"Interwidden insulation - gasket material between the crowns wooden house (Baths) made of timber or logs. "

"Interwidden insulation - gasket material between the crowns wooden house (Baths) made of timber or logs. "

Good day to everyone who decided to look at my blog!

Since a long time, wooden buildings were insulated with a pantry. That is, natural material pushed between the brothers (more about it in more detail). It is worth mentioning that the current insulation materials went far ahead, in terms of practicality. Therefore, today we will try to find out what to choose an interventic insulation for a bar and logs? Consider different types. And natural, and partially natural, and synthetic. Go!

Of course, a tree as a material has a lot of advantages. However, insulating the crowns, it is necessary. If the insulation is laid or properly incorrectly, it will not be united with the tree and the valuable properties of wood will be bad.

Main requirements for insulation

- Uniform density and good elasticity. It must well close the seams between the bar not only during construction, but also after the shrinkage of the building;

- Must have a low thermal conductivity;

- The ability to absorb and give moisture is like a tree (this allows you to maintain the necessary moisture content of wood and protect the house or bath from dampness);

- Resistance to temperature differences and solar radiation action;

- "Reziness" in relation to insects and birds (the "harvest" for nests);

- Durability and preservation of its operational qualities;

- Absence harmful substances for our health;

- Antiseptic propertiesthat prevent the biodegradation of fungus and mold.

"Wrong insulation"

Materials with a closed pore structure (Penoplex, etc.), synthetic sealants (silicone, acrylic, etc.), sprayed and foamed polyurethane foams - it is impossible! Why? Because they are playproof.

Materials with a closed pore structure (Penoplex, etc.), synthetic sealants (silicone, acrylic, etc.), sprayed and foamed polyurethane foams - it is impossible! Why? Because they are playproof.

A wet steam comes from the building, at the point of dew will begin to turn into condensate. And the fraught condensate inside the thermal insulator, more than once it was said, for example,.

Types of interventic insulation

To begin with, we divide all the material into two types: natural and artificial.

It should be noted that x / b and wool for interventional insulation of the house or bath is not enough. They have one common drawback. Guess? Well absorbed and do badly give moisture. And they "respect" insects and birds.

What you need to know about the density of the insulation? By the way, each self-respecting manufacturer, indicates this parameter. And he should be:

- For houses from glued timber:ranging from 300 to 400 g / m. square, with a thickness of 4-6 mm.

- For a pinned log: - from 450 to 550 g / m. square, with a thickness of 8-12 mm;

- For profiled timber:- from 250 to 350 g / m. square, with a thickness of 2-3 mm;

If the wood has an uneven surface, the seal must be thicker.

So, what kind of natural options are most suitable for construction wooden houses Or bath? It is a pack of flax, jute or hemp; Long fuel moss and not a woven felt. Now about these components in more detail:

Let's start with forest moss

"Not every moss is suitable. Typically use such types: red, sphagnum and cukushkin Lyon. "

Kukushkin Lon.

Kukushkin Lon.  Build a bath

Build a bath

Looking moss, it is necessary to leave a fringe (as in the photo), which is subsequently stuffed into the slot with a special tool with an experienced specialist, that is, you. A year later (after the log house gives a shrinkage), moss must be treated: where you need to sink, and where and somewhere ...

Tow

"This material is waste from the initial processing of certain types of plants. It includes cellulose, lignin, pectin and a little wax. "

Modern natural materials

Jute bars

Perhaps one of the best in the ratio of "price-quality".

Available in several sizes. The width varies from 2 to 100 cm, thickness from 4 to 12 mm, the density is ≈ 700 g / m². You can comfortably and quickly roll right into the groove, in the course fixing the stapler. After laying, the jute canvas compacted and becomes resistant to moisture and wind. Great for timber. Seam looks symmetrically, and its golden shade is pleasantly harmony with the color of wood.

"The jute canvas is practical for the bath, because his fibers are well removed by moisture."

Linnatin

Depending on the manufacturing technology, it may be called differently. Refers to a stigled canvase (made by a needle-crying method).

Caution!Buying this product, pay attention to the structure. Will not notice very short fibers, trimming threads, twine and splashing other colors, know - in the material there are recycling products. For example, utilized mischromatic, rags, etc. It is not quite good. Such a heater will be fragile. And besides, it is unknown, under what conditions processed products were operated.

Synthetic interventic insulation

Hollofiber

Non-woven material based on polyester fibers. Basic application: as a heater for outerwear and bedding. The kind of synthet known to us.

Non-woven material based on polyester fibers. Basic application: as a heater for outerwear and bedding. The kind of synthet known to us.

It is produced in two types: the canvases (rolls) and the formation (hardhas) having different rigidity and density. The choice in each case is due to wood features.

Especially valuable quality - elasticity (recovery of volume). For example, there are no grooves in an unpainted bar, and during seasonal drying it twists it. When the traditional seal is used, there are gaps that need to be caught in such situations. In addition, natural heaters are pressed and dried under the pressure of the bar. Hollofiber due to elastic regeneration ensures efficient filling of cavities.

The material is now produced in Russia, at the "Thermopol" plant in Moscow.

Polterm.

In a sense, this is a kind of holofiber.

Polterm is sold in the form of a tape: width: from 30 to 250 mm; has a thickness of 8 - 20 mm; restored after compression by 90%; Color is golden-beige. All parameters and characteristics are similar to holofiber, so we will not list.

