IN lately For the construction of a bath on country sites, the brick has become increasingly. This is explained by the fact that from chopped buildings such baths are distinguished by the durability of the material and the possibility of various finishes. But before building a brick bath, you need to familiarize yourself with the rules of work to carry out all the construction procedures.

In this article, we will look at how to build brick bath with your own hands, we describe all the processes of construction from bookmark the foundation before outdoor decoration.

When choosing a material, first of all, it is necessary to take into account the high humidity of the premises under construction. Experts recommend the following options.

- Full-time brick is good for masonry walls. It is strictly forbidden to lay out the oven.

- Chamoten. Very durable I. refractory material, Perfect option for a bath oven.

- Hollow. Such a brick can be used to build partitions, but in no way for the walls and the more foundation.

- Red ceramic. This material has high indicators of moisture resistance and refractory, and this is the most suitable option for the construction of walls.

- Clinker brick. Also a suitable option. It is made of high quality clay, it is not "afraid of" high temperatures and resistant to mechanical damage.

Note! When choosing a brick, pay attention to its color. For example, the bright-scarlet shade says that it was sustained quite a bit in the furnace, and this was reflected in the quality of quenching. Also unwanted brick with a purple-brown tint - this is a checked low quality material.

Choosing a place

The most convenient version of the bath is near a small reservoir, but at the same time minimum distance From water should be at least 15 meters. Also, according to fire standards, such buildings cannot be placed next to residential buildings, although now many people neglected by these requirements.

Before making a brick bath, a place for construction is purified from all garbage and remove the top layer of soil for 200 mm. Then, using pegs and twine, place a place under the foundation.

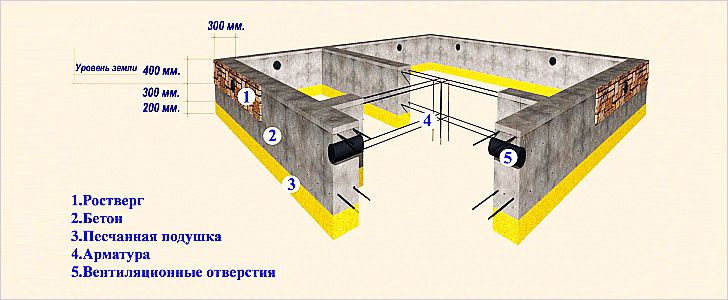

Technology of the Fundament Device

- Initially, you need to divide the place.

- Then an approximate markup is carried out, while it is taken into account that the width of the foundation should be 10-15 cm greater than the wall.

- Place the first need from the inside. For this S. inner corners Knock pegs and stretch the twine between them.

- After the exemplary width of the wall wall is calculated, and pegs off the outdoor side, also stretching the twine between them.

Note! After you fully place a place under the foundation, you need to roughly measure the distance between the internal marks. A small discrepancy is allowed in 2-3 cm.

After the markup rushes a trench. Before the filling of the solution to the bottom, it is necessary to fall asleep sand and gravel (15 cm). All layers shed water and tamper. Then on top of this layer you need to pour cement mortar, about 10 cm, and leave for 5-6 days.

While the solution dries, you need to build a formwork and install it inside the trench. Make it by 30-40 cm above the soil level. Then it is necessary to carry out reinforcement, it will give the strength of the foundation. To do this, you can use any metal waste: corner, channel or fittings. They are distributed inside the trenches and bind steel wire.

Phased fill of the solution

- The finished solution must be poured with small layers of 30 cm.

- After the fill, each of the layers is carefully compacted.

- When the trench is filled with 10 cm above the soil level, you need to pave asbestos or plastic pipesequal to the length of the width of the foundation - for ventilation, and pour the rest of the solution.

Note! The first 7 days the solution will gain strength. Honeycomb will begin not earlier than this period, and if the work is carried out in hot time, the foundation must be moisturized to avoid cracking. In rainy weather, on the contrary, the entire surface is better to close the rubberoid. Work on the construction of walls can be started only in three weeks.

