No matter how convincingly the manufacturers of wooden entrance doors advertise their products, they are undoubtedly inferior in strength and reliability to their steel counterparts. However, even among the metal brothers there is a gradation that divides them into categories according to degrees of protection, according to the terms of impeccable service and aesthetic qualities. The steel entrance block is not a cheap purchase. Therefore, before you go to the store, you need to figure out how to choose an entrance metal door, what you need to pay for, and what you shouldn't spend on.

The priority of choice is reliability

Let's not deceive ourselves and others, proving that we like the "iron" protection for aesthetic reasons. Although the latest Italian and domestic models can be called attractive without reservations. We decide to install a steel "barrier", first of all, because of the ultra-high physical and mechanical characteristics of the material and because of the ability to equip the structure with the maximum number of protective devices.

First of all, you need to pay attention:

- on specifications products specified in the manufacturer's documentation;

- on the design features of the frame and canvas front door;

- on the number of built-in devices that can complicate the solution of the problem of unauthorized entry as much as possible.

Moreover, for yourself personally, you need to determine in advance the necessary and sufficient limit of reliability, since the search in these indicators entails not only an increase in price. Often, super reliable metal doors create absolutely unnecessary problems for owners. Too complex crab locks are irretrievably broken with jamming of the upper crossbar, after which it is necessary to install corny new door... Too heavy canvas is difficult to open / close for children and elderly family members. In addition, the mechanisms quickly wear out, the frame is deformed, the canvas sags on worn out hinges.

Necessary and sufficient technical characteristics

Let's start with the quality and thickness of the metal, which determines the weight of the structure and the price. Iron is not used in the production of iron entrance doors. In general, it is not used anywhere in its pure form, only alloys. Doors are made of sheet steel obtained by hot or cold rolling. Since we are figuring out how to choose a metal door, we need to compare the properties of the material:

- Hot-rolled metal is cheap and dark in color, but its blackness is not visible under the decorative coating. It is more susceptible to rust spots on its surface, and is quickly eaten away by corrosion. If the manufacturer used this particular type of material, the document will contain GOST number 19903.

- Cold rolled alloy is more expensive than the previous version. Without treatment pleases with the standard color of galvanized steel. Doors made from it will not suffer from direct contact with atmospheric troubles. GOST number 19904 will tell you about its application in the manufacture of doors.

If the alloy is oversaturated with carbon, it loses its ductility. A high content of alloying elements is also useless. Medium alloy (up to 11%) and medium carbon (up to 0.6%) steel alloys are considered optimal for the production of doors and their further operation.

Next, we will assess the prospects and choose an iron door designed to protect our property by the thickness of the steel sheet. We will also find this indicator in technical documents. Its values \u200b\u200bcan vary from 0.8 mm to 4.0 mm, according to which:

- doors made of sheet steel with a thickness of 0.8-1.0 mm do not belong to the clan of entrance structures. Suitable for the arrangement of outbuildings intended for storing low-value things, garden tools;

- a sheet of two sheets with a metal thickness of 1.0-2.0 mm is a suitable solution for equipping an office space in a multi-storey business center with security;

- 2.0-2.5 mm - the norm for the door leading from the apartment to the staircase;

- 4.0 mm is the best option for a country mansion, especially if they do not live in it permanently.

The thicker the sheet steel, the heavier and more expensive the door. It will be more expensive not only because of the cost of the material, but also due to the special installation scheme, additional powerful hinges and a reinforced frame. The optimal weight of an iron door for residential buildings is 70 kg. Bank doors and bulletproof versions weigh 90-100 kg and more.