For a few simplified understanding, I will give a comparative table. Many parameters of the usual jute and polytermone interventional tape are compared here.

| Name | Jute (ribbon) | Polyterm (tape) |

| Do you need a re-cachat after shrinkage at home? | yes | not |

| Repailability after complete compression,% | 20 % | 90 % |

| Absorption at 100% air humidity | Up to 25% | 0% |

| Exposure to gradual rotting | yes | not |

| Gigroscopicity (vapor permeability) | weak | high |

| Operational resource (years) | 10 years | 50 years |

| Reuse | yes | not |

However, there is one thing, but ... polyterm - relatively new Material And many years of history (at least more than 10 years) its use, we do not know. Therefore, an objective analysis of its capabilities can be done in a few years. In the meantime, Polyterma suppliers can say whatever!

Now, personally my feedback. Working with similar materials for more than one year, I will say the following: better and practical "Jute Wheel", you will not find. Verified in practice! The same, can confirm my friends builders. Maybe we just do not want to recognize the synthetics?!

By the way, recently (on the eve of the new year), my companion-colleague, bought a flax-jute canvas in the company "Winter House". He liked communication with a consultant (from his words, he perfectly understands in matters of wooden house-building) and the price of the goods was quite "lifting". This is not an advertisement - just a consultation, which is always useful. For residents of Moscow and Moscow region i recommend that this company. Moreover, the company specialized and not the first year in the construction market.

Well, perhaps, everything I wanted - said. If it was informative, then do not miss the exit new information. Are there friends who build a bath or house? Recommend the article to them.

Good luck and warm, well-cocked walls. Until!

Wisdom quote: So men are arranged: they can resist the most intelligent arguments and do not resist the only look (Bazzak).

Despite the ever-growing assortment of modern building materials, from the use of natural wood for the construction of houses, no one is in a hurry to refuse. You can even, probably, even notice the reverse tendency - the popularity of wooden construction is only growing, apparently, because there is something to compare with, and these comparisons play only "on hand" natural material. Indeed, if evaluating the combination of quality - availability, low thermal conductivity, ease of treatment, absolute environmental purity, the ability to create a completely unique healthy atmosphere in the house - none of innovative materials can be compared with wood.

There are, of course, the tree and its drawbacks, and one of the main things can be considered the absence of plasticity and a tendency to deformation when changing external conditions. As if it was not for any details for the construction of log or brusal walls, to achieve the complete absence of cracks between them is still impossible. And this means that it will have to provide for a seal between the elements of the church. For these purposes, a special material is applied - an interventic insulation for a bar which to choose - tells this publication.

Even if the future owner of the house does not have carpense skills and is going to attract the team of specialists to the construction of a church, never will be able to control their work. Unfortunately, there are often "Shabashniki" who, trying to extract the maximum benefit and accelerate the performance of work, go to all sorts of unscrupulous "tricks", the consequence of which can become weak healing, wall-producing. This is often detected only after some time, with the onset of cold weather, and often the correction of such flaws even requires a complete bulkhead. It is better to keep it under constant control.

Before switching to the consideration of the varieties of internet insulation, it is necessary to insert a brief on its purpose - it will be easier to subsequently make the right conscious choice.

- The use of such material significantly enhances the natural thermal insulation qualities of the tree. The cold does not penetrate the joints deep inside the log (bar) walls, wood is less freezing outside, and this is a decrease in the number of cracks appearing, and by and large - the overall increase in the entire service life of the wooden house.

- A high-quality interventic insulation compensates for wood fluctuations when drying it or, on the contrary, swelling from high humidity.

- Properly installed insulation prevents entering the lumens between the bars of water or excessive moisture, which can intensify the processes of rotting the wood or become a favorable environment for the development of foci fungus or mold.

- Properly selected interventic insulation will become an obstacle from penetration into the house of insects.

- The compacted joints between the bars not only do not allow the purge and getting into the room - the level of noise penetrating from outside is sharply reduced.

- High-quality interventical insulation do not violate the normal balance of humidity and temperature under all weather conditions - the most important advantage of the wood is maintained - the ability of the walls to "breathe"

So, the importance of this material for the construction of a qualitative and durable cut is difficult to overestimate. It remains to find out what types interventical insulation There are, and what advantages and disadvantages have.

Varieties of interwetant insulation and their specific features

It would be a big mistake to believe that any available material is suitable for the insulation of interventian jacks. It happens that a low price for some thermal insulation materials provoke buyers to ill-conceived acquisition, such as mineral wool, but the result is sad.

Special operating conditions require the interventional insulation and the corresponding characteristics - low thermal conductivity, mandatory elasticity and ability to restore the volumetric forms after compression, durability, strength of the fiber structure to breaks, resistance to biological decomposition, to the effects of the Sun, elevated and low temperaturesAnd at the same time preserved naturalness, remaining completely "clean" and harmless from the point of view of ecology.

It is enough to choose the material that would fully answer all the stated requirements. Nevertheless, a number of natural or synthetic insulation are very close to excellence, therefore, they were widespread for wooden construction.

Natural interventic insulation

The history of wooden architecture goes deepstairs, and with the problem of insulation of their housing, people always faced. Naturally, the most different natural materials that have been available. Gradually there was a kind of "selection" - the materials were not justified by hopes, but those that have proven their viability are actively used and understood.

Moss - material for insulation of cutters

Residents of the wooded and taiga medium and northern strip, where quite a lot of wetlands are usually used for the insulation of moss houses. Interestingly, this available natural material not only defended at home from purging, but also provided the long-term safety of wood. Incredibly, but the fact - even after many decades of operation, the logs remained intact, and x them calmly could be disassembled and used for construction in a new place.