Before the construction of the walls, the entire surface of the foundation is paced rubberoid. For reliability of the attachment at the beginning, it is lubricated with bitumen.

Foundation for a brick bath

For brick bath The foundation is made on several technologies, to choose which affect the characteristics of the soil at the construction site, the size of the baths and the materials used.

- Monolithic or ribbon foundation for a bath. This option is more suitable for sand or rocky soil.

- For clay or peat soil it will be more suitable pile option foundation. It is also suitable for the construction of a bath on the slope or in lowlands.

Masonry method

You can lay out the walls in two ways.

- You can make a 1.5 or 2 brickwork and additionally insulate the walls from the inside.

- An embodiment of double walls is also used, which are connected by the transverse partition, and the emptiness between them is filled with heat insulator.

Brick Wall Masonry Rules

- The first row is defined completely throughout the foundation. Use the option with double masonry only from the second row.

- Bought bricks are used only laying a spoonful row, from the inside of the wall. It is strictly forbidden to use broken bricks for laying out columns, simpleness and corner dressings.

- For the beam overlap, only the brick is only a tile row.

- If used ceramic brick, it is necessarily wetted by water before starting laying.

- When laying out the wall for uniform load distribution, masonry dressing should be drawn.

- Longitudinal vertical seams need to be tied to the Polkirpich.

Note! The shift of the transverse brick is carried out in each row on half of the brick, it is a time-consuming, but reliable system of lays down the walls.

Roof production

Depending on the option of the roof device (one or bounce), the choice of material and the sequence of operation depends. For the roof you can use any material, and all bearing structures, beams and jumpers must be processed by antiseptics to prevent rotting.

Warming roof bath

After the construction of the walls and the roof, the brick bath must be inspired. Particular attention should be paid to the roof of the structure. This process is as follows.

- In the attic room, the bath is installed in a 50 cm increments.

- A layer of fiberglass is placed on it.

- Then follows the insulation layer - it is recommended to use basalt cotton wool or polystyrene slabs.

- The insulation is closed with a construction foil and close the shapper plywood impregnated with antiseptics.

Note! When thermal insulation, the ceiling must be treated with a special impregnation all the rails used for the root.

Outdoor finish

If, in the case of a chopped construction, the walls themselves are a good finish, then, given the specifics of the material, a brick bath has a greater choice for outdoor and interior decoration. You can perform almost any finish option, starting with conventional plaster and ending with laying thermocaves.

Inner cladding

Such work also does not represent any particular difficulties. It is necessary to carry out the entire surface with the laying of insulation and vaporizolation. The lining rolls on top of the roaring. It is only necessary to take into account that the steamroom uses deciduous woods, and the pre-banker and the washing department can be separated by a coniferous lumber.

Note! When buying lining for interior decoration, special attention is paid to the quality of drying material.

Construction of a brick bath is not easy. But if you choose this particular material, you can embody any designer idea.

This Russian bath can be built not only from traditional logs, but also from the same environmentally friendly, fireproof and durable brick. This material is better to carry high temperatures and high humidity, and there are no equal in durability. It is important only to competently produce all insulation and waterproofing work. And how to build a brick bath correctly, will tell our article with schemes, video and step-by-step photos. So, we build a brick bath yourself - with the portal site

Advantages and disadvantages of brick bath

Here are the advantages of the brick as a material of the Bath structure:

- From brick, thanks to its design properties, real architectural elements can be constructed - any form and configuration.

- Paired, built from this material, much more durable than wooden - their service life exceeds 150 years.

- Fireproof the brick bath is several times higher than that of the chilled.

- Baths made of beautiful facing bricks At all, they do not need an external finish and perfectly look at any plot.

Here are what flaws, before making a brick bath, you will need to take into account:

- Price: The construction of a brick bath is always more expensive than chopped.

- Big heat capacity of bricks, and therefore the bath will always have to be pulled out longer. This problem can be solved by good thermal insulation.

- Brick inclined to be cheat and collapse, because He has much worse than wood. But this deficiency is easily corrected by high-quality ventilation and vapor barrier.