Steel door design features

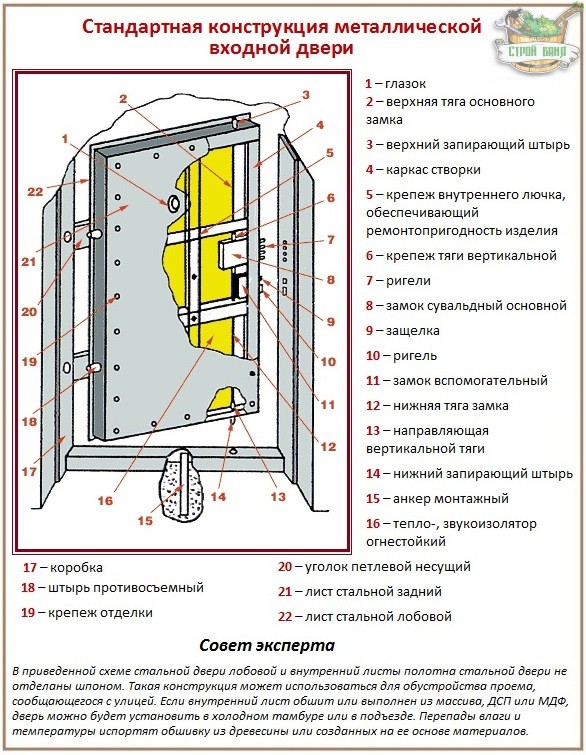

Two main components of any door block - a canvas and a box, it is a frame, which is more consistent with a product made of steel billets. The most reliable is a monolithic frame bent from a profile pipe with one welded seam, a less reliable frame welded from four sections of hot-rolled profile pipe. The most "flimsy" type is welded from four sections, each of which, in turn, is welded from two corners of equal length.

In short: the more welds, the worse, according to the engineers. In their opinion, welding changes the initial design geometry. The consequences of violation of the calculated geometric parameters may not appear at all immediately after installation, among them:

- distortions and the accompanying need for effort;

- directly opposite drafts and slots, allowing you to cut off internal hinges, open the door with a crowbar or a pry bar;

- jamming of the leaf, crossbars of the locking system.

There should be no welds on the face of the web. The outer part must be made of a monolithic sheet, otherwise it will not withstand a strong blow with a heavy sledgehammer.

Canvas as a guide to choice

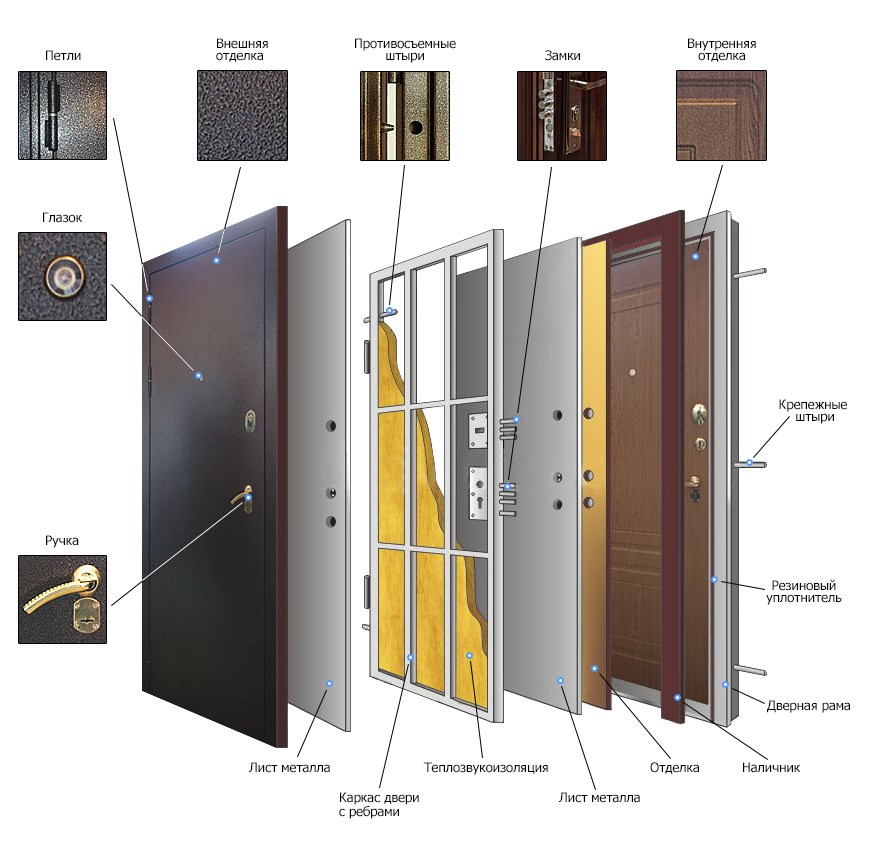

The canvas itself is a rectangular frame to which two metal sheets are attached. It can be one steel outer sheet and an inner panel of solid, MDF or particle board, coated with laminated film, veneer, cheap vinyl leather. This feature differentiates the entrance blocks to be able to withstand attacks from the atmosphere and not able to resist the sun's rays and moisture.

If the owner decides which of the metal doors to choose for installation in an opening connected to the street, the answer is unambiguous - completely iron, since temperature drops and fluctuations in moisture level will make wood and materials created from its fibers unusable. They equip apartments with blocks with metal-MDF tandem or an additional entrance to vacation homeleading from the closed vestibule to the housing.

