It is good when the planned budget for the construction of a bath is enough for a beautiful interior decoration, and for a spectacular cladding with foreign siding, and for a smart automated heating system. But what if the boiler room is ready, but there were not enough funds for an expensive imported boiler? In this case, you can make a good boiler for a bath with your own hands: from metal barrel, sheets or pipes. Of course, it will be far from automation, but it will be cheap and cheerful. In Russian, so to speak.

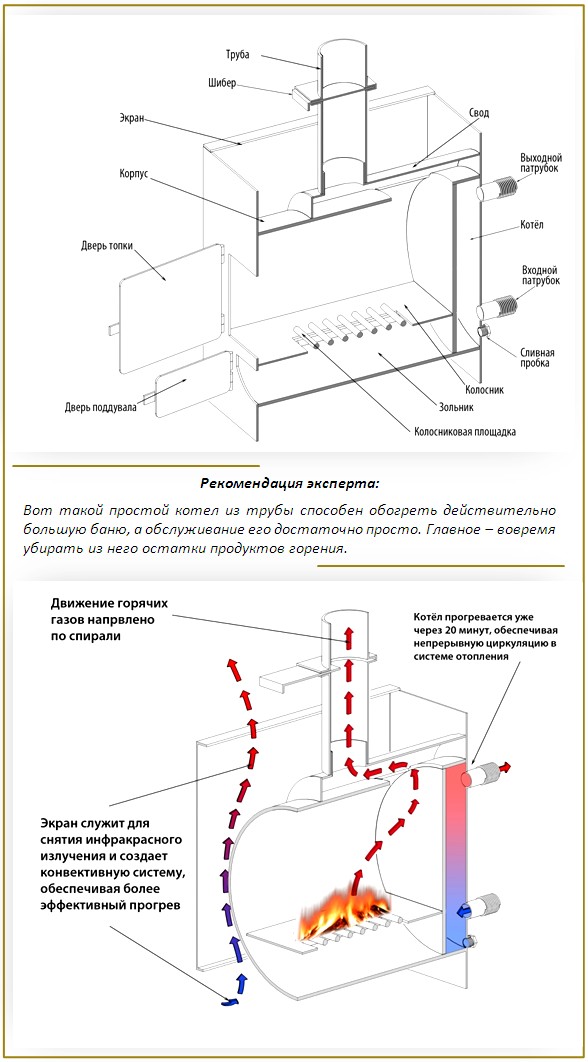

How to weld a boiler into a bath from a metal pipe

The simplest home-made boiler for a bath is made of a pipe, iron or metal. But you can position it both vertically and horizontally - the first and the second method have their pros and cons.

In general, for work you will need a welding machine, an angle grinder with discs for metal and a diesel or gasoline generator.

Horizontal structure assembly technology

The pipe must be laid and plugged on one side - a door is installed on the other. All this is a firebox, into which you can then weld a knee for water. A metal tank is placed on top, and each fresh portion of water, during heating in the knee, will enter the tank, and cold water will take its place. All heating will occur fairly evenly.

A stove should be installed on the side of the pipe - the most common shelf with stones.

Vertical design and its features

But if such a pipe is put on the muffled side and another plug is welded into its middle, the bottom will become a firebox, and upward it will serve as a water tank. The stone shelf itself can be welded on the side.

If the thickness of the metal of the pipe is significant, then it is more rational to manufacture the upper and lower parts of such a boiler separately - due to the overall massiveness of the structure. Moreover, a thin-walled barrel is enough for a tank, then when the bottom needs to be made only from a thick-walled pipe. Moreover, the thicker it is, the longer the boiler itself will last.

And, finally, between the firebox and the tank, you can make a heater, cut out an additional door for it and weld cast iron grate inside. The pipe from such a boiler must be installed strictly in the center, and the barrel itself must be put on it already, having scalded the junction to 100% tightness. In addition to everything in the pipe, it is also desirable to make a damper, which is usually closed after the firewood burns out. By the way, a metal pipe must be released from the boiler, but you can put both iron and asbestos on it. After all, such a combined pipe - with an asbestos top and an iron bottom - is the safest. It should be easily put on metal, because materials always have different coefficients of expansion when heated.

Such simple boilers for a bath with your own hands are a great temporary alternative to an expensive industrial one, which can be bought in a year or two, when it is financially convenient.

