The construction of the bath and the choice of the desired type of furnace seem basic on the initial segment of work in this direction. Assessing the readiness of the walls, gender and roofs of the building, accurately knowing, which stove will heat it, you can move to the decision of the next task - installing the heart of the whole building.

The preliminary stage of the solution can be accurate place definition, where will stand oven, capacitance with cold and hot water. These important moments Arrange the construction of its premises from the project.

Depending on the size of the log, it is planned to split a common space on 2, 3, 4, sometimes more parts. If the dimensions are limited, then the steam room and the washes are united. In some embodiments there is no buildings pregnant. The optimal solution may be installation bath Furnace In a steam room. If the design of the device and planning the room- The firebox is displayed in the pre-banker, and the boiling water tank is installed in a washing or steam room.

General rules for the installation of various types of aggregates

For all bath stoves (from brick or metal using any fuel) there are some general rules Installations:

- Sturdy base.

- Walls, partitions, any combustible items are at a considerable distance from the furnace housing (more than 26 cm).

- The playground in front of the furnace is protected by thermal insulation and metal apron.

- Chimney is reliably isolated from the surfaces of the ceiling and roof.

The main condition for installing all embodiments is the rules Snip 41-01-2003. On its pages you can find accurate fire safety standards, compliance with which will help make any safer bath.

The main condition for installing all embodiments is the rules Snip 41-01-2003. On its pages you can find accurate fire safety standards, compliance with which will help make any safer bath.

Depending on the type of body used by the type of fuel, installation requirements Firemen can have significant differences. A visual example can be compared to brick and metallic constructions. A separate line should select the features of the installation of chambers that use gas or liquid fuel. They have the differences in the installation and electric heaters.

Brick stove

The most functional, beloved by all the stove has big weight Even bath modifications that are significantly less than their home "sisters" weigh more than can withstand the floorboard.

- The first stage of their installation is always the manufacture of reliable foundation. The type of base used is determined depending on the design of the furnace, climatic conditions, type of soil, groundwater availability. It may be ribbon foundation, in the form of piles or durable columns. One of the requirements for any reason - its size which must be more than the size of the structure.

- The next stage is the use of stable masonry to high temperatures Brick, good composition of the clay mixture. An experienced cook - the Mason accurately knows the proportions of such a composition. For a beginner builder simple decision The tasks will be acquiring a ready-made dry mix.

- The masonry process is performed in compliance with the usual norms, according to the selected project. Special attention should be paid to compliance with all geometric proportions Accurate location of flue mines and dampers. Important tools that help achieve good masonry quality will be the usual building level, Full or homemade plumb.

- Structurally brick models have many differences, but the main elements for each of them are stack with confusion Kamenka and the smoke removal system, if the project is not planned to drown in black.

- Socheption requirements are presented to brick stoves the dangers of fire. The walls of their housing, isolated from bricks can not heal to such high temperatures that are capable cause fire Before them can be touched by hand and not get a burn.

- However, the wooden floor in front of it failed by a sheet of iron, but chimney excreted through the ceiling and roof in compliance with the usual firefire requirements - The gap between the pipe and the combustible materials of the ceiling is filled insulating materials (glasswater or its analogs).

Installation of metal furnaces

Any metal brazier has high class fire hazard. Corps, even placed in a special protective screen. It has a sufficiently high temperature, as well as open areas of the chimney pipe.

Any metal brazier has high class fire hazard. Corps, even placed in a special protective screen. It has a sufficiently high temperature, as well as open areas of the chimney pipe.

Installation metal products The famous brands purchased in the trading network is made by either masters installers who work in the firm where the brazier is purchased or independently.

In any case, this design is attached detailed instructions on installation with a detailed description of the requirements for the place of installation, its sequences and necessary materials.

Alone made metal stove can mock in the following order:

- Taking into account a small mass, the device does not require an additional foundation, but the base under it should be prepared. It should be smooth, durable and reliable platform (The usual size of 70 × 70 cm). It can be performed using brick masonry or other materials. The base height is greater 10 cm and does not exceed 20 cm.