How to choose a place for a brick bath

The most important thing is that the place for the construction of a brick bath was dry. Therefore, if nearby - a lake or river, the construction point should be at least 30 meters from them, otherwise, with the spring spilling, it does not avoid high humidity in the air or even flooding.

In addition, it is important to take into account firefire requirements - The distance to any neighboring house should be no less than 12 meters - if the bath will be treated with firewood. But if a gas or electric boiler is planned as heating, and there will be no smoke, then this distance can be safely reduced to 5 meters.

However, a brick bath can be attached to any other residential building - so there will be not only the materials saved, but it is much easier to post power supply and sewage.

Features of the construction of foundation

The most convenient for construction of a brick bath foundation is a ribbon. Its blind must be at least a meter, and clay soils are even more. For its arrangement, this is what:

- Step 1. Drove the pit, in which 15-20 cm of sand falls asleep. Next, it needs to be well pouring water and compact.

- Step 2. The second layer on the sand is laid out 10 cm rubble in cement-sandy solution, and again sand. And so alternate several layers.

- Step 3. Now the formwork is stacked and installed armature carcasswhich is then poured with cement mortar. After that, steam barrier, consisting of two strokes of the rubberoid, and to protect against rain - from oily clay and gravel with sand is constructed a sloping gest course with 1 meter wide.

- Step 4. A comprehensive drainage system and draenage system

Yes, this foundation will have to spend money, but it is better not to build it for the brick bath.

Proper masonry and construction of walls

For the construction of walls, the bath is most suitable for red brick and silicate. Many still before the start of construction are wondering: how much is a brick on the bath? Here the calculation will be purely mathematical: the planned height and width of the walls of the bath must be divided into multiplied height and width of the brick. But it is in the perfect version. And it is still desirable to add 1 cm to the width and length of the brick due to the clutching solution, and plus 5% to the total resulting result due to possible broken bricks.

To build a bath, brick is better to put on one and a half or two bricks - then the wall thickness will be 38 cm, respectively and 51 cm. And already internal partitions paired to do in? or? Brick, which will give 6.5 and 12 cm.

When building a bath, brick walls can be made of such three species:

- Walls with balloons inside them - up to 6 cm wide.

- The walls of ring-shaped masonry, where thermal insulation is covered between the outer and inner rows - as a transverse one.

- Walls without internal voids, but lined with the inner side a good dense insulation.

The most economical option is the second. After all, the thickness of the masonry is much smaller here, but the heat engineering indicators turn out to be at the height. The main thing in their erection is special attention to pay a thorough dressage and accuracy of the seams.

The base and the brick part of the foundation of the bath, where there is lower waterproofing, perform better with the use of full-scale brick, but above the waterproofing - use already hollow.

And the solution for construction is better to knead such: cement, water and lime are added to the sand with grain size from 1 to 2.6 mm. The desired volume is noted in the bucket, after which the water is added - until the solution is well distributed over the surface and empty areas will not remain.

After the end of the masonry in the walls you need to knock down the pins and with their attaching wall bars. Next, the beams of overlapping are installed directly on bricks, in special nests, and to protect - turn on the rubberoid. But the ends of the beams must be left open by filling the gaps between the walls and beams with heat-insulating material.

Right insulation of brick bath

Brick bath must be insulated. To do this, the empty space between the walls of the masonry is filled with a mixture of sawdust, lime-membranes and light slag in a 2: 1: 2 ratio. Fall asleep this mixture is needed to a half-meter thickness, and each layer is poured by a solution of the lime of creamy-shaped lug.

Another type of insulation is tile. Panels need to be attached to the inner walls using synthetic binders and special fixtures. After that, from the plates you need to cut strips and put them with an interval of about half a meter to each other and put on the outer wall - so that the air layer remains between the wall and insulation.

Also outside the brick bath can be insulated with foam, after which it is possible to follow and entertain siding - even under the logs, if the Russian style is so important in the design. But inside inside the foam can not be insulated - dangerous phenol will evaporate from it during elevated temperatures.