The simplest boiler design is based on a barrel

Here is the technology on how to make a homemade boiler for a bath of the simplest design.

To do this, you will need a large, thick and durable barrel from the Soviet era - exactly one that is much stronger than any modern ones. In it, you need to cut out with a chisel or an ax upper part... After that, a piece of pipe is cut off separately to release smoke - by 150 mm. Next, a hole should be cut in the barrel and this pipe should be welded to it.

Now, from another, already ordinary 200 liter barrel, you need to cut out the bottom cover, and in its center there is a hole for a 10 cm pipe. Now is the time to make it - it should be 10 cm in diameter and slightly higher than the height of the barrel.

Then you need to cut off 4 pieces of the channel and weld them to the lid of a 200 liter barrel. And on the other side of the lid, weld a 10 cm pipe.

Now the top cover for the boiler is made from an ordinary sheet of metal and a special hole for the pipe by 10 cm is cut with a chisel - so that the pipe itself sits tightly, but still moves freely. After that, with a clamp, you need to attach the boiler itself to the chimney pipe - but before that, be sure to insulate it with asbestos or fiberglass.

After all this, you can already put 1/3 of the volume of firewood in the boiler - this will be enough for the first check. A pipe with a well-welded lid is placed on top, immediately on the wood - it must be aligned in the center of the boiler so that during the downward movement nothing clings to the walls of the boiler themselves. And already on top of the pipe you need to put on the top cover.

It remains to throw a little kerosene into the pipe and throw a match. There will be no smoke or smell - everything will be drawn into the chimney. And so that the firewood does not burn out quickly, you need to cover the blower.

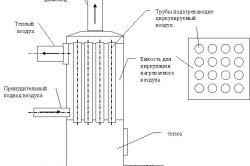

Features of the design of a long-burning boiler

In an ordinary solid fuel boiler, firewood burns quickly - about 2-3 hours. But bath procedures usually take longer, and therefore, so that you don't have to run to throw firewood from the steam room in one towel, there is nothing better than homemade boilers for a bath long burning - it's simple. With the same volumes of firewood, it will burn for all 20-30 hours, and all thanks to the restriction of air intake.

The very principle of operation of the boiler is as follows: through the loading hole, which is located above the middle of the body itself, a batch of firewood enters and is ignited in its upper part. Above the fuel is a limiter, which rests on the wood with a tapered shank. In the course of burning wood, this air supply restrictor slowly lowers to the bottom of the stove and serves as a kind of signaling device for the next batch of fuel to be loaded. Moreover, such a boiler can be heated not only with wood, but also with briquetted peat, coal and fashionable pellets.

To make this boiler, you will also need a thick-walled steel pipe - better with a diameter of 30 cm and a length of 8 m 50 cm.In its upper part, you need to weld a branch from another pipe - with a diameter of 100 mm, and a length of no more than 40 cm.The whole secret of this design is in limiting the combustion zone of the fuel, which compresses the firewood well, and therefore does not allow excess oxygen to rapidly burn fuel. And all this is done by a special device - a piece of pipe of 60 mm, the length of which is greater than the length of the furnace - 90 cm. A special 27-diameter steel disk with an impeller - six arcuate blades - must be welded to the lower end of this limiter. Moreover, the inner diameter of the pipe will be limited to 20 mm in order to limit the amount of air that enters the combustion zone.

The upper part of the boiler must be closed with a removable round cover with a central hole, the diameter of which is slightly larger than the outer diameter of the restrictor stem itself - this will allow it to move freely inside the entire fuel device. But in the lower part of the body, a rectangular hole with a door is made - for periodic removal of combustion products. By the way, there will be much less ash in such a stove, as well as soot in the chimney. But the heat that will be formed during the combustion of fuel will immediately go to heat the coolant with the liquid. Why in the tank - a rectangular parallelepiped - there is a pipe welded to the chimney of the furnace. Pipelines are attached to the tank itself, through which water is discharged and supplied.

That's all the wisdom of how to make boilers for a bath with your own hands - study the drawings, watch the video and feel free to take on the welding machine. Everything will work out!

