Boiler indirect heating considered the most economical and practical for heating water, since it does not have a heating element in its design. It heats water by interacting with external heating units such as central heating, a boiler or solar panel. Although some models have been improved with an additional heating element, these are already combined models.

In our article, we will consider the principles of operation, device, selection rules and popular models of these units. As well as questions about how to descale them and other important points.

Indirect heating boiler

Many owners of private houses are wondering how, through the heating system, to supply the house not only with heat, but also hot water... Why does this question even arise, because the market is simply teeming with offers of electric and gas storage and instantaneous water heaters? Everything is very commonplace - electricity is not cheap, and gas water heaters are not capable of providing a comfortable constant temperature for use. Therefore, indirect heaters are an excellent option for a home with heating from a gas boiler, moreover - economical.

Many owners of private houses are wondering how, through the heating system, to supply the house not only with heat, but also hot water... Why does this question even arise, because the market is simply teeming with offers of electric and gas storage and instantaneous water heaters? Everything is very commonplace - electricity is not cheap, and gas water heaters are not capable of providing a comfortable constant temperature for use. Therefore, indirect heaters are an excellent option for a home with heating from a gas boiler, moreover - economical.

Device

The indirect heating boiler is a large cylinder-shaped tank. Its design consists of the following elements:

- body;

- thermal insulation;

- stainless steel tank;

- heat exchanger;

- magnesium anode;

- thermometer.

Thermal insulation is laid between the body and the boiler tank to minimize heat loss up to 3-4 degrees per day. The heat exchanger is curved spiral tube made of steel or brass, which is also called a coil. The coil itself is the most important part of the boiler and the more curls it has, the more efficient the heat transfer. Usually it has a very complex device and is located closer to the bottom, which makes it possible to evenly heat the entire volume of water.

The magnesium anode, which is also used in conventional electric water heaters, is designed to combat corrosion of the tank caused by galvanic processes. The anode will take over all the electrochemical reactions, leaving other metal parts of the system intact. Special it is important to protect the welds from destruction, therefore, periodically it will be necessary to replace the worn out magnesium anode with a new one.

Modern boiler models combine several heat sources. They can work even after the heating season, using electricity, gas for heating, and some models even heat water using the sun. Such modifications have two tubular heat exchangers at once, one for water from the heating system, the other for an alternative source.

Work principles

Usually, an indirect heating boiler is purchased together with the boiler. There are also double-circuit boilers that can provide households with warm water. But the volume of heated water in double-circuit boilers is small, and indirect heating boiler can heat much larger volumes, due to which the supply hot water will be carried out without interruption.

Usually, an indirect heating boiler is purchased together with the boiler. There are also double-circuit boilers that can provide households with warm water. But the volume of heated water in double-circuit boilers is small, and indirect heating boiler can heat much larger volumes, due to which the supply hot water will be carried out without interruption.

As stated in the title of the article, an indirect heating boiler is a type of water heater that operates by external heating systems. The heat carrier (water) is supplied from these heating sources through a coil, which is located inside the tank. Water in the boiler heats up due to the circulation of the coolant through the coil, which is possible thanks to the pump. The walls of the coil serve as a heat transfer surface. As soon as the water temperature reaches a certain point, the pump will automatically shut off. Naturally, during the operation of such a boiler, the temperature in the heating system decreases slightly. But you should not worry about this, if everything is installed correctly, then temperature changes are almost invisible.

In order for such a system to have as little heat loss as possible, it is insulated with special heaters such as polyurethane, expanded polystyrene, etc. In fact, it resembles a huge thermos that keeps warm well.

The water is supplied to the boiler through an inlet pipe that connects to the heating system. Through this pipe, hot water enters the coil and heats the water, and the outlet pipe supplies hot water to the place of its use.

How to choose the right boiler?

The important characteristics of the indirect heating boiler are:

- volume;

- coil material;

- tank material;

- insulation material;

- the presence of an additional heating element and alternative heating sources.