Note. The condition for full protection against burglary by ingenious thieves methods - a crowbar and a crowbar is steel cashing and porches. They will close all unreliable areas and prevent access to critical parts.

Let's recalculate stiffeners

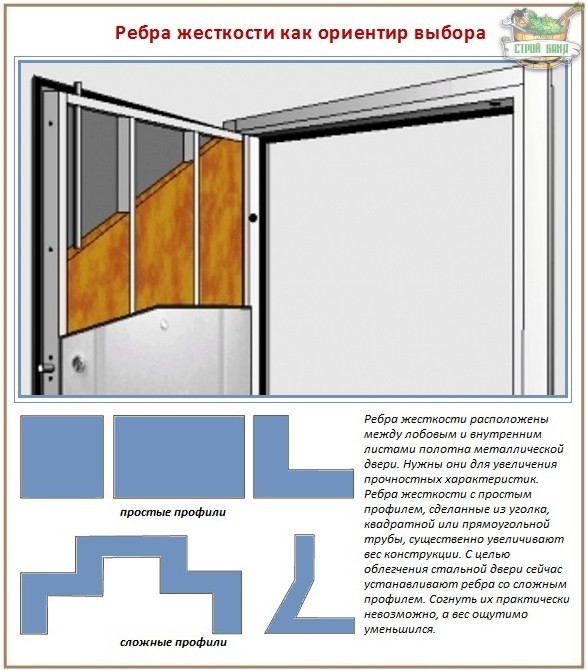

Between the outer steel sheet and the inner panel, no matter what material it is made of, there are ribs of cruelty. At a minimum, there should be two vertical and one horizontal. It is best if the edges are greater than the specified limit, because their number increases reliability. But along with reliability, they will add weight.

In order to reduce the weight, the ribs are not made from the usual corner or rectangular steel pipe, and from long products with a complex profile. It is almost impossible to bend the complex-profile ribs, and they make the door slightly heavier.

Reliable door hinges

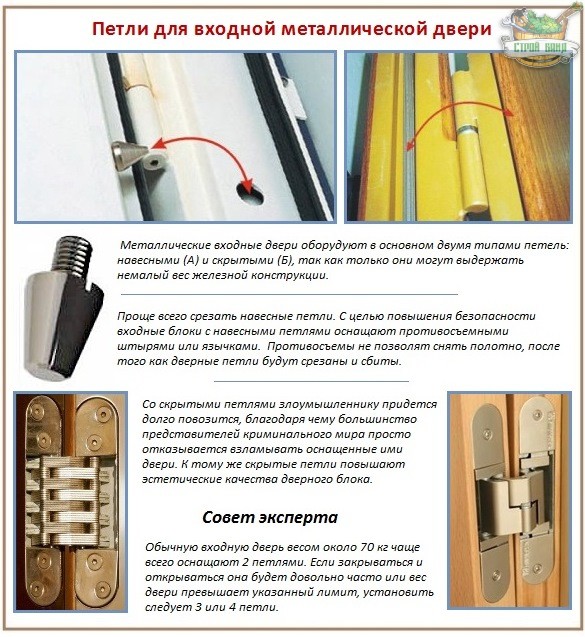

Those who want to know how to choose the right front door should also focus on the hinges. Steel door blocks are equipped with two types:

- hidden loops, unconditionally eliminating the desire to cut;

- ordinary external ones, which, in principle, can be cut off, but anti-axle devices will not allow removing the canvas - small steel pins "recessed" into special holes in the frame when the door is closed.

For unexplained reasons, the latter type is most often used. Apparently, because the degree of protection is provided by anti-removal.

The number of loops determines the weight of the fabric. For a standard of 70 kg, two hinges are sufficient if the door is not operated with increased intensity with closing 50 times a day. Those who are going to actively move back and forth, and those who decided to install a bulletproof door, will need 3-4 hinges. The hinges must have a support bearing, which will extend the service life of the devices and facilitate operation.

About warmth and how to keep it

A metal door does not contribute to heat retention, as the material is excellent at conducting heat waves. Thermal insulation is placed between the outer and inner sheet of the canvas, for which mineral wool insulation or expanded polystyrene is most often used due to the resistance to combustion and environmental priorities. Do not rely on the presence of insulation, cold bridges are still formed in the area of \u200b\u200bstiffening ribs and along the perimeter of the frame. But with insulation it's still warmer than without it at all.

A rubber seal will relieve drafts and odors. Most manufacturers equip canvases with two rows of it, but experts believe that one is enough.

