the thoroughness and fortress of the constructed walls.

- Multi-row masonry: one brick is installed across, five - along. Such a system makes it possible to significantly save on storage materials and reduces masonry time. But in terms of strength, it is somewhat inferior to the one-row option.

Laying bricks

Whatever the masonry method you chose, you will need to prepare a cement solution to connect the bricks with the addition of sand, lime and water. The mixture should be plastic, but not very liquid, so that it did not spread through the material.

Council. For high-quality fixation of bricks, lay the cement mortar with a layer of 7-10 mm.

When you finish with the walls, proceed to the construction of the roof. First you need to put on the upper strapping of the walls of lags or rafters - they will perform the role of the roof. Then score the crate on the established base, and already fasten the root on it: slate sheets, metal tile or professional flooring. Do not forget to leave a special hole for chimney.

Stage 3: Waterproofing and insulation

So that your brick bath is full and functional, it needs to be highly insulated and insulated.

Waterproofing can be carried out by two methods:

- Spray - The inner surfaces of the structure are carefully treated with coating waterproofing compositions: bitumen mastic, rubber mixtures or epoxy resins.

- Powered - surfaces are facing panel or roll Materials: rubberoid sheets or foil polyethylene. As a clamp can be used or adhesive compositions, or wooden slats with self-draws.

Internal arrangement bath

Insulation is performed according to the following scheme:

- Walls: A doomle is stuffed to the surface, its spans are filled with insulation, and then the design closes the fiberglass and foil.

- Floors: The insulation is laid on the surface, it is fixed on top with a metal mesh and poured into a thin layer of the cent.

- Ceiling: The scene is mounted on the surface, which is filled with insulation and is closed by plywood or foil sheets.

As a heater in a brick bath, you can use: thermal floors, foam, minorvatu, fiberglass, penplex.

After these two procedures, proceed to the internal arrangement and steam room.

As you can see, brick - a good option For those who want to get a bath, but does not burn with the desire to deal with the usual tree. Of course, this material It is not easy to work, so in the construction process will have to work seriously, but if you are clearly followed by the foregoing instructions, a successful result in the form of a functional and comfortable pair will be provided with you.

Brick Bath Construction: Video

Brick Bath: Photo

Own bath is an indispensable tool for meetings with friends and relaxation after tense labor everyday life. But for many people, appeal to construction company For the construction of a turnkey bath - too expensive pleasure. And they prefer to deal with the construction of themselves.

This is a rather complicated process in which a huge number of parts must be taken into account. Already at the stage of design and drafting the estimate of the future bath, many questions may arise. We hope that many of them will help clarify this article.

Blocks (beugoned to the point of the marzlot and surface);

brick;

Concrete poured into a non-removable formwork with armorcase inside.

When erecting a brick bath, the most optimal choice will be a ribbon foundation of deep downstream. His construction takes not one day and costs quite expensive, but it is possible to be sure that the foundation does not seek under the severity of massive walls.

Type of masonry wall

It may be lightweight and solid. With solid masonry, bricks are laid at least two rows without voids between them. With a lightweight - two walls are laid out of bricks, and the emptiness is left between them, which are filled with heat-insulating material (small slag, basalt wool, etc.).

When building a bath, as a rule, a lightweight type of masonry is used, as it allows you to reduce the weight of the walls and, accordingly, the load on the foundation. It is also important that with a lightweight masonry consuming much less bricks.

Tip: Solid masonry should be applied only in cases where increased structural strength is needed.

The optimal option for masonry walls is a silicate brick (white color). You can use clay (red). It is more durable, but it is more expensive.

| Name | Mark. | The size | Appearance | Retail price | Picture |

|---|---|---|---|---|---|

| Funny single brick | M100 | 250x120x65 | Ceramic, full-length, corrugated | 10.11 rub. | |

| M125 | 250x120x65 | Ceramic, full, single, corrugated | 11.48 rubles. | ||

| M100 | 250x120x65 | Full-time, smooth | 12.55 rub. | ||

| M175 | 250x120x65 | Full-time, smooth | 14.12 rub. | ||

| M100, M125, M150 | 250x120x65mm | Fluted | 19.6 rubles. |

GOST 530- 2012. Brick and stone ceramic. General specifications. File for download

Calculation of the number of bricks

To avoid unnecessary costs, you need to accurately calculate the amount of bricks that need for masonry. To do this, first calculates the size of the exterior and inner walls, then the area of \u200b\u200ball door and window openings is subtracted from it and the resulting figure is multiplied by the wall thickness.

Also, when calculating the required quantity of bricks, it is necessary to take into account the thickness of the dissolved seams and the thickness of the bricks. Newbies often do not take into account this moment and buy for 30-40% more bricks than really necessary for construction.

Tip: Trying to make these calculations on your own not necessarily. On the Internet you can find construction tables and services for calculating the required amount of bricks for masonry taking into account their size and seams.

Video - Construction of a brick bath with their own hands

Video - a visual example of construction of a brick bath

Location and size of premises

In the simplest projects, the bath can consist of only one room, in which you can, and soar, and wash, and change clothes. But such options are not too comfortable. Classic Russian baths provide for the presence of three rooms: pre-bankers, steam rooms and washer.