Boiler volume

You need to choose the volume of the boiler based on the power of your heating system, since it is she who has the load of heating the water. If you buy a unit that is too large in volume, then there is a possibility that your heating system may not be able to handle it. This is fraught with the fact that the water temperature in the heating devices will be low to heat the room. In order not to miscalculate, you need to find out the volume of the boiler coolant, it should be no more than 30-40% of the volume of water in the heating system, otherwise its performance will noticeably suffer.

You need to choose the volume of the boiler based on the power of your heating system, since it is she who has the load of heating the water. If you buy a unit that is too large in volume, then there is a possibility that your heating system may not be able to handle it. This is fraught with the fact that the water temperature in the heating devices will be low to heat the room. In order not to miscalculate, you need to find out the volume of the boiler coolant, it should be no more than 30-40% of the volume of water in the heating system, otherwise its performance will noticeably suffer.

How much boiler volume your family needs is very easy to determine. On average, 60-80 liters per person for taking a shower. Heating of 200 liters takes about 6 hours. Based on these figures, you need to take the volume of the boiler, which is enough to cover the needs of the family, taking into account the time until the next heating.

Materials

One of the most important parts of the boiler is the coil, so you need to inquire in advance about what it is made of. Cheap models have a steel coil that is simply welded to the tank. In more expensive models it is removable and made of brass, which is much better in many ways. Moreover, the removable version can be dismantled and descaled.

What the tank is made of is also very important, since a common problem with any water heater is leakage. Inexpensive models have a layer of enamel inside, but it quickly forms cracks from temperature changes. And this, in turn, is fraught with quick corrosion of the metal. It is best to buy those options in which the tank is made of stainless steel. It may be more expensive, but it will also last longer, subject to timely replacement of the magnesium anode.

The quality of the insulation is also an important factor in the effectiveness of such a system. Sometimes they use ordinary foam rubber, but it loses on many points. It is best if polyurethane and similar materials are used as thermal insulation.

Other parameters

In addition to the fact that the boiler can have two sources of indirect water heating, also it can be equipped with a heating elementas a source of heat outside the heating season. Such designs are much more expensive than conventional designs, but they are extremely practical.

The type of boiler can be of two types: wall-mounted or floor-mounted. It must match the type of heating system. So, if the system is wall-mounted, then the boiler should be of this type. Only models with a volume of less than 200 liters can be wall-mounted.

Advantages and disadvantages of indirect heating boilers

Like any other unit, such a boiler is in some ways better than other water heaters, and in some ways worse. After evaluating all the advantages and disadvantages, you can decide whether such costs are justified.

Advantages

What are the strengths of the indirect heating boiler.

As you can see, there are enough pluses, in fact - this is the perfect design to provide the family with hot water. There are some downsides though, especially in constructions where only one indirect source is used.

disadvantages

This boiler also has weaknesses.

- The cost of such a unit is quite high. In addition, you need to take into account that it goes to the cost of the heating system. Buy separately electric storage water heater or a double-circuit boiler is cheaper.

- Water heating takes longer than in electric storage boilers. It will take several hours to heat 100 liters of water, during which the temperature in the heating system will be slightly reduced.

- The very design of indirect water heating is quite cumbersome. It is usually installed near the boiler, sometimes a separate room is needed for this. At the very least, you need a carefully thought out place for this.

Manufacturers and prices

Indirect heating boilers have a huge range of volumes - up to 900-liter giants and more.

The most popular manufacturers and models of indirect heating boilers:

- 70 liters Valliant (Germany) - 32 thousand rubles;

- 160 liters "Drazice" (Czech Republic) ≈ 30 thousand rubles;

- 100 liters with heating element QUATTRO (Sweden) ≈ 45 thousand rubles;

- 500 liters combined Hajdu (Hungary) ≈ 90 thousand rubles;

- 210 liters of ACV (Belgium) ≈ 50 thousand rubles.

