Boilers indirect heating create the desired temperature of the water poured into them at the expense of other heat carriers. For example, water or antifreeze heated by boilers, central heating systems, and so on. The advantages of using similar storage water heaters owners of city apartments who want to significantly reduce the amount in their bills for hot water supply and electricity are also able to appreciate.

Which indirect heating boilers can be considered the best?

Some important criteria for choosing indirect heating boilers

Volume of the tank

This parameter is selected in a similar way to electrical "storage", depending on the number of active users and goals. Only in this case, the power of the connected boiler and the temperature of the coolant in the heating system will also matter.

Heat exchanger design

Can be applied:

- Tubular coil. One - in a standard format, two - in models with the ability to connect to an alternative source of thermal energy;

- Boilers with tank-in-tank system. They consist of two containers (usually made of "stainless steel") of different sizes, inserted into one another. The inner one is filled with the so-called sanitary water, the second contains a heat carrier that provides heating.

Tank material

There are 3 options:

- stainless steel;

- enameled steel;

- titanium coating.

The first two varieties are most often found. In any case, the anti-corrosion properties of the material are important, and for greater reliability you should pay attention to the presence of a magnesium anode (especially if you choose a less expensive boiler with an enamelled tank).

Maintained working pressure

This parameter can be seen in the specification. Depending on the model, the range varies from 6 to 11 bar (usually 6-7).

A very important indicator for those who install a boiler in an apartment. Domestic plumbing systems differ in pressure surges, sometimes exceeding the standard by half, and the safety valves can become clogged. And in order not to swear an innocent manufacturer, there is a reason to install a reducer at the inlet and calmly rejoice at the boiler's flawless operation without any leaks.

The presence of heating elements

No matter how good and economical indirect water heater, and sometimes heating may simply be absent. Then the combined models with the addition of electric (gas) heating elements are relevant. Simply put, a model with a heat exchanger and heating element, if the supply of the coolant from the outside is unavailable, is capable of operating as a conventional storage electric water heater.