- Before installing the furnace, it is desirable to take care of the adjacent walls. As a rule, the location of the roar is the corner of the steam. It is adjacent to 1 or 2 walls and a septal of the pre-banker. If the partition is often made of bricks, the walls are also necessary to put the brick or porcelain stoves, isolate Heat insulating materials and install reflective heat screens. The distance to the side walls should be more 0.5 m,from the top of the furnace to the ceiling - 1.2 m, from the furnace to the wall - 1.25 m.

- For models that are planned to be trammed from the pre-banner, the hole is made of the desired size in the partition between the rooms pair and pre-bankers. Its size is selected with a reserve so that there was a small distance between the metal and brick (due to the expansion of metals when heated). The resulting gap will be filled with heat-insulating material.

- On the prepared base, the layer of heat insulator and the iron sheet is placed on which it is established metal design Firecate to the partition and it is gently inserted into the prepared hole.

- Kamenka is filled with selected stones in advance.

- Wooden (any combustible) floor boards opposite the furnace closes protective metal apron, Fastened on top of the heat-insulating sheet. Length sheet - 0.7 m, width - 0.5 m.

- Mounted decorative pad for the front of the furnace, the cooker, the ash bar.

- The pipe is installed in compliance with some norms. Height of a part of a pipe serving over the surface: flat roof - more than 0.5 m;distance from Skad. double roof - more 1.5 m, and the height of the pipe is 0.5 m;located at a distance of up to 3 m from the skate duscate roof, The pipe cannot be lower than the skate of the building.

- The mandatory element for any chimney is the damper. A convenient place for its placement will be the steam room. The hole and gases removal pipe can consist of several parts that must be reliably fastened with each other. Lower pipe Can be made of metal or used stainless alloy. Wall thickness - 0.5 mm. Located in analyst space Part cannot remain without thermal insulation (a lot of condensate is formed due to a sharp temperature difference).

- To the place of the alleged contact of the pipe with the ceiling is welded metal screen, which helps to properly organize her transition through the ceiling, protect the surface of the ceiling from high temperatures and reliably connect one part of the pipe on the other.

- Some models are equipped with special brackets reliably locking the pipe and the screen to the ceiling. Such fasteners give additional stability of the entire design.

- Installation heat exchanger and tank for hot water It is performed in parallel with the main pipe if the model of the "self-type" type is used.

Installation errors

Installation metal oven - It's not easy business. Independently cope with it is difficult even to have experiences of such works.

One of the mistakes of amines is the refusal to the store installation services. Many firms provide such services to their customers and the stove purchased by you will bring and install experienced masters. The advantage of such an installation is guarantee on performed works. Fault furnace The resulting installation work due to improperly conducted independently, is not included in the conditions of warranty service.

One of the mistakes of amines is the refusal to the store installation services. Many firms provide such services to their customers and the stove purchased by you will bring and install experienced masters. The advantage of such an installation is guarantee on performed works. Fault furnace The resulting installation work due to improperly conducted independently, is not included in the conditions of warranty service.

Limited dimensions Some garden sites force their owners to build a bath near other buildings, which is a mistake that violates the convenience of using all neighboring buildings and a threatening fire there.

To protect buildings from the fire, in this case, the pipe above the bath must be above all the adjacent roofs and on top of it must be put sparking grid.

Sometimes the owner of the bath makes completely independently all the work from its construction before mounting the oven. Experienced masters give advice to check wall thickness A new furnace, especially homemade before plays it with bricks. The quickly burned metal will require a quick change, and the brick label is additional labor and materials.

Installation of the bath furnace can be entrusted to experts or spend on their own. It is important to correctly appreciate your capabilities and accurately. perform instructions on installation and fire safety.

Video

Video instructions for installing a bath furnace:

With the weight of the heating device within 400 kg, installation of a furnace is allowed in the bath on the wooden floor without facilities a separate foundation. The main tasks of the home master are: compliance with the fireproof regulations of the SP 4.13130, ensuring the comfort of the building and decline in the construction budget to the lowest possible level.