Warming the foundation of the brick bath can also be mineral wool. And the soil under the floor must be filled with a thick layer of clay or slag - so from under the lag will not go raw cold.

This is done like this: in the brick set, wooden plugs are driven, on which the rails are stuffed. And the gaps between the walls and the slats need to be insulated plate MaterialOr the "blanket" from mineral wool, pergamine or packle. After that, vaporizolation is built from the foil.

And the thermally insulating blanket itself is done so. For its manufacture, it is convenient to use a specially built table with sideboards, the length of which is equal to the height of the wall that will be shifted, and the width is the width of the parchment. Between the boards themselves, it is advisable to leave a gap of 1 cm

So, Parchm must be spread on the table, on top of it - the selected thermal insulation material, and on top - again pergamine. After that, you can sew the "blanket" - just through the gaps of 1 cm, which was specifically left in advance. And firmware is made using twine.

By the way, if the plating the bath will go horizontal boards, then instead of the "blanket" you can use clamzit, having previously killed special racks with a thickness of 16 mm.

Waterproofing and vaporizolation of the structure

Before building a brick bath, it is important to think more in advance how to make it so that the brick does not touch in any place with the soil - it is unacceptable, because the brick perfectly absorbs moisture, which quickly leads to mold and the overall destruction of the whole building.

And in order to prevent it, you can use inlet or paint waterproofing. The painting method is to deprive the walls by the bitumen of all places where moisture can penetrate. To do this, you can buy special mastics based on bitumen. But the salabing is made by any rolled material - rubberoid, for example, but before that, all the cracks and gaps are always closed.

The laundry hosts build a bath on long years. Wooden buildings do not correspond to this parameter, so the brick is often used. This material is great for capital construction. It turns out a reliable, durable and durable bath, suitable for taking cleansing procedures and for receiving a noisy company. Construction of brick bath One goal is carried out - to get a warm structure for a very long time. Good houses are more expensive than wooden, but in contrast to this brick walls are perfectly kept inner heat.

The main stages of the construction of brick baths

1. Walls and installation works. Construction of a brick bath can be made independently if there are appropriate skills and experience, however, it is best to hire specialists to masonry walls. This is again the financial costs and appreciation of the final cost of the project. Please note that it is better to use a red ceramic brick for wketched steam room. It is more expensive, but has greater resistance to absorbing moisture and is thermal resistance. For masonry, cement mortar based on portland cement and sainted sand. Frequently add crushed solids, which will allow to avoid cracking in solution.

2. Fundam. Brick walls are obtained very heavy, so a solid foundation is required for their normal stability. A ribbon type of base with gluing is below the ground freezing level. Be sure to make ventilation, waterproofing of the structure, while the foundation tape should be 15-20 mm thick. It is advisable to build a small base to separate the walls from the surface of the soil. For a two-or three-storey bath, only a monolithic foundation is suitable, and these are significant cash costs.

3.

Roof. As a roof, you can equip one or double roof on the rafter scheme. The ceiling and the floors of the brick bath must be insulated, such a structure will be very warm and will last for many years. The wise quote reads: "It is not always good what is beautiful," therefore it is very important to comply with the construction of a brick bath all the rules and demands of guests and SNiPs.

3.

Roof. As a roof, you can equip one or double roof on the rafter scheme. The ceiling and the floors of the brick bath must be insulated, such a structure will be very warm and will last for many years. The wise quote reads: "It is not always good what is beautiful," therefore it is very important to comply with the construction of a brick bath all the rules and demands of guests and SNiPs.

4. External I. interior decoration . The bath can not be considered complete, if the internal and exterior finish. For walls, it is optimal to use shuttering, and the steam room is separated by natural lining. The chic odor of the tree is provided. For staining inland walls Apply special mastics based on bitumen. This is excellent waterproofing. Such processing will allow you to get brick walls that will not fit moisture. The steam room is additionally insulated. For this use mineral wool slabs. Additionally put steam barrier from foil paper. For the outer decoration it is quite suitable for inexpensive siding ( big choice By color), and more with the walls do not have to do anything. Such a cladding will delight the owners of the bathhouse with beauty. You can use a facing brick that allows you to create an excellent decorative effect. Doors, windows optimally use natural wooden. You can hang them yourself.