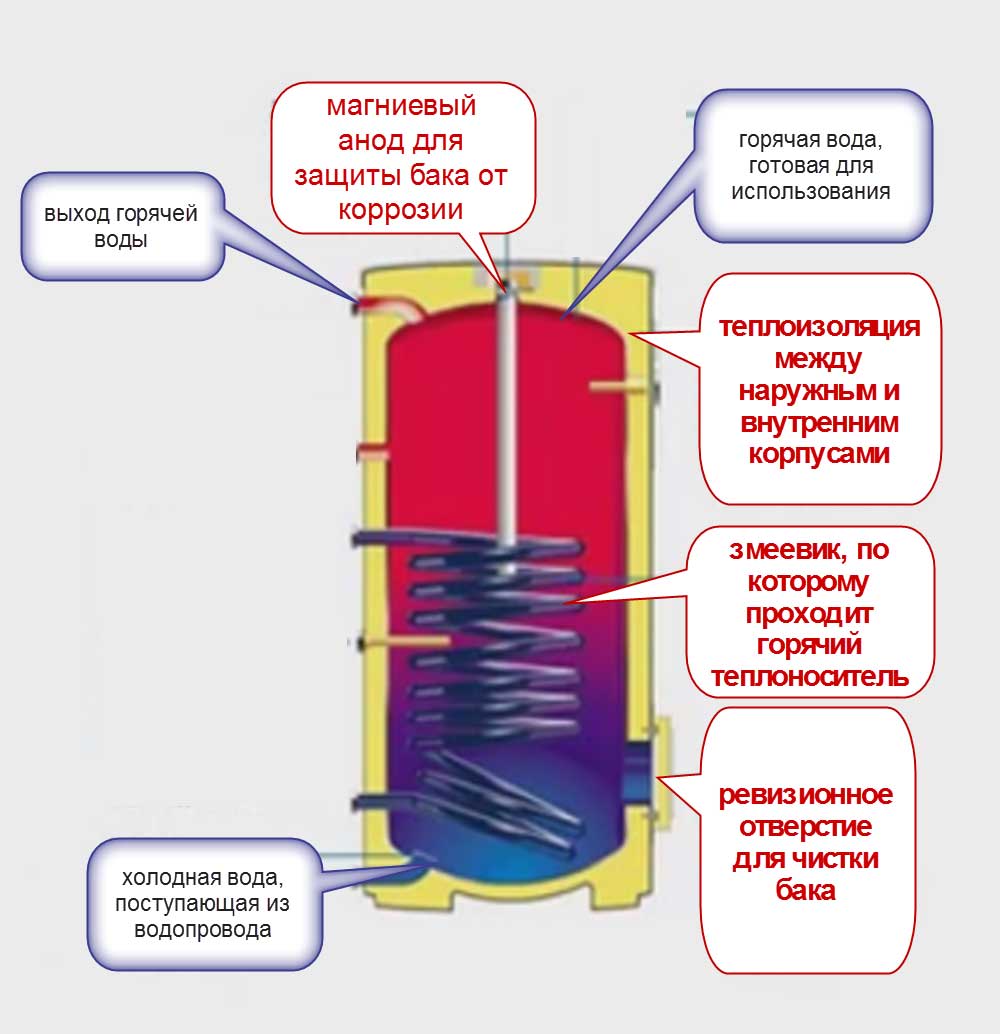

An indirect heating boiler is a unit for the preparation and accumulation of a certain volume hot water for household needs. The design of the boiler includes a heat exchanger and heating agent and water circulation systems for hot water supply (DHW). For the operation of the heat exchanger, the heat carrier of the heating system or other possible sources is used.

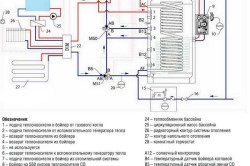

Wiring diagram for an indirect heating water heater.

From the very name of the unit it is clear that its device does not provide for a direct heat generator. Water is heated by heat exchange with an already heated liquid. The latter circulates through a coil located in the tank, or flows between the walls of the body, giving off heat to the heated water. Before choosing an indirect heating boiler, make sure that it is advisable to install it, taking into account the operating conditions of the unit.