The classic Russian sauna has a unheated pre-banker, a woeted steam room. Modern projects It is much more convenient to operate, usually have the following layout:

- pre-banker - the furnace firebox usually leaves this room;

- parik - inside this room there is a furnace and a heater;

- washing - equipped with large-sized drain (ladder or siphon);

- the lounge is a separate room inside the bath or in the attic floor.

Bath layout option and stove location.

Therefore, the furnaces are equipped with a remote or telescopic fuel channel, mounted inside the walls / partitions between the steam room and the pre-tribades to heat all the available rooms separated by partitions from each other.

Remote fuel canal bath furnace.

At the same time, the heating device established in this way should be isolated from carrier / enclosing structures from combustible material:

- the furnace is stacked by a sheet of iron, asbestos or any other non-combustible material (brick, clinker, porcelain stoneware);

- the places of adjoining walls / partitions to the furnace are plated by ceramic or clay brick (cutting);

- an aprons or screens from heat-resistant sheet material are attached to the walls (you can bind to improve the quality of the interior).

In most cases, the bath oven has chimney, inside which high temperatures are preserved, there are sparks, dangerous wooden designs building. Therefore, in places in passing pipes of the chimney of overlaps and the roofs are mounted by cutting filled with thermal insulation materials.

Important! Ensuring the complex of these activities is mandatory for a wooden bath or buildings with wooden floors, regardless of the energy carrier used in the heating device.

Inside the steam room itself, the furnace can be positioned in different ways:

In both cases, it should be noted that according to existing fire safety standards, the minimum allowable distance from not lined from within metal furnaces to combustible wall structural materials is 1 m. The furnace in the center of the steam room is very uncomfortable in service and during paired procedures. Therefore, in 99% of cases, protective screens are used, allowing the heating appliance to the wall as much as possible.

Montage with your own hands

In the manufacture of vertical / horizontal cutting and screens, an instruction manual of a bath furnace should be followed. This document indicates specific values \u200b\u200bof safe distances from the heating device body to combustible materials, screens, protected and not protected. wooden overlaps, door openings Depending on the real thermal power of the stove, the nuances of its design.

For example, in some modifications, the thermophore minimally the permissible size of the brick vertical cutting is 61 cm. Therefore, the oven will not turn into an angle close.

Brick cutting vertical

Regardless of the planning and configuration of the bath, the installation of a factory stove-stove with a remote fuel canal is carried out only in two ways:

The thickness of the cut-portal is ¼ - ½ brick to save the construction budget. However, furnace manufacturers take into account that the remote fuel can be embedded inside the walls of greater thickness, so provide the necessary amount of size.

The main difficulties in the cutting of the cutting traditionally occur in the nodes of the conjugation:

Tip! Due to the small volumes of masonry, it is possible to use facing ceramics to get rid of plaster and putty.

Screens

For metal bath furnaces, several types of screens are used:

Even before buying or make a bath oven with your own hands, it is necessary to decide where and how it will be installed and how much space can be allocated for it. Since this largely depends the choice of its type and size. Only proper installation Furnaces in the bath will make it, at a truly comfortable and safe place.

How to locate the oven in the bath

The most rational arrangement of the furnace in the bath is when it can be heated and a steam room and a place of rest and a pre-tribbon. It makes no sense to build several stoves for this, since it is not entirely convenient and requires high costs.

The most rational arrangement of the furnace in the bath is when it can be heated and a steam room and a place of rest and a pre-tribbon. It makes no sense to build several stoves for this, since it is not entirely convenient and requires high costs.

Of course, much here depends on the planning of the bath itself, and from the type of furnace and its size. So for the location of metal bathing stoves, the most suitable option can be considered the one in which part of the furnace with steam stones is in the steam room, and its front part, with a floppy door, goes into the rest room. In this case, both places of the bath will be heated. In addition, the process of the furnace will be carried out beyond the wage, which means there will not be trash from firewood, and the process itself can be carried out even when there are people in it, while nor slightly interfering with them to relax.

In the same way, you can arrange a brick oven, but since it takes more space and is built on the spot, the place under it must be chosen at the construction of the bath. Brick furnaces require a more reliable base. The foundation is best suited simultaneously with the basement device under the bath itself. If the bath consists of three rooms, the installation of the bath furnace is best done so that all these rooms outgoing from it, all these rooms are modeled for maintaining the necessary temperature in them.