Traditional material for interventation insulation - moss

It's all about the natural qualities of some MShs - their biochemical composition includes a large number of phenolic acids, which, as is well known, is powerful antiseptics, easily packed with most of rotary and other pathogenic bacteria. Naturally, contact with such a insulation provided transmission and log cabins of additional resistance to biological decomposition.

Mosses are actively used in construction and today. They have long been justified by their qualities, and especially attracts that the material is-fully free, except for their own labor labor on the workpiece of raw materials.

Of course, working with insulation from MCH is more difficult than with ready-made belt materials. But in some cases, their use becomes even more efficient. This is especially true for the buildings that are erected from hand-treated logs or non-profiled timber. In such conditions, it is precisely such material that it will be more convenient to adjust the thickness of the layers for the maximum dense filling of the lumen between the crowns.

In addition, none, probably. Another insulation will not be compared with the moss according to the atmosphere of the wooden house of the wooden house. It is characterized by a unique forest fragrance, saturated, among other things, therapeutic components that are capable of rendering health effect For people with chronic diseases of respiratory and skin.

Of course, not all MAs of the diversity existing in our nature are suitable for such purposes. As an interventory insulation, only two types are applied - sphagnum and "Cukushkin Len".

- Sphagnum An acquaintance is likely, all those who at least once visited a peatlar swamp. Usually thickets of this moss cover the wetlands of the forest with a dense, extremely dense green carpet.

It is easy to collect such a moss - from fairly easy to give in, leaning together with the root of thick beams.

It is recommended for a sphagnum to go to good clear weather so that the moss assembled is the maximum dry from above. The fact is that the sphagnum does not use immediately - it requires a certain drying in the copper under the canopy, from one to two weeks. And the land the material was when collecting, the shorter will be the preparatory period.

It is not necessary to be afraid that after grazing the stems and leaves will become fragile - the dignity of such MCH is that it is drying. In contrast, for example, the grass does not lose its qualities, remaining dense, elastic and preserving the porous structure of the mass, which predetermines the high thermal insulation properties.

Laying dry sphagnum on the crowns is a fairly troublesome, requiring a certain skill - it is necessary to achieve a uniform and complete fit of the logs or bars along the entire length. But the wood will receive highly efficient natural protection. The antiseptic properties of the MShs are expressed precisely from the sphagnum to the maximum extent. No wonder his Icestari used as healing folk medicine, in military field surgery, in veterinary medicine, etc.

Video: How to harvest the moss sphagnum for the warming of a church

- "Kukushkin Len"in fact, it has nothing to do with the real flares, nor to the cuckoo. The name apparently went from some similarity of the fibrous structure and small leaves. And the cuckoo silhouette resembles a box that is formed on the top of the plant's stem.

Such a moss also grows extensive glades on peat swamps, and it can be collected quickly in large quantities. It is recommended to look for forest "plantations" - there "Cukushkin Len" will not be so saturated with water. The length of the stems protruding above the surface is usually 150-200 mm, but it happens that they reach the height even 400 mm and more.

It is already recommended for its collection, rather, cloudy, non-fit weather - it is believed that under such conditions it preserves its qualities better. The collected moss is placed by long stripes for light drying, but it is impossible to excessively zealous - the risen stems can be somewhat brushed, and they will have to keep their moisturizing before laying. By the way, often such a insulation laid on the crowns even immediately after collecting. No extra drying.

The layout is carried out in layers, with interleaving the direction of the fibers. After the end of the burning of the cut, the protruding fringe is permanent into the joints between the bars.

During the operation of the house, a qualitatively stacked insulation should not deliver the hassle - it does not grow inside the joint, does not scatter, well supports the balance of moisture in the wood. The disadvantage can be considered that Cukushkin Flax willingly consume many birds in food, trying to pump it out of the gaps. It requires a very careful caulkit, and even better - the cover of insulated junctions is also a jute rope. In addition, the outer caper will still have to update from time to time - the protruding the outwards of the fibers gradually acquire the brittleness and fly away.

Linen-based interventic insulation

One of the traditionally ragged cultures in our places for a long time is flax. After processing the collected raw materials, thin fibers became material for the manufacture of fabrics, and coarse and short - walked into the pass. And the direct destination of the pakley has always been - the caulking of the gaps.

Pacle, in principle, a very good thermal insulator and the seal, but to work with it during the construction of a church - just as difficult, as with Mkhami. It is quite difficult to lay out this material with a necessary layer, with the same roughly density, achieving full filling of gaps and lumen. In addition, this inconvenience can still be aggravated by windy weather. Another minus pacles - her fibers love to use birds to build their nests.

It is much more convenient to use special material on an interventional insulation on a linen basis. It is often referred to as flaxed or linen felt. And for its production, non-sorted flax waste, and high-quality raw materials are used. As a result of special treatment using pressing, a nonwoven canvas is obtained, a thickness of from 5 to 8 mm, which is cut into strips of various widths (from 8 to 200 mm) and comes on sale in rolls up to 20 meters long.

The width of the rolls is selected depending on the size of the bar or the profile grooves available on it, designed specifically for laying a belt interventor insulation. If necessary, for tight fit of the crowns, the laying of two or even more layers is practiced - depending on the geometry of the bar or logs. Laying itself is easy - the tape of the insulation is shot to the draft stapler brackets, that is, windy weather will not be able to prevent.