Advantages and disadvantages of an indirect heating boiler

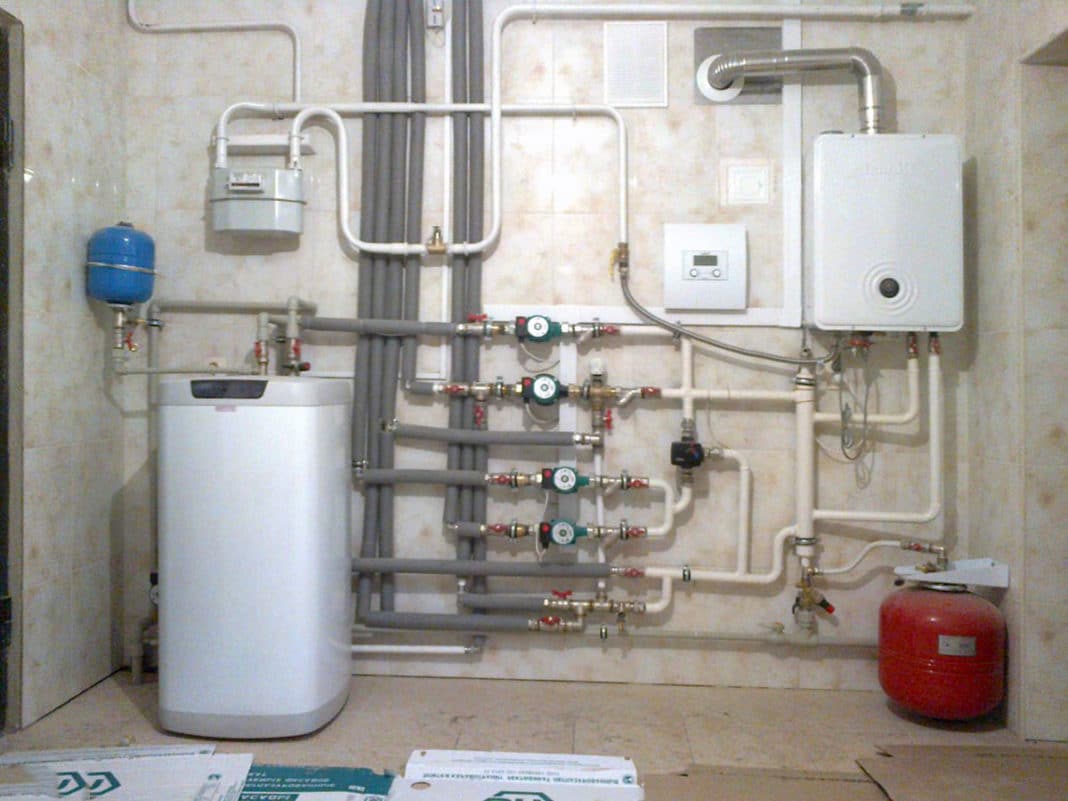

The indirect heating boiler is operated in tandem with a single-circuit boiler. Therefore, the unit takes up more space than the installed double-circuit boiler. But the use of the principle of indirect heating allows you to constantly have a sufficient amount of hot water of the desired temperature.

If hot water, heated directly, is consumed from several taps at once, its pressure begins to drop. The boiler operating mode changes. When draining hot water from different taps at the same time when the direct heater is operating, the water temperature decreases. If cold water from another tap is used in parallel, the flow through the direct heat exchanger is reduced. Due to this, the water temperature becomes higher than required.

The boiler serves several water intake points, ensuring stable water parameters. Its consumption is limited only by the capacity of the unit. It is convenient for frequent interruptions in water supply and power supply. When you open the tap, hot water flows immediately without preliminary draining, which is typical for instantaneous water heaters.

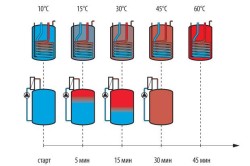

If indirect heating is used in the installed boiler, it should be noted that ensuring hot water possible only during the heating season. In the summer, it is necessary to periodically turn on the boiler or a seasonal transition to an alternative source of heat carrier. The disadvantage of using this type of unit is the inertia of its operation - it takes a long time to heat a large volume of water.

A gas or solid fuel boiler, a centralized heating system, solar panels or a heat pump can serve as a source for heating the coolant. Models are produced with two heat exchangers to use different heat sources.

Selecting a boiler based on performance

First of all, when planning a purchase, you should decide on the installation site and the possibility of fixing the unit, if it is wall-mounted. Indirectly heated boilers with a tank capacity of up to 200 liters can be floor or wall mounted. Devices with larger tanks are mounted on the floor only.

The performance of the indirect heating device depends on the manufacturer of the unit and the model selected. The distinctive properties of the boiler include:

- device power;

- heating time to the required temperature;

- the degree of equipment with automatic protection and regulation;

- installation dimensions, tank volume and body shape;

- operating parameters: pressure in the supply line and the heating medium circuit;

- maximum temperature of media;

- additional functions provided by the manufacturer.

You should choose an indirect heating boiler after determining the appropriateness of its use. The purchase of a unit for use in conjunction with a single-circuit boiler is economically justified for a family of five or more people with periodic consumption of hot water over 4 l / min. With less consumption, it is more practical to install a double-circuit boiler. In this case, a 10 kW boiler will be able to provide hot water supply with a flow rate of 3 l / min.

To select an indirect heating type boiler with the required capacity, you should take into account the average rates of hot water consumption per person for various needs:

- washing - 5-15 liters;

- washing dishes - about 25 liters;

- taking a shower - 50-100 l;

- bathing in the bathroom - 150-200 liters.