Interestingly, only the Belgian ACV models do not have a spiral coil as a heat exchanger, but a barrel with a grooved surface that is installed inside the tank, that is, this is a barrel-in-barrel design, which is a very interesting alternative to the coil.

Boiler service

Once or twice a year, the indirect heating boiler needs maintenance - replacement of the magnesium anode and descaling. How can this be done at home?

Once or twice a year, the indirect heating boiler needs maintenance - replacement of the magnesium anode and descaling. How can this be done at home?

First of all, you need to check if there is scale on the heat exchanger empirically. Scale significantly reduces heat transfer, so you need to measure the temperature at the inlet to the boiler and at the outlet. In this case, the difference should be about 15 degrees, that is, if the coolant enters at 80 degrees and exits at 65 degrees, then so far everything is in order. But if the coil is "overgrown" with salts, then the heat transfer is ineffective and the temperature of the coolant at the inlet and outlet has a difference of only 5-10 degrees, and the water will be heated more and more slowly.

If the temperature at the input-output differs by 12-14 degrees, then things are not so bad so far and you can cope with the method of heatstroke. For this you need to completely drain the water from the boiler and let the coolant from the boiler through the coil at good power for 10 minutes. So, the coil will warm up well, not having where to give heat, and then you need to refill the boiler with cold water for 3-5 minutes. Such a sharp jump in temperature should peel off the scale from the coil. Now you need to rinse the boiler and repeat the procedure.

If the situation with deposits is more complicated, then more effective methods need to be applied. It is necessary to use chemicals that are recommended by the manufacturers of a particular model. If you use accidental means, you can harm the parts of the unit. Special cleaning agents for indirect heating boilers diluted in water and poured into the boiler containerto completely cover the coil. You need to wait 4 to 8 hours and the dirty water must be completely removed, and then you need to draw 2 times of cold water and drain. Cleaning complete!

Alternative for indirect heating boiler

Is there an alternative to an indirect heating boiler? Let's compare different options for heating water:

It is up to you whether you need an indirect heating boiler or some other water heater. If you look at the advantages and features of this method of heating water, then we can definitely recommend an indirect heating boiler for large private houses. In winter, hot water will be an additional bonus from the operation of the boiler, and in summer period you can turn on heating from a heating element or other additional source.

Many people in the private sector want to equip an uninterrupted supply of hot water, so they use storage boiler indirect heating, which uses energy from the heating boiler during operation. The tank runs on gas, electricity, solid fuel, etc. Other methods can also be used to supply hot water, for example, equip a gas boiler with two circuits, mount a flow-through device or install a storage unit that runs on electricity.

But each method has a number of limitations, for example:

- a flow-through device provides high performance in order to supply hot water to several points, but at the same time it cannot provide a constant heating temperature;

- the storage unit, with all its positive qualities, has a significant disadvantage, since it spends a large amount of electricity.

All this does not make it possible to use it in the mode in which we would like it, since there may not be enough water for all needs. And if you connect an indirect heating water heater to the water supply system, then you can not limit the number of consumers.

Device and types of the unit

A water heater of this type is a device with a large container, equipped with a source for heating water, which is located either inside or outside. The design has:

- body;

- magnesium anode

- heat exchanger;

- thermometer.

Water is heated by a water or steam heat exchanger, which has a closed loop in which hot water is circulated. In the form of a heat source, there can be: gas (external) and electric burners (internal).

Some models have combined heat sources that have two or more heaters. On the outside, the storage tank has a thick heat-insulating layer and a special protective casing. A thermostat is also attached here, with which the water temperature is regulated. If the sensors record a decrease in heating below the set rate, then the shades are automatically turned on.

Note that an indirect water heater is of two types:

- pressure head (closed);

- free-flow (open).

The first type is installed with a centralized water supply, when more than two points of water intake are used. For this type, the tank is made of stainless steel, copper or enamelled steel. A pressure gauge, an expansion tank, a pressure reducer and a thermal mixer are inserted into the closed boiler. During the operation of such a unit and heating the liquid, various defects do not appear on the body.