Usually when laying such a heater on a bar without special profiling or on a log, try to avoid hanging on the sides of the wall. It is better to adjust its edges when laying inside - so you can avoid a tiring procedure of subsequent cacopkka. It gives a uniform reliable seal along the entire length and width of the wall part of the wall.

disadvantages Material:

- Linovatin is not sufficiently protected from biological damage - debating or rotting. In addition, it can start the nest of very harmful insects - bugs, moles, gribers and others. Therefore, the issue of antiseptic treatment of wooden parts is particularly relevant.

- In the manufacture of jute felt, the flax content usually does not exceed 10%, but the fibers in the production stage are mixed. The linen component smoothes the stiffness of the jute, does not allow fibers to stick together, and the total strength and pronounced antiseptic qualities are not at all lost.

- The quality of thermal insulation and noise absorption is the highest.

- Wool does not fall over time, does not lose elasticity, perfectly fills all empties, not leaving no chance for the "cold bridges". When wood deformities in one direction or another, the elasticity of the felt will not give to the slits - the density of the fit will be maintained.

- Well treated wool is not afraid of moisture and will not rot, it will help to maintain the optimal humidity balance.

- Insulation material quality - very high. And the elasticity and elasticity, not lost during the entire period of operation, provide complete filling of all voids and lumen, both in the construction process and the entrance of the deformation oscillations of the church.

- Despite the synthetic origin, the polyterma has excellent vapor permeability, that is, it will not disturb the normal humidity balance of air and wood. At the same time, it has severe hygroscopicity, does not absorb like a sponge water. When it is used, you can do without additional externally cacked.

Unprotected cross-jocked joints - a real "find" for birds. The optimal option is to close from jute ropes.

Jute interventian insulation

An excellent insulation of the crowns are jute and materials based on it.

Dut is obtained by processing annual high Plant (Far "relative" of our Linden) with the name of the same name - it is very widely cultivated in the regions with a tropical climate. As a result of processing, long and durable fibers are obtained, which have gained very widespread use.

A distinctive feature of the jute fibers is the high concentration in them lignin - natural resin with severe antiseptic qualities. The material practically does not rot under the influence of moisture, does not lose its strength - it was always the jute ropes in the shipbuilding that it was always famous for the shipbuilding. Jute is completely unattractive for birds, insects, rodents - also an obvious plus.

The material is able to "share" with its own antiseptic qualities and with the in contact with it - the logs or the bars of the log cabin receive additional protection.

However, the high resin content has both "reverse direction" - this leads to a gradual gluing fibers among themselves, loss of plasticity - jute can overcome and become rigid. To eliminate this disadvantage, but to fully maintain the merits of the material, in the production of interventic insulation, it is usually combined with linen fibers. There are various options here.

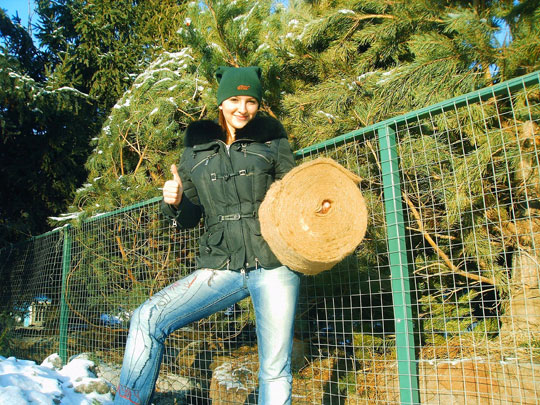

Roll of flax-jute felt interventory insulation

In addition, ropes (ropes) are produced from pure jute, which are also widely used for interventional insulation - for the final external cacking of the joints.

Laying of jute interventic insulation in principle does not differ from the above-mentioned use of linen materials. The only difference is that the jute, as already mentioned, do not disappoint the birds, and its natural color is well harmonized with shades of wood, that is, a slightly protruding layer of cacopate or the jew rings scored on the joints only give a piece of particular accuracy.

Insulation based on natural wool

It is quite natural that in the regions where animal husbandry traditionally was traditionally at a high level of development, wool waste was used for housing insulation. It is practiced in our time.

Woolen fibers come special processing to prevent their insect damage, and fell on specially technologies in felt canvas of various density and thickness - from 10 to 20 mm. Then it is cut on the ribbons with a width of 80 to 200 mm - and in this form, the insulation comes on sale.

Such an interventic insulation has many advantages:

The disadvantage can be called, perhaps, only a high price for similar insulation, which in principle and are predetermined not so widely applied compared with the materials of plant origin.

Synthetic interventic insulation

In addition to natural insulation, artificial, on a polymer basis has become increasingly widely used. Many this approach causes certain concerns due to the unnaturalness of the material, but manufacturers are convinced that their products are fully adapted to wooden construction, completely harmless, and on operational qualities even sometimes exceeds natural materials.

As an example, several varieties of such interventical insulation can be given.

Rolls "Polterm" of various widths

Polyterm is produced on the basis of polyester fibers, completely harmless to humans and nature. The material with time is not decomposed, fully preserving its chemical formula, that is, it is not necessary to fear the allocation of any toxic substances.

Special convenience in the construction of a log - Special curly elements for logs of log connections or timber

The service life of such an interventory insulation, according to the manufacturer, is almost unlimited.

"Avaterm"

It is nice to realize that domestic producers can produce top quality products. An example of this is the interwetant insulation of the Avaterm brand, produced by the same company from St. Petersburg.

This material, also on a polyester basis, was developed taking into account all available modern technologies, and at the same time special attention was paid to the adaptation of the insulation precisely to the Russian climatic conditions of operation.

"Avaterm" has all the advantages as "polyterm", and at the same time the manufacturer boldly declares that the service life of the material can reach 200 years.