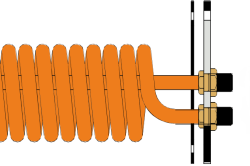

The larger the coil in the boiler, the faster the water heats up.

The rate of increase in water temperature in the tank also depends on the flow area (pipe diameter) of the coil. A thicker heat exchanger tube will heat the water faster, but will require a higher performance of the heat generator - the heating boiler.

The approximate heating time for a 20 liter boiler is about half an hour, for a 200 liter boiler is about 3 hours. Having calculated the needs of your family, it will not be difficult to determine the parameters of the container. The choice of boiler depends on the capacity of the heating system (capacity of the installed boiler). Will the heat generator cope with both space heating and hot water supply?

Design features of indirect heating boilers

Most often, heat generators for such devices are gas or solid fuel boilers... It is impractical to use such a heating scheme when installing an electric heating boiler. Taking into account the time of heating water for DHW, the overconsumption of electricity will be significant.

Studying the design features of the boiler intended for purchase, you should pay attention to the possibility of dismantling the coil. Over time, scale forms on the surface of the part, and it will be difficult to clean a rigidly fixed heat exchanger. Coil material is preferred from brass or silver plated.

The number of installed heat exchangers is also significant. Some units are equipped with two heat exchangers, the second is designed to use an alternative heat generator powered by solar energy or a heat pump.

The material used to manufacture the container also plays an important role during operation. The model is effective in which the body has a double shell. The water supplied from the boiler to the unit circulates in its inner cavity. At the same time, the inner tank made of stainless steel is more durable. In more expensive models, the most reliable titanium sputtering is performed.

To reduce the cost of the product, there are designs of the internal tank made of glass porcelain, using enamel and fiberglass. But reducing the cost of the model implies a decrease in the life of the internal elements of the device. The protective layer of the container is prone to cracking. As for the thermal insulation layer, polyurethane provides better thermal protection than foam or fiberglass.

The durability of the coating is affected by the quality of the water in the water supply system and the load of the indirect heating boiler over time. The criteria for choosing indirect water heaters include the type of corrosion protection of the inner surface of the tank (anode or cathodic).

Additional devices in the design of the unit

The magnesium anode protects the tank from galvanic corrosion.

The ability to replace parts of the structure is also important when choosing. The more popular types of units have a built-in magnesium anode. It serves to protect the tank material from galvanic corrosion. This process is blocked by the anode due to its smaller electric potential in comparison with the metal of the container. The element takes a destructive effect on itself and is replaced as it wears out (every six months or a year). Cathodic protection involves connecting the electrode to the mains and does not require replacing it.

Choosing a model of a suitable design, find out whether a heated water recirculation system is provided and whether the heating element is installed as an additional (autonomous) source of water heating.

When choosing an indirect heating boiler, the capacity of the heat carrier source is taken into account. If the boiler uses about 50% of the boiler's capacity, this will affect the operation of the heating system. To regulate the supply of the heating agent to provide DHW, the systems are equipped with three-way valves and thermostats.

When the temperature of the water in the storage tank of the boiler falls below the set temperature, a signal is sent to the three-way valve from the thermostat. The heating agent supply is redirected to the water heater, its circulation in the boiler continues until the set parameter is reached. Then turns on autonomous work heating system. The regulating device allows optimal use of the boiler output. But, despite this, the boiler is selected with a performance margin of 20-30%.

For safe operation the water heater, it must be equipped with a safety valve.

Features of various models of indirect heating boilers

A suitable option for boilers for operation at the end of the heating season will be units equipped with a heater powered by electricity. The pre-installed heating elements are equipped with water heating devices of Slovenian manufacturers Drazice. The models of the Czech company Gorenje provide for the installation of a heating element as a backup heater.

Models of different companies differ in material storage tank and its thermal insulation. Stainless steel tanks have a longer service life. The use of enamel in the manufacture improves the ecological qualities of the prepared water, since there is no direct contact with the metal. For example, Ferroli BF boilers have enamel bodies. Stainless metal is used in the production of Baxi Premier series units. Most branded firms use polyurethane foam as a heat insulator for the case.