If the volume and performance of the heat exchanger are calculated correctly, then the boiler evenly and quickly heats the water, and its temperature will be the same at all points of the intake. A tank with a capacity of 100 liters can provide 500 liters of hot water per hour, at the same time its principle of operation is in the so-called tandem with the heating system.

If the volume and performance of the heat exchanger are calculated correctly, then the boiler evenly and quickly heats the water, and its temperature will be the same at all points of the intake. A tank with a capacity of 100 liters can provide 500 liters of hot water per hour, at the same time its principle of operation is in the so-called tandem with the heating system.

During the operation of the system, the heat of the coolant is transferred from one circuit to another, that is, from the heating (boiler) to the second (hot water supply).

Heaters, this type of boiler, can have several, for example, a boiler for solid fuel, pump (geothermal heating system), solar collector. Each has its own pipeline for moving the coolant, but they are all connected by heat transfer.

How an indirect boiler works

A coil is located in the tank, a coolant passes through it, heating the water. In the latter, a magnesium anode is installed, which protects all elements of the device from corrosion (galvanic).

In order for the coolant to circulate in the coil, the circuit is connected automatic pump... The water heats up evenly and the heating system does not cool down. To reduce heat losses, the tank is closed with thermal insulation, which is used as expanded polystyrene or polyurethane foam. Each device of an indirect type has a branch pipe (inlet and outlet), which are connected to the heating boiler, and the already heated water goes to the supply point, passing the outlet pipe. This is the principle of operation of indirect heating water heaters, when choosing them, the performance of boilers is taken into account, since if it is not high, then the time spent on heating will increase, and this has a bad effect on the entire system as a whole.

When purchasing such a unit, the useful capacity of the device is taken into account. Its value is influenced by many factors, including the number of residents, lifestyle, habits, etc. When calculating the required volume of liquid, it is assumed that 80 liters of water is needed per tenant.

The existing models of the indirect storage boiler are 200 - 1500 liters. But choosing the largest volume significantly increases the cost of the heat carrier.

The second factor affecting the choice of a particular boiler model is the flow rate of the coolant that passes through the heating circuit (they are indicated in the technical passport of the product). If we consider their percentage, then this number should be 40% of the total mass of liquid passing through the heating boiler.

The third factor is the material of the tank and its quality. The best and most expensive are stainless steel tanks. There are other parameters by which a high-quality water heater is selected, but the main ones are considered here.

How to make your own indirect heating boiler

This requires the following elements:

- body;

- a heating element;

- fitting;

- insulation.

Any large-sized container is used for the tank, and the coil or heating element is assembled from copper pipes. Then they act according to the following algorithm:

Any large-sized container is used for the tank, and the coil or heating element is assembled from copper pipes. Then they act according to the following algorithm:

- Prepare the tank, it is better if it is made of stainless steel or plastic (heat-resistant), which is sewn with polyethylene or propylene.

- A coil is made from a copper pipe, the length of which is determined by multiplying the pitch of the spiral and the length of the inner circumference of the tank. But sometimes it is replaced with an ordinary pipe, which in cross section coincides with the neck of the tank.

- Before installing the coil in the lid and on the bottom of the container, fittings are cut in here.

- Mount the coil in the heating system. To do this, holes are cut out in the center of the bottom and lid of the container, one end of the heater is inserted into one end, and the other into the other. Using couplings and locknuts, they seal the device. To do this, a thread is cut at the end of the heater, locknuts are screwed in (they must rest against the cover and bottom) and washers and couplings are put on them at the exit.

- Next, the indirect heating water heater is connected to the water supply by hand. Check the tightness: drown the fitting (lower) pour water, but check the coil before installing it in the drive.

- The structure is insulated, for which it is wrapped with mineral wool or foil-clad material.

Conclusion

If we consider the advantages of an indirect water heater, then we can note the fact that hot water can be used at several points at the same time, and its temperature in all places will be the same. This cannot be achieved with a different type of boiler. Such a unit can be designed and assembled on your own, it is important to understand a little about this matter.

