To mount electric chain, some wires are often not enough. After all, the cable must be attached to the good, hide or protect in any way. Give the aesthetic appearance of cables and wires is also important. For these purposes, a variety of metal and plastic products are created in order to perform operation electric conductors The most convenient, aesthetic and safe.

At home, cables and wires are most often hiding in the wall, climb into the plaster. It is beautiful

output from the position. The wires are not visible, they are reliably hidden behind the layer of plaster or cement, which not only reliably hides the cable, but also serves as a good dielectric, provided that the coating is dry (Fig. 5.2).

There are several significant minuses in such a situation. First, it's very difficult to get to the wire. If the chain is damaged, it is extremely difficult to find out exactly where the breakdown or leakage occurred. When it becomes clear, then it is a sorry to handitray ceramic tiles or wallpaper, because by completing the repair, you will have to restore everything as it was. Secondly, to change the wiring to more modern and reliable, you will have to do repairs again. It's not for everyone by pocket.

There is another way: put the cable not inside the walls, but on top of them. This type of wire laying is called open. However, in this case, the conductors will be visible, and this is not quite aesthetically. In addition, they are easy to kill them, accidentally taped with any object. In fact, all this is not so scary. For open laying of wires of any type inside and outside the premises there are special boxes, plastic or metal (Fig. 5.3).

Plastic applied indoors, and metal - outside or in production, as well as in office space. Plastic boxes for cables and wires are called cable channel or electrical box.

Channel Channels

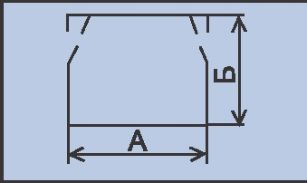

In essence, this plastic profilesIn the section having a letter "P", the open side is covered with a lid, which adjacent to the profile using a double lock. This type of box is common most widely. In addition to the P-shaped form, they are triangular, hemispherical, and sometimes another bizarre form intended for a wide variety of surfaces. The color of the cable channel is usually white, but there are others. The material from which it is made is non-combustible PVC or polyethylene.

The boxes are attached to the surface with the help of dowel-nails, screws, screws and metal brackets. For this, some types of cable channels have special holes. In addition, the plastic, wooden and spacious surfaces can be simply glued. For this, special glue is applied. Cable Channel is designed for laying any types of conductors: information, power and lighting.

As a rule, the electrochannels are produced as segments of 2 m in length. Products of foreign firms may have other dimensions. For example, the French LEGRAND company produces a box with a length of 2, 2.2, 2.5 and 3 m. Width and height depending on the section and the number of conductors can be from 10 to 60 mm. In more detail, the main sizes of the cable channel are presented in Table. 5.1.