Products of German companies Buderus, Vaillant, Junkers Bosch Gruppe, Reflex, French company Saunier Duval, Polish Galmet, Italian Beretta and Baxi are popular among Russian buyers. The Belgian model of the ACV boiler is equipped with a heating medium circulation system inside the body (without a coil). The quality and reliability of these brands are of the same high level. The choice of a particular brand depends on the buyer's preferences in design features and affordability.

In order to receive timely warranty service of the device, you need to make sure that there are nearby services accredited to repair the purchased model of the boiler. Ask about the possibility of purchasing spare parts in case of replacement of components.

Most Popular Blog Articles of the Week

Since we are talking about the calculation, then the figures of the initial data will be required. Each person uses water differently. For some, it is enough to stay in the shower for 5 minutes, while others swim in the bath twice every day.

If you decide to purchase a boiler and choose the type and model, first of all, study your needs. At least measure the time for bathing and washing dishes. Let's calculate how much hot water is needed, what volume of the boiler is needed for this and its power. How much and what will he take from the boiler and what the boiler will need for this.

Indirect heating boiler

The quantities

We consume water in liters, and we measure its temperature in degrees. Water, in order to heat up, uses thermal energy in Joules based on its mass in kilograms. The water heater produces power in watts, and the efficiency is calculated as a percentage. Let's translate these units of measurement into one understandable plane.

- According to the laws of physics, in order to increase the temperature of 1 kg of water, which is equal to 1 liter, 4.187 kJ of thermal energy is required by 1 ° C, which is 0.001 kW / h of the power of the heating device. Type, manufacturer and losses are not included. Whoever made the heater and in whatever conditions this mechanism is not, water always needs just that much energy.

- The water entering the boiler in winter (the boiler does not work in summer) has a temperature of about 10o. Insulated supply pipes will reduce the temperature difference between the boiler inlet and outlet and help save fuel.

- On the control panel of the device, the number 60 ° is set. This means that the liquid in the unit will be heated to this temperature. Therefore, 60-10 \u003d 50о. It is not worth setting a large heating value. Such a load will entail increased wear on the equipment.

- It is required to raise the temperature by this amount. We multiply the found difference in degrees by the energy required to obtain each of them - 50 * 0.001 \u003d 0.05 kW / h of power will be required by the boiler for such work.

So, to heat 1 liter of water to 60about you will need 0.05 kW / h of boiler power, and to increase by 1about - 0.001 kWh of his efforts.

Hot water, which we take from the tap to wash or wash the dishes, has a temperature of about 40o. Above it will be hot, below it will be cool. In order for the calculation of the operation of the boiler, not only indirect heating, but also any other type of heater to be correct, it is necessary to take into account that we are mixing two waters, each of which has its own temperature.

- Hot water is thermal energy... We calculated that 1o \u003d 0.001 kWh .

- The water we want should be 40o, which means 40 * 0.001 \u003d 0.04 kW.

- Cold water has 10 °, which means that 0.01 kWh is already available. This is 25% of the required heat volume.

- This means that you need to add another 75% of the temperature, which will be 0.05 * 75% \u003d 0.0375 kW / h.

Power consumption

Boiler, connection

Boiler, connection Having come to a decision about the need to purchase and calculating the volume of an indirect heating boiler, you need to calculate how much warm water is needed for normal existence. Imagine a family of 4 people and carry out an average daily analysis for a week and a peak (morning of the working day) study of hot water consumption.

- Weekly analysis

- In order to wash the dishes, you will need about 5 liters of warm water per minute. The rinsing time is taken into account, this is about 5 minutes. Twice a day I wash my plates, we get 50 liters of warm water used for kitchen utensils per day. We multiply by 7 days a total of 350 liters per week.

- Each person takes a bath 2-3 times a week, spending about 170 liters. 4 * 2.5 \u003d 10 * 170 \u003d 1700 liters in 7 days.

