Our company over the years has been one of the leading suppliers of electrical products. Controls, cable channels and trays of leading Russian and world manufacturers, including brand, you can buy from us at prices below market. All realizable products have passed the required certification and corresponds to the best international standards, which is confirmed by the necessary documents.

In the process of laying power and computer networks, an important task is to ensure their protection against external access and damage. An ergonomic component is important: the ergonomic component: randomly lying everywhere, the unfinished wires are not only attached to the room, but also prevent the walking and cleaning. To solve these tasks, the channel cable is perfectly suitable, which is a plastic or metal box manufactured by the company. These elements allow you to securely hide the wires and fit well into the interior of any room.

The plastic box has a convenient design for installation - it consists of a base and a cover, which ensures the speed and ease of assembly. Thanks to this, working with it does not require special training - almost any person can do everything. In the general case, the actions algorithm looks like this: Initially, the base is attached to the surface, along which the network will go, then the wires are kept on it, after which they are tightly closed with a lid. Thus, using a plastic or metal box, which is a cable channel and a tray, you can quickly and easily perform all installation work.

Depending on the operating conditions, the material should be selected correctly. If it is supposed to lay the network on the street, it is recommended to purchase a protective casing of metal. In the premises it is advisable to use plastic products: they are cheaper, easier to install and completely safe from a fire point of view, since they are made of a material that does not burn. At the same time, cable channels and trays have different design options, making these boxes organically fit into any interior. They also differ in size, due to which you can choose a protective cover, which is most suitable with the specifics of your situation.

Being one of the most confident leaders in the electrical product market, we offer more than 200,000 items of products designed to solve a variety of tasks. If you need a protective box for electrical or computer communications, then cable channels and trays from the best manufacturers, including from the company you can purchase at our attractive prices anytime.

Thanks to the rich experience of the work and the presence of a wide state of qualified specialists, all orders are processed in as soon as possibleAnd the conduct of flexible marketing policy allows us to offer conditions, much more profitable compared to competitors. Therefore, by purchasing any kind of cable channels and trays, you not only buy products of excellent quality, but also save considerable money. The high-level confirmation of the services provided is a large number of regular customers, as well as our impeccable business reputation of one of the most reliable suppliers of electrical products. Svetolektro enterprise offers a wide selection of boxes and cable channels at attractive prices.

Cable Channel - This is a specialized box that is used to ensure the mechanical protection of various wires (low-voltage networks and power cables), as well as special devices. The cable channel is called a specialized device (profile). As a rule, the box is made of plastic and aluminum.

Produced boxes and mini-channels allow you to quickly mount various systems. Products have different colors and types of surfaces, providing high aesthetics in any type of premises. The presence of a full range of accessories allows you to provide a systematic approach when designing a cable of carrier systems.

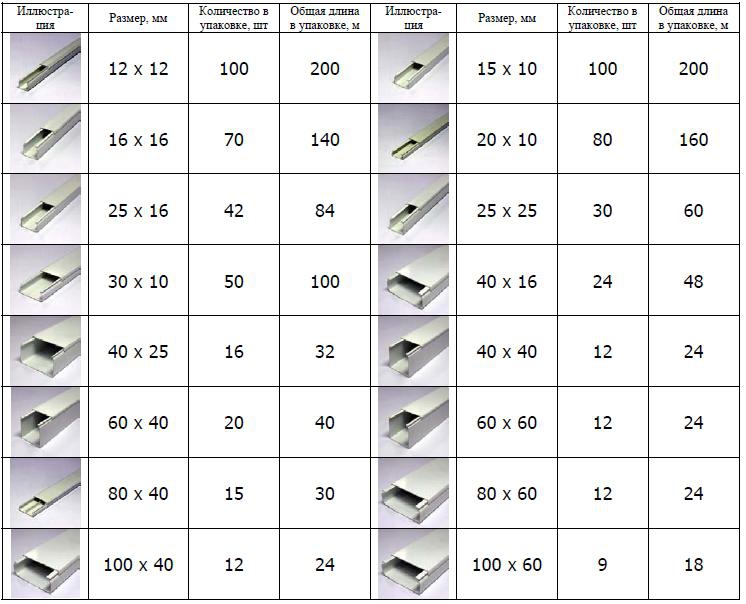

Views and sizes of cable channels in one picture:

Types and their characteristics

The construction goods market presents cable channels of various designs.

Leading manufacturers produce such products:

- outdoor;

- perforated;

- flexible;

- trunk;

- transparent;

- stair;

- mini cables;

- parapet;

- plinth;

- corner;

- wire;

Products are made of aluminum, steel, as well as plastic:

Products are made of aluminum, steel, as well as plastic:

- Today, plastic cable channels enjoy the greatest popularity, as they possess excellent characteristics. These models are often installed on the street.

- Aluminum models are characterized by excellent fire figures. Therefore, they are used in enterprises and factories:

- flexibility;

- moisture resistance;

- strength;

- softness;

- Steel products They boast of various colors. High-quality galvanized steel has a special coating that prevents corrosion formation. Steel products have a long service life. Perforated base simplifies the installation.

Plastic channels are most popular:

- Outdoor. Special design allows you to install channels in hard-to-reach places. Oval shape reliably protects cables from mechanical damage. Also models are beautiful appearance.

- Plinth. These models are used in apartments and private houses. A significant advantage is a special form of channels, which fits perfectly into any interior.

- Parapete. As a rule, such channels are installed in offices and enterprises. Most often, they are used to protect wires from air conditioners and other devices. The design of the channels has strict shapes and proper geometry.