5. oven.. In a brick bath, you can put a furnace of any type. Brick is distinguished by strength and fire resistance.

Should I choose a brick bath?

Bath technology from brick is quite simple, the main thing is to correctly perform the masonry of the walls. All other works are carried out standard. It will only be left to buy wooden furniture and solve a number of tasks that will make a steam house complete, unique and original. Upon completion of construction, the brick bath will be an excellent addition to the finished estate for many years. This place will surely become the main rest for your family and friends.

- Advantages and disadvantages of brick bath

- What brick masonry choose?

- Brick Bath Stages

- Waterproofing and thermal insulation brick walls bath

- Features of the construction of a roof of a brick bath

- Useful recommendations in the construction of a bath

Brick baths are worthy competitors bathing from a log cabin. Brick is more durable and durable, easily devastable to internal and external trim.

A significant disadvantage of a brick bath is that brickwork during construction requires special skills and technology knowledge. But this question can be solved if you carefully examine the technology with your own hands.

Advantages and disadvantages of brick bath

What advantages has a brick bath:

- First of all, it is quite a long service life. They are durable, can be operated 150 years and more.

- External appeal, coupled with solidity and thoroughness.

- Facing brick does not need additional decorative external decoration.

- Have good thermal insulation characteristics.

- Have enough aesthetic appearance And perfectly fit into the general architectural ensemble, look pretenuate and thoroughly.

- Such construction materialAs a brick, allows you to build buildings that differ in the variety of forms, sizes and configurations.

In addition to the advantages, a brick bath, like any product market, have their drawbacks:

- The heat capacity of the brick is greater than that of the wood, so the planer Bani will take longer.

- Brick conduction is also inferior to wood, so the design needs a high-quality ventilation system and vaporizolation. Otherwise, the construction will start to calm down.

- Quite high cost.

Back to the category

What brick laying to choose?

The construction of a brick bath should be started after the work on waterproofing the foundation, wall markup and the definition of the future location of all door openings. Solid sections of walls in length should be painted brick size and take into account the size of the solution in the seams. As a rule, the walls of such buildings have a minor thickness, therefore it is advisable to build a design on a single-row dressing system. It is strong enough and easy to perform and is a replacement of the tychk rows with spoonful.

A spoonful row is a row of bricks located long side along the wall. The twitch row is a row of bricks located to the outside of the wall with short ends. This method is used in the construction of walls, in the design of which is missing facial layer of facing brick.

The foundation of the construction is placed on the depth of the fruit of the soil.It must be quite powerful. Basically, it is made of bricks, boot, concrete or slag concrete. It is possible to use reinforced concrete, but it will significantly increase the cost of the project.

To bookmark the foundation, it is necessary to pull out the trench of at least 30 cm to the trench and the width - 25 cm. At its bottom, the sand layer is 15-20 cm, which is watered with water and trambet. From above laid a layer of rubble approximately the same thickness, produce a stake and pour all concrete. When concrete freezes, it is necessary to lay a layer of waterproofing from the rubberoid.

The base is constructed from a brick of laying height in 4-5 bricks, it should be provided with ventilation products.

The foundation and base are laid out of full-scale bricks up to the lower level of waterproofing, and the empty brick can be used above. This is explained by the fact that a full brick is durable, resistant to freezing and penetration of moisture.

Hollow brick has good thermal performance and less weight. For insulation of the design from the inside, you can use the lining.

Back to the category

Brick Bath Stages

- step 1. Erection of corners.

Construction of brick buildings must begin with corners.

Each of them is laid out several angular bricks, which are connected by a special cord. The cord is designed to reconcile the straightforce of the rest of the rest of the bricks.