The household equipment market offers many alternative means to ensure the autonomy of the communication supply at home. For example, they allow you to create an optimal microclimate in rooms without centralized heating, and modern pumping stations effectively solve water supply problems. However, satisfying the hot water demand requires another unit. For such needs, an indirect storage water heater is used, which helps to solve household tasks. For example, if you choose equipment with a tank of a suitable size, then household chores in the form of washing, washing dishes and cleaning will be performed regardless of the main supply of hot water.

Water heater device

Structurally, any water heating unit is storage tank, that is, a boiler. In it, water is heated using a heat exchanger. The system also organizes the infrastructure of pipes that form a closed loop. Most modern models are indirect ones that differ effective work and convenient control. As a material for a tank, manufacturers usually use stainless steel, and the surface is covered with a special enamel protection against the effects of aggressive media. A magnesium anode is also provided inside, due to which the control takes place electric potential in the boiler.

The outer surface of the tank also has a heat-insulating coating. As a rule, polyurethane acts as a heater, which is practical, affordable price and resistance to long-term use. In the upper part, domestic indirect water heaters contain flanges with sleeves. This is a very critical area, as it houses the temperature control sensors, thermometers and the anode holder.

Features of indirect heating

Manufacturers and prices

In the initial segment, fairly high-quality models are offered by Protherm. Units with a capacity of 100 liters and 200 liters with a capacity of up to 30 W can be purchased for 15-20 thousand rubles. In the middle price segment, drives worthy of their characteristics are represented by the Gorenje brand. In particular, for 25 thousand rubles. you can purchase an indirect water heater with a heating element capacity of 2000 W. If you need not only a powerful, but also a reliable unit, then you should turn to the Baxi line. For 50 thousand rubles. the manufacturer implements the Premier Plus model, which has a 100-liter tank with a capacity of 300 kW and a pressure of 7 bar.

Conclusion

Equipment of this type is unique in the absence of a worthy alternative. Of course, it is possible to envisage other schemes for heating water with its subsequent distribution along the circuits in the house, but any of them will be much more complicated in their configuration than indirect water heaters with their compactness and ease of management. Of course, they are not without drawbacks. Users, for example, note inaccuracies in the operation of automatic regulation systems, poor pressure control, problems in the water supply, etc. But most of these shortcomings are characteristic only of models from the lower price segment.

However, indirect heating boilers are successfully used for the same purposes for apartments, office premises, at an enterprise and any other facility where hot water in pipes is indispensable. What is such a boiler, what are the types of indirect heating boilers, how to choose and install such a unit in your home, let's figure it out in this work.

Indirect heating boiler

First of all, you should understand: an indirect heating boiler differs from other types of heaters in that the water is heated in it not by electricity or gas burner, but with the help of the heating system. In this case, the heating source can be located both inside and outside the tank, or the boiler is capable of combining two or more heating elements. Such a combined source allows the use of heating elements even when the heating season ends and there is no longer a need for heating the home.

2

As a rule, a combined boiler is of a pressure (or closed) and non-pressure (open) type. And it is the type of closed indirect heating boiler that is used if the system has more than one draw-off point. The volume and power of the boiler tank are calculated based on the power of the heating boiler, because in the end the water temperature indicator depends on this parameter.

Combined pressure boiler

Outside, the indirect heating boiler is barrel-shaped, but new models are produced using more standard, rectangular-shaped bodies. This allows them to be installed in close proximity to the boiler, thereby saving space. Depending on the installation method, a distinction is made between wall and floor water heaters. The wall-mounted boiler, in contrast to the floor-standing one, has a limited capacity, which does not exceed 200 liters, but the floor-standing ones have no capacity restrictions and are mainly used in large country houses or in production.

To understand the principle of operation of an indirect heating boiler, first, let's look at what it consists of. I must say that the device for an indirect heating boiler is very simple, and some craftsmen even make it themselves. But at the moment we are still talking about such a version of this device, which is easy to buy in a store.