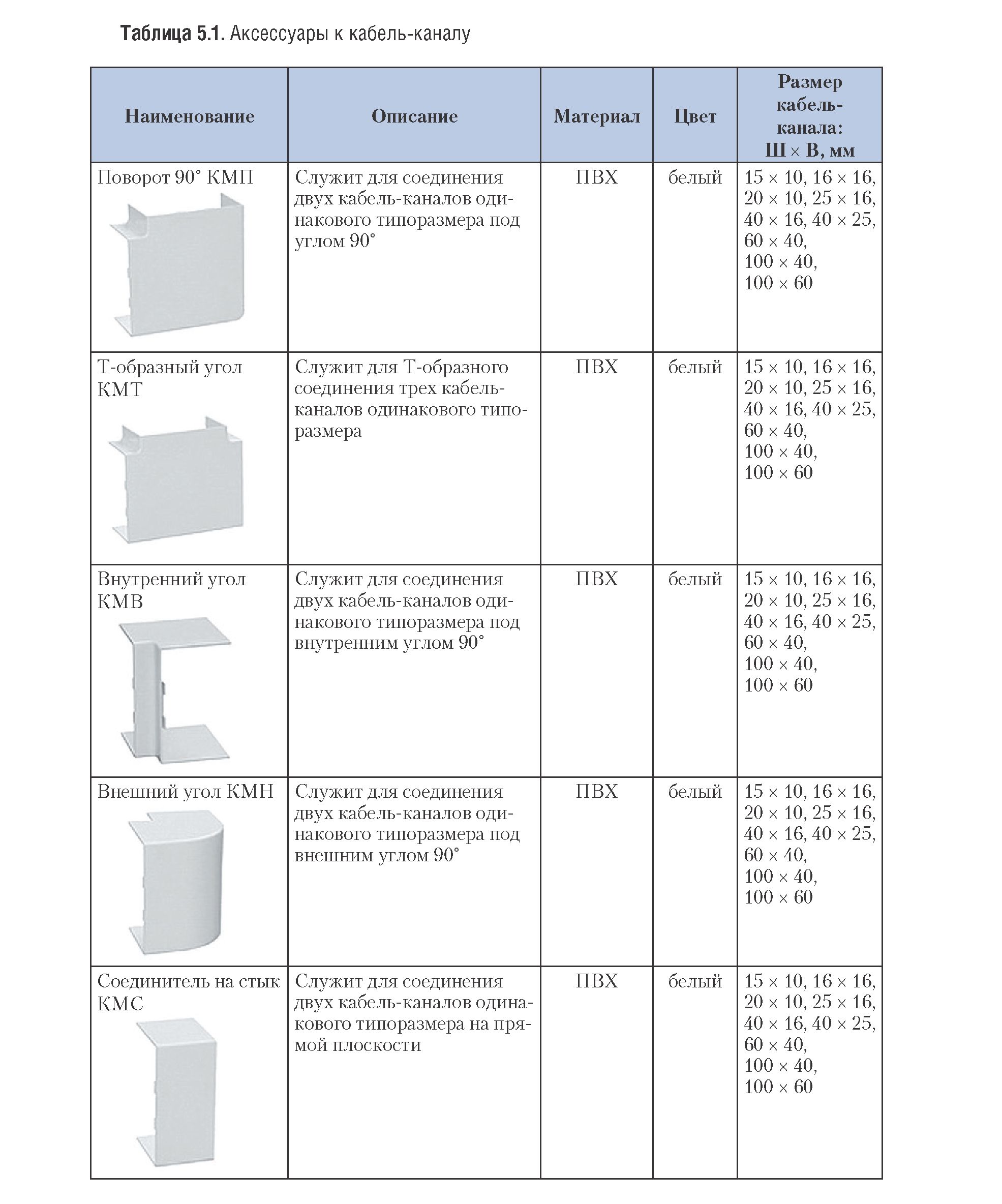

Table 5.1. Accessories for cable channel |

||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||

Table 5.1 (continued) |

||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||

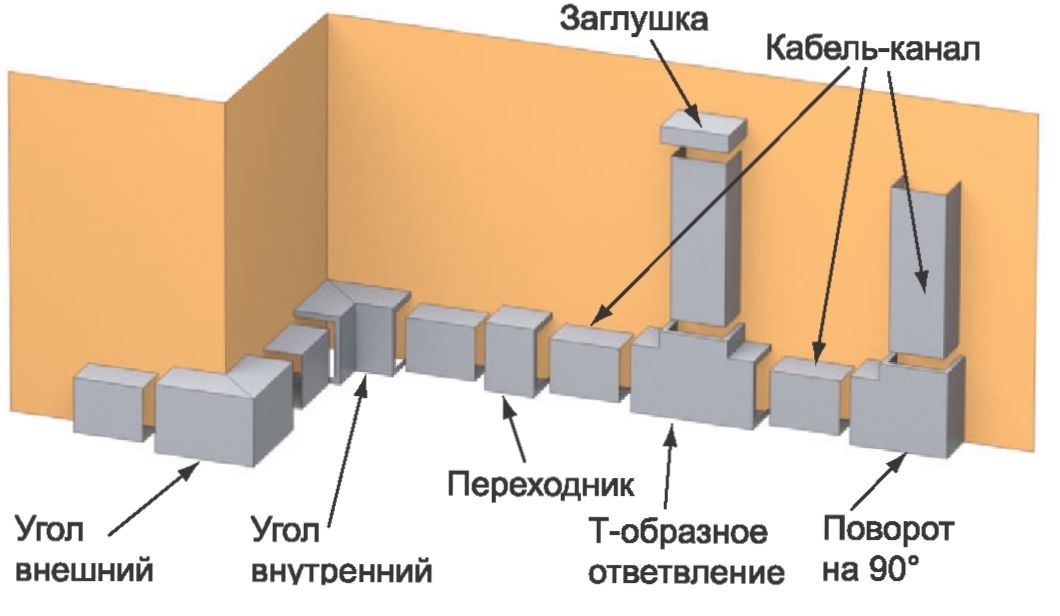

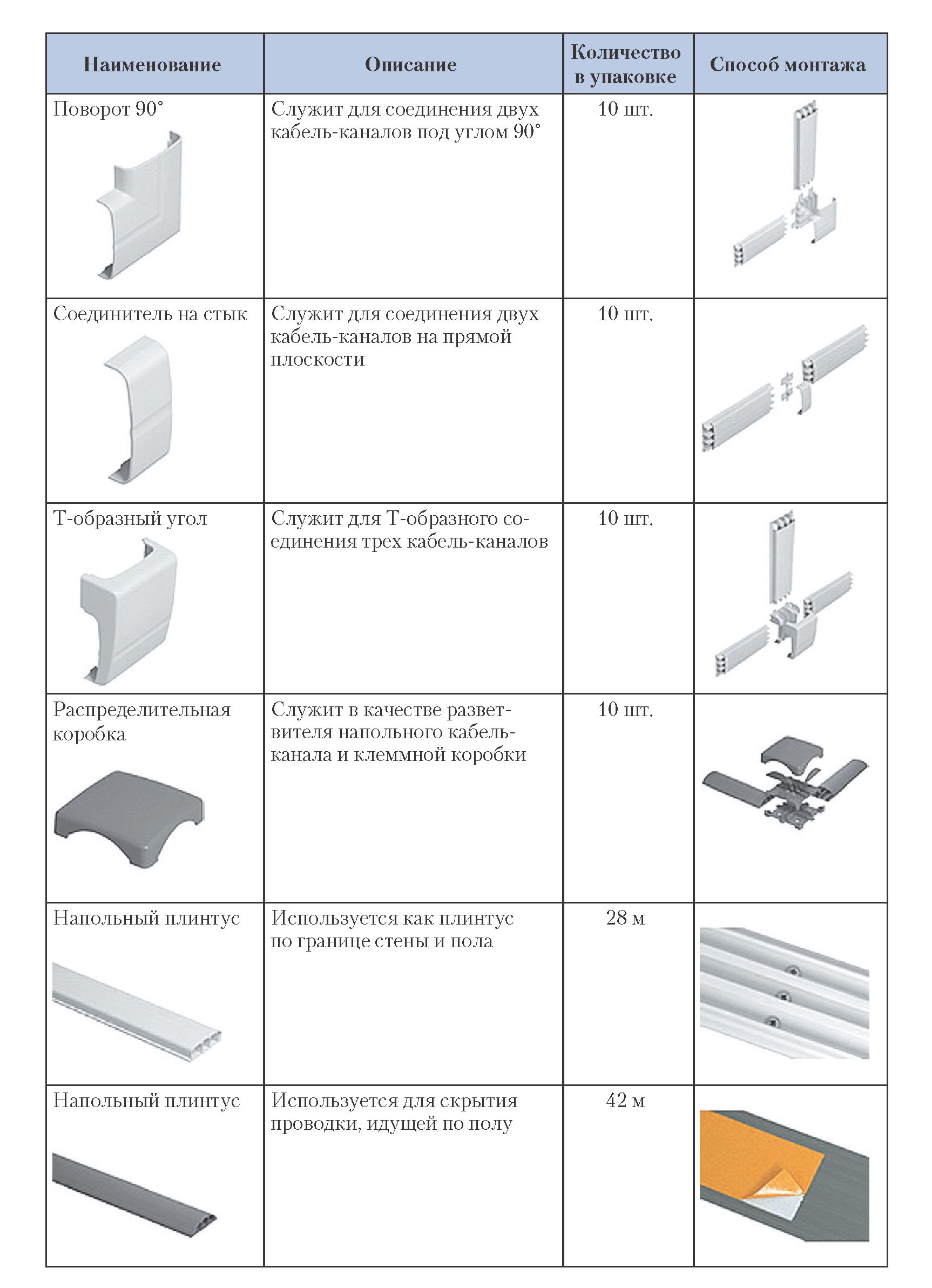

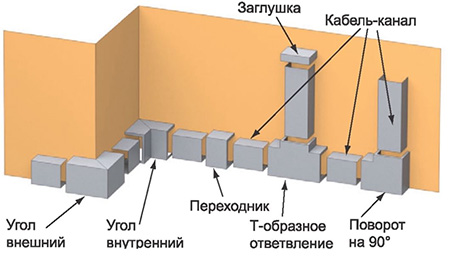

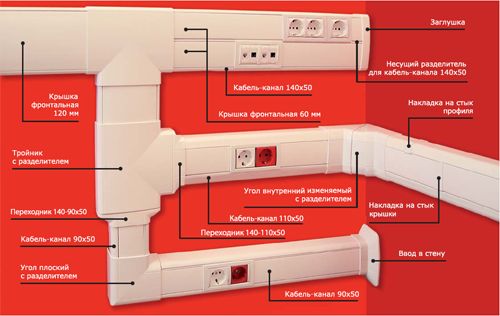

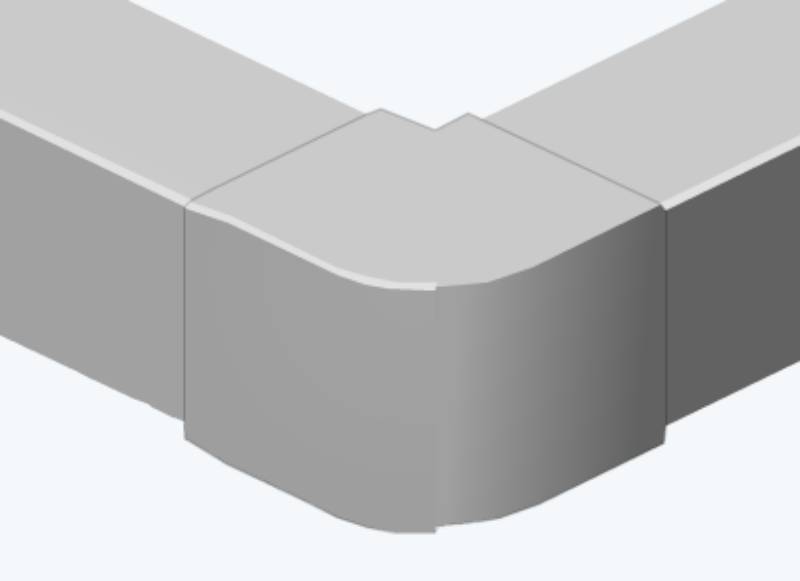

With various accessories, rotary angles, tees and plugs to the cable channel, presented by Table. 5.1 and 5.2, electrical networks of any type of complexity are mounted (Fig. 5.4 and 5.5).