The color of the execution plastic channels are:

- light;

- white;

- colored;

- under a dark and light tree;

Today, trays under the tree are most popular. In offices, as a rule, use PVC channels.

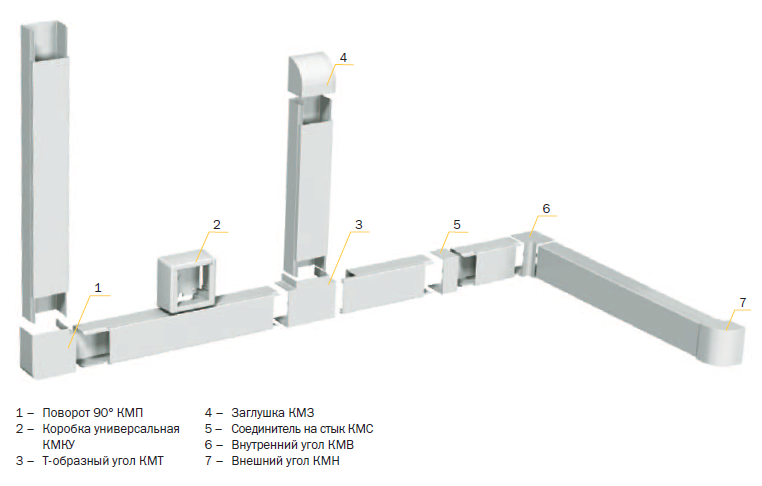

Modern areas of use of specialized channels are very diverse. This is caused by a wide range of accessories for its installation:

- plugs;

- connecting angles;

- t-shaped corners;

- l-shaped corners;

- external and internal;

Today, the manufacture and sale of specialized boxes is engaged in a large number of companies. The most famous of them are:

- Omis;

- ASKO;

- Teko;

- Moll;

- Legrand;

- REPLAST;

- ELEKOR;

double castle

The main advantages of modern cable channels are in a double castle.which combines flexibility and elasticity, as well as the strength of the connection. The material itself is a plastic that is self-fighting. It allows you to install cables up to 1 thousand volts.

Also, there are mini-cables on the market, which differ in their shape. These fixtures have rounded corners and a special mechanism for fastening the lid that creates an illusion monolithic design And it closes all the seams, which is particularly valuable for office aesthets. In addition, the device is flexible and durable.

Modern models do not require unlocking cleaning. Since after installation, the cable cover completely covers the base itself.

Quality cables have such advantages:

- Certificate of Rosset.

- Increased level of dustcakers.

- May be installed both inside and outside the room.

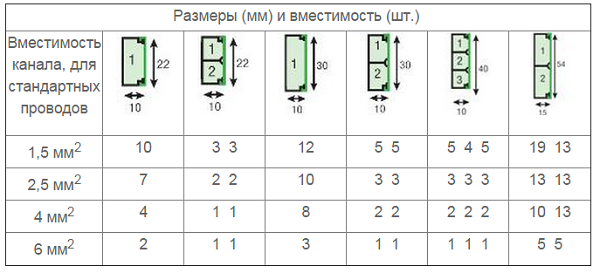

The main parameter when selecting specialized boxes is a conductor cross-section. With the Internet cable, a mini-model of 10 per 15 millimeters is suitable for the most successful, which fits perfectly into ergonomics.

Such a model has such advantages:

- Rounded shape.

- Aesthetic look.

- Made From environmentally friendly materials.

Dimensions

Modern technologies allow you to make specialized cores of various sizes and structures:

- polygonal;

- triangular;

- other;

Product length in packing is:

- 15 m;

- 16 m;

- 20 m;

- 42 m.

- 70 m.

- 100 m.

Section:

- 12 × 12;

- 16 × 16;

- 20 × 10;

- 40 × 16;

- 60 × 40;

- 80 × 40;

- 100 × 60 and others;

Of course, in the construction market there are standard devices that have averaged characteristics.

Plastic square shape covers are very popular, which are used to protect various cables.

cable Channel 100 × 60

These devices have different sizes and characteristics. Installation of products is carried out in 2 ways. Thanks to special latches, the installation of the box is carried out in the shortest possible time. In order to choose a model, you need to consider the number of wires. Since this will depend on the size of the device.

The most common sizes of specialized boxes:

- 80 × 60;

- 60 × 40;

- 40 × 16;

- 25 × 16;

- 12 × 12;

- 100 × 60;

- 80 × 40;

- 40 × 25;

- 25 × 25;

- 16 × 16;

The most common are cables in size 100 * 60 and 12 * 12. For connecting boxes, various couplings are used. As a rule, the models are sold in the form of planks (2 meters). All plastic models are attached standard method.

With the help of a screwdriver, the device is screwed to the surface. All additional structural elements and accessories must be purchased separately.

Methods of strip

Usually, the cable channel is attached to the wall on the self-tapping screw. However, some craftsmen do it on a three-sided adhesive tape or liquid nails. It is desirable to install an old and proven way.

Determine the length of the piece can be 2 ways:

- With roulette.

- Apply a box to the wall Where possible, and celebrate a pencil.

A separate topic is the execution of joints.

It is important to cut the cable cable gently with:

- stationery knife;

- hacksaws;

- reinforced scissors;

Modern cable channels are resistant to fading. They are not aging and not yellow with time. Also, they have resistance to the propagation of combustion, since they are made of self-refining ABS plastic.