The range of products corresponds to the common types of profiled timber - the process of laying the insulation in the parts of the parts becomes extremely simple. Special varieties for logs are provided, for the usual, profiled and separate - glued bar, taking into account the characteristics of these building materials.

The convenience of such insulation when assembling the log cabin also in the fact that the material is not wound on the drill under the drill, it easily passes through it, leaving smooth edges.

The thickness of the produced ribbons is 8, 15 and 20 mm, the width is from 100 to 200 mm, the length in rolls, depending on the thickness - 10 or 20 m.

Of course, many will delight the pricing availability of material - it allows you to significantly reduce the total costs of building a house.

Plastic sealants for sealing seams

It should be immediately agreed that such sealants are in principle, in principle, are not full-fledged interventory insulation and in no case replace the use of the materials mentioned above during the construction of the house. Their destination is the sealing of the remaining or armed between the bars or logs or the protection of the protruding edge of the cacopa from external influence. They are widely used for repair - filling in deep and wide cracks formed on wooden details.

Very often used in a complex with an elastic harness, for example, their foamed polyethylene, which is pre-clogged into the gap, and close the sealant.

There is a lot of varieties of sealants of such purpose. They can be acrylic (more suitable for internal works), on silicone, latex or polyurethane based. It is often possible to select the selection of sealant, so that the seam lines harmoniously looked on the wooden log cabin.

The popular brands of such sealants can be attributed to the "Neomid - warm seam", "Wepost Wood", "ConsEal", a wide range of Weatherall products for a wide variety of cases. Before the acquisition, it will be necessary to pay attention to the scope and on the specific purpose of the material - there may be significant differences in this matter.

Video: Sealant for fire "Neomid - Warm seam"

So, the main types of inter-night insulation were considered. Each of them has its own "bouquet" of advantages and disadvantages. The choice is for the owners of the house, and he must be realized, taking into account the future conditions of operation of housing, and from the point of view of purely economic feasibility.

At the end of the publication - another video dedicated to interventovate insulation:

Video: Several recommendations for the choice of interventory insulation

Traditionally wooden construction Bath or residential buildings are used by an interwetant insulation for sealing joints in the walls.

The main purpose of the material is the warming of the cutting structure and improving the operational characteristics of the wood.

Most insulation includes natural components, however, in some materials there may be an artificial filling, which is categorically not suitable for wooden buildings.

The interwidder insulation is a universal material, so it is widely used for houses and baths from a log-of-type log, profiled and glued timber. In this case, the density of the insulation can be about 750 g / sq. M. With a thickness of up to 11 mm.

To reduce heat loss, the insulation is placed in one layer. It is important to remember that when using an uneven or non-silent timber, the insulation laying is made in several layers.

Insulation contributes to timely pair and thermal insulation wooden design, high quality air exchange rooms.

During the construction of a log of a bath or house, an important condition is to minimize possible gaps between logs and bars. It is for this reason that work is carried out on the sealing of high-quality insulation.

Such measures are aimed at effective protection of the building from adverse climatic conditions.

Performance features

High-quality insulation, which is placed between logs of logs or timber, must comply with high quality and safety standards. Therefore, the main operational characteristics of the material include:

- High elasticity and density, storing properties throughout the entire operation time. Due to elasticity, the insulation is able to take the right shape, and the density is to fill out the existing gaps between the crowns.

- Low thermal conductivity for effective protection of walls from heat loss.

- High moisture and vapor permeability.

- Resistance to mold, fungi and malicious microorganisms arising from the effects of high moisture and heat.

- Resistance to ultraviolet exposure and adverse weather conditions.

Types of interventic insulation

Modern building market offers big choice Natural insulation.

The most common options are felt, jute, moss, linen and combined.

Also manufacturers offer wear-resistant synthetic insulation materials - foam, mineral wool, polystyrene foam plates, silicone sealants.

Without a doubt, they have higher performance in comparison with natural analogues, but they are not suitable for insulation of structures from wood.

Felt (sheep wool)

Natural material for insulation, which, according to its operational properties, is superior to ribbon insulation from plant fibers.

Felt is a decent option for structures from a profiled timber. For insulation of residential buildings and baths, it is simply indispensable, although it is not cheap.

In the process of production, the felt seal is carefully processed by special flame retardant compositions, as a result of which it absorbs moisture well and quickly gives it when heated.

It is resistant to the appearance of fungus and mold, does not fit during operation.

Felt is suitable for the insulation of the walls and partitions of log cabins and baths.

Material from Jute is a modern representative of belt insulation, which has a dense and homogeneous structure. Jute is an expensive material, as opposed to flax, but at the same time better.

Distinctive characteristic of jute - high hygroscopicity.

Jute Meznetant insulation produce from annual tropical plants Malvic families that grow in hot countries. Plants contain about 25% lingin - natural resin, which has high antiseptic properties.

Jute has a lot of advantages that advantageously allocate it among major competitors:

- Environmental friendliness and safety;

- Good thermal conductivity;

- Resistance to rotting and damage to fungi;

- Durability and practicality;

- Ease of installation;

- Attractive appearance.

The disadvantages include susceptibility to keeping and high cost.

Wall insulated with a junteen ribbon do not need additional decorative finishand the seams are smooth and dense.

Jute is presented by the following varieties: Jute Pakle, Felt Jute and Jute Len.

- Pacle has whole and long fibers. Used for cavulus cavities.

- Felt is characterized by increased fragility and rigidity of fibers. Used to seal door and window openings.

- Jute Len is a mixture of linen and jute fibers. Differs in high wear resistance and elasticity. Suitable for the caulking of walls and partitions.