3

So, the entire design of an indirect heating boiler consists of a body (metal or plastic), a tank, a device for measuring the water temperature, a magnesium anode and a heat exchanger.

Manufacturers make a tank for an indirect heating boiler from stainless steel or copper, and sometimes from the same steel, only covered with a layer of enamel. And in the tank itself there is a coil-shaped heat exchanger (steel or brass), through which water is drawn from the heating boiler system, thereby heating the water in the tank.

In addition, in order to avoid excessively high pressure, a safety valve with a thermostat is provided in the boiler kit, and a magnesium anode, which requires replacement from time to time, protects against corrosion. At the same time, the combined boiler can be additionally equipped with a heating element for heating water in the summer.

Actually, based on the above, you can already guess about the principles of operation of an indirect heating boiler. Water from the heating system, passing through the heat exchanger, heats the water poured into the boiler tank. In order for it to circulate continuously, an automatic pump is provided, and a layer of thermal insulation helps to reduce the loss of heat in the water tank.

The principle of operation of an indirect heating water heater

Like any unit, an indirect heating boiler has its advantages and disadvantages. And in order to choose the model that is right for your case, it is advisable to clearly understand what parameters to focus on when buying such a heater. One of the most important parameters is the volume of the boiler, which is selected based on the number of people using hot water, their rhythm of life and habits. On average, it is believed that one person consumes from 80 to 100 liters of water. These are pretty rough estimates based on averages for one person:

- 15 to 25 liters per day for dishwashing;

- 5 to 15 liters for personal hygiene;

- from 50 to 100 liters per shower;

- from 150 to 200 liters per bath.

Of course, for each person, these indicators may differ in one direction or another, depending on individual characteristics and habits.

Therefore, in the line of heaters, you can find units with a total volume of 200 to 1500 liters.

However, one should not make a choice in favor of the maximum volume, since this is not always economically justified: in addition to the fact that such a heater will be quite expensive, it will require a lot of resources for its operation.

It is best if the boiler device has the ability to remove the heat exchanger for periodic cleaning.

4

Firstly, during operation, the indirect heating boiler does not use electricity (at least during the heating season), and therefore the wiring and the electrical network do not experience significant overload.

Secondly, its performance allows hot water to be supplied simultaneously to several taps, which means that several people in the house can use hot water at once without agreeing on the sequence of its use (as is the case with flow heaters). At the same time, there is no need to worry about the arrangement of an additional chimney if a solid fuel source of energy is used.

Moreover, any energy source installed in the building can be used to heat the water, even solar panels. In addition, if there is a storage tank in the volume of 1000 liters, the indirect heating boiler can provide water supply not for 150 liters of warm water, but for all 1000 liters of the tank.

Thirdly, the additional advantages of the heater include the absence of contact with running water, which favorably affects the service life of the unit, and the supply of heated water almost immediately, when opening the corresponding tap, without the need to drain cold water or wait for it to heat up.

Heating water by a boiler

However, it cannot be said that the indirect heating boiler has no negative sides. First of all, the disadvantage of this heater is its significantly higher price compared to gas or electric types of similar devices.

And the initial heating of water after starting the heater takes from 60 to 120 minutes, and during this time the quality of heating may decrease.

The biggest drawback of the heater is, perhaps, its large size.

So, if its volume is more than 100 liters, then you will need to allocate a separate room to accommodate such a large unit.

5

Before proceeding with the installation of the boiler, you must make sure that you have chosen the right place for installing the heater. It should be located as close as possible to the boiler or in the immediate vicinity of the central water supply outlet.