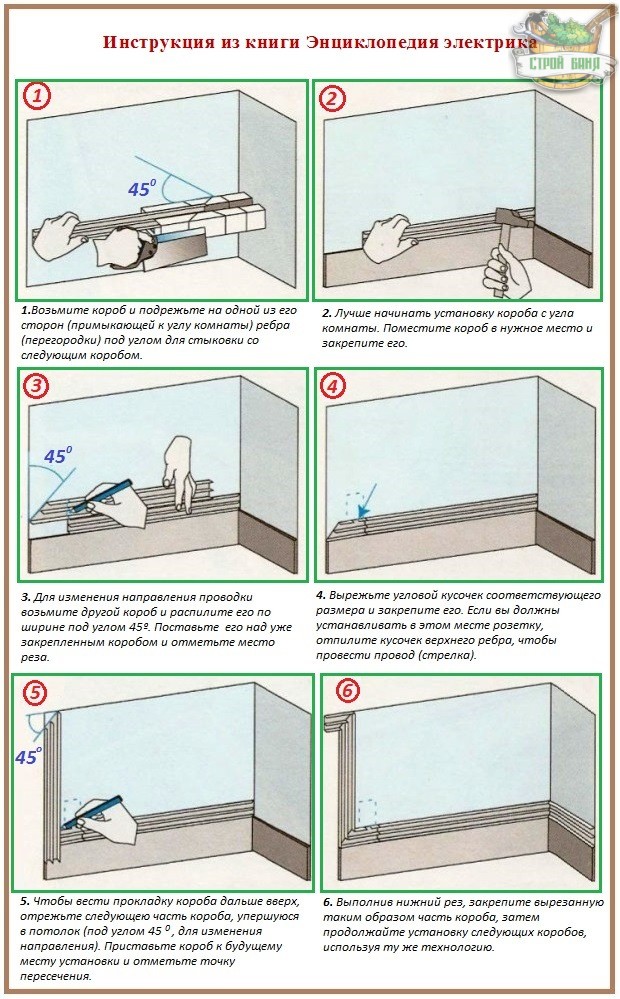

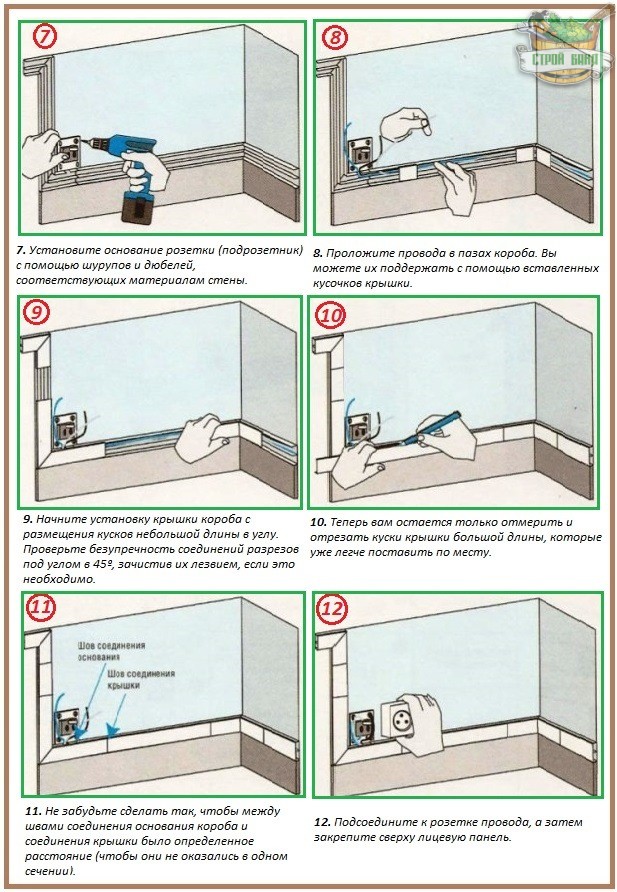

Installation instructions

The profile of new cable channels is supplied with special holes. You significantly save time, because you do not need to drill the bottom of the profile. In addition, the finished holes allow to align fixtures by level.

The profile of new cable channels is supplied with special holes. You significantly save time, because you do not need to drill the bottom of the profile. In addition, the finished holes allow to align fixtures by level.

There are 2 options for attaching a profile to the wall:

- Classical.

- With dowels and special tools.

Mounting result is great. The separation partition helps to thoroughly align the profile at the junction. When all profiles are sharpened, the shake pad is adapted to the depth of the profile and simply glued.

Follow the proposed instructions to install the cable channels:

- Unpack the product.

- Remove Top covers.

- Create Necessary marking along the walls.

- Trim on the required length (for this you can use a saw or knife).

- Remove From the channel top.

- Place box in the required place.

- Put on the product level.

- Align channel.

- Make holes (To install with a dowel-nail).

- Secure the product (For this you can use glue, dowels, etc.).

- Put Required wires (if necessary, install sockets).

- Close product.

- To clean up At the construction site.

There are 2 types of partitions:

- carriers;

- separation;

Bearing partitions allow mounting covers on multisection cable channels. The flat angle is mounted as simple as possible. Its design ensures impeccable separation of sections of insulated wires.

Internal angles varying, they consist of 2 parts:

- top;

- lower;

They adapt perfectly to the corners of the walls and are easily installed on the cable channel profile. External angles are also varying, and easily fasten to the profile. By its design, the corners are one-piece accessories, completely ready for installation.

Corner separators exist for multisective cable channels. They are supplied with corners and provide a real separation of weak and strong currents when passing wires in the corners. The angles are smoothly vary in the range of 60-120 degrees, which allows installation on any configurations of the walls.