Small-sized ovens, especially electrical, are often installed directly in the steam room. For heating other rooms, the bath in this case will require another source of heat. One of the options may be warm floors: water-connected to the water heating system or electric. Using water warm floors It is most advisable if the bath or sauna is within the house or in an extension to it, and the house itself is heated with the water heating system and there is a boiler power supply for connecting an additional circuit.

Deciding with the location of the location, it is also necessary to know how to install the stove into the bath is correct, given the rules of fire safety. In principle, it is easy to make it yourself, especially in the case of a small metal stove, but at the same time it is necessary to take into account all the nuances and the features of such an installation, which depend on both the type of furnace and the material of the bath itself. If the furnace was bought ready, then you need to consider all the requirements that are set out in the instructions for installing and operating. In addition, regardless of whether it was bought or was bought with their own hands, with its installation it is necessary to follow the general rules of installation, which will allow it convenient and safely to exploit it.

Rules for installation of the furnace in the bath

Below are the basic rules that must be followed by performing independently mounting the furnace in the bath:

- Base. Bathing stoves of outdoor execution must be installed on a reliable non-aggravated base. It is best if it is a separate foundation from concrete or brick. Such a base should be smooth, horizontal and calculated on the weight of the stove. If it is installed directly to the floor, then in this place should be covered with asbestos sheet, a thickness of at least 12 mm and sheet gland, a thickness of at least 1 mm. The dimensions of such a coating should ensure the distance from the furnace case to the combustible material of the floor: from the heat door, at least 50 cm, from other sides - at least 3 cm.

- Distance to walls. The bathing door of the bathing stove must be located toward the door and not closer than 1.5 m from the combustible design of the opposite wall, and its side and rear surfaces are not closer to 0.5 m (for metal - not closer 1 m). It is best if the burnable designs of the bath in the furnace zone will be protected by a brick screen or sheet metal with thermal insulation material. The size of such a screen must exceed the size of the furnace at least 30%.

- Chimney. If the smoke tube is performed from the brick, in the places of its passage through the overlap, it is performed with the thickening of the wall to 25 cm, and in the place of the adjuncing the roof is insulated with sheet iron or special slats, depending on the roof material used. If chimney Metal, at the site of overlapping or walls of combustible materials, it is satisfied with the cutting metal cutting with a non-combustible material. To prevent the formation of condensate, the metal smoke tube, in the outer part of it, should be insulated or made of the "sandwich tube". But such a pipe cannot be installed immediately after the stove, first there must be a plot of a conventional tube from the heat-resistant steel. The distance from "Saintwich-Pipes" to the combustible structures of the bath should be at least 13 cm, and the usual metal - at least 38 cm.

- Ceiling over the oven. If it is made of combustible materials, its area above the stove, exceeding 1/3 of the heating device, must be protected by a metal sheet with thermal insulation layer of basalt cardboard or minit.

- Ground. If an electric furnace-heater will be used in the bath, then it must be grounded using a separate circuit, arranged in all the rules or circuit of the grounding of the house, if any. It is also desirable to use in this case a protective shutdown device (UZO).

- Isolation of a hot surface. To prevent burns from hot surfaces of the furnace (especially concerns metal structures) It is necessary to arrange a convection metal or brick screen around them. In addition to the issue of security, this screen allows you to more evenly heat the air in the bath and soften the thermal radiation from the heated metal surface. You can also, for this purpose, make a wooden fence around the stove, but at a distance not closer than 0.5 m from it. This will protect people from contact with a hot surface, if they slip.