The castle is a friend and loyal watchdog

"Incorruptible guard dogs", that is, there are no unpickable locks. The difference between an unreliable and a reliable lock lies only in the length of time that an attacker will need to spend on opening. True, too complex locking systems sometimes let down the owners themselves, therefore neither manufacturers nor sellers of iron doors advise to get involved in constructive delights.

The most effective locking option, both consumers and manufacturers, recognize the presence of two different types of locking systems. It is desirable that the main one be equipped with crossbars for locking in several directions for a long time, and the auxiliary one suits the owners, who often close the door for a short period.

There is no sense in talking about which entrance doors are more beautiful and which ones are better to choose for arranging a house or apartment with an existing interior and exterior. Everyone has individual opinions, there is no need to bring them to a common denominator. One can only advise buying door blocks with an external anti-vandal coating that protects the appearance of the entrance group from those who like to spoil beautiful things. By the way, you can apply it yourself after installation. So, at the top of the search cliff, we will strengthen the flag with the inscription "reliability", measure the opening according to the rules that can be found in the corresponding article, and rush to conquer the sellers with awareness, not forgetting that we came to buy a super strong iron barrier.

When choosing a reliable and functional front door, we are guided by many principles. Nice design is, of course, good, but for demanding developers, the issues of solidity and solidity of structures usually dominate. It is difficult to resist if in some salon we are offered a metal door of increased thickness, which is "better and stronger than any competitors." In fact, not everything is so simple. For example, doors made by comrades from the Middle Kingdom have always been famous for their normal and increased thickness, but they still have irreparable problems with durability and burglary resistance. This means that not everything depends on the thickness of the canvas, it seems that it is important here what materials are used in the production, and how the assembly / welding of the door block itself takes place, how well the design is thought out. Let's see what makes up the thickness of the canvas at all steel door, and how it affects the working and consumer qualities of the products we are interested in.

If you have not yet decided on the choice, see our offers

Free call of the measurer

The field "Your phone" is required.

The first thing that most of all affects the thickness is the section of the stiffening ribs, which form the strength frame of the canvas. Here, various rental options are used: corners or channels, but most often a profile pipe with cut dimensions is used: 40X25, 40X40, 40X50. In this case, you need to pay attention to the wall thickness of the stiffeners. Naturally, there will be a significant difference in the strength of the door if the wall thickness is one millimeter, or two or three, and the cross-section of the ribs itself affects the strength and burglar resistance indirectly. Unfortunately for the buyer, you can find out exactly what kind of metal is used by the manufacturer in the frame only by visiting his workshops.

Sheathing sheets

The second factor in the thickness of the web is the characteristics sheet metalwhich is used for cladding a steel door. The Chinese actively use thick sheet metal with a thickness (together with painting) of the order of 0.5-1 mm for these purposes. Such a door is lightweight, convenient for installation and even beautiful, but it can be opened in two minutes with any available tools. Using sheathing sheets with a thickness of 1-1.5 mm, many (especially foreign) firms with special equipment make rather reliable and practical doors that meet current regulatory requirements for doors as fencing building structure... In fact, in order not to injure the psyche of the consumer and remain competitive, the declared thickness of the metal is usually overestimated by the manufacturer by a couple of "millimeters". Checking and detecting this is also quite difficult. In fairness, we note that doors with thin or even one-sided siding in some circumstances will be quite suitable, for example, as technical, interior doors.

In our country (statistics and practice show this) the most optimal sheet thickness is about 1.5-2 mm. They are relatively easy to weld with commonly available equipment and provide sufficient strength with a moderate weight of the finished product. Sometimes, in the manufacture of doors, metal with a thickness of 3-4 mm or an additional 2 mm sheet (usually from the outside) is used. It is obvious that such a structure will have a higher resistance to forceful action... But in order for this to really increase in the class of burglary resistance, it is also necessary to apply all other measures - high-quality high-security locks, special armored plates, reinforced hinges, a functional crab mechanism, a special installation ... Otherwise, we have only a useless increase in the mass of the door structure with all the consequences operational implications, and a tangible increase in value.

Unfortunately, very often people confuse the concept of "sheet thickness" and "thickness of a steel door leaf". To prevent people from being very clever, sellers deliberately (or without realizing it themselves) plant such delusions, and meanwhile, as you noticed, the relationship between sheet thickness and canvas thickness is insignificant. But if you see a thick and relatively inexpensive door, then you should inquire about the thickness of the cladding metal and the thickness of the walls of the ribs.