Fig. 5.4. Accessories for cable channel

|

||||||||||||||||||||||||

|

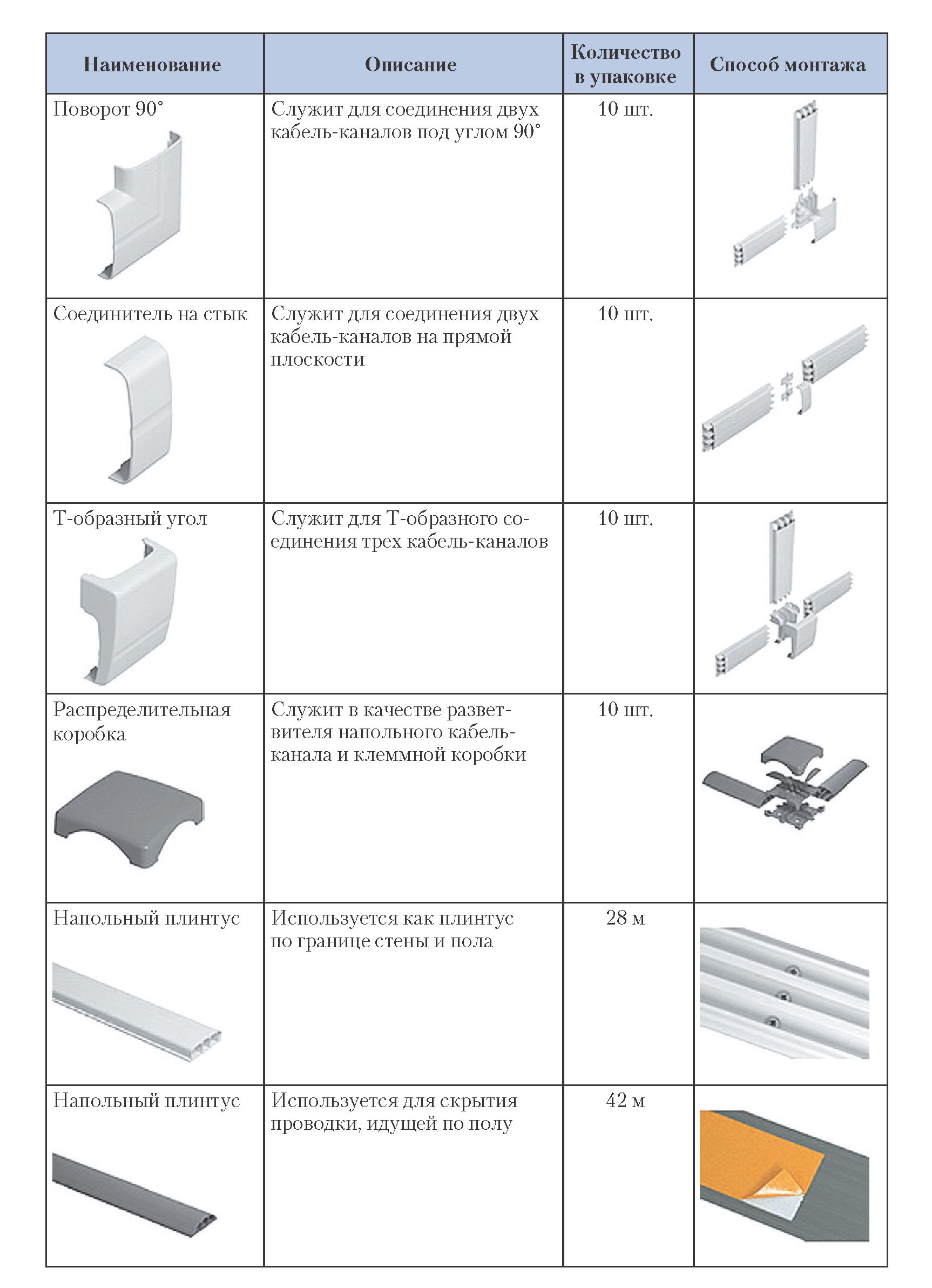

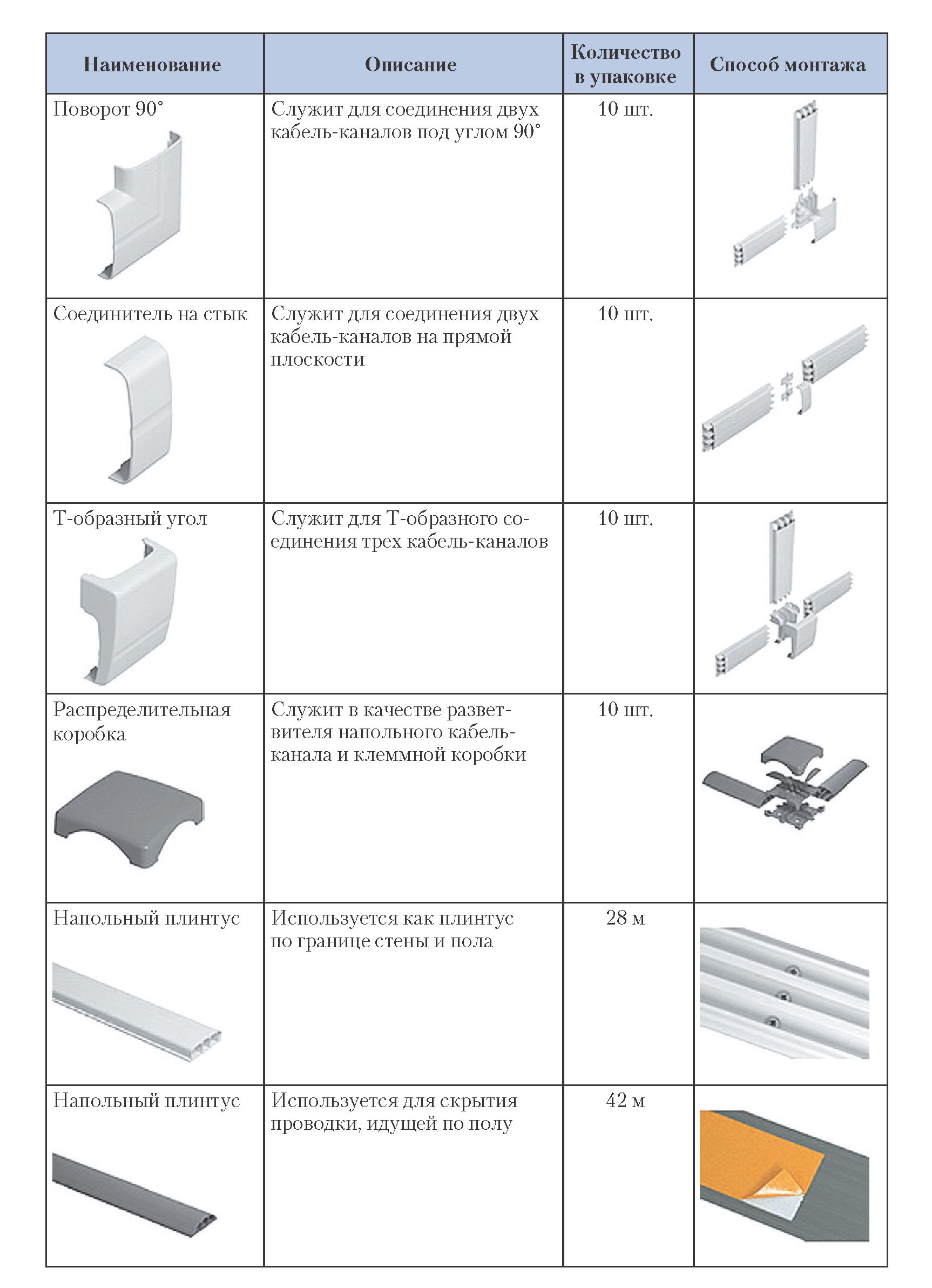

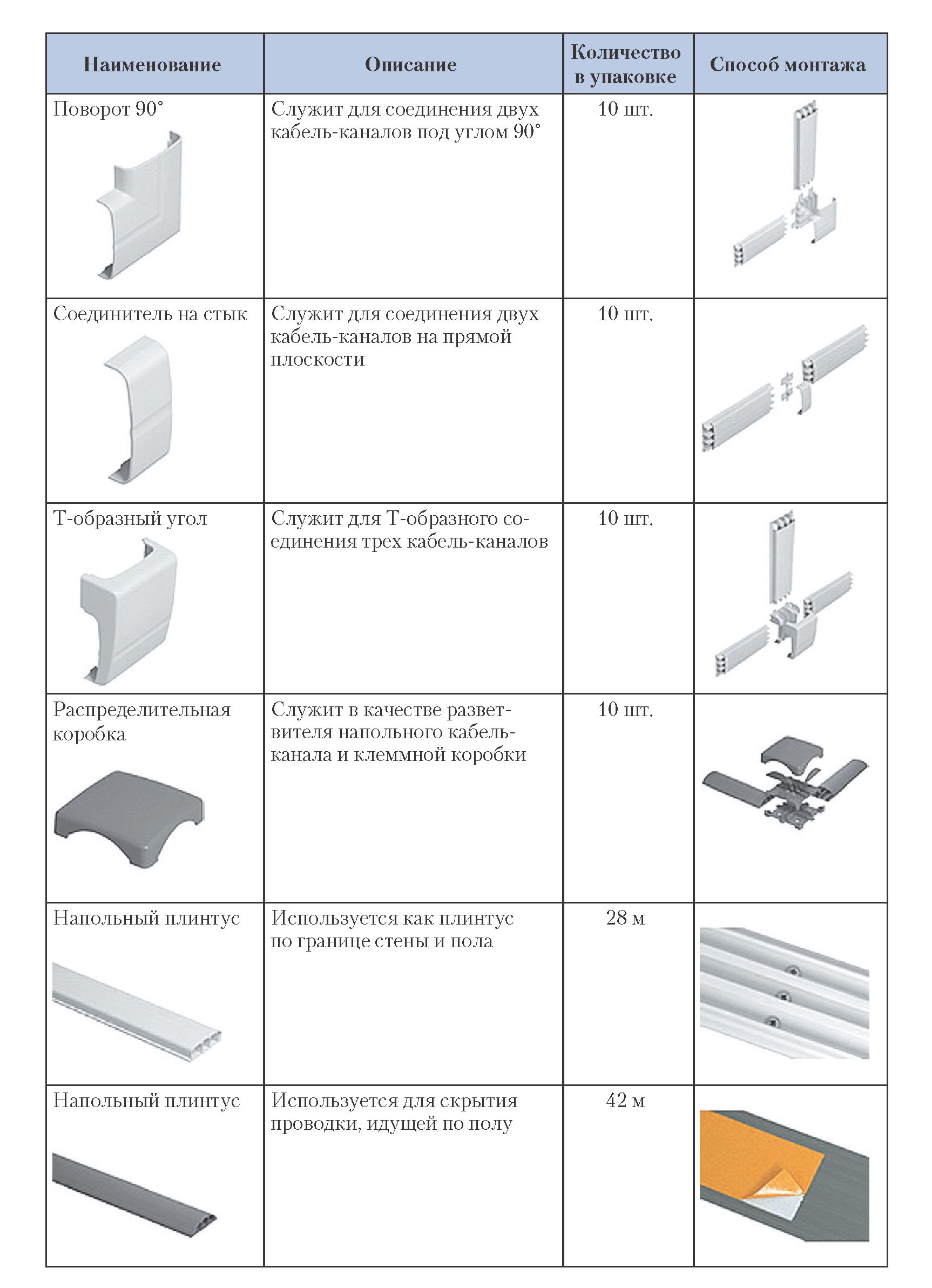

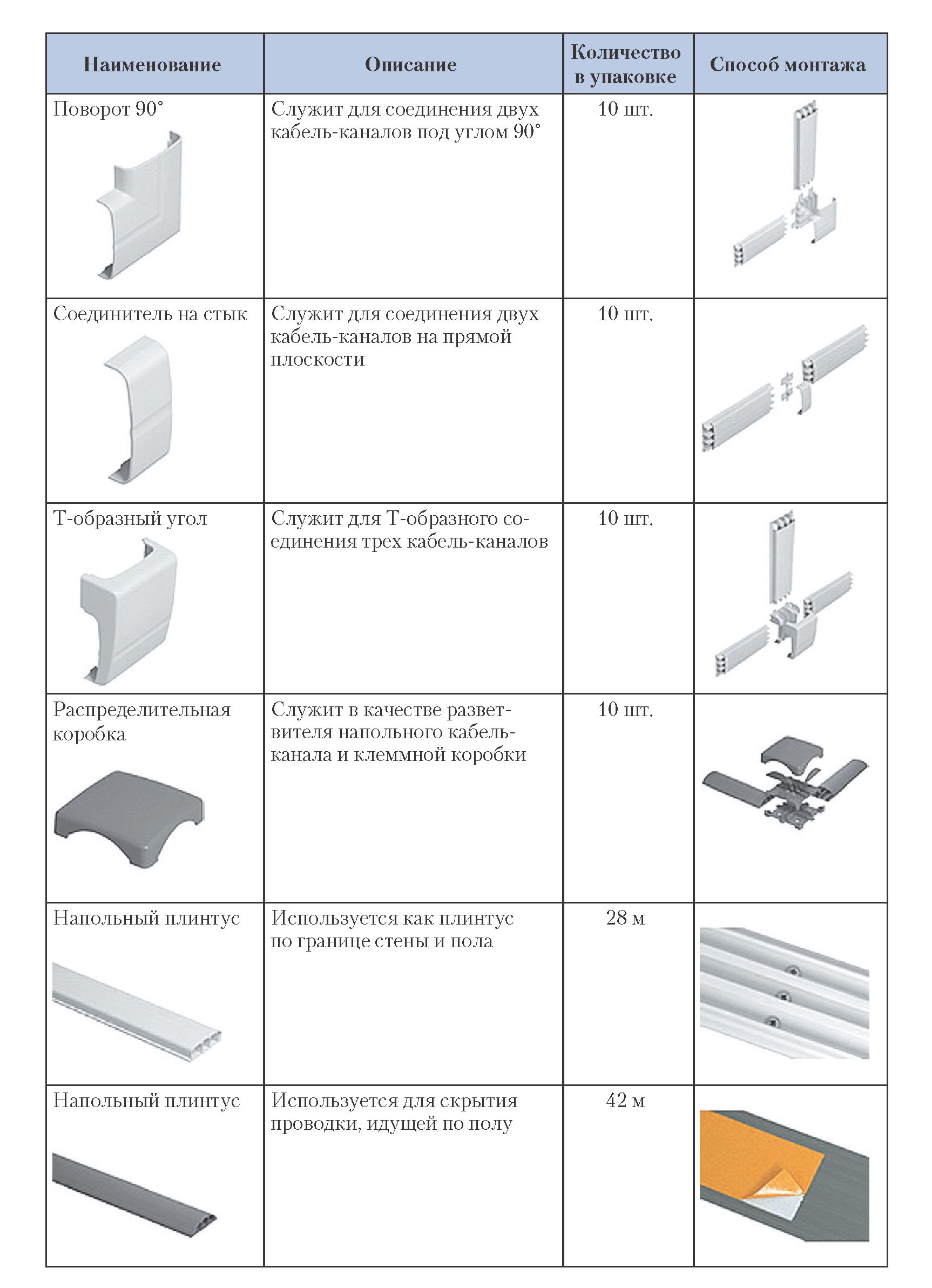

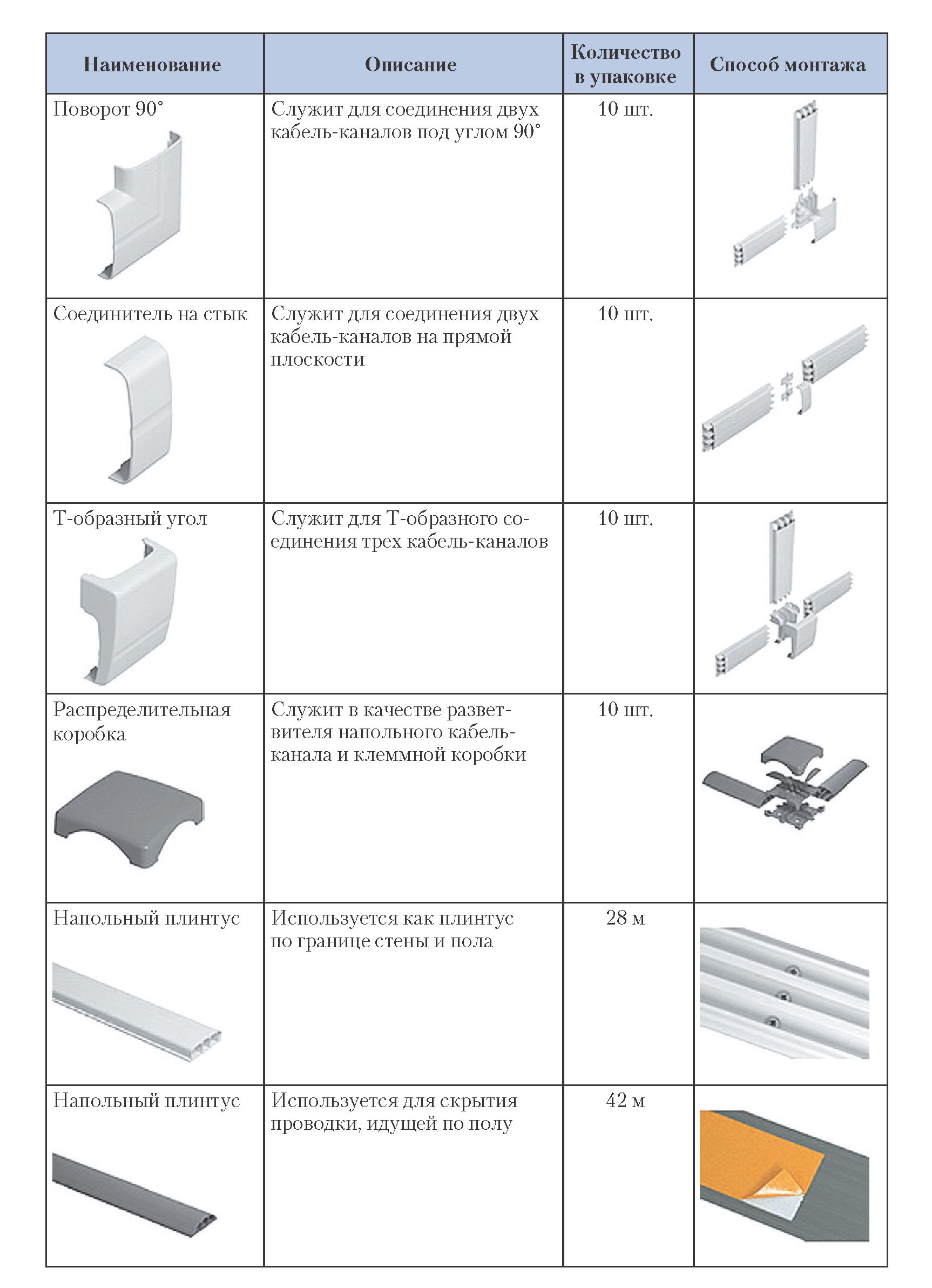

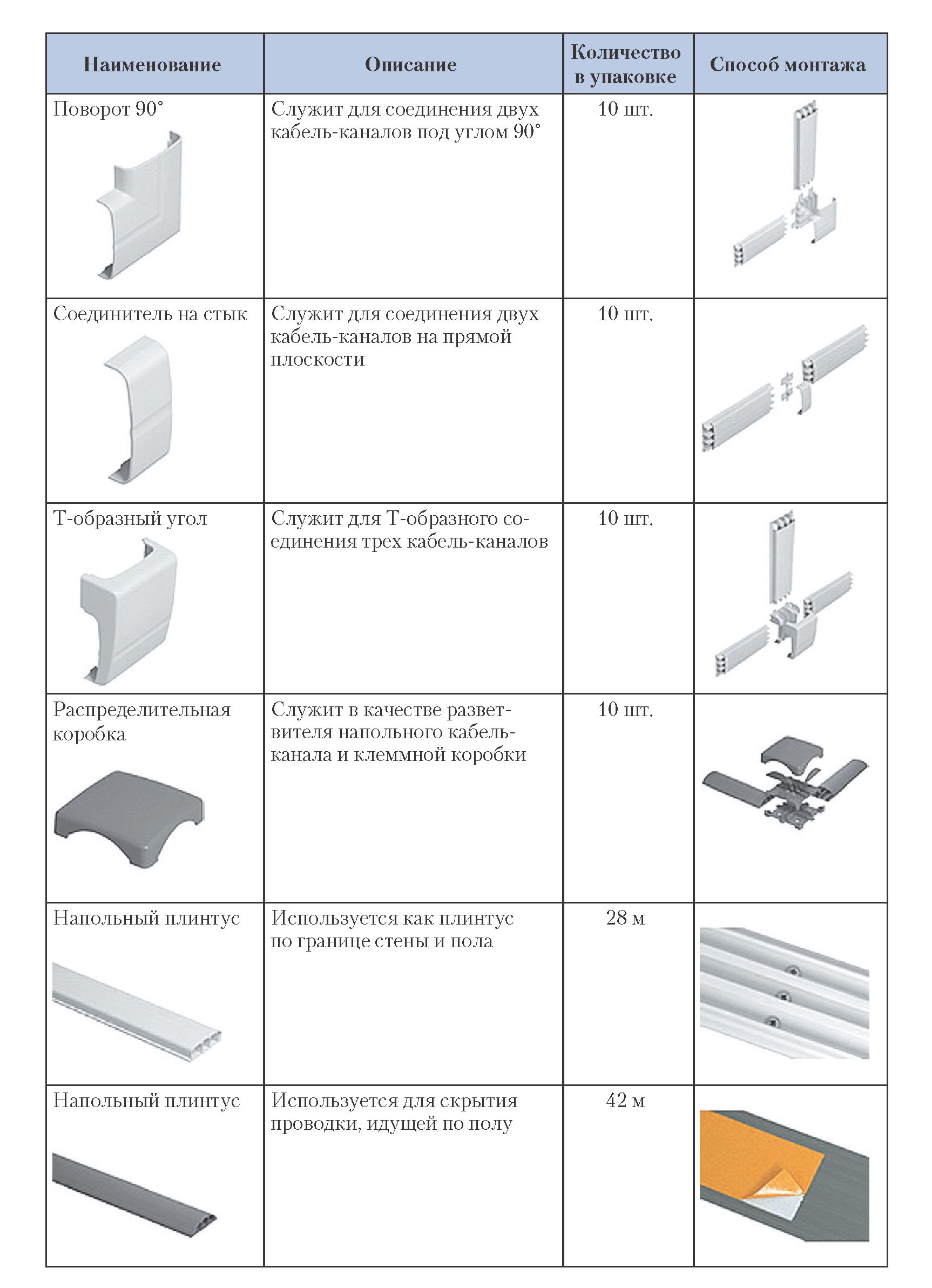

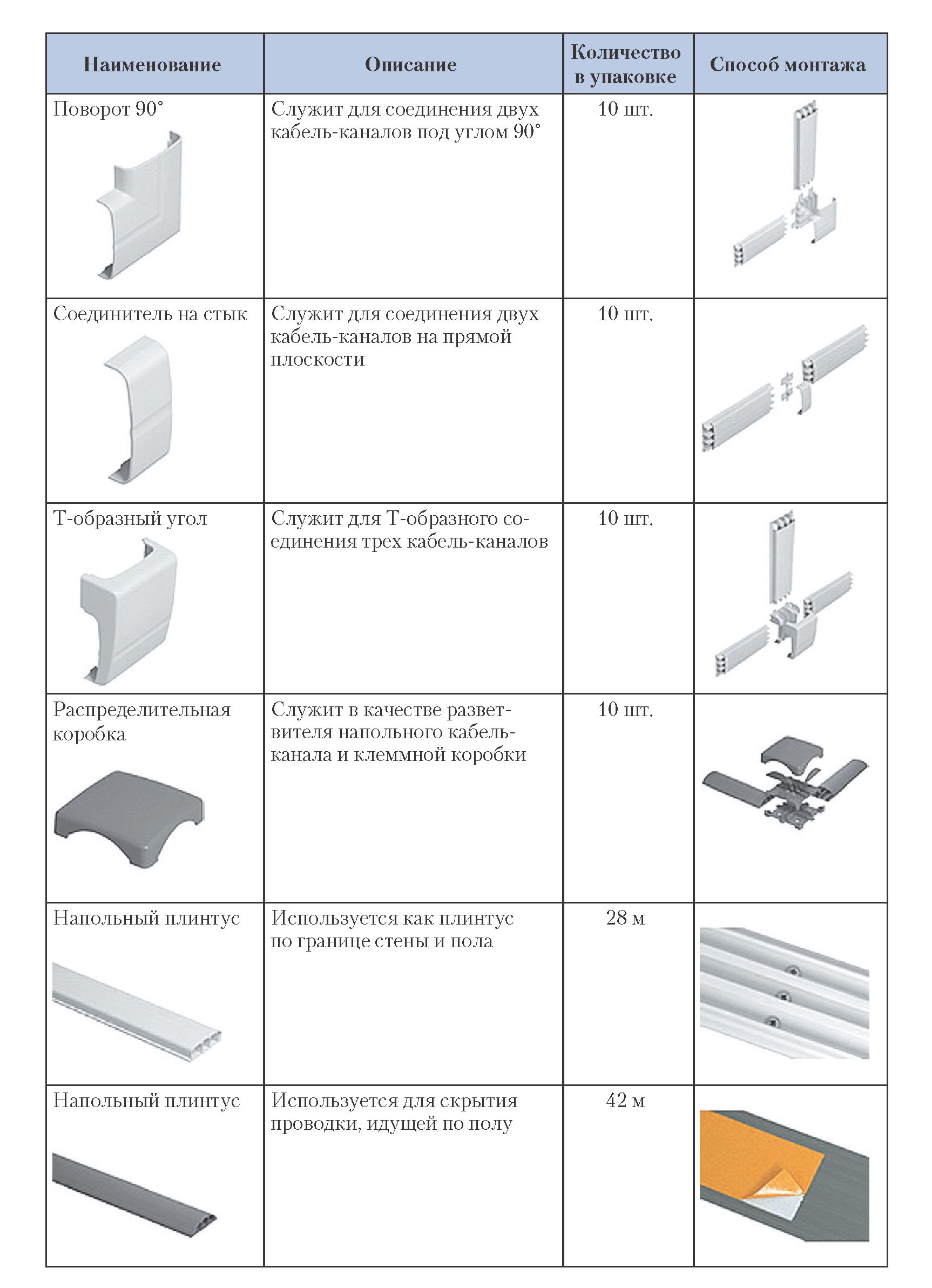

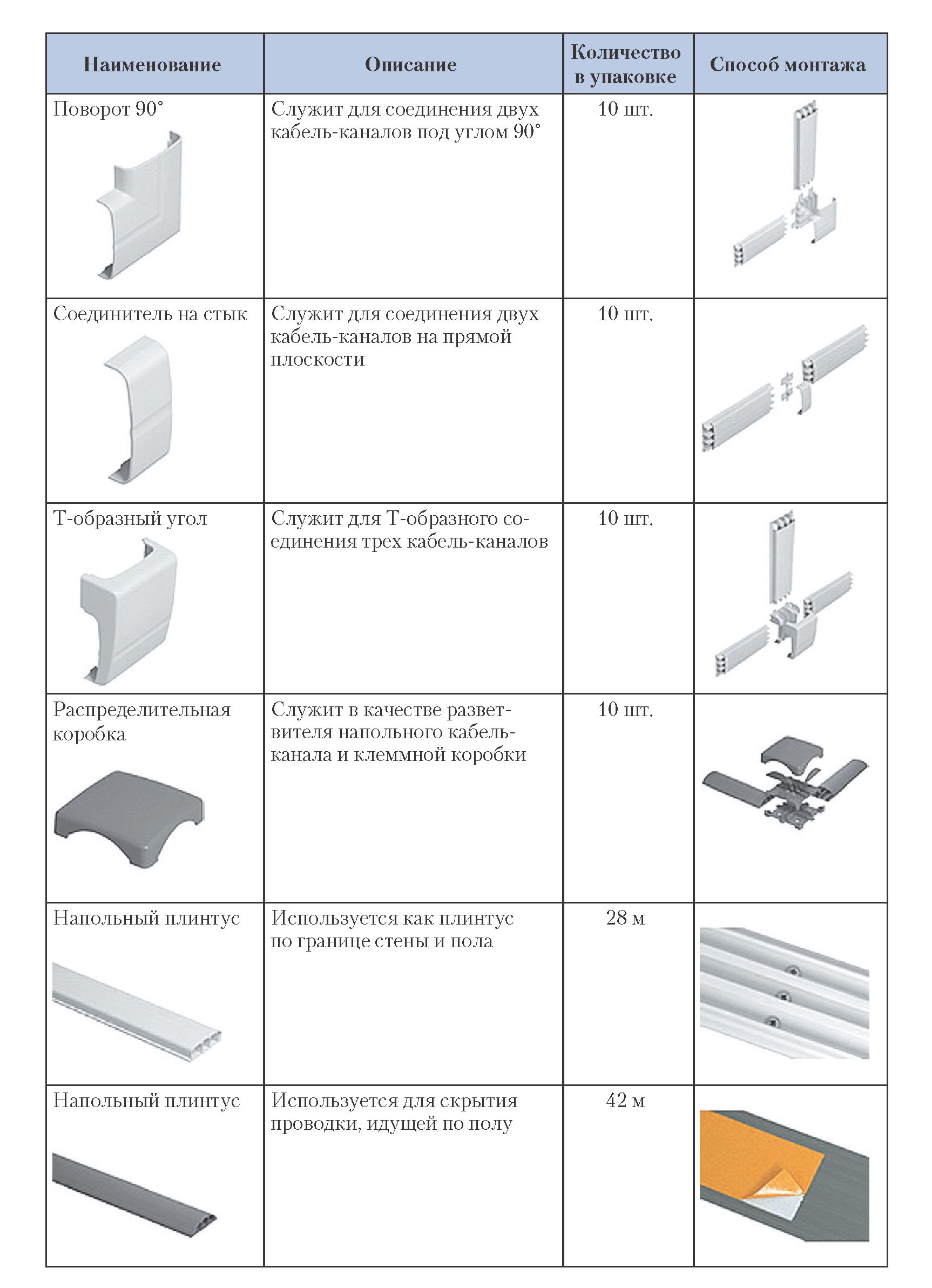

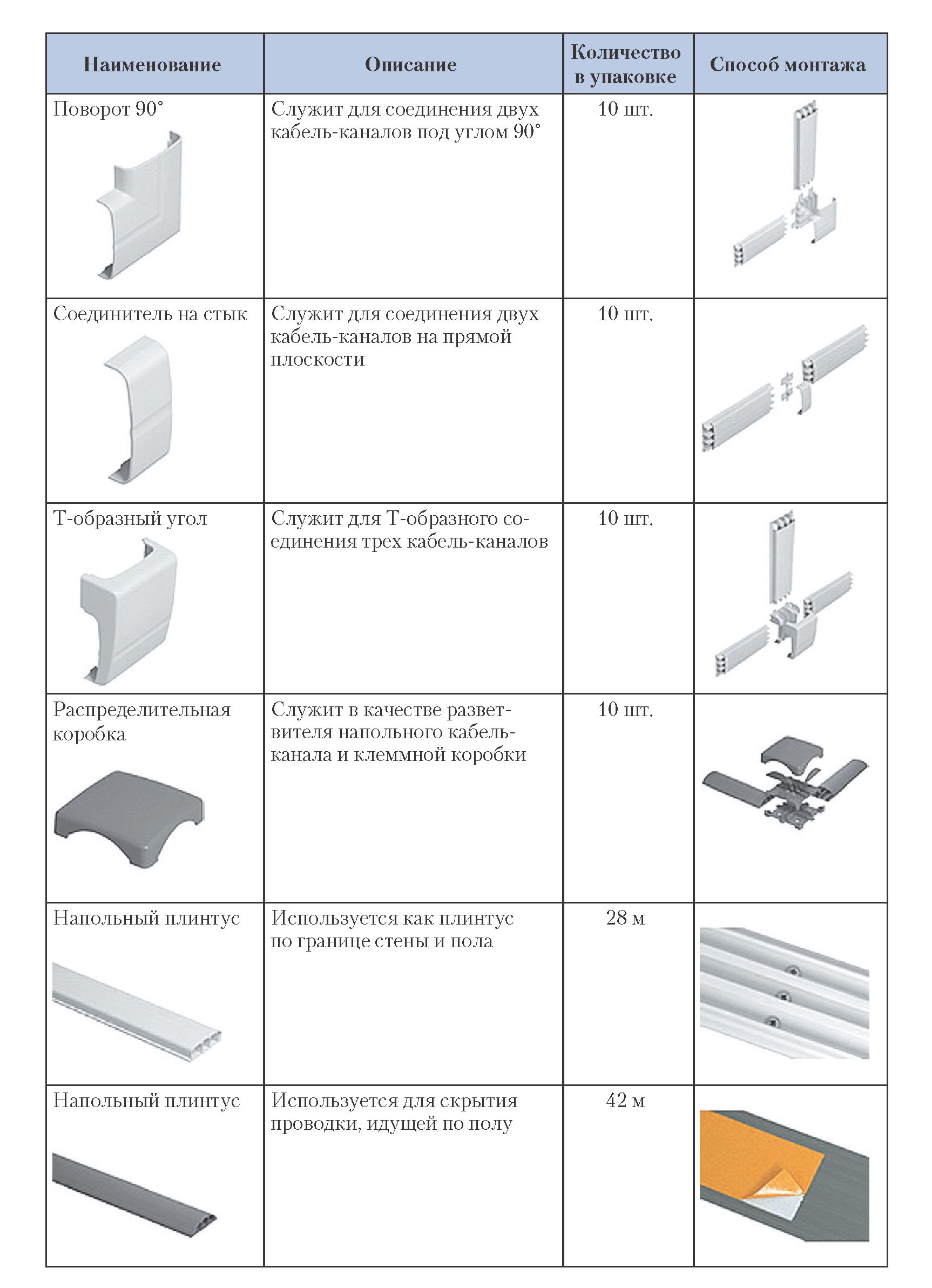

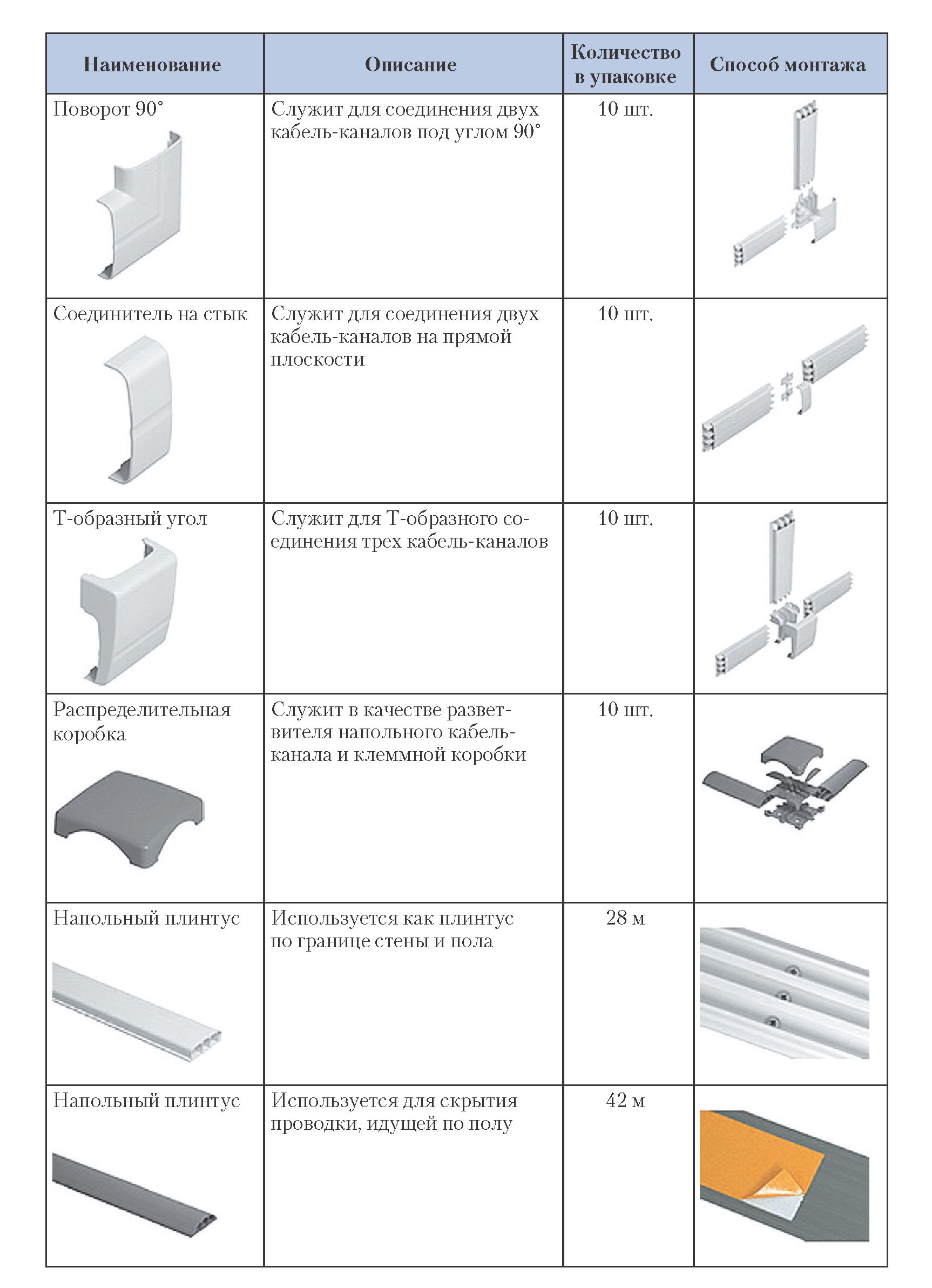