Cable holders hold all wires inside the profile and provide you with even more installation convenience. The plug adapts to different sections due to the streamlined parts, and the front part of the plug will not be lost during operation.

Flexible covers are easy and simply mounted along the entire length of the cable channel and on the corners, and the appearance of the installation is simply delightful. The cover on the cover of covers with a non-lost decorative lid allows you to make a light dock with the next lid. The new specialized box provides you with a complete set of solutions even for the most difficult installations.

The corresponding lid is mounted on the carrier partition. This carrier partition can also serve as a separator for separating 2 sections with the same lid.

- First thing You need to look at the appearance. The appearance must meet your requirements.

- Thereafter You need to watch the plasticity of the device. For this, the box should be twisted. If the profile returns back, then the quality of plastics is good.

- The easiest way to check the model, it is bending, open the lid. The device must bend and not break. If the lid breaks, it means too much added to the composition of other components.

- NaturallyIt is necessary to pay attention to the presence of a double lock. After you close the castle, it should be fixed and not open.

What can be done still to check the quality? Considering that the specialized box will be somewhere on the wall or ceiling, the lid must withstand the weight of the cable that will be pressed on it. Let's point out what characteristics of the model can be found experimental.

In order to see how fastest, the cover is attached to the box itself, it is necessary to make the simplest device - to hang a piece of the box, and cut the cover into 2 parts. First you need to secure 1 part.

Double lock must slam down. Then it is necessary to make an ordinary piece of metal strip and rope. The bar is inserted into the box and closes with a lid. As a result, a special system is obtained. In order to check the strength of the design, you can pick up a brick or another subject.

Electrotechnical box - the optimal solution for organizing wiring in the baths. Make a power grid in the structure of a bar or logs in a hidden way too expensive and difficult. However, the strict regulation of PUE is prohibited open installation of a power cable in rooms with vaporization characteristic of them and high moisture content. It is easier, cheaper and more convenient to install boxes that combine the advantages of open and closed wiring. With the installation of these protective fixtures without problems, any home master can cope. No difficulty will arise if the future performer finds out how to fix the channel cable and how to put the wire in it.

Electrotechnical boxes are simple design, made of galvanized steel alloy, aluminum or from a solid, not supporting plastic burning. The main element of the two-meter profile with the P-shaped section, which is to be attached to the wall. It is placed in the power cable and low-current wires, then closed with a lid. Here, in fact, all things.

But the simplest process has several important nuances at first glance. They should be found out to find out the independent master so that the result does not require improvements or global alterations.

The family of electrical boxes used in the organization of electrical wiring according to the open scheme include:

- wall cable Channels with one-sided or double-sided lock;

- outdoor plinth with sections for wires, mainly low-current;

- ceiling analogue of the predecessor;

- outdoor systems with protection from mechanical impact;

- trays and artworks used mainly for wiring device in utility rooms and on the outer sides of the walls.

Because The operating conditions oblige into the chapter of the choice to put practicality, the outdoor options do not make sense even to arrange rest rooms in the baths. From the aesthetic considerations, we will leave thoughts about wiring in the corrugation and in trays for outdoor work.

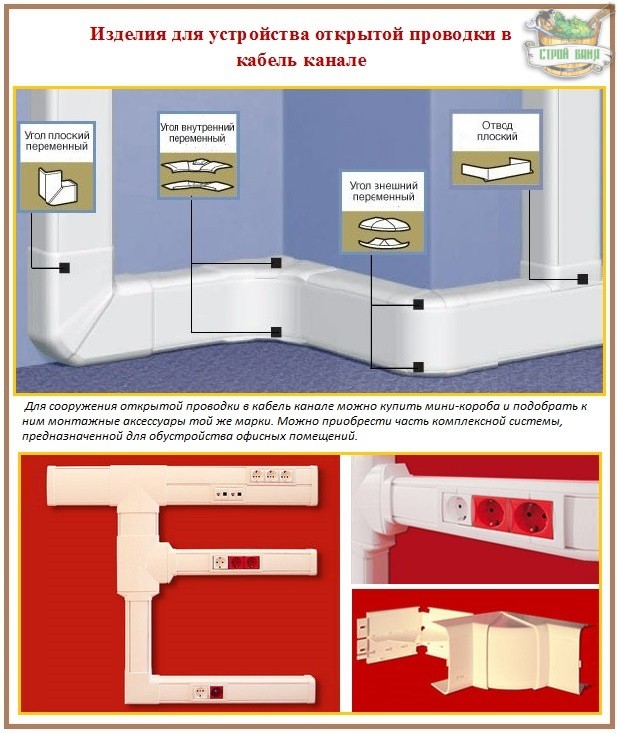

Consider the most common type of cable laying in the wall canal from plastic. These are the cheapest and simple in the processing of the box that do not require workshop and special knowledge from the artist.

What canal cable need a bath owner?

For the organization of electrical wiring of an open type, an extensive range of different in shape, dimensions and color of products is now produced. Democratic white plastic boxes from 2 m with variations in a couple of tens of dozens with variations in a couple of dozens are dominated.

Who want to choose products exactly wooden walls There is a chance to buy channels of the required color. There are complex systems with a complete set of accessories to form a network of any degree of complexity. There are mini-channels without additional fixtures that facilitate installation.

Cutting cable channels for the required buyer size in stores are not performed. Cooking segments to mounting a highway will need to be independently. We need to be stocking it will be a hacksaw of metal, better than a grinder. It will take a stubble for cutting blanks at an angle.