At the corners should be put in 6 rows of masonry, fixing the cord with nails strengthened in the seams. Such a cord is fixed in each row, withstanding 3-4 mm from the vertical of the masonry. After tensioning the cord, you can lay bricks. In order to avoid rapid drying of the solution, it should be applied to the sections about 1 m long;

- step 2. Decorating solid walls. In order to qualitatively put the brick, it is necessary to make a solution properly. In the process of work, it is necessary to serve it in small portions, laying out a smooth layer with a thickness of 2-2.5 cm without skips.

Laying the tiley rows, cement should be applied with layers, retreating from the sides at least 1 cm when filling the seams and 3 cm when laying into a wastelife. For spoonful rows, cement must be layered with trimmed strokes - about 20 or 30 cm.

For 1 masonry tier, you should take a solid brick, starting a row with outdoor bricks. Lohanned bricks can be used on spoonful rows from the inside of the design. In no case should they apply them to build simpleness, angles and reference zones.

Internal bearing walls must be not thinner than 25 cm, and the transverse partitions should be laid in 1/2 or ¼ brick. If the simpleness or partition, laid out by quarters, exceeds 1.5 m long, they are subject to reinforcement every 3 rows.

- step 3. Masonry over door and window openings.

In the side surfaces of the door and window openings, wooden bars are laid similar to the brick size. They turn around the rubberoid or are spotted.

Door and window openings are installed directly during the masonry process. Over them It is necessary to establish conventional jumpers with a height of 6-9 rows, the width of the opening is 50 cm in length. For jumpers, a milking formwork is constructed with a thickness of about 5 cm. But if you mount the door and window openings in advance, they can perform the role of formwork. Before that, they must be protected by a roofing layer.

A layer of solution of 20-30 cm is applied to the formwork in front of the formwork, in which 3 reinforcing rods with a diameter of 4-6 mm are stacked. Armature starts behind the edges of the openings at least 25 cm and bend around the brick;

- step 4. Baths.

Erected brick walls should be placed from 2 sides. For plastering walls, cement-lime solutions containing warm light aggregates are used - small slag, crumples, pimme. Stuning the walls are preferably not only outside, but also from the inside. For greater strength, the plaster is applied to the challenge, stretched on nails ribboned in the seams. Before plastering the front surface of the walls, the seams are filled with a solution with a depth of 10 or 15 cm.

If from the inside of the walls will be chosen by clapboard, plastering them optionally, the seams should simply be melted with a solution with a solution with a surface.

Back to the category

Waterproofing and thermal insulation of brick walls of a bath

One of the features of the brick is its ability to quickly and quickly absorb moisture. Therefore, when the brick wall is erected, it is important to prevent their contact with the soil. To do this, their waterproofing is produced.

Waterproofing can be several types:

- picky. In places of penetration moisture walls are cooked bituminous mastic with the addition of lime and asbestos;

- powered. Any house is glued to the wall of the house. rolled materials (for example, rubberoid), and all the gaps and cracks are closed and embarked.

You can insulate the walls of the bath, attaching mortar beacons for them, forming air 2-4 cm. Such a mount can be performed by wooden slats, brightened to the plugs in the seams of masonry. These rails should be fill the insulating plates from light concrete, arbolit, mineral wool, etc. Inside the pre-sash walls are triggered.

Clean the clap can be both unprepared brick. To do this, it is necessary to drive wooden tubes into it to secure the guides from metal or wood on them. The hollow space between the clapboard and brick is insulated with a foil or tiled insulation. Also as a heat insulator, you can take mineral wool, pass or pergamine. If the lining is replaced by horizontal boards, bulk clamzit is well suited as the insulation.

Often owners country house He thinks about the construction on its part of the bath. The presence of a bath on the site allows a person to relax and relax. There are many different projects Ban for country sites. They differ in both their complexity and the material from which the bath is performed. The most common materials for building a bath is a tree and brick. Each of these materials has its advantages and its drawbacks.