Currently, moss remains affordable and cheap option for the insulation of the crowns in houses and bats from a log or bar. Moss is a natural thermal insulation material that has unique performance:

- Ecology;

- Countertilebility;

- Resistance to fringing and deformation;

- Antiseptic properties.

Moss quickly absorbs excess moisture and provides good air exchange. As an interventory insulation, it is recommended to use sphagnum (white moss) and Cukushkin Flax (red moss).

The most durable and wear-resistant is a red moss, which is characterized by a high content of antiseptic components and resistant to the effects of high moisture.

White moss has high thermal insulation properties and reliably protects wood from fungal lesions.

Despite explicit advantages, Moss has some drawbacks - low fire resistance and complexity of laying.

Linen materials for insulation are used for a long time. Len hypoallergen, provides good air exchange, does not create static charges, resistant to the appearance of mold on the walls. The interventic insulation of this type has:

- High elasticity and soft fibers;

- Long service life;

- Low thermal conductivity coefficient;

- Resistant to the effects of UV radiation, microorganisms and mold;

- Available cost.

Currently, manufacturers offer two types of linen insulation - panels and flanutin.

Differs low cost and complexity of installation. The interventic insulation for timber has a high hygroscopicity and a tendency to rot, therefore it is more expedient to apply it to seal window and doorways.

When using a pacle, the cachatka is carried out twice - in the first year after the end of construction, and for the second year - after a shrinkage of the building.

Linnatin

Material that is made from linen fibers on special equipment.

To give strength, the finished canvas is flashed with threads. Fleeting is distinguished by the available cost and simplicity of installation. This is a good economical option that is suitable for insulation of houses and baths.

Often it is applied after a complete shrinkage of the structure.

Combined insulation

They have the unique operational properties of the material from which are made.

Flax in combined materials contributes to an increase in elasticity and practicality, jute - increasing focusing and peeling.

The special structure of combined insulation satisfies the needs of building material, taking into account the climatic conditions in which it is used.

What insulation is suitable for a bath?

Often, novice masters are wondering, - what insulation to choose for the walls of the bath?

The best representatives are insulation from moss, jute and flax, as well as their derivatives. They are successfully used for caulking wooden houses and baths.

To understand what better to choose the insulation for the bath, it is worth paying attention to the main characteristic of the material - density.

For structures from a bar, an insulation of 4 mm thick was used at a density of 350-450 g / sq.m.

For pyligues from the rounded log, 5 mm thick and density are not lower than 600 g / sq. M.

For houses in 2-3 floors, combined with a bath, a material is 9-11 mm thick and a density of up to 750 g / sq. M.

To choose a high-quality seal, you need to know which type of wood is used to build a log.

For bathing from a bar and logs of a rounded type, you can choose a thickness of up to 10 mm thick - felt from jute, felt from flax, combined option with jute and flax.

For a chopped type bath, it is better to choose insulation up to 15 mm thick - felt from jute and flax, pacle in ribbons and bales of flax or jute, moss.

Methods of sealing interventical gaps

Regardless of which type of material was selected for the insulation of a wooden structure, installation work is performed by several available methods:

- Without bends;

- With a bend on one side;

- With a bend from two sides.

Laying the insulation without the use of bends is distinguished by the high quality of fitting and small technological gaps.

The material is decomposed along the perimeter of the cut on the base, the following element is laid from above. Fixation is performed by a construction stapler.

For buildings from a bar, a single-sided bend mounting method is used. For this, the seal is taken, the width of which exceeds the width of the log twice. The band is mounted with a one-sided bend on the lock. From the outside of the wall, the jute or flax rope is additionally installed.

Installation of a double-sided bending insulation is carried out for buildings from a wild church, a booke board or logid-type logs.

Often similar construction Materials Different with uneven sizes at different ends.

The interventic insulation for timber is fixed using a stapler, while the bands are folded twice and shifted in width. This allows you to perform the correct laying between different sizes. In addition, this method prevents full wood shrinkage.

Choice better option The insulation for home or bath depends on the set of factors that experienced masters take into account at the beginning of construction.

Content:Jute is considered one of the best interventic insulation. It is environmentally friendly, not crushed, does not absorb moisture and tightly closes the space between the bar. But modern jute produce various species, which one is better and what they differ in told in this article. We learn how much the jute inter-night insulation in large cities, such as Ufa, Kazan, Moscow, St. Petersburg.

Why do jute better than other insulation?

Made a jute insulation from the fibers of the tropical tree of the same name. The reasons why this tree is used is two:

- Objective. The jute tree in its texture is akin to flares and henebees, and they were used for the insulation of wooden houses more our grandfathers. In its chemical and physical indicators, they are close.

- Subjective. The traditional hemp is received from hemp to get in Russia difficult, for a number of reasons. It is difficult to grow and preserve flax, so flax goods in Russia have almost ceased to exist. For this reason, in Russia there was a shortage of raw materials. For the manufacture of linen insulation. Therefore, the jute fiber has become in demand on Russian market, despite your foreign origin.

Pros and Cons Jute Material

For the insulation of a wooden house from a bar, the jute inter-night insulation has a number of advantages that are only characteristic of this material:

- Golden painting which is close in a color of a bruster of pine or ate.

- Of all the insulation, only the jute contains the largest amount of lignin. Lignin is a resin, which not only protects the insulation from rotting, but also glues a bar making interventional space hermetic.

- It is more hard, therefore it is practically not crushed over time and retains heat in the house equally, both immediately after construction and after 10-15 years.