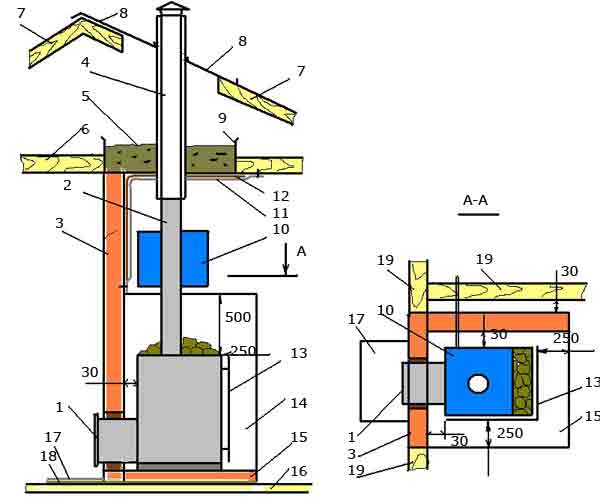

Fig.1One of the options for installing a metal bath stove with the supplied firebox in wooden bath: 1 - firebox; 2 - metal chimney; 3 - a brick wall with a thickness of 12 cm (1/2 brick); 4 - "sandwich tube" or ordinary insulated; 5 - filling the cutting of non-combustible material; 6 - overlapping; 7 - Wooden roof elements; 8 - metal adjoining sheet; 9 - Outlet of sheet metal; 10 - water tank; 11 - Screen made of metal sheet; 12 - heat insulation (minvat or other non-combustible material); 13 - screen providing air convection; 14 - screen (brick wall in 1/2 brick); 15 - non-combustible base (here a brick layer on the edge); 16 - floor; 17 - metal sheet; 18 - asbestos; 19 - wooden interroom partition;

It often happens that all the attention and strength of the homemade master sends to the construction of a bath furnace, and when the unit is ready, it will fall into place, not intelligible in subtleties.

However, the installation of a furnace in the bath with their own hands is a stage that will depend on the further safety of people, the serviceability and longevity of the boiler.

The same is true about the factory models of boilers and fireplaces. All you need to know about mounting, read further.

Compare these two types of furnaces.

The advantages of the metallic option:

- Heat quickly.

- Occupy a little space.

- Weigh relatively little.

- Cheaper than brick.

- It's easier to make with your own hands.

Disadvantages of metal boilers:

- Also quickly cool, as heated. In the bath heat, while the stove is token.

- Extremely hot surface, dangerous for people.

- High fire safety requirements - installation of protective screens on the floor and ceiling, distance to wooden walls, etc.

- The inability to dump several rooms and large rooms.

Brick furnaces can rarely meet in the baths, due to the complexity of their facilities and high costs. It is also necessary to consider that sharp temperature differences, especially in winter, for masonry - extreme! In all other parameters, this is a great option for the steam room. Heat from bricks soft and uniform, stays long.

If a brick oven was chosen, about the place of its placement, sizes, foundation and chimney, the Lacke thinks in advance and as it is erected. There is an opportunity to simulate the design under the features of the room and the requests of the owner.

The metal furnaces may differ in the way of installation depending on which type of fuel it works (there are electrical boilers, liquid-fuel, gas and most popular - solid fuel).

In the bath there is a constantly high concentration of steam, so it plays a very important role. Consider the principles of the device of the air exchange.

In the bath there is a constantly high concentration of steam, so it plays a very important role. Consider the principles of the device of the air exchange.

Step-by-step instructions for the manufacture of a bath boiler are presented with their own hands.

Metal is simple for processing material, so many prefer the metal bath furnace. How to make it with your own hands, look further :. All from assembly to installation.

Rules for installing a bath furnace

Choosing a place

The array of the furnace is located in the steam room. To protect wooden walls From fire, the boiler should be 50 cm from all combustible materials.

The door should be no closer than 1.5 m from the nearest wall.

Excellent if the coil opening goes to the pre-banker. This makes it possible to warm up two rooms, and it will be more convenient to trammed.

![]()

Stove in the bath

Part of the simpleness is cut into so that the hole is more than 25-30 cm boile from all sides. This empty space is filled brick masonry or other material that will be a fire layer.

When choosing a place of the boiler, see where the hole or the door of the heater will go (if any).

In no case, the hot steam should not break away in the direction of the climb. Best of all, if the Kamenka is facing an angle.

Base

The base should be non-aggravated and reliable. Perfect solution - concrete platenot related to the foundation of the structure. Sizes of the plate: 5 cm more furnace with each side. but cement base Do hard and expensive. You can lay out a layer of chamotte brick.