The third point that affects the thickness of the metal entrance door leaf is the type of finish. Naturally, painting with soluble paints affects the thickness least of all. Powder spraying will give a little more layer, especially if done with texture. And different cladding panels are quite another matter. For example, the thickness of MDF and similar materials can be on average 8 to 14 millimeters. As for the door finishing with solid wood, here the panels can reach a thickness of 25 mm or more. As for the "blown" finishes, such as "leather + synthetic winterizer", here the thickness depends more only on the imagination of the master. Note that door cladding outside and inside the room can be made with different materials.

In any case, the thickening of the door due to these layers performs quite utilitarian functions, in particular, insulating. Facing panels and soft volumetric finishes significantly increase the thermal insulation characteristics of the steel sheet and the entrance group as a whole, which is especially important if the door is used outdoors. Also, additional layers help stop sound waves - noise will not pass through the door.

Making the right conclusions

So, the average thickness of the front door pie is the following: 40 mm (stiffening ribs) + 2X2 mm (sheathing sheets) + 12X2 (MDF panels) \u003d 68 mm. Of this indicator quite enough for the implementation of the entrance to most residential premises. The maximum is usually about 100 mm. Let's immediately confirm your assumptions: a larger amount of insulation can be installed in a wider canvas - indeed, this is so. But this does not mean that the insulating properties of the door will increase proportionally. Much depends on the quality of assembly and installation, as well as on other design features of the steel door: the presence of cold bridges, the type and quality of the seal, the shape and density of the porch, the type of slopes ... For the front door, in order to exclude condensation, it is still better to organize a buffer thermal insulation mode - using a cold vestibule or an additional inner door.

It should be understood that if the thickness of the web in terms of indicators significantly falls out of the average values \u200b\u200bof 50-90 mm, then difficulties arise with other elements of the system. This primarily applies to cut-in parts - locking mechanisms and fittings. In particular, it is technically impossible to properly install a reliable lever lock or open the bolts of the crab mechanism in a thin sheet (less than 45 mm). A web that is too thin is extremely difficult to make suitable for abutting a porch of complex shape and establishing several sealing contours. Such a door is the lot of openings, to which there are no special requirements in terms of decor and thermal insulation.

The increased thickness of the door will require troublesome and expensive selection of long cylinders for cylinder locks, handle parts, and a peephole. In any case, such doors weigh more, so the hinge group needs to be reinforced, including by increasing the number of hinges. Do not forget that for a massive canvas, more materials will be required, and, therefore, the price of the product will also increase. It makes sense to install structures approaching ten centimeters in thickness in the most critical places, especially if the steel front door is operated on the street - the entrance to an office or, say, to a private cottage.

The thickness of the iron door leaf depends on several indicators:

- stiffener parameters;

- the thickness of the sheet metal used to create the door leaf and frame;

- type of finish.

Stiffeners are included in the complete set of doors with high resistance to mechanical burglary. For the manufacture of these elements, specialists use several options for rolled metal: shaped tube, corner, channel. The thickness of the stiffener walls is important, which on average varies from 1 to 3 mm.

The thickness of the steel for the front door, as discussed above, varies over a wide range. It should be remembered that the strength of the entrance block to force is also provided by high-quality fittings: locks with a complex secrecy mechanism, protective armored plates, reliable hinges, etc.

Today, craftsmen use a variety of materials to decorate the canvas. Paints and nitro enamels do not affect the thickening of the entrance block, unlike cladding panels and "blown" finishes. MDF entrance doors often have a door leaf thickness of 70 mm or more. MDF boards can increase the thickness of the product by 10-16 mm or more. The thickness of the wooden plates is often over 25 mm.

Standard door thickness

How thick should the front door be in order to maximally protect the room from thieves?

Some manufacturers of metal structures provide customers with the opportunity to choose the thickness of the entrance door to the apartment or other premises. When deciding on the thickness of the input block, it is important to consider the following nuances:

On russian market widespread doors 50-90 mm thick. This indicator is sufficient for structures intended for the entrance area of \u200b\u200bresidential premises.

The thickness of the fire door depends on the design features of the product and the fire resistance limit of the entrance block. The average thickness of a fireproof door leaf varies from 50 to 70 mm. Fire doors are most often made of cold-rolled steel and equipped with fittings that are resistant to extremely high temperatures. Fire doors have a small leaf thickness: from 1.2 to 1.5 mm.

At StroyStalInvest production, metal with a thickness of 2.2 mm is used for standard doors. This is the optimal value to ensure the resistance of the door to opening without weighting the entrance block. The thickness of the door leaf is influenced by the design features of a particular model. For example, the thickness of MDF panels is from 10 to 16 mm.