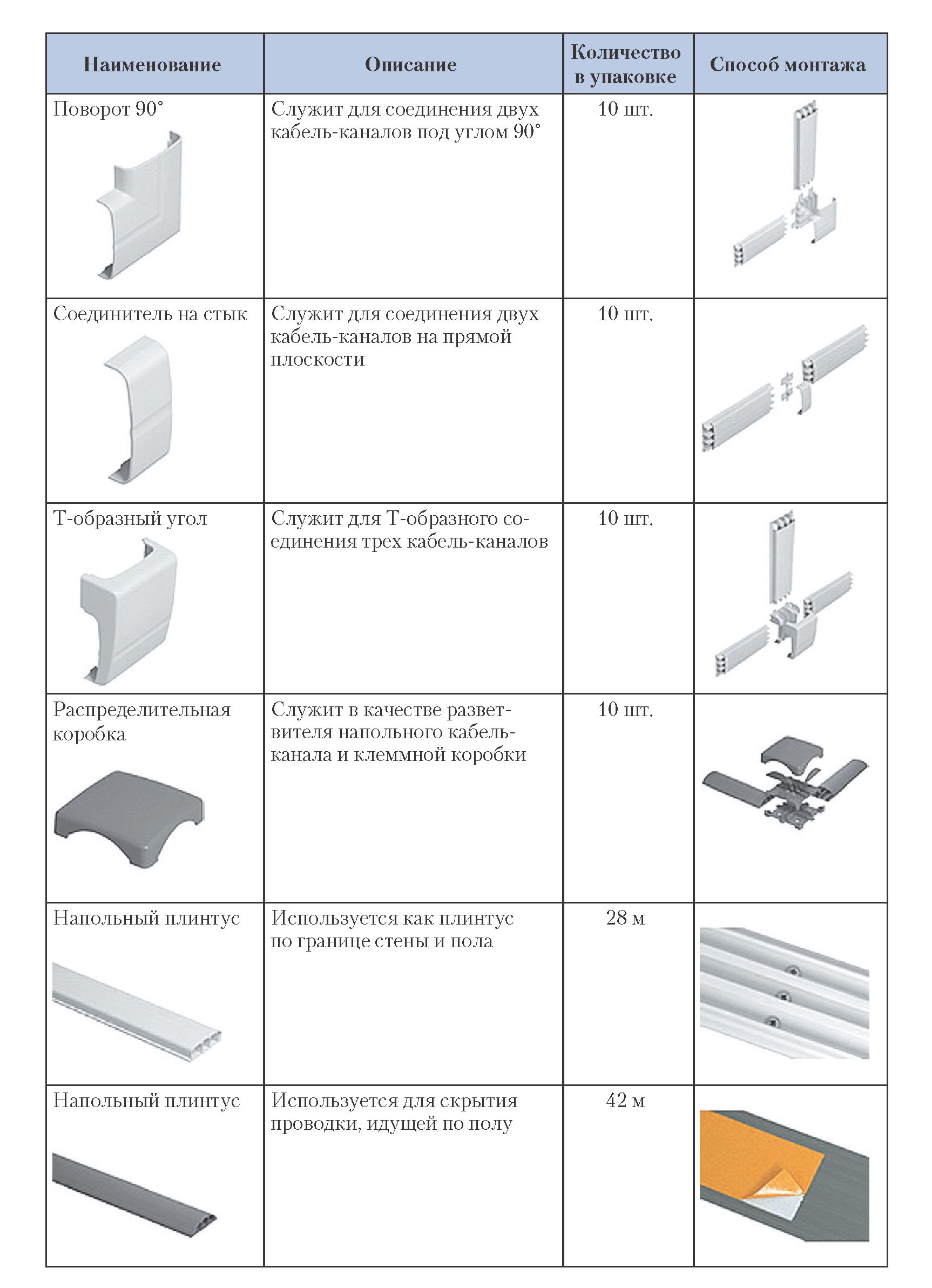

| Name | Description | Amount in a package | Method of installation |

|

Used to connect two cable channels at an angle of 90 ° | 10 pieces. |  |

|

Used to connect two cable channels on a straight plane | 10 pieces. |  |

|

Serves for T-shaped connection of three cable channels | 10 pieces. |  |

|

Serves as a splitter of an outdoor cable channel and terminal box | 10 pieces. |  |

|

Used as a plinth on the edge of the wall and floor | 28 M. |  |

|

Used to hide wiring on the floor | 42 M. |  |

Data on accessories of floor cable channels are presented in Table. 5.3.

In addition to the rotary elements there are special inserts for mounting outlets and switches directly on the surface of the boxes (Fig, 5.6).

In addition to the main types of cable channel there are specialized products. These include outdoor and plinth boxes. They differ in the venue for the channel - along the floor or ceiling, therefore they have a specific shape (Fig, 5.7).