Economy option for a furnace base is a metal sheet, laid directly on the floor through an asbestos cardboard with a thickness of about 12 mm. In this case, the sheet must be outside the boiler for 5 cm from three sides and 40 cm with frontal. But this option will be admissible only if the owner is all a hundred confident in reliability of Lag. If not - better all the same concrete.

Brick base for stove

Shielding

Metal boilers We need shielding. The construction of brick masonry from two to four sides is, first of all, reliable fire protection of the walls. But not only!

To be near the split items of large sizes is unsafe by definition. Serious burns can end the fact that the person will be bad, or he slip next to the boiler. The screen is made of brick, although heats up, but not to such an extent.

Brick masonry accumulates heat, which will not be superfluous, because the metal is quickly late, but also boils rapidly.

Sometimes the screen is not made because of its massiveness, unwillingness to mess with brick and not so hot external view. Then you can make a thin aesthetic screen from porcelain stoneware. It will be more expensive, but solid.

Fire protection

![]() A sheet of non-flammable material should be protected by the floor before furnace.

A sheet of non-flammable material should be protected by the floor before furnace.

It is better not to save on metal sizes, because the danger is not only in heating with radiant energy. The burning corner or smoldering head can fall out of the firebox by depth.

Also protect the ceiling above the stove. And the surface of the insulating layer here should be greater than the dimensions of the heating device by 1/3.

Chimney

The perfect chimney is without knees and slopes, not less than 2 meters in height (this will provide normal traction).

The pipe must be mounted on the pipe - a sewer that will allow you to regulate the intensity of the combustion process.

Warming of chimneys is necessarily for all types of boilers. A convenient modern version is a sandwich tube, in which there is already a qualitatively made layer of insulation. But it can be used on a plot passing over the ceiling, where in the winter there will be minus temperatures (by the way, without insulation, a huge amount of condensate and nagar will be formed in the pipe).

On the first land from the furnace, where the heat is maximum, it is impossible to use sandwiches. For this segment use stainless steel (especially if the pipe passes through the water tank).

Installation of the chimney sandwich in the bath

The place where the pipe passes through the ceiling is isolated non-combustible materials (A metallic box is often made, filled, for example, clay). The thickness of the isolation layer to the wooden elements of the overlap is at least 13 cm. The brick chimney is expanding in this place, the rush is made, thickening the pipe by 12 cm on each side.

For sealing joints, high-temperature sealant is suitable.

If you can choose chimney, preference is worth paying a ceramic pipe. She is very heat-resistant and durable. And the best brand of steel AISI 310 S.

Ventilation

This item sometimes misses the owners of the Parilov, because it may seem that in the room where the roads each kilodzhoule should not be any extra holes.

This item sometimes misses the owners of the Parilov, because it may seem that in the room where the roads each kilodzhoule should not be any extra holes.

But it is not. Metal boilers burn the oxygen strongly, and the sliced \u200b\u200bair becomes an excessive load for humans.

Yes, and the wet room needs constant ventilation, otherwise the materials will rapidly destroy, darken, to be covered with mold.

Ventilation in the bath can be made so that the incoming air immediately heated from the furnace. Then the influx is placed near the boiler, in the wall or from the sample (especially well, if the boiler is on the legs). But it can be problematic if a high concrete foundation is used.

The size of the ventilation channel according to the standp standards - from 10 cm.

In order not to lose heat through ventilation, you can make a pipe with a deaf valve. This will give the opportunity to open the vent hole when it is convenient.

Electric furnaces and fireplaces

These units are powerful enough and establish them without coordination with the fire service.

For an electrocotel, grounding is made. Powerful equipment is connected via a separate branch through the RCD.

Installation of the electric furnace from the manufacturer's company can cost a lot - about 10% of the cost of the boiler itself. But in this case, you protect yourself from errors. Yes, and when breakdown, the manufacturer will not arise the loopholes to shift the guilt on poor quality installation.

The order of installing a metal furnace in the bath with your own hands

- All overall dimensions of the heating device are removed.

- Measurements are made in the room, and the optimal location is determined, according to the requirements set out above.

- The base is performed by the selected diagram (see above).

- The protective screen is laid out.