The choice determines the purpose of the work:

- if the task is in or outlet, it is enough to purchase an overhead variety of this electrical product and buy one mini-channel to it;

- if the electrification of the bath will be produced from scratch, it makes sense to buy partially or fully a set of channels with accessories: angular and T-shaped adjustable elements, plugs, fixtures for a device of outlets, junction boxes, switches, etc.;

- if it is planned to properly arrange a simple chain with a cable laying in low-cost plastic boxes, you need to pre-compose a scheme, calculate the metrar of the channels and stock accessories of the same brand.

Buyers of the complex system along with pleasant acquisition will receive detailed instructions On the installation of basic and additional elements for pitching them into a single highway.

Homemade crafts, who made the decision to use mini-box for organizing wiring, will not be offered the instruction. I am also useful to an article about how the channel cable is carried out and what rules need to be observed.

Wiring device to cable channel

To the implementation of any idea, and even more so such responsible, as the electrification of the bath, should be prepared. It is necessary to think about everything in advance, and, of course, distribute the stages of work.

Those who decided to pave the cable in the electrical box to be:

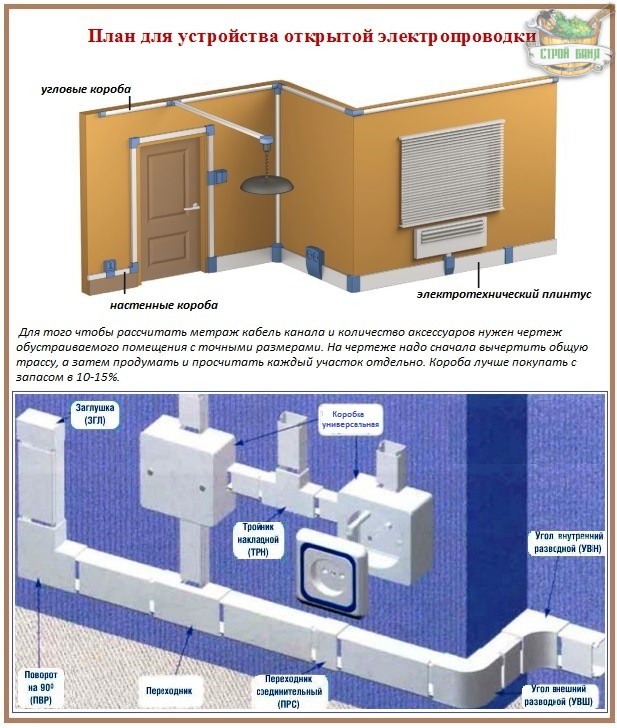

- make a drawing of an equipped object with precision sizes;

- decide with the number and type of wires, lay which will be required to the channel cable;

- choose the optimal track of the wiring and apply it to the plan;

- buy boxes with accessories according to the scheme made;

- place the wiring path;

- properly prepare the installation box;

- to build a channel for laying a cable;

- put wires, correctly fasten them and close the lids;

- install switches and sockets.

For laying power and low-current wires in one cable, it is desirable to purchase a box with sections. Power and low-current lines should not intersect or twisted in the harness, otherwise there is no interference when transmitting the signal.

The cable laying should be carried out in the channel cable, the size of which allows you to freely arrange the entire set of required wires. The lid must straight without effort so that the whole design does not "swallowed" from random touch.

When you purchase, it is necessary to check the cable cover of the closing channel. Do not shy by the seller "Close" by the lock several times. It will be a shame if the lid will simply "hold" in the already established base.

Planning - Warranty Success In

The wiring gasket in the box refers to the discharge of open schemes, because in the mandatory observance of horizontals, perpendicular and verticals there is no need. After all, the track is completely looked. Those. If you wish to hang the shelf on the wall, the threats will accidentally break the cable. Diagonal lines are allowed, all kinds of zigzags, steps. However, the irresistible traction of the owners for clear geometry most often makes adhere to strict directions inherent in the closed wiring scheme. Typically, the lines are parallel to the planes of the floor and walls, stretched along the window and.

You can draw the track, as the soul will be pleased. The main thing is that there are no situations for random damage to the power grid, and so that "tied" to it switches and sockets it was convenient to use.

There are no regulatory regulations for the open wiring device, there are recommendations:

- it is convenient to use the switch if it is set near the door from the handle side at an altitude of 90 - 160 cm from the floor plane;

- it is desirable to retreat min 15 cm from the ceiling, from the window opening Min 10 cm;

- closer 30 cm from the floor plane Horizontal wiring lines and electrical installation devices should not be placed due to the possibility of random moistening during cleaning. Exception - plinth with cable channel, but it is often used to lay low-voltage wires used to connect the Internet, telephone, antennas.

According to the personally made scheme, we purchase the material, acquire accessories, flattering the cutting tool.

Beginner masters are desirable to stock up a box of 10-15% more than the designation. It is not necessary to cut all the material at once on the segments required for installation. In fact, deviations peculiar to domestic construction will be revealed.

It is better to act consistently: I remembered - for confidence put to the installation site - it was carefully cut off - attached. And so with each segment, for the attachment of which on the wall you need to place the place of installation by a simple pencil. In the process of marking the future track, it is not necessary to navigate the floor / wall pairing lines, wall / ceiling, etc. Real position Unimpose the level and plumb.

Electrotechnical box mounting options

The method of fastening electrical boxes is determined by the material from which the walls are folded. Wishing to engage in independent installation of a plastic channel cable can:

- we tritely glue the base to the wooden, marked wallpaper, painted wall, to the partition made of moisture-resistant drywall or trowed plywood, any stove of extruded woodworking waste;

- scout galvanized screws to a wooden surface;

- fix the base on concrete or brick wall with the help of a dowel-nail;

- complete the adhesive method with mounting on the self-tapping screw.