Bath construction is a rather expensive process. If you purchase all the equipment in a store, then a steam room can cost a significant amount. Therefore, folk craftsmen and simply people who want to see this building on their personal plot tend to equip the steam room with their own hands. Last but not least, this applies to heating devices.

Which is better: take a ready-made boiler to the bathhouse or make it yourself? To solve this dilemma, you need to consider all the pros and cons. hand made and indicate the possible difficulties that may arise during its production. It must be said right away that it is better not to try to make a gas boiler for a bath yourself.

First, a self-made unit can fly up into the air, taking with it a bath.

Secondly, the operation of such equipment is strictly prohibited by safety precautions.

At the same time, a boiler for a wood-fired bathhouse can be made by yourself, if you have all the necessary equipment, and your hands grow from the right place. Wood-fired bath boilers can be made from a metal barrel with thick walls, pipes or sheets of steel. There is no shortage of them in any subsidiary plots.

Any oven, including bath boilers, consists of the following elements:

- A furnace in which the process of burning wood, coal and other fuels takes place. It is made from thick metal. This is due to the fact that the furnace has the highest thermal load, the metal of insufficient thickness will quickly burn out, and the homemade boiler for the bath will become unusable. A wood-burning boiler for a bath, namely a firebox, must be equipped with grates. Through them, the ash from the burnt fuel spills into the ash pan. The thickness of the metal from which they are made must be at least 0.5 centimeters.

- Chimney through which smoke is removed. When deciding how to make a boiler for baths, you need to properly understand the principle of the chimney system and carefully calculate its dimensions. The slightest mistake during the installation of the chimney can lead to insufficient efficiency of the stove (heat will go into the chimney) or the inability to cope with the removal of combustion products. The chimney must be equipped with a damper with which the draft level is regulated. In winter, a tightly closed valve contributes significantly to the preservation of heat in the room. The flue pipe can run through the heater or be part of a heat exchange system.

- Ash pan designed for the accumulation of ash. This boiler element is located under the firebox. In addition to its main function, it is responsible for the air supply, which is an integral component of the combustion process. Making a boiler for a bath with your own hands from pipes, you should carefully calculate the dimensions of the ash pan. It must be able to contain enough combustion products to be cleaned once a day.

- Heater redistributing and diverting thermal energy... It is a built-in or hinged container in which stones are laid. Its volume depends on the size of the boiler and the steam room. A small stove will not be able to warm up the room, and a large one will take too long to heat up. During this time, boilers for water have time to boil, which becomes the reason for filling the room with water vapor. In this case, the steam room will become uncomfortable. The size of the heater and the water tank must not differ. It is possible to make a boiler without a heater, but this is not very convenient. The room will be heated only from the walls of the boiler. In addition, it will not be possible to "add to the park."

- Water tank, which is part of the heat exchange system. Cast iron boilers for a bath with a water tank are the most common solution.

After the main components of the device that gives heat are indicated, one should move on to the main question: how to make boilers for a bath from scrap materials?

What materials and tools will be required to make a boiler

Steam room boilers for Russian baths are made using the following tools:

- welding machine;

- grinders, with a cutting wheel designed for working with metal.

We'll talk a little later about how homemade boilers for a bath are made from a pipe or barrel. First, you should talk about the most common option from sheet metal... In addition to it you will need:

- small pieces of reinforcement and channels - they are needed for the manufacture of internal partitions;

- a thick sheet of metal (at least 0.5 centimeters) - it is necessary for the production of grates;

- pipe with a diameter of at least 10 centimeters;

- awnings for firebox and blower doors;

- tap for the tank.

Talking about how to weld boilers for a bath, mention should be made of the manufacture of a heat-distributing screen. It is best made of bricks. All you need to do is to line the boiler with it.

Barrel stove

How to choose boilers for baths? What material to use for their production?

Such decisions should be made independently, taking into account the availability of component parts. It is more convenient for someone to use sheet metal, while someone believes that it is better to make boilers for a bath with their own hands from a barrel or pipe. They do not differ and can boast of the same heating of water in tanks and the room as a whole. The difference lies in the production method.

In fairness, it must be said that it is much easier to make a boiler in a bath with your own hands from a barrel. This is the most simple construction... All you need is to find a metal container with a wall thickness of at least 0.3 centimeters. Thinner metal will quickly burn out.