In contact with

Dignity

Although wooden baths were built on Rus since a long time, nevertheless, recently began to have a large brick bath. Such a bath it has the following advantages:

- durability. The service life of the brick bath reaches 150 years;

- increased fire safety;

- pleasant appearance. For example, when using red facing bricks, an external finish is not needed;

- good thermal insulation characteristics;

- the brick bath usually harmonizes well with other buildings on the site;

- the strength of the structural elements of such a bath allows you to create a structure of a complex configuration.

The most important lack of brick bath It is considered the inability to quickly warm the bath in cold conditions. In addition, to create a good room in a brick bath, a multi-layered structure of thermal insulator and a vapor barrier film is needed.

Device

Brick baths differ According to its size, planning or other characteristics.

Brick baths differ According to its size, planning or other characteristics.

The project companies have both economics designed for 2-3 people with a small parillery and small dressing room, and solid projects of a brick bath with the second floor for adopting guests and accommodation there. In addition, sometimes various extensions are provided to large baths in the form of terraces, veranda or arbors. After all, often the bathroom in the country site is not only a place of adoption of water procedures, but also a meeting place with friends and loved ones.

There are typical projects that are characterized by the fact that they are cheaper and have already passed the time check. The same customers who prefer exclusive buildings on their plot offered individual projects Brick baths.

Normal standard bath, including a brick sauna, consists of a pre-banker, washing and wage. For heating in the bath, there is usually a furnace with a tank for hot water.

A variant of a brick bath is proposed, in which the partial partition is made of hydrochloric bricks, which are made by drinking them from salt boulders. In this case, the hot humid air in the steam room is saturated with healing salts. The walls of salt bricks skip light, which allows to reduce the number of lamps, and due to the refraction of light passing through salt bricks, unusual light effects arise in the steam room.

Inner part of a brick bath Usually insulating. For this, the insulation is used, to which the layer of vapor barrier is placed. From above, the inside of the bath is covered with wood. Typically, the lining is used for this. Right is the finish of various rooms of the baths with different types of wood.

For example, the pair must be finished with larch or lime. These wood breeds do not overheat and can last for a long time. A pine is usually used in the locker room, which emits an indescribable bath fragrance, which is very useful for health.

One of the types of brick bath, designed not only for the adoption of water procedures, but also for cultural time in the company, is a two-storey bath. In such a bath, except for the pre-banker and steam, other rooms can be accommodated:

- additional residential premises;

- billiard room;

- gym;

- woman reading, games and recreation.

A particularly convenient option is a two-story brick bath is for a relatively small country plot. In case of construction of such a bath, you can significantly save the area of \u200b\u200bthe site.

Along with the savings of the area of \u200b\u200bthe site in such a project there are economic benefits. In case of construction two-story bath From the brick, there is no need to build a separate foundation and a roof for additional buildings.

Ownership reviews

Since brick baths began to be built later than wooden, then not too much reviews for the use of brick baths.

Since brick baths began to be built later than wooden, then not too much reviews for the use of brick baths.

Most of the owners of bricks from bricks note the greater stability of brick baths to rot. Here the wooden bath is rotten, and the brick bath is worth it. Some owners choose a brick bath due to the fact that all the buildings on the plot are brick. And for the fact that the view was more aesthetic, the bath must also be brick. Difficulties are noted when heating the bath in the cold season and the owner has to spend a lot of firewood.

Some lovers who want to have a durable bath and wash in wooden bath, Make a combined building - the structure of the bath is made of bricks, and the inner bulkheads and the steam room are made of wood.

Beautiful brick baths. Photo

Construction organizations offer a large number of various brick bath projects. Among them, projects as a very simple brick bath with open terrace Both shower and brick baths, in which a swimming pool or brick bath is built with a brick brazier.

Most brick baths Outside there are no finishes. Brick on the view is quite aesthetic. At the same time, the walls of bricks are made of both red bricks and from white - silicate.

Photo and brick bath projects (brick plans from brick).

Beautiful brick bath on the project E 080-1k looks like a palace with columns. Its size is 12.5 x 6.8 m. It includes a washing, hammam, veranda and economic area for equipment.

Other projects, including brick bath projects with a terrace.