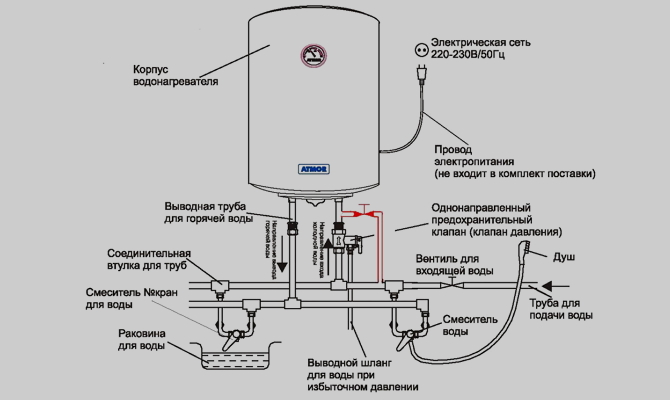

The water is supplied to the boiler to two circuits: heating and water supply. Connecting the unit to plumbing system, it is important to ensure that the cold water supply enters the bottom of the tank, and the outlet for heated water is located in its highest point... At the same time, it will be necessary to connect the heating circuit so that the direction of movement of the coolant passes from the upper point to the lower one (hot water from the heating system should be supplied to the upper branch pipe, and cooled water should go to the lower one). The recirculation point is located in the middle of the boiler tank. Observing the above rules when connecting, you can expect that the boiler will work with maximum efficiency.

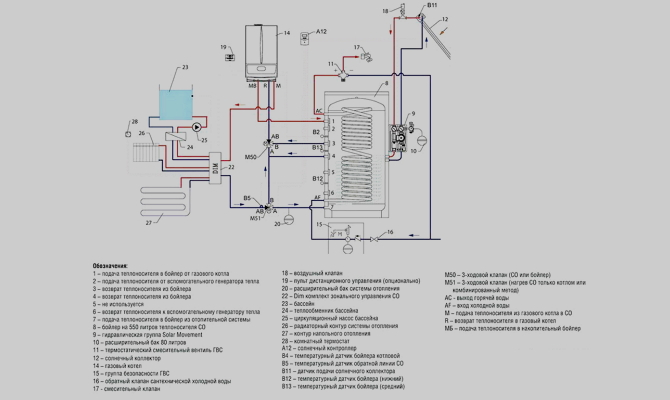

As for the connection diagrams, three main diagrams are mainly used. The most popular connection is through a three-way valve. This valve is controlled by signals from the thermostat, which, when the water is cooled to a lower value, redirect the flow of the heating medium to the heating circuit. As soon as the water temperature reaches the required value, the thermostat switches the valve back to its initial position, returning the flow to the heating radiators.

Water heater connection diagram

Such a connection is most often used with a high flow rate of hot water. But you should carefully consider the thermostat setting so that the set boiler temperature value is less than in the heating system. Otherwise, the boiler will be fixated on heating the water in the boiler without returning to the heating system.

The next most popular scheme involves the use of circulation pumps and is called a two-pump connection scheme. In this variant, the connection of the boiler heating line and the heating line occurs in parallel, and a separate circulation pump is connected to each of the lines. At the same time, the same signals from the temperature sensor of the water heater switch the operating mode of the pumps.

Just as in the previous scheme, in a two-pump scheme, a short-term shutdown of the heating line is assumed when the DHW circuit is operating, but, as a rule, a significant decrease in the room temperature does not occur in a short period. However, this situation can be avoided by connecting two boilers instead of one, while the function of the second will be focused on switching modes.

And the last of the widespread connection schemes is a scheme involving the use of a hydrocollector, or, as it is also called, "hydraulic arrow". Such a scheme should be designed and installed only by experienced specialists, since in this case it is supposed to use several heating systems at once: radiators, underfloor heating, the heating circuit of the boiler itself, etc. It is for balancing the flows in different circuits that a hydraulic distributor is used, which includes a combination of the said hydraulic arrow and a manifold.

Thus, when choosing an indirect heating boiler, you should pay attention to several parameters at once. After all, one has to take into account not only the manufacturer and the price, but also the provided volume of water, the presence of a built-in electric heater (for summer use of the boiler) and many other nuances. It is best to get competent advice from the seller, as well as carefully review the passports and accompanying technical documentation. Indeed, with the right approach, this unit will serve you for more than a dozen years.