It is necessary to make a boiler for a wood-fired sauna from a barrel in the following order:

- The bottom of the container is completely cut out. Instead, a sheet of iron is installed, at least 0.5 centimeters thick. It is necessary to weld the legs to it in advance, which can be made from scraps of a T-beam.

- At a height of 5–7 centimeters from the bottom, you need to cut out a small window (about 20 × 15 cm). The blower door will be installed in this place. It is made from a sawn piece. It is required to weld the hinges and the handle to it, and then install it in its rightful place.

- The second door of the future boiler for a wood-fired sauna is installed 20 centimeters above the blower. It should be much larger than the first (approximately 25x45 cm). Otherwise, the logs will not fit into it.

- The boiler for a wood-fired bath contains grates in its design. They should be placed 5–7 centimeters below the firebox door.

- A stove must be placed above the firebox. The most convenient location is the second third of the barrel. The partition between these sections of the boiler must not be continuous. It is made from channels. The size of the stove is equal to the second third of the barrel. A door is needed in the middle of the heater. Through it, stones are laid and water is poured, if desired, "add to the park."

- A boiler for a bath with a tank can be made from a barrel. To do this, use the remaining third of the barrel. The heater and the tank are separated by a solid partition, the seams are well welded. A chimney pipe should be installed in the center of the tank.

Having studied the drawings of such structures, you can easily build a furnace. This is not difficult. All that is needed to make a boiler for a bath with your own hands is to strictly follow the existing instructions. Before operation, the manufactured sauna boiler must be cleaned from scale and rust.

If desired, it can be painted with heat-resistant paints and varnishes. That's all. A DIY boiler made from a barrel is ready. It can be installed in a bath.

Heating in a bath from a pipe is done in the same way. The only exception is the initial stage. You will not have to cut the bottom of the barrel, but you will need to keep the dimensions by cutting the pipe 1.2-1.4 meters long.

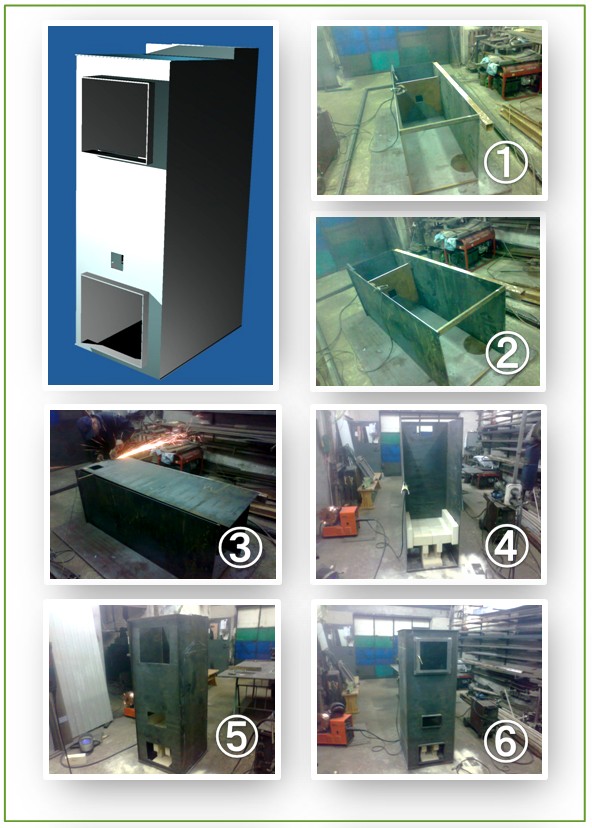

Sheet iron heating device

A similar stove with a metal boiler for a bath is the most difficult to manufacture. This is due to the fact that there will be no prepared workpiece. In principle, such a device is no different from the one described above. It also contains 4 compartments: an ash pan, a firebox, a stove and a tank.

The production of such a furnace will take longer. Especially you will have to tinker with the water tank, which should be practically sealed. But the result is a product that is no different from that produced at the factory.

Horizontal boiler for a bath

Along with vertical heating devices, they are equally popular homemade stoves from pipes and barrels with a horizontal structure. Such products are made simply:

- You need to take a two-hundred-liter barrel and cut several holes in it. Two of them are designed for the installation of a heat exchange tube. It must go right through the barrel. Two more will serve as a blower and firebox doors. The last hole is required to install the chimney.