- The assembly is established on the base.

- Mounted chimney. It is carried out through the roof, it is insulated, the headband is installed to the aggregate.

- Fire protection for the ceiling is made.

- A heating tank is installed (if it is not a single integer with the heater).

Whatever high quality isolation, the last stroke is recommended to place a fire extinguisher in the affordable place.

Conclusion

When installing a bath furnace, you can not neglect the rules that may seem tricks. Yes, and bother to the size and thickness of the heat insulating materials, is also not prudent, especially in a wooden structure.

Video on the topic

Own bath is the desire of many people. This is no wonderful, as the time of time, this survival was not just a venue for hygienic procedures, but also had almost a mystical meaning. But the times go and increasingly can be seen as someone refuses to build a bath in favor of installation, such as a shower cabin or limited to the bathroom equipment. It is good or bad to solve everyone, but almost certainly one can argue one thing - nothing compares with a bath on the therapeutic effect and a special atmosphere, which is created there. However, after the construction of a bath to enjoy all its capabilities, it is necessary to solve a row, so to speak, technical issues, one of which is how to install the stove into a bath with your own hands and what the rules and features are there in carrying out this process. This will be discussed further.

Types of stoves

In order to respond to the above question, it is necessary to start saying a few words about which kinds of baths for a bath. What type of bath furnace will be chosen to a large extent, many nuances of the work will be dependent.

First of all, the furnaces can be divided into several groups, based on the type of fuel used in them. So you can designate:

- Solid fuel furnaces. This kind of stoves is quite common and the oldest of all others. It is easy to guess, for work such a stove uses solid fuels such as firewood and coal. This type can be rightfully called traditional, since it was exactly that bath furnaces were initially. Among the indisputable advantages of such an option, environmentally friendly, obviousness and ease of use can be distinguished, as well as the versatility of use.

- Furnaces on liquid fuel. Another kind of furnaces installed in the bath, using a fuel, for example, kerosene. It can be used in most cases, but it is important to understand that such furnaces will have an increased fire hazard, and therefore their use should be carried out in compliance with all safety precautions and safety regulations.

- Electric furnaces. In principle, this type of furnace can be considered one of the safest among others, but it is worth saying that the work of the heating elements will require a very decent amount of electricity, which will entail not only the costs of payments, but also to refine the wiring.

- Furnaces on gas. This option is quite practical and very simple, but it is necessary to constantly monitor the serviceability of the equipment. Otherwise, there may be no dangerous situations.

To understand how to install the furnace, you need to know the fact that they may differ in both manufacturing materials.

So, for example, the distribution received metal, stone and brick furnaces. The process of creating a brick or stone furnace requires a separate detailed consideration, but the installation of the metal stove can be considered within the framework of this material.

One kind of furnaces used for installation in the bath is an electric oven. Among the most significant performance characteristics of such such types can be mentioned:

- Universality application.

- Aesthetics of appearance.

- Safety use.

- Relative ease of installation.

- Does not require additional maintenance.

- It does not need an additional room for fuel storage.

Easy and easy operation

The list of positive characteristics can be continued, but most importantly, it is worth noting - to be able to fully enjoy all the advantages of the device, the furnace needs to be installed correctly and install. It is worth saying that the process is not distinguished by a special complexity, but consider the algorithm of actions, however, it is worth it.

- Before starting work on installing an electric furnace, it is necessary to ensure that a solid and even base for it is mounted. To do this, it is necessary on the surface area, which is expected to install, hold a concrete tie.

- The electric oven consumes a fairly large amount of energy, which means that for its comfortable and secure operation, the installation of a separate power point will be required (waterproof socket), equipped with its own grounding.

- Since the electric furnace (especially the models equipped with remote control) is a rather complex device, it is necessary to assemble it in strict accordance with the attached instruction. The assembly is advisable to spend immediately at the installation site, but if for some reason this process is difficult, then you can also be installed on the basis of the product already collected.

- After installing the stove, it must be connected to the power grid and conduct trial use. There should not be problems and difficulties.

As an additional precautionary measure, you can mount a protective screen from wooden plates, which should close all elements subjected to direct heating.