There are a box with a sticky ribbon, planted on the basis of the factory conditions, but they are preferred to be used to organize temporary wiring due to doubts in reliability.

You need to cut boxes together with covers snapped on them. When building a track of several segments, it is necessary to try to make the places of dusting of two bases did not coincide with the lid pieces. Simply put, change the lids in some places: Close the long section first with a short lid, then long and vice versa.

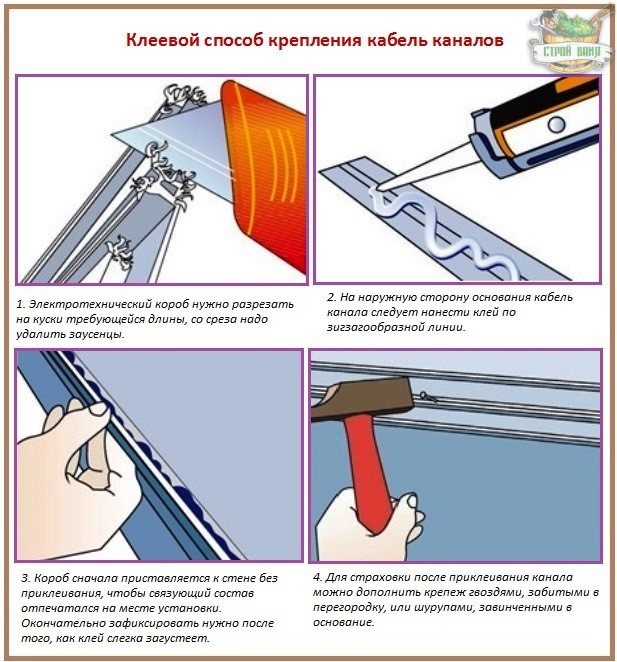

Specificity gluing Channel Cable

Print easier, but you need to consider that the dismantling of the glued box must be forgotten. Just to tear it out, only with a piece of wall or her finishes. True, it will take a minimum of effort and time for installation, from consumables only glue, for example, "Liquid nails".

The algorithm is the following:

- the adhesive composition is applied a peculiar zigzag in a step between the "vertices", equal to approximately increased by 1.5 times the width of the box;

- the base-processed base applies to the wall, but do not fix on it, but remove to the side;

- we are waiting until the glue trail remains on the wall thickens;

- we establish the channel in place and press with an effort;

- again waiting for the pouring of the glue.

For its own soothing and improving reliability, you can add adhesive fastening with nails, clogged along the central axis of the box in 50-60 cm increments.

Only after frozen can be started to lay the cable, which is needed to be fixed for convenience in the channel. For constant fixation, special plastic holders will be useful. Economical wizards can take advantage of undergraduate devices: cover cuts or channel cable itself. Temporary devices out of doubt need to be removed before mounting the lid.

Council. The cable laying in the construction system is more convenient to perform, alternating with a linging of the cover. Installed part of the wiring in the channel, then snapped, etc.

Nuances of applying self-uses

On the inner surface of the base of the channel you need to pre-make holes. In the narrow profile it is possible to position on one line, in a wide box along a zigzag scheme. The step between the holes depends on the quality of the wall leveling. For a flat surface, it is enough 50 cm. If there is minor slots between the cable applied to the installation site, there are minor slots, the step needs to be reduced to 30-40 cm. In general, "lumens" between the wall and the electrical box are undesirable. Installation of channels is made on a thoroughly aligned base.

The channel cable prepared for the installation is applied to the wall and screw the screws through the formed holes.

Subtleties of use of dowels with screws

The method is quite time-consuming, used for the construction of a cable line on top of brick or concrete walls:

- cooking the base of the channel: drill holes in advance;

- we apply it to the place of attachment in order to mark through the available holes of the point of the upcoming drilling of the wall;

- 6-mm drills drills at the noted point lines under the dowel-nails of the recommended size of 6 × 40;

- apply the basis of the box to the place of fastening;

- insert a dowel and tighten the screws.

Without experience in the field of installation of boxes, drill the foundation at once on the wall and immediately insert a dowel undesirable. Well, if the result of errors closes in the consequence directly by the cable channel. And if not?

Instructions for performing angular joints

The basic requirement of this work is the lack of visible "spank" between the elements after snapping the covers. In order not to make the slots, it is necessary to carefully measure and gently cut, using the web for metal and stupid or crossing. Because wishing to independently build a system cable of channels persistently recommended to use accessories that hide all flaws.

Minor errors can be masked sealant chosen in color, but there is still a way to form a neat angular transition. Instead of cutting two blanks under the traditional 45º-like angle, you can simply trim the base walls on their full width. Boxes in such cases are installed. Cuts and cutouts on the walls of the channel cable make metal scissors.

Make sure that there is no special wisdom in the attachment of electrical boxes. Connecting outlets and switches to the highway laid in them is performed in a standard way. If the performer is becoming patient and mobilizes his own accuracy, the result can be proud of right.

Open wiring must be available at any time. But this "openness" should be safe for wiring and aesthetically look.

Therefore, the wires are stacked into special fastening structures, which in turn are fixed to the surfaces of the walls, ceiling and even moving doors.

A variety of devices fasteners are combined with the name "Cable Channels". Common for all constructs feature - protection of wires from mechanical damage.

Cable channels for wiring are conditionally divided into the following types and types:

- flexible: chain-shaped, sectional, tubular;

- hard: open box, box with top removable lid, hollow plinths.