- A stove can be made in the upper part of the future stove. Part of the barrel is cut off, and in this place reinforcement rods in the form of a lattice are welded. Next, you need to weld the structure of iron sheets in the form of an unfinished inverted pyramid.

- The furnace blank is equipped with legs, after which it must be connected to the chimney and heat exchange system.

Making such a structure is no more difficult than a boiler from a barrel, installed vertically. The disadvantage of this product is that it takes up a lot of space.

Electric heating in the bath

If there is a need to heat only the steam room, then a solid fuel stove is the ideal solution. Otherwise, when you need to heat the dressing room, shower room and other rooms available in the bath building, this option can be safely dismissed.

For heating a large area, it is better to use an electric boiler. Its manufacture and installation do not have any technical difficulties. All that is needed is to weld the water-heating heating elements into a container with water and correctly equip the heat exchange system.

The advantages of electric boilers are obvious:

- there is no need to equip the chimney system;

- ease of installation, operation and maintenance;

- high efficiency.

Along with the advantages, there is a significant disadvantage: significant power consumption.

Installation work

How to install the boiler correctly so that it evenly heats the steam room and possibly adjacent rooms? Boiler installation is a complex task. When installing, take into account:

- The path of the chimney and piping of the heat exchange system. When deciding how to install the boiler, you need to remember that the chimney, like the pipes of the heat exchange system, should not be very long. In the first case, the stove will have a weak draft, in the second, a large volume of water in the system will not be completely heated. At the same time, they should not be too short. This is fraught with “heat escape into the pipe” and rapid boiling of the system. Thus, when deciding how to make a boiler, you need to correctly calculate the dimensions of the associated structures.

- Distance to flammable structures such as log walls... If the boiler has a brick screen, then this problem is not relevant. Otherwise, the distance to the walls must be at least a meter, or they must be finished with heat-insulating non-combustible materials.

- Distance from shops. In a steam room with metal oven it is very easy to get burned. Such a structure is very dangerous, therefore it should be installed at a considerable distance from the shelves.

It is necessary to strictly follow the installation rules. How the stove is installed determines not only the efficiency of its operation, but also the safety of visitors to the steam room. Scheme correct installation heating equipment is attached.

So which one to choose: a self-made oven or a ready-made version from a store? You don't even have to install it. Companies selling such products do their own delivery and installation.

Choosing an acceptable option, one should take into account the expended forces and funds. People weld homemade products, spending money only on electricity and electrodes, everything else can be found in every subsidiary farm. Thus, a boiler for a bath costs "three kopecks".

Making a device from iron sheets can take more than one day. Not the fact that everything will work out the first time. If you want to save money and eat free time, then you can safely start assembling. Otherwise, we recommend choosing an option that is acceptable in terms of power in the store.

Own bath is a dream of many people. Almost anyone with minimal construction skills can build their own steam room. One of the most crucial stages in the arrangement of such a room is the installation of the boiler. Ready-made boilers for a bath are quite expensive. That is why many owners prefer not to spend money on buying ready-made equipment, but to make a boiler for a bath with their own hands.

How to make a boiler into a bath from a metal pipe

The easiest way is to make a boiler in a bath with your own hands from iron pipe... Such a unit can be positioned both horizontally and vertically - both the first and second methods have their own advantages and disadvantages.

To make such a boiler for a bath with your own hands, you will need the following tools and materials:

- Grinder with discs for metal.

- Gasoline or diesel generator.

- Welding machine.

- A piece of pipe about 100 cm long and about 80 cm in diameter or a 200 liter barrel with thick walls.

- Metal circle from 50 mm thick for the bottom of the pipe.

- Reinforcement bars 30 mm long and 14 mm in diameter.

- A circle of metal up to 50 mm thick for a grate.

- A circle of metal 5-10 mm thick for the boiler lid.

- Metal sheet for boxes and partitions.

- Galvanized steel water tank (stainless steel is also suitable).

- Firebox door.

- Chimney pipe section.

The pipe must be laid down and plugged from one end. A door is mounted on the other side. The resulting structure is a firebox, into which a water elbow can be welded in the future. A metal tank is installed on top. Each new portion of water in the process of heating in the knee will enter this tank, and the cold portion will move to the place of the previously heated liquid. The heating process will be fairly uniform.