Cast-iron oven.

In the bath, along with other options, you can install a cast-iron furnace. This option is quite interesting and rational. The cast-iron furnace has the following operational characteristics:

- Easy installation.

- High heating rate of the room, due to the good thermal conductivity of the material.

- Easy installation and use.

- The ability to dismantle and move, if necessary.

Work on the installation of such an oven is reduced to the following:

- First you need to make a solid base. Cast iron - metal is quite heavy and the average weight of the stove from it will be about 200 kg. In this regard, the execution concrete screed Or the additional enhancement of the floor is simply necessary.

- Next, you can go to the assembly. Separate parts of the furnace in principle can be transferred alone, but still, it is better to invite someone else to help. The assembly of the furnace is made in accordance with the instruction attached to the product.

- After installing the main elements of the furnace, it is necessary to mount the chimney. When performing work, it is necessary to monitor the tightness of the connectivity of the elements.

- Bath stoves are most often supplied with a special place to lay the so-called "Kamenka". Here you should add that for these purposes it is necessary to use only clean, washed stones.

After the work performed, it is necessary to conduct a trial ignition of the stove and, making sure that all the elements are mounted qualitatively, the product can be used.

Installation of a metal furnace

First, it is worth noting that the furnace made of metal can be installed independently and in the premises of almost any type, that is, wooden, block or other. At the same time, both purchased models and self-made options can be used. Among the most significant performance characteristics of a metal furnace can be allocated:

- Reparatively small sizes. This circumstance allows you to install the stove in almost any room, while other options require initial planning place of placement.

- Universality use.

- High efficiency.

- Relatively low weight due to which there is no need to enhance the foundation.

- Pretty large variety of models.

But there is one pretty substantial minus - the walls of a furnace made of metal will quickly cool compared to counterparts, so to ensure a long-term effect, the room in which the stove installation is planned, it needs good thermal insulation. In addition, the stove walls can be chopped by a brick, which will allow to achieve comparable with the "classic" variants of heat transfer indicators. Such a stove will warm up longer, but it will cool longer.

So, the immediate installation of the furnace in a wooden bath, as, however, and in any other is made as follows:

- First prepared the basis. This means that even at the construction stage, it is necessary to concrete and align some space that will be required to install the furnace and the formation of the accepted space. It is important here to take into account the type of fuel used, since, for example, if you use coal, it is necessary to reduce the risk of fire hazardous situation, it is necessary to protect the equipment of a fairly large sheet that will protect flooring from departing sparks.

- A stove is installed on this base. As it was mentioned above, a ready-made version can be used, and you can make the stove and independently. But you need to understand that for the manufacture homemade stove It will take not only the availability of tools, but also considerable experience in conducting work, so it's better to just buy a finished furnace. Especially since the models in the modern market is abused. Usually, with the products of this type, accompanying documentation follows, in which the process of installing the furnace is described in sufficient detail.

- After the furnace housing itself is installed, it can be chopped by a single-row brick masonry. As mentioned above, this technique will improve the heat transfer of the stove.

- Next is the installation of chimney and heating tank. In the case of using the finished furnace, the chimney is mounted in accordance with the instructions. It is important to ensure that all the places of joints of individual structural elements were sealed. The heating tank can be located both indoors and heat up directly from the combed fuel and in the attic of the bath, where heating will occur from hot smoke raising by chimney. How easy it is to guess, in the first case the process will occur faster, but will require the presence of some place, and in the second case you can save space, but you have to sacrifice time.

In addition, it is necessary to add that in order to avoid the formation of a land and condensate on a piece of chimney that has contact with unheated spaces, it must be insulated.

In conclusion, you can add that the installation iron furnace For a bath, a rather rational solution to solving the problem of heating the room, as well as water heating. Of course, for independent work, some experience will be required, but with proper desire and sufficient information, this task is quite fulfilled. For the most complete understanding of the essence of the process under consideration, you can get acquainted with the video on the topic.

Video

In this video, it is talking about choosing a stove for a bath. You will learn a lot of useful information about homemade and manufactured furnace furnaces:

In this video, it is described about the installation of a metal furnace for a bath with their own hands:

Photo