Pregnant

This room plays the role of locker room. It can also store fuel for the furnace (coal, firewood) and bath accessories. Often this room is used as a rest room and besides wardrobes in it, chairs, sofas, table are installed in it.

Tip: It is important that the door to the pair will be opened towards the pre-banker. If the door goes towards the defendant, it will be easier to open it in an extreme situation if someone becomes bad in the steam room.

For each person who in the steam room should have at least one square meter of the square. And it is without taking into account the stove area (on average, the furnace also takes about 1 square meter) and the fire prevention distance to the walls. It turns out that, for example, the area of \u200b\u200ba comfortable steam room for three people should be at least 4.5-5 meters.

Tip: In order to save ways you can close spaces under the shelves and thereby reduce the heated volume of steam room. This will reduce fuel costs. Indeed, in this case, the heated volume of heated area decrease, but not to the detriment of the capacity of the room.

Design and oven type

To begin with, it is necessary to determine the material of the future furnace. It can be both brick and metal. Each material has its advantages.

- eco-friendly;

- durable;

- well warmed the room and they cool for a long time.

Metal furnaces:

- faster heated;

- cost cheaper;

- have a smaller mass.

Video - How the bath oven is arranged

It is calculated based on the area of \u200b\u200bthe pair and its structural elements. To begin with, the total volume of heated space should be measured. When calculating, it is necessary to take into account the heat loss, so each square meter of uncovered thermal insulation surfaces will add 1.2 cubic meter to the total volume of steam room, the glass door is 1.5 cubic meters. If, for example, the result was obtained in 8 cubic meters, it would take 8 kW oven for the steam room.

Type of furnace

The main thing is to decide with the type of heater. It can be both open and closed. Outdoor stoves are very quickly heated, but cool also quickly. Stones are heated to 200-250 degrees.

The stoves with a closed heater are warm for a long time - an average of 2-4 hours. But at the same time they cool down for a long time. The temperature of the stones in them reaches 400-500 degrees. Also, the advantage of such furnaces is that smoke of them does not penetrate the steam room to other rooms of the bath.

Video - All about bath furnaces

Where to install the oven

It can be installed both directly in the steamer itself (for example, in the center or in one of the corners) and in the neighboring room, namely the pre-tribbon or shower (in the latter case, the Kamenka is located in the stew, and the furnace door is located in another room or even on Street). A steam room is put in the steam room with a shortened fuel channel, in adjacent rooms with a remote fuel canal. It is also necessary to consider the type of fuel for the furnace. If gas will be used for extracts, it is impossible to put the furnace in the steam room.

In the center of the steam room, only an electric oven with a wooden protective side is installed around, since the use of metal models is fraught with burns for people in the bath.

The window is better to place from the western side, as closer to the evening, from this side, much more than the sun.

The bath must be located with a leeward side to the rest of the buildings so that the fire does not shine on it in case of fire. True, for brick buildings, this is not so relevant as for wooden, but if possible, it is still worth being followed by this rule. The distance to the rest of the buildings should be at least 5 meters. But this rule must be necessarily observed, since such a distance is directly indicated in technical and sanitary standards.

The entrance door should be located on the south side, as it is much smaller in winter on this side.

Tip: If the area of \u200b\u200bthe plot is small, and the owner wants to place several buildings on it (for example, a barge for tools, summer kitchen, Bathroom), it is better to combine them with a bath. Otherwise, you can not meet the distance between buildings installed by technical norms.

Pair

Of course, this room is necessary to sow wood. But not every breed. In order not to burn when touching the walls or shelves, it is necessary to give preference to rocks with a minimum density of wood, which are slower than hot: maple, oxine, alder, lip, northern pine.

Tip: Due to the big humidity and temperature drops, the tree will quickly darken. This is quite normal, you do not need to think about repair, noticing it.

In this room, by definition, the maximum humidity will be, so it's best to separate the floor with a tile. Of course, it is possible to choose wood (preference should also be given to breeds with minimal density), but whatever moisture-resistant it was and no matter how the compositions are not treated with gradual darkening still inevitably.

Pregnant

For finishing this room, any materials are suitable: lining, stone, tile.

Tip: With a limited budget there is no need to choose the highest quality materials. The room will be low humidity, room temperature, so even if you separate the walls of cheap pine clapboard to make repairs in the room will have to be very soon.

To improve the thermal insulation, it is necessary to place the windows as low as possible and make high thresholds in the steam room. Also important is the area of \u200b\u200bglazing windows. What she is more, the more heat loss. Therefore, the project should not be provided by large windows. Determine their size is very simple. The area of \u200b\u200bthe window in the bath should not exceed 5% of the floor area. And of course, they all cracks in them should be legitimate, and the frames are tightly driven to bindings.

Council. Also reduce heat loss will help double glazing windows.

Ventilation

In traditional baths, there is a comfortable supply system of the supply and exhaust type (with forced or natural circulation). It includes a sweatman for air inflows and exhaust holes. Holes for air inflows are best placed under the bottom of the stove so that the air is faster than heightened. The exhaust canal is located just below the ceiling. If the furnace is placed in the steam room, the exhaust channel must be placed at the maximum distance from it. In large pairs with powerful furnaces you can do two exhaust channels.

Tip: It is necessary to place special dampers on the outlet holes in order to control air flows in the steam room.

Video - Ventilation in Ban with your own hands