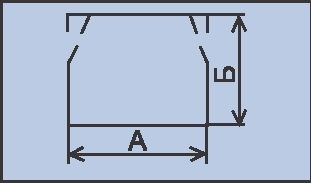

Table 5.3. Assortment of floor cable channels |

|||||||||||||||||||||||||

|

|

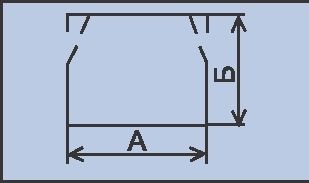

Dimensions a x b, mm | Useful section S, mm 2 | Color | Quantity in packing, m |

|

20 x 10. | 180 | White | 96 |

|

25 x 16 | 360 | White | 50 |

|

25 x 25. | 563 | White | 32 |

|

30/2 x 10. | S T \u003d 135 x S, \u003d \u003d 135 | White | 32 |

|

30 x 25. | 675 | White | 32 |

|

40/2 x 16. | S T \u003d 210 x S, \u003d \u003d 350 | White | 30 |

|

40 x 16. | 576 | White | 30 |

|

40 x 25. | 900 | White | 24 |

|

40x40. | 1440 | White | 24 |

|

60x40. | 2160 | White | 18 |

|

60 x 60. | 3240 | White | 12 |

Table 5.3 (continued) |

|||||||||||||||||||||||||

|

For laying single cables, such as an antenna, there are special plinths that are no different from ordinary (Fig. 5.8). The middle of such a hollow product, covered with a lid. This plinth is perfectly suitable to hide 1-2 wires without installing additional boxes.

Pluses of plastic boxes:

It is not necessary to fulfill labor-intensive work on the stroke and plaster overlaps;

Easy access to the cable;

Metal boxes

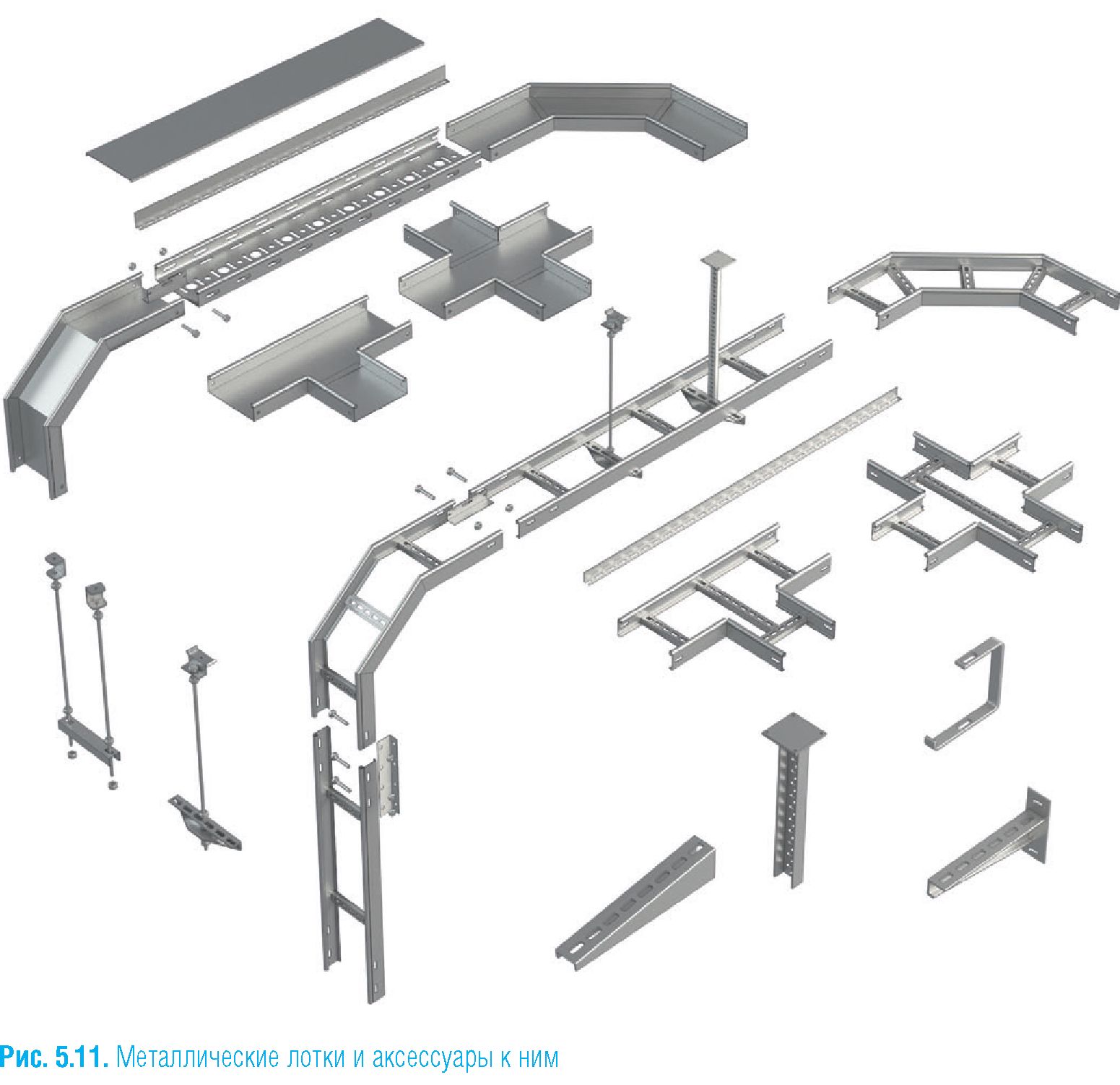

They are also called trays. Since metal boxes are very rarely used in household conditions, they can be briefly described. Designed for cables inside and outside the premises. The main task is to protect the cable from mechanical damage and compose their set in one track. Trays are made of galvanized steel, have the form of a P-shaped profile covering the lid. There are perforated and smooth (Fig. 5.9 and 5.10).

Perforated products are easier, they are easier to assemble with fasteners, smooth are installed on special supports (Fig. 5.11).

Boxes are used when laying power cables in industrial premises, raised floors or suspended ceilings.

Just like plastic boxes, have a lot of accessories for laying turns and fastening them to overlaps (Fig. 5.12). The main dimensions of metal trays are presented in the following table (Table 5.4).

|

|||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||

Corrugated plastic pipes

In addition to boxes there are plastic and metal pipesDesigned for cable laying. This type of product has a wider range of applications. Cable Channel mainly stacked on a flat, smooth surface - it prerequisite For correct installation. Pipes can be mounted almost on any surface, where they can be attached using metal brackets and special clips. In addition, the corrugated flexible tube (or corrugation) can be rotated under any corners or even put twisted.

The corrugation is designed for laying any type of conductors both indoors and outside. Protects the cable from mechanical damage and high humidity, as well as protects people from lesion to the current (Fig. 5.13),

Fig. 5.13. Protected by corrugated wire

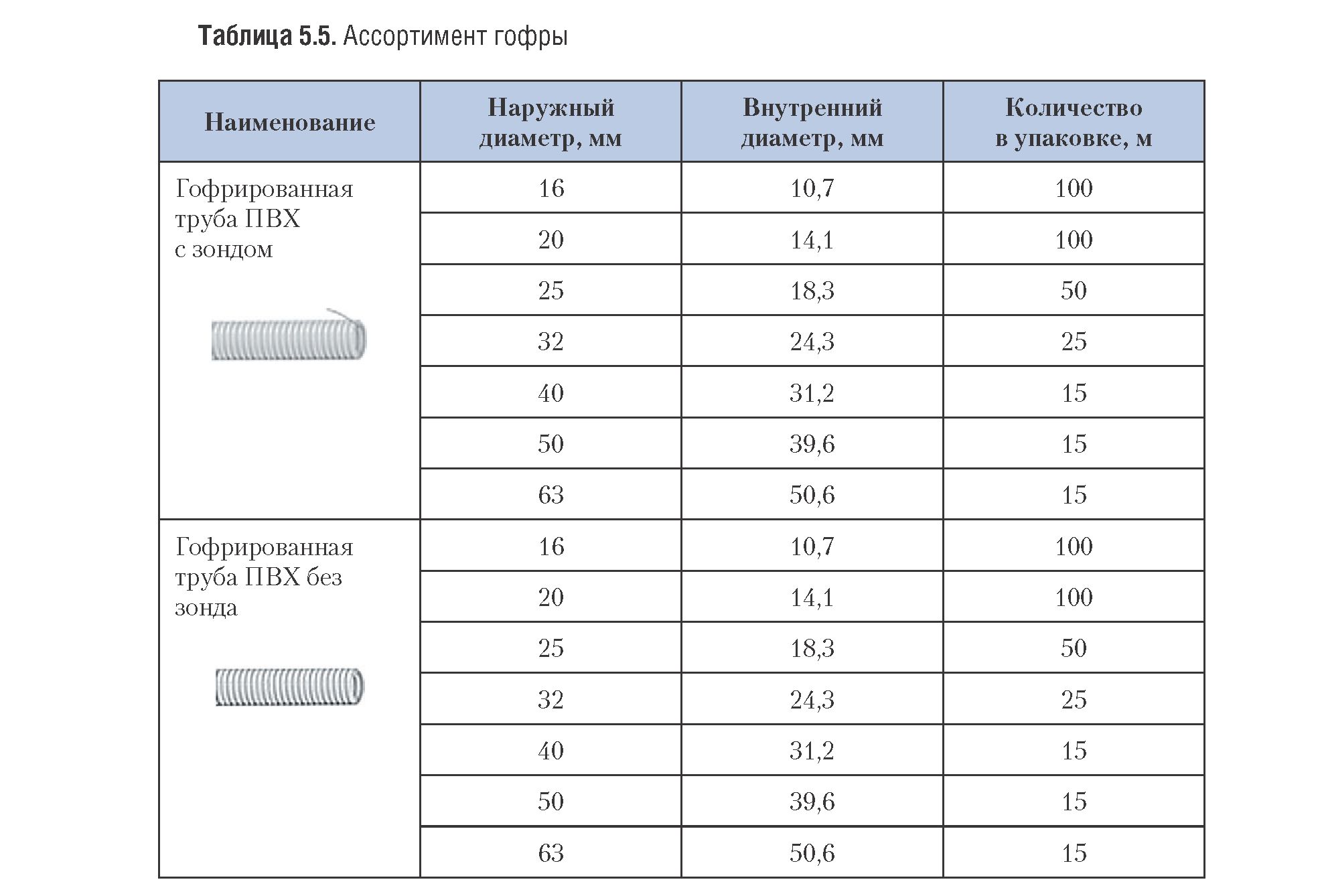

Distinguish light and heavy pipes. The first species is used for the most part inside the buildings. Severe with high strength and moisture resistance - outside (Fig. 5.14). Both the first and second view can be with a steel probe to pull cables or without it. Made corrugated pipes from non-combustible PVC.

|

Fig. 5.14. Corrugation conducted on the outer wallbuilding |

The diameter of the corrugation ranges from 16 to 32 mm.

Such pipes are stretched in rooms with a complex leakage of overlapping or under suspended ceilings, inside drywall partitions, etc.

ATTENTION!

Light plastic corrugation is easily bursting and breaking on the cold, so do not regret the means - it is better to buy a heavy option for outdoor gasket.

The range of corrugated pipes is visualized in Table. 5.5.

Table 5.5. Assortment of corrugations |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Corrugated metalpipes (metalworkwood)

Very similar to plastic corrugation, but made of steel galvanized tape (Fig. 5.15).

Applied in the same place, where and corrugations (Fig, 5.16).

Main differences - Increased protection against mechanical damage. In addition, when connecting a grounding wire to a metalworker, it performs the role of an electromagnetic screen, which is important when laying information cables.

The dimensions of the metalwork are shown in Table. 5.6.