Materials for cable channels must meet several requirements: high strength, elasticity, non-causing. Additional plus, if the material is electrical insulating.

Therefore, metals (galvanized iron, aluminum) and non-combustible plastics (PVC with additives - hardeners) are on the manufacture of channel cable.

Hard cabinets

Cable Cable Channel is a straight box of metal or plastic.

Cable Cable Channel is a straight box of metal or plastic.

The following types of hard cable channels for wiring are manufactured:

- box with holes in the walls and day, without the top cover;

- box with deaf walls and bottom, without top cover;

- the box with a removable snap-down lid and deaf walls.

Metal cable Channels (without covers) are used in mounting hidden inside framework wiring structures: suspended ceilings, inland partitions, raised floors.

The convenience of such boxes in the simplicity of fastening: Cable Channel is screwed to carrier structures Scores, wires are stacked inside the box and are fixed by plastic clamps.

In boxes with profiled slits, the cooling of the wires is more uniform, which is positively affected by electrical conductivity.

Closed boxes are designed for mounting on the surface of the walls and the ceiling. Manufacturers of electrical fittings are used in the production of cable channels for electrical wiring self-painting plastic PVC (polyvinyl chloride).

Pure PVC is very flexible, but various mineral additives (plaster, marble) make it solid. Plastic holds paint perfectly and does not fade over the years.

Color cable Channels for wiring stand almost as much as white. But there were technologies for applying on the plastic drawings by the "Photoprven" method. Abstract drawings are more expensive, because it is "designer new items."

Wide cable channels may have several internal walls for individual lines.

Aluminum cable Channels look on the walls elegantly and expensive. There are such Italian and German delifferers are not cheaper than the most exclusive "photoprints". Metal boxes have one plus, which is deprived of plastics - isolation from electromagnetic interference and tipping.

Separate type of boxed cable channels - hollow plastic plinth. The box under the wire is attached to the wall, and the lid (at the same time being a decorative part "plinth") is fixed and covers the floor joint and wall. The design of the plinth is the most diverse, including "under the tree" (casting mimics the pattern of wood).

The boxes are completed with the connection elements: transitions from wide channel cable to narrow, turns on 90 o, tees, crosses, angles (internal and outer), boxes.

Elements are equipped with covers and are connected to the "long periods" so that they seem to be uniform.

Flexible Channel Cable

The need for flexible wire protection is dictated by the features of the "relief" of the walls of the house and household buildings. If there is irregularities on the wall (seam, the joints of the plates, the difference), the height of which exceeds 2 mm, consider that the channel cable will show it "in all its glory."

The need for flexible wire protection is dictated by the features of the "relief" of the walls of the house and household buildings. If there is irregularities on the wall (seam, the joints of the plates, the difference), the height of which exceeds 2 mm, consider that the channel cable will show it "in all its glory."

In the residential premises, you can and even need to level the walls, but in wooden surplus buildings such a "luxury" may be too road. It is for such cases that a flexible cable channels for wires have been created.

Types of flexible cable channels:

- "Flexible chains" (or "Tracts") - multisective structures that can bend along the entire length in one plane (up-down). Each element of the chain is connected to the adjacent swivel links and has a snap-on lid. There are small intervals between the links, so the cable channels are called "half-closed".

- tubular: Flexible Channel Cable for Transition to Door;

- cast of soft plastic or artificial rubber.

"Flexible chains" are complex in manufacturing, so their cost is quite high. Used in production to connect machines. The owner of the private farm can use such a cable channel to protect the cable to a boring or grinding machine ("emery"). Or in the garage. The width of the "flexible chains" - from 2 to 23.4 cm.

A flexible cable channel for transition to the door consists of a flexible metal hose and two fasteners (attached to the wall and door). "Flexible Armor" can bend countless times, but provided that there will be flexible wires inside (penetrated with thin wire).

Typically, such transitions are used to power electrical locks and sensors.

Cable Channels, cast from rubber or soft plastic, can be called "protection against all types of damage." Quite thick walls can prevent moisture from entering. In a private house, cast cable canal can protect the wiring of the bath (except the steam).

Sizes of cable channels

The dimensions of the box cable channels for wiring are varied from 0.7x1 cm (for signaling wires) to 6x10 cm (for cables and thick wires). Wall thickness: mini-channel - 0.7 mm, medium (20-40 mm) - 1.3 mm, trunk (60-100 mm) - 2.4 mm.

Standard sizes and photos are shown in the table below:

Typically, the cable channel is released 2 meters long. It is recommended to buy material with a reserve of 10% on the envelope of complex areas, random damage.

Installation cable channels

Hard cable Channels are attached to aligned and trimmed walls. If the walls are covered with dry-fiber sheets, small screws are used for fastening - self-tapping screws (1.5 cm) with a flat head.

Hard cable Channels are attached to aligned and trimmed walls. If the walls are covered with dry-fiber sheets, small screws are used for fastening - self-tapping screws (1.5 cm) with a flat head.

The box begin to mount from the place of fastening the socket or lamp (the end of the channel cable is joined with a box with a minimum gap). The distance between the attachment points is 0.3-0.5 meters. The ends of the boxes are joined with a small gap (1.5-2 mm) so that with increasing the temperature in the room when the plastic expansion did not finish the design.

Plastic is soft enough and sweetly saws fine saw. Mini channels can be cut with a sharp knife.

To plastered walls, the cable channels are mounted with small dowel-nails (2.5-3.5 cm). The holes under the dowel-nails are painted by a perforator in 0.4-0.5 meters.