- High density gives the material with high heat-saving properties.

By the cons of the jute insulation, its rigidity can be attributed, the ribbon is harder to lay as out of flax or hemp. It is more difficult for them to make an additional caulkit, so it is better to lay the jute tape of a smaller width, and to perform a pantry with a cord. And if you select the density of the jute insulation correctly under each breed of wood, the rigidity will not be scary.

Myths - True or fiction?

Myths that are increasingly possible to read in the network about jute insulation are not all true. Consider some more:

Myths that are increasingly possible to read in the network about jute insulation are not all true. Consider some more:

- The jute interventical insulation gives a uniform warming and shrinkage of a wooden house, providing protection better than flax or hemp. This applies only to high quality jute insulation, but often in our stores there is a very poor quality material. And the mixed species are made not with the addition of flax fiber, as stated and with dust from the rope, vessels. Heat wooden house Such material and wait for good indicators from it.

- Jute has the highest ecology. This is true, but not the most, since both flax and hemp are made of natural raw materials. And if you purchase a poor-quality jute, then it contains many different chemical additives.

- Jute do not love birds and do not take it into their nests. It is not true to birds anyway, what kind of natural or non-carrying material to drag into the nest. Therefore, the jute pluck out the walls in the same way. It is necessary to acquire the material from short fibers not more than 3 cm, then the birds will not be interested.

- Jute insulation has a shelf life of 75 years. Indeed, Danish scientists conducted research at the Finnish "Eurolne", which has nothing to do with the Russian jute insulation. Therefore, to say exactly how much service life at Jute is accurately difficult, it may be even more.

What interventical material is produced on jute fiber

![]() Jute insulation is currently producing three various species. Just every company can call them in its own way and add the composition of various components.

Jute insulation is currently producing three various species. Just every company can call them in its own way and add the composition of various components.

- Pakle jute in the form of a tape.

- Felt from jute.

- Combined jute with various impurities.

Jute Packs are produced from 100% jute fiber. It is soaked, scratch and passing through special machines produced in the form of a ribbon. The material has a smaller density, but there are no extraneous impurities in it. Moreover, processing the jute fiber in a similar way fibers do not burst, as in the production of felt. It is convenient for them to care houses or baths from the bar, as it is practically like flax in the softness of the panel. The main characteristics of the jute paneling in the tape: width 15 and 25 cm, length 80-150 m, density 80g / m or 550 g / m. (Thermal).

Jute felt reminds usual out of wool, but tougher and dense. Reviews of it are mostly positive. It is manufactured by dumping wet small fibers Jute. It has high density and hard enough. It is good precisely to use between the crowns. It is difficult for me to pant. Various manufacturers of cunning and use in the manufacture of jute felt only 90% of jute, the rest of the various additives (flax, the fiber from flax processed into small fibers, etc.) minus felt in his sweeping, as it is hard enough. This leads to the increment of the insulation, but softens its texture.

Mixed option when the jute add flax or other components. This species was specifically designed for several reasons:

- Reduce the cost of production.

- Help the buyer who cannot determine what is better than flax or jute.

A mixed insulation has a pleasant texture and at the same time strong enough, since soft flax fills the spaces between the rigid fibers of the jute (Lenjut).

In a separate group, a jute insulation combined with synthetic fibers can be attributed. He keeps the form well, but at the same time loses its environmental friendliness. And the worst thing is that such material sellers are not rarely issued for natural jute, from here bad customer reviews.

FEATURES OF MONTAGE

Any of belt insulation can be bought by the necessary width, so it is not difficult to choose a different log size or timber.

Any of belt insulation can be bought by the necessary width, so it is not difficult to choose a different log size or timber.

To fully fulfill all the stated requirements, you must select the correct density parameters and the width of the insulation. And you need to pay attention not to the thickness, but on density. Only so you can determine the material load from the walls of the house or bath.

For permanent residence in the house, it suffices to take a thickness of 5-6 mm, with a density of at least 400-600 g / m. If a bot is a good quality, it is enough to lay a tape into one layer. In case of questionable quality, wood can be found in a 2-layer.

When choosing, take a jute consisting of a fiber more than 2-3 cm, then the hard insulation will be sprinkled and the uniformity of the material will be unequal. And all its qualitative characteristics will be lost.

It rolls uniformly throughout the surface of the log and attached the stapler in 50-100 cm increments

.

The price of material in major cities

The price for the jute interventic insulation in large cities, such as: Ufa, Kazan, Moscow, Nizhny Novgorod and St. Petersburg, Novosibirsk differs little. It is a mixed type of cheaper than natural. Felt due to the specifics of the manufacture is more expensive than pacles, but has a greater density. It is good to use it for the insulation of a bath of a bar ,.

You can buy material on the construction market, in specialized stores, or the Internet. And the price on the Internet may be at times lower. The cheapest option to buy directly from the manufacturer, the minimum wholesale party from 50,000 rubles. For the construction of a big house, this is enough, will remain on the bath.

The average price for insulation from jute in major cities:

The most expensive material in the city of Novosibirsk. Just in Moscow and St. Petersburg a lot of wholesale vendors, and in Novosibirsk and Ufa, they are mainly working overbugs that acquire the material in larger cities and resell. It is more profitable to buy material via online stores, the price will be below 10-20%.

No matter what insulation from Jute you did not have chosen to insulate your home or bath, the main thing is its quality. If the manufacture of unauthorized ventricular components, Jute loses a number of their qualitative characteristics. The correctly selected material will serve not to one generation and will reliably protect the walls from the cold.