Table 5.6. Metal worker sizes |

||||||||||||||||||||||||||||||||||||

|

Smooth hard pipes

The second name is PVC pipes. This is a hard option plastic pipe. As it is clear from the name, such pipes made of polyvinyl chloride, non-propagating burning (Fig. 5.17).

Serve to protect and laying wires. They may be closed in plaster, concrete floors, etc. This is extremely convenient, because the wires are hidden, and extract them for repair and replacement is very easy - just pull out the outside. PVC pipes are fireproof, protected from defeat electric shock. Since they do not bend, numerous accessories are used for turns and wiring: tees, rotary angles, couplings and plugs (Fig. 5.18-5.21).

The sizes of the pipes are indicated in Table. 5.7.

Table 5.7. Dimensions of PVC pipes

Outer diameter, mm |

Inner diameter, mm |

Length, M. |

Cambricks

This is a kind of covers - flexible hoses from PVC or polypropylene, which are put on the cable on top of the shell or isolation. Cambrick is used to give a cable more aesthetic type and additional protection or when you need to combine several wires together.

Products for laying cable provide the following mounting options.

The cable channel is attached using the most ordinary dowel-nails of 6 x 40 sizes. If the partition material is a tree or soft plastic, you can fasten the cable-channel screws with screws or just glued.

Metal trays are fastened with the help of anchor clamps, dowel portions and bolted connections. Print trays will not work. In addition, there are sometimes special shelves and brackets for their attachment.

Corrugated plastic and PVC pipes are mounted using special clips, which, in turn, are attached to overlappings using screws or dowel-nails. It is extremely convenient to use this type of fastener, the installation of a finished pipe is carried out by one hand movement. At the same time, it is very easy to remove the pipe back.

Metal bracket is used to attach metalworks, corrugations and PVC pipes. This is a more reliable fastening than a clip (see Fig. 4.59).

Plastic clamp or screed applied in cases where it is necessary to fix pipes on skouring hand (Fig. 5.22). In addition, this is a very cheap and simple method.

Open electrical wiring is much faster mechanically or thermally damaged than closed. To protect it from such factors, a special electrotechnical box is established. There is a wide range of cable channels, species and dimensions of which differ in each other. It helps before installing determine which type of box installed will be most appropriate for residential or industrial premises. Installation Channel cable for electrical wiring and cable tracks allows you to increase the level of fire safety and is distinguished by flexibility and cheap installation.

A feature of the box is the ability to fasten the wires in the upper and angular parts of the walls, gender, ceiling, and even the doors open.

For installation apply the following types of boxes:

- flexible to which sectional, tubular or chain-like;

- hard - most often choose open boxes, with a removable lid or closed plinths.

The installed channels must be durable, elastic, non-combustible and electrical insulating. Therefore, aluminum, galvanized iron or special non-combustible plastic materials are used in the production of wiring boxes (PVC using additives that contribute to the operating plastic). However, some people want to organize wiring with a channel cable similar to the color with natural wood. The manufacturers of boxes took into account this, and began to produce insulating channels with a colors "under the tree".

Coloring "Under Tree"

This color is used in the production of information and power channels. Typically, manufacturers have at least 2 color solutions in their range: a light tree along a linden type or alder, and a dark or red tree, similar to an oak or mahogany texture. So that such a box looks more aesthetically, when installing electrical wiring tracks, special angles and turns with color "Tree" use in the box. In addition, it is possible to use special installation mechanisms, the drawing of which is also performed "under the tree".

Main species

All applicable cable channels are conventionally divided into the following types:

- outdoor;

- plinth;

- ceiling;

- corner;

- wall.

To protect the fiber optic cable, information wiring and other applies a channel cable of a floor-type. Thanks to this room in the room, electrical safety is achieved during redevelopment or organization of jobs.

Cable Channel Outdoor Type

Due to the special design of the channel cable, in case of damage to the wiring, emergency departments are easily accessible. For cable or wires to service racks, cable boxes of an outdoor type are also used. The base of the channel may be metallic materials (steel or aluminum) or plastic, quickly pluming and very durable PVC. Such cables are operated at temperature -15 / + 60 o C. The color solution of the selected cable box can be any, including "under the tree".

Some people prefer telephone, television, computer, electrical power and other wires in their residential or industrial premises were hidden under the plinth with the output at the desired point. To date, the special cable "under the plinth" canal use more often. Besides on the installation of the box by type outdoor plinth During repair work, you can safely save.

Cable Channel "Under Plinth"

Structurally cable channel "under the plinth" consists of several cameras, with which it is possible to carry out separate or informational lines. To organize multiple jobs, it is much better to pave the canal under the plinth, rather than piercing holes in the walls. The wiring hidden under the plinth can be removed anywhere. Thanks to its color "Under the tree", the channel paved is externally, it is very difficult to distinguish from the plinth of the tree. This is one of the significant advantages over other boxes. There are also such types of channels that can be covered with linoleum when the use of the plinth indoors is not provided.

For installation in the corners of the building, the angular cable channels are used, which complement the plinth and ceiling. Corner boxes are domestic and foreign production. Them minimum cross section It is only 10 mm, and the maximum can exceed 300 mm. In one hole of such a box, you can immediately have several wires. In the form of angular boxes are straight and rounded. So, in direct cables of the Czech company Kopos, the length reaches 2600 mm, and the German company Hager cable has a rounded shape and a length of up to 2500 mm.

Cable Channel Corner

Flexible, perforated and parapent box

Flexible, which is called a rolled box in construction, the cable has a hard rectangular shape. The two-way tape plastic channel applied to the sides of the plastic channel allows you to quickly and high-quality installation. Also, the convenience of installing is emphasized by the presence of holes for fastening the box for electrical wiring on the tapping screw. For the production of flexible channel cable, a durable and instantly fading PVC material is used. Color execution can be anyone (white is standard), and

Flexible

its dimensions can reach 18x33 mm, the minimum is 7x12 mm.

The need to use a flexible box is usually in the design features of the walls of the room. If there are irregularities exceeding at a depth of 2 mm, the hard box will look less aesthetically rather than flexible cable channels. For those who want to use the hard box, it is necessary to level the walls that the flexible channel does not require.

For installation, such types of specialized materials are used as:

- flexible chains;

- tubular;

- cast from soft materials.

The high cost of flexible chains is determined by the complexity of manufacture. They are usually used in production for various machines or in the garage. The length of one flexible chain exceeds 230 mm.

![]()

Flexible chain

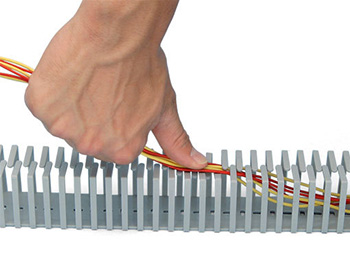

The perforated channel is designed to be installed in the control cabinets and switchboards of electrical wiring. The perforated system allows us to correctly distribute the wires along the type and functional accessory. Such a channel is maximum protection of cables and wires. Perforated boxes for electrical wiring are made from materials that do not contain in its composition halogens. Durable planks contribute to the rapid adaptation of the system to the large number of wires or other electrical wiring cables. Mounting length is 2 m.

Cable Channel Perforated

Using external, flat and inner corner The parapent box is made as accurate and fast installation. The dimensions of the supplied parapet channels usually make up about 2 m in length. The use of refractory, plastic, impact-resistant and resistant negative influence chemical environment PVC is produced according to GOST. The range of operating temperatures of the parapet box is -32 / + 90 ° C, it indicates that in most regions of Russia it can be mounted both indoors and outside. Only the installation itself is better to carry out at temperatures -15 / + 60 o C.

A large selection of good parts allows you to collect the design of any complexity.

Hard cabinet and flexible cable Channels

There are boxes of a metal or plastic case type. For wiring used:

- box without holes for self-tapping screws and without lid;

- box without holes and with a removable lid;

- controls with screw holes and with a removable lid.

Installed metal cable Channels are used for mounting suspended ceilings, raisedps or partitions. Thanks to the metallic, the wiring tray is isolated from electromagnetic effects. Such cable channels differ in an easy installation when the box is screwed to the necessary structures and placed in it. Its fixation is carried out with the help of plastic clamps.

In the presence of special profiled slots, the wiring is better and evenly cooled. Such a cable favorably affects electrical conductivity. Fully closed boxes are used for installation on walls or ceiling.

Ceiling Cable Channel Metal

As for plastic boxes - they are made of PVC, which is in its pure form of flexible, but with the addition of mineral elements it strongly harden. Wide rigid cable channels have several walls for each line. The color solution can be absolutely any, but the application of abstract drawings according to the technology "Photopris" significantly increases the cost of the finished product.

There are hollow plastic boxes under plinth. They are fixed to the wall and closed with a decorative lid with a coloring "under the plinth of wood". The sizes of such a box for cables range from 7x10 mm to 60x100 mm. The main canal has a wall thickness of 2.5 mm, an average is 1.3 mm, and a small one is only 0.7 mm. So that the obtained view was finished, all components are connected by the "long periods".

The channel cable channels are particularly popular, because they protect the wires from absolutely all types of damage. Such channels are applicable in a private house or bath without a steam room.

In contact with

Each residential building is equipped with a power supply system, and its installation is quite commonly produced using a box for wiring. It is convenient, rationally and safe.

1

To hide the electrical cables and wires before was carried out. It was associated with the use of perforators and created certain inconvenience when the power problems occurred inside the house, since it was difficult to find a problem place. I had to disturb the integrity of the wall at a high length. This operation is performed now. When interior walls Houses are separated cement-sandy solutionIt is best for further decoration with decorative species of plaster, make a hidden wiring. But here there is a risk. When there is a need to replace the wires, such a covering of the walls will need to violate. So that this does not happen, all the work should be charged only to those skilled in the art.

Now, in the production of mounting work, a wiring box can be used, which can be made of special plastic, metal and, which is quite rare, tree. Most often, plastic is still used, as it is easier in the installation, has an aesthetic look, is easily cleaned from dust and dirt, does not require additional coloring or processing other means. Any box, whether plastic or metal, is installed on the already decorated wall, under the ceiling, under or above the plinth. Otherwise, the type of such wiring will not look like aesthetic.

The boxes are a rectangular design, for a device of several branches from the central wire, special additional elements are used. The fastening of these boxes, depending on the material of their manufacture and sizes, is carried out using nails, adhesive compositions, screws.

2

Metal boxes for electrical wiring are made of high-quality steel, which is covered with a composition of zinc that protects the material from corrosion. In addition to galvanized steel, metal trays can be made of stainless steel, although it will be much more expensive. But the advantage remains at the galvanized metal due to its affordable price And ease in work. The zinc coating is made in the factory conditions, where the product of steel is immersed in special baths, as a result of which the thickness of the protective film from zinc or zinc and aluminum alloy, called aluzink, is formed.

Such products are used when it is necessary to make electrical wiring, where the voltage can reach 1000V. Metal box are produced in various modifications - solid, perforated, single-channel or multi-channel.

Installation of electrical wiring in metal boxes allows you to maximize it from mechanical exposure throughout the service life. It is most convenient to use perforated metal trays that can be as with a lid and without it. In these hole structures are on the side, which makes it possible to quickly enter cables, and if necessary, make a different length of the track, cutting the metal to the existing holes.

In Dn. metal Korobov There are round-shaped holes through which it is convenient to connect corrugated cables, i.e. In a metal braid or cables located in a thin corrugated pipe. As well as cables and wires, characterized by small plasticity, tough.

In addition, the installation of wiring in boxes is convenient, these products protect cables and wires from overheating due to the existing holes, and even from ignition. Metal trays covers are equipped with grounding, which provides complete electrical safety during operation of the energy supply system at home.

3

And yet, despite the best protection against mechanical impact on wires and cables metal boxesThe plastic boxes for wiring are now greater popularity.