- Shower 4-5 times for 10 minutes at a flow rate of about 12 l / min. 4.5 * 10 * 12 \u003d 540 per family member, respectively, for all 2160 liters per week.

- Small hygiene (wash hands, shoes, clean the house) - about 10 liters per person per day will amount to 280 liters for the study period.

Total - 350 + 1700 + 2160 + 280 \u003d 4490 liters per week. Let's add guests who came in and just in case we get an approximate figure of about 5000 liters per week. But the boiler counts in hours, you need to translate into its units. 5000/7/24 \u003d 30 liters per hour of warm water is the average consumption of a family of 4 people.

Based on our figures for the ratio of temperature and power, we obtain the required average power consumption - 30 * 0.0375 \u003d 1.125 kW / h.

Peak consumption

Indirect heating boiler, diagram

Indirect heating boiler, diagram Based on the above, it seems that even the smallest heater will suffice. Alas, not everything is so smooth in life. When calculating the volume of the tank and the required power of the unit, it is required to take into account that in the morning the whole family wakes up and gets ready for work or school at about the same time. There is simply no time to wait until the water in the boiler is fully heated. There should be enough stock of accumulated liquid and heating the flow during the time it is consumed by consumers.

- According to statistics, utility services morning hot water consumption is about 30% -40% of the average daily value for 1.5 hours. The period is taken from 7 hours 00 minutes to 8 hours 30 minutes. Let's take an average figure of 35% and we get that our family will use 5000/7 * 35% \u003d 250 liters in 1.5 hours, which is equal to 170 liters per hour of warm water. For such an amount, we need 170 * 75% \u003d about 130 liters of hot water and 170 * 0.0375 \u003d 6.5 kW of water heater power.

- But that's not all. As the fully heated water from the tank is consumed, cold water will be added to it, which needs to be heated, and this takes time.

- The average heating rate in continuous flow mode depends on the coolant temperature and the surface area of \u200b\u200bthe circuit. Since the heating liquid comes from the boiler, its temperature will be constantly about 70 - 75 °, and the heat exchanger is calculated relative to the volume of the tank and the declared power of the device.

- The average indicators are approximately equal for devices of all manufacturers and are about 0.3 l / min for a boiler with a 10 kW heat exchange circuit load at a temperature difference of 50 ° that we set. For one hour, the volume of heated running water will be 60 * 0.3 \u003d 18 liters.

Thus, the calculation of the volume of an indirect heating boiler shows that for one morning of the working day, a family of 4 people will need an apparatus with a capacity of at least 10 kW and equipped with a tank with a capacity of more than 100 liters. With an increase in the capabilities of the heat exchange circuit, the heating rate will increase in proportion to the increase in power, but the amount of heat taken from the boiler will also increase.

Heat carrier consumption

Since thermal energy is taken from the heating device, it means less of it will go into the heating system of the house. But only the average consumption will affect the overall temperature in the room, the peak indicators are short-term and will not have a particular effect on the heated heating system.

- We have calculated that the average power consumption will be 1.125 kW per hour. But after the morning and evening parsing of hot water, the tank will be filled with cold liquid, the unit will heat it up and will maintain the temperature all night or day.

- This means that the idle heat consumption should be taken into account, at least two full cycle per day, which will amount to 200 * 0.0375 / 24 \u003d about 0.3125 kW / h.

As a result, we get the result, according to which the boiler will give about 1.125 + 0.3 \u003d 1.5 kW / h of its power to ensure uninterrupted supply of hot water to the family. If we add heat losses during transportation through pipes, through the boiler body and unforeseen water consumption (gathering of guests for an anniversary, shoe shine, etc., etc.), it would be more correct to take the figure of 2 kW / h.

In carrying out this study, the average figures were taken into account. To get a more accurate calculation of the indirect heating boiler, the calculator, presented by power and manufacturer, takes into account the features of each specific heater model and specific operating conditions.