So since ancient times it was necessary that the real Russian bath was built only from the most suitable natural material - wood. Technology training logs or timber, provides for a decrease in heat loss through the walls of the cut. For this make various groove systems.

But, as practice shows that in the conditions of a manual logging, that in the conditions of production, it turns out, it is impossible to achieve an accurate fit of the material to each other. And this means that when you drown a bath, heat will go out, respectively heat it to the optimal temperature will not be possible.

Therefore, at the initial stage of construction - the construction of a church, each row of logs (crowns) is paired by insulation. It is he who plays the most important role in holding heat inside the steam room.

What are used as an interventory insulation?

It is often necessary to hear that now the choice of them is very big, in truth, they shook these comrades. The most common and in demand, it turns out only three is moss, jute and flax.

Moss

It began to be applied together with the appearance as such, i.e. a long time ago. And over the centuries, he had no alternative. Yes, and in general, it did not arise in this particular need, he perfectly copes with his task to this day.

Moss, being natural, endowed with a number of positive properties.

His advantages:

- Environmental,

- contains antiseptic substances

- Paro - and gas permeal,

- even being under pressure, forms in the interventory layer of the network of aircraft, they hold heat, and also contribute to the breadwinning of the waterproof

- Durable (Cukushkin Len).

Laying on sphagnum

Of course, there are not any kind of moss in construction, but only two are white and red.

Red or Cukushkin Flax meets everywhere and grows sometimes on very limited squares.

Benefits:

- less moisture, than sphagnum,

- easy,

- hard, elastic and durable,

- contains a large amount of substances that prevent rotting, the formation of mold and fungus,

- It is long, facilitated by laying,

- Durable.

From disadvantages, it is possible to note only one thing - it is difficult to prepare in the desired volume.

White moss or sphagnum grows everywhere, it can be found on any small swamp. For most indicators, he is inferior to the Red Moss, but many builders are forced to build a log house on it, because It is much easier to prepare it.

Of course, it is impossible to argue that only negotiatory builders are allowed to stacking logs on sphagnum. In general, he is not bad: it contains these same antiseptic substances, albeit in a slightly smaller quantity, it also perfectly holds heat. The only substantial disadvantage can be called exposure to its destruction over time. But in most cases, it is enough for the average battery life.

As you can see, Cukushkin Len turns out to be preferable to its green relative in many indicators, but the whole trouble is that it does not occur everywhere, so choose sometimes and do not have to come.

You can familiarize yourself with the features of the preparation of Sfagnum in this.

Jute

He is becoming increasingly popular, in cities he almost displaced traditional moss. It is a product obtained by processing annual plant with the same name.

What is it good?

- He, like moss, environmental (if complied production technology),

- perfectly keeps heat (but does not exceed moss),

- It is easy to lay (ribbon),

- saves time when assembling a log house,

- a nice color, similar to natural wood, allows you to successfully fit into the interior of the room,

- Lignin, contained in the fibers, prevents the rotting of the insulation and wood,

- Durable.

We note from the disadvantages: over time, it is glorified, the cost and limited use in logs from logs.

Three varieties of product distinguish: Jute Pakle, Jute Felt and Len-Jute.

- J. Pakla - it turns out with minimal processing of the plant, the fibers are obtained by one-piece and long. This circumstance allows you to use it in the baths of the hand logging, as well as the material for the cavulus of the seams.

- J. Felt - It turns out a deeper processing, it is hard and pronounced. In this regard, a certain amount of flax is added to it, which significantly increases its strength and ensures the uniformity of the jute canvas.

- Len-jute is a mixture of flax and jute fibers approximately in the same proportions (depends on the manufacturer). One other complements, which allows you to get a very high quality and good product, subject to the compliance with the production technology.

Ribbon insulation

Felt and Len-Jute are produced in the form of a tape, this fact limits its use in ordinary fires, because Uniform in density and even along the entire length material is unable to fill uneven grooves. It is great for baths collected from a rounded log, conventional and profiled bar.

Linen

Luck was used in the old days along with moss. Currently there is a package and a modern product - flanutin.

Linovatin or as it is also called "EUROPEN" Made by modern technologyAs a result, a tape is obtained consisting of the intertwined fibers of this plant.

From the advantages of the product, we note:

- high elasticity and softness,

- durability,

- excellent thermal insulation properties,

- Little hygroscopicity (less than Jute),

- Ecology,

- availability and low cost,

- How any other natural product provides a good microclimate.

Pacle in the form she existed in the last century - in bales, it is probably used for cachatka only.

Now they are also made in the form of a tape. The production technology is considered to be the most gentle (normal Česky on machines), the product is obtained more natural.

Not such a dense structure of the material, like the jut-tape allows it to use it in all types of log cabins.

Other insulation

In addition to the above materials, although it is rare, the use of others is practiced:

1) Woolen fiber (very expensive and in the properties ambiguous).

2) Thermal insulating tapes (everything is good - keeps heat, does not let water, does not rot and it is not destroyed, only you can forget about good microclimate).

3) insulation on a mineral or synthetic basis (not for the Russian bath),

4) batting, syntheps, sealants, etc. (see the 3rd point).

If you still decided to build a bath according to the national tradition from, then the insulation choose natural.

Be careful before buying, the material should not contain foreign impurities and feel free to request certificates for products.

After reading the article, many, probably, will not get an unequivocal answer to the question "What insulation is better?"

Allocate only one is really difficult, each has its pros and cons, you can only recommend the following:

- Moss and pack of flax will suit for the cutting cutter

- For docking and bar - moss, Len-Jute, Fliminatin.