They are made of materials resistant to acids and alkalis, fire. As a material for the manufacture of these structures, PVC (polyvihloride) is used, which does not support open fire, and when it occurs, the plastic mass is self-filing. This type of plastic is withstanding a significant mechanical impact, and if it is not specifically trying to destroy it, applying gross strength and tools, the wires in such a box do not threaten anything.

There are such structures with a cross section of different sizes. There are so-called mini-channels, the cross section of which starts from 22x10 mm and reaches 40x16 mm. Microchannels and is less, their width does not exceed 16 mm, and height is 12 mm. In addition to these species, plastic products are made to conceal the wiring sizes of the section from 100 × 40 mm and up to 200 × 80 mm. Moreover, the size of the section 100 × 40 mm or 100 × 50 mm is considered standard and most often used in residential and public buildings.

When fastening plastic trays, it is most often used or bricks, if the installation is made on wooden walls, the screws on the tree are used. In a plastic box, sockets can be installed, which are easily moved if necessary to the desired location of any electrical instrument or equipment. In addition, you can easily add new sockets without any problems if such a need arises. Manufacturers of these structures can offer additional elements and accessories, and the box themselves with separate sections, which makes it possible to divide the wiring to various branches.

If the electrical wiring is carried out by a closed method, then you need to know that under the wires and cables you need to pave a non-flammable heat insulating material, which is mainly used by sheet asbestos. Also, a junction box for hidden wiring is installed. This product is a box of a circular or other form in which holes are provided for the input of the wires. From above the box is closed with a lid. Distribution boxes are made of plastic and using the use of use for open or hidden electrical wiring. The use of these elements makes it possible to connect wires of different highways. In addition, it is here that the first search for all faults in the wiring is happening.

When the device is hidden wiring, it is impossible to allow cables or wires to cross each other. If you need to hold a cable through the wall into the adjacent room, the hole is made, where the pipe is inserted and plastic boxes in both rooms are put into this pipe. After that, the wires are pulled through the pipe and stacked in their places in the trays.

Content:

In some cases, the only option electrical network Speakers. It can be mounted different ways. Plastic boxes for wiring are most popular, the size of which depend on the amount and cross section of the stacked wires. Controls and also known as cable channels. Plastic box and fully provide electrical and fire safety And they look much more attractive metallic and.

How to choose a plastic box

First of all, the sizes of the cable channel are determined. Right choice implies free laying of cables in inner space box a. At the same time, it is recommended to make a certain stock in the case of laying wires in the future. Horizontal elements located at the top along the ceiling must be more those that move vertically to switches and sockets.

It is necessary to calculate in advance and the total length of the boxes. The standard length of plastic box A is 2 meters, so the stock must be taken within 15-20%. This is due to the inevitable marriage and advance planned waste of products. The color of plastic boxes for wires is selected according to its own taste, in accordance with the interior of the room.

Many well-known manufacturers are equipped with plastic box and additional accessories - internal and external corners, tees, transitions, plugs, joints and other elements. Thanks to them, the appearance of the boxes are significantly improved, and the installation work is performed faster. Attention should be paid to the quality of products, it is especially true of locks and latches. The poor-quality castle is simply not able to hold the cover, which will constantly fall out. Sometimes on the contrary, it is necessary to hit the lid too much, why the plastic bursts and the box for wires is unusable.

Preparation for mounting

First, the ceiling preparation and walls are preparing. In the absence of normal geometry, drops and irregularities, the installation quality will be extremely low. Between the surfaces of the walls and the boxes will necessarily appear slits, the box and will be twisted and it will be impossible to align them. Therefore, it is necessary to perform the alignment of ceilings and walls. Direct installation is recommended after completed the finishing of the room.

Before installation, prepare all required tool. Plastic can be cut with a sharp knife or sawing the web. Bulgarian is considered the most efficient and productive. Marking boxes are performed by a simple pencil. The mount is carried out in accordance with the material of the walls of the room. In many cases, structures are simply glued with liquid nails and other types of glue. Laying the cable is made only after complete drying of the glued surfaces.

Channel Cable Fastening

TO wooden walls The box and are attached by ordinary screws, through the holes drilled in advance. Mounting to concrete or brick walls It is carried out by dowels and screws. The box with holes is applied to the wall, markup is performed. Then in the concrete or brick, the holes under the dowels are drilled, the box is screwed down in a screwdriver or a screwdriver.

The desired length of each element is determined by measuring the roulette or by applying it directly to the wall. The horizontal leveling is controlled by the construction level, and vertically - plumb. In some cases, construction corners are used. The lids boxes are cut and folded separately.

Special attention is paid to the joints in the places of transitions from the vertical on the horizontal direction. After the box closed with a lid, there should be no visible slots and other holes. Most problems are solved by using various accessories. Controls involved on angular transitions must be the same size. For T-shaped connections, this requirement is no longer relevant, since in the main channel you can drill a hole of any size under the exhaust cable.

Laying in box and cables and wires

Laying cables in the box A is considered a fairly responsible and time-consuming process. In some designs, longitudinal inner partitions are provided for convenience so that the laid cable does not fall back until the cover closes. It is recommended to lay the entire in advance of the measured cable to the cable-channel. The high-quality lock of the lid must hold the entire staple cable and open under the action of its own weight. Marking must be performed in such a way that there are no coincidence of the joints of the covers and joints of the boxes. In this case, the entire laid line will look like a single integer.

When plastic boxes are mounted and for wiring, the size and ending of their covers is of great importance, especially when there is no accessories. The places of angular transitions and T-shaped joints become problematic, as well as the points where the plugs should be installed. In the absence of plugs, the lid is cut down a little more than the box and fears so that the end is closed. Such techniques act well only in relation to cable channels with a small cross section, the covers of which have weak rigidity.

At the end of laying the cable, you should not stick the lid or sew the box with plasterboard sheets. In the future, it will significantly make it difficult to replace or laying the wires.

Installation Korol A.

There are no cases when administrative and residential premises need to install external wiring. Such a need arises when new electrical appliances are installed in the room or a section of the wiring passing in the wall comes into disrepair.

The stroke of the walls is not always possible or leads to a protracted repair, and in industrial premises there is no need to hide the wires into the wall. A good solution for neat and safe laying of wiring over the walls is plastic box.

Benefits

Plastic Cable Channel, as a differently called a plastic box for a cable, is a fairly successful design of polyvinyl chloride. So, compared to other fixtures or types of laying, the plastic box has such advantages:

- aesthetic appearance;

- variety of colors, which allows you to choose a box to the interior of the apartment;

- the strength of the product that is resistant to shocks and allows you to withstand weight heavy cable;

- fire safety corresponding to the current rules;

- resistance to temperature drops;

- easy installation and maintenance.

Thanks to these properties, plastic boxes for wires are becoming increasingly popular when installing an external wiring.

In addition, the most well-known manufacturers of plastic cable channels, such as Elekor and LEGRAND, complete their products with various accessories, which helps to significantly emphasize and ennoble the design of the plastic box for wires. Elements such as end plugs, tees, internal and external angles, allow you to get rid of holes in the highway and significantly accelerate its installation. Production of PVC cable channels is carried out using modern technologies And constantly improving.

Selection and calculation of the material

In order to make the normal and reliable installation of the PVC-box, it is necessary to determine some details and conditions for the upcoming work.

When planning the installation of the Cable Channel from PVC, the following factors are taken into account:

- Wiring thickness and other cables that will be installed.

- Dimensions of the box for individual sections of the installation.

- The ability to install additional wires and cables in the future.

- The surface material on which the cable channel will be installed.

- The ability to use PVC plinth with a cable channel to locate wires in it, when the rooms are wiring.

![]()

There is a plastic box for wires of 2 m in length and a wide variety of width and height sizes. The form of plastic cable boxes may be the most diverse.

They can be made in the following form:

- rectangle;

- square;

- triangle;

- semicircle.

Based on shape and size, plastic box can be:

- Ceiling type. This product is the smallest size, as it contains thin wires intended for chandeliers or point lamps. Used, as a rule, when laying a new line on the slab overlap. In addition, when installing suspended ceiling From PVC panels, the box is used to spread electricity to fans and luminaires. A good solution is to use a perforated plastic box for placing wires on the ceiling when installing stretch ceilings from the PVC film. The ability to quickly make a side hole in the walls of the box when it is fixed on the surface, significantly saves strength and time.

- Wall type. The wall option serves to bring the wires to the outlets and on the ceiling. For sockets, pretty thick wires are needed that can withstand powerful electrical appliances. Based on this, the corresponding size of the box is selected for them. Conclusion of the wire on the ceiling, it is best to carry out the cable channel installed in the corner. There he will not rush into the eyes, but tastefully selected in color - can harmoniously add the interior of the room.

- Sex type. The floor plastic cable channel completely successfully replaces the usual wooden or plastic flooring. The size here does not have such a value as for wall and ceiling products. The large size of the sex box can be regarded, rather as a plus. In addition, it closes the gap between the wall and the floor, the presence of spare space under the lid, can be useful for subsequent laying in it satellite television cables, alarm or internet.

On a note: Plastic products white color Presented in the largest assortment. They are easy to give the desired color, painting or salaling the film.

Installation of plastic cable channel

Before installation, the channel cable must be decorated with dimensions, quantity and color of products that will be applied during operation.

Project preparation

The design is to compile the layout of electrical wiring, television and optical cables in the room. Based on the thickness of one wire or their beam, the type and size of the box is selected. In the scheme, all these nuances are noted in detail.

- connecting slats;

- internal and external corners;

- mounting PVC boxes for wiring;

- plugs;

- tees;

- fastening material.

When will the required quantity be calculated of different types Box, you can find out the quantity of fasteners. Usually, screws and plastic dowels are used for attachment. The highway is fixed on the surface every 30 cm. You should multiply its overall metrarix by 3.3 to obtain the number of self-tapping screws.

Purchase of material

Before you go to the shop for purchases, it is recommended to familiarize yourself with the product assortment and its prices on the sites of construction stores. This will help save not only money, but also time.

If the purchases have to do in several places, it is better to hire a cargo taxi. So the goods will be in preservation and under control. PVC products in the trunk of the passenger car are not recommended - they can break or scatter.

During the purchase, it is necessary to carefully examine both panels and components.

Attention must be reversed as follows:

- No deformation. When storing parts on short racks or stacked unevenly, they are curved and take an irregular geometric shape that it is impossible to change.

- The presence of mechanical damage. Cracks in products can lead to a breakdown of individual fragments during the installation process.

- Coating condition. It should not be evaporated, shabby or burntown in the sun. Such defects will strongly spoil the general type of construction.

Purchase material with durable walls. You can try the reliability of the lock connection on one of the fragments of the box when inspection - its cover must be gently, with a little effort to remove and, easily, without shocks, closed. The absence of a sharp click says about the quality of the product.

Instruments

The process of the highway device itself, after this process is designed and prepared, represents a fairly simple event. Everything that remains is to prepare the tool.

For work it will be necessary:

- perforator;

- screwdriver;

- hoven for metal;

- stuslo;

- a hammer;

- acute knife;

- pliers;

- pencil or marker.

The set is simple and is in every home. Having collected it and checking the serviceability, you can proceed to work.

Installing Channel Cable

Having in the hands of the project, the material and the desired set of tools, work easily and pleasure.

The stages of this work are as follows:

- Conducting on the surface. The location of the highway is applied, marks for drilling.

- A holes are made in the surface, plastic dowels are inserted into them.

- The case of the box is screwed.

- Wiring and cables are styled. They can fit one or in a bundle using a plastic screed.

- Wired wires.

- Installed sockets, angles, plugs and housing lid.

The work is done.

Video of the Cable Channel Assembly