The walls may have surface defects (waves), so when installing it is necessary to mount the "without tension" box, with little freedom.

Useful video on how to choose and install a cable channel.

Metal cable boxes - Products intended for mounting wiring or any other cable, box can be equipped with a snap-down lid, which securely holds the cable or cable system inside the box.

Cable boxes can be supplied to various colors for the international RAL catalog, produced different species and sizes apply to the possible options for their use.

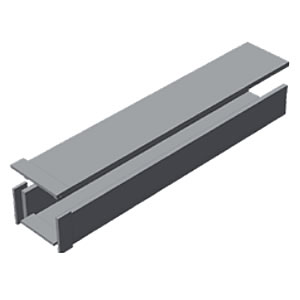

Game productsWebsite of electrical products GEM SZPKCable Metal KP TU 34-43-10-167-80. Kap kp It is used when laying cable and wires with voltage up to 1000V outdoors, inside buildings and structures. A box made of steel with paint and varnish or zinc coating according to GOST 9.302-88. Cable Metal CP Metal cable box type |

|

|

Cable Metal Cable CableBox cable metal SCR for laying cable runs with voltage up to 1000V inside and outside buildings, in horizontal and vertical planes.Standard execution UHL2.5 |

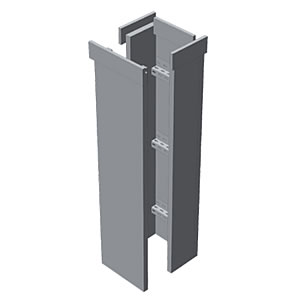

|

Fire-resistant cable boxesBonded cable fire resistant metallic with a lid, for laying cable networks and wires with voltage up to 1000V inside and outside buildings, used in horizontal planes.Length of the straight section: 2500 mm. |

|

Bad vertical refractoryCable box for laying wires and cables voltage up to 1000V in the horizontal plane inside and outside the premises. Fire resistance 40 minutes. Used in explosive environments.Length of the straight section: 2500 mm |

|

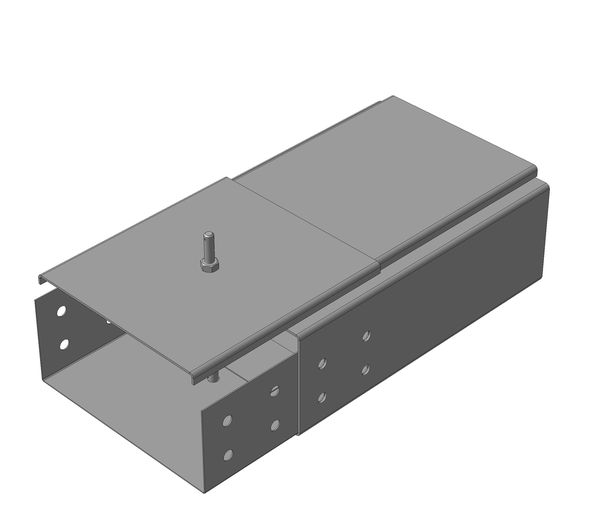

Box Cable Flat Seismic Resistant CPPS SeriesThe KKPS box is designed for laying wires, control and power cables with a voltage of up to 10 kV inside and outside the buildings.Degree of protection: IP20. |

|

Cable Flat Seismic Resistant CPP SeriesBoxes Metal cable kps are designed for laying in them of power and control cables and wires with a voltage of up to 10 kV inside and outside buildings, as well as in cable structures of TPPs, nuclear power plants and industrial premises.Coating according to GOST 9.032-74 * or metallic (galvanized) according to GOST 9.302-88. |

|

Box Cable Metal Block KKBSGPK produces seismic-resistant cable blocks of the CKB-P series, CKB-UNP, CKB-UVP, CKB-EGM, CKB-UGP, CKB-PO, CKB-UGG, CKB-UN, CKB-uv.Korobacable block type Metal are designed for laying power cables and joint-and-power and control cables through maintenance sites, farms, columns and walls under the floors inside buildings and structures, as well as outdoors on special and technological overpass and other supporting structures. Degree of protection: IP20. Standard version U1 and U5. |

|

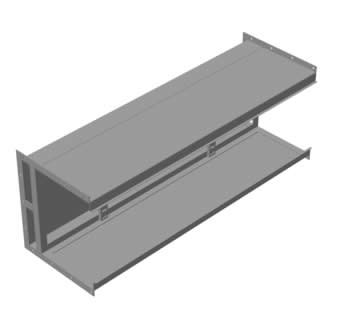

Box Metal SLVLaying wires and cables voltage up to 1000V when laying cable lines In the vertical plane inside and outside the premises. Used in corrosive and aggressive media, in petrochemical enterprises, gas, chemical and metallurgical and food industries.Standard execution: UHL2.5 under the order ut1,5 |

Benefits cable boxes SPC

SGPK is a leading manufacturer of electrical products that has branches in the largest regions of Russia. Since 2012, we have made and installed over 1 000 000 m. Cable trays and boxes to our customers in Russia and abroad. All products correspond to GOST, at all stages of production passes strict quality control.Wide use cable boxes Due to convenience when installing external wiring, the ability to add and remove the wires and cables, a sufficiently low installation cost and, with the help of cable boxes, it is possible to maintain aesthetic appearance and safety during the operation of cable systems.

Metal cable boxes Different with high strength. Special durability in operation and high safety provide galvanized cable boxes. The use of cable boxes when laying cable systems create conditions for a simple, convenient, low in terms of installation, and most importantly provide safe operation Cable systems with the possibility of change and additions when needed.