A stove is installed on the side of the pipe - the most ordinary shelf with stones. It will help to figure out what elements this homemade boiler consists of.

If you install this pipe on the muffled side and weld another plug into its middle, then the top will serve as a water tank, and the bottom will serve as a firebox. The stove can be welded on the side.

If a boiler for a bath is created with your own hands from a pipe with fairly thick walls, then the lower and upper parts of such a unit are more convenient to make separately - due to the overall massiveness of the structure.

A thin-walled barrel is also suitable for a tank, while the bottom can be made exclusively from a pipe with thick walls. The thicker the walls are, the longer the service life of such a boiler for a bath will be.

Between the tank and the firebox, you can arrange a heater by cutting out an additional door for it and welding cast iron grate inside. The pipe from such a boiler is installed strictly in the center of the structure, and the barrel itself is already put on it. The junction is welded to absolute tightness. It is advisable to make a damper for the pipe, which usually closes after the firewood burns out. It is necessary to release from the boiler metal pipe, and you can put on asbestos. This option - with a metal bottom and an asbestos top - is the safest. The upper tube should slide freely over the lower tube, because these materials have different coefficients of thermal expansion.

Such boilers for a do-it-yourself bath are a wonderful temporary alternative to a finished factory product, which can be purchased in a few years - when there is money for it.

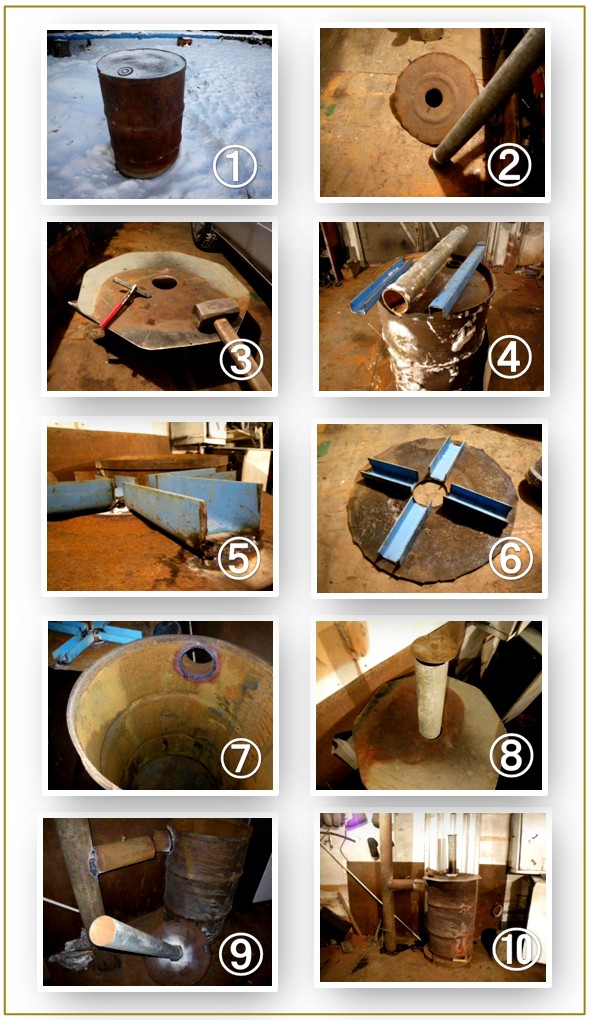

How to make a boiler for a bath from a barrel?

An excellent heating unit in the bathhouse is made by hand from a barrel. The technology is extremely simple and straightforward. To do this, you need to get or buy a strong barrel with thick walls.

It will help to figure out how to make a boiler based on a barrel. And on the next one you can see photos of each stage of work.

First, you need to cut the top of the barrel with an ax or chisel. Further, for the smoke to escape, you need to cut off a piece of pipe separately - by 15 cm. Then a hole is cut in the barrel, to which the prepared pipe is welded.

Now, from another 200 l barrel (even a thin-walled one is suitable), it is necessary to cut out the bottom cover, and in its center make a hole for a 100 mm pipe. The height of the pipe should be slightly higher than the height of the barrel.

After that, you should cut off 4 pieces of the channel, and then weld them to the barrel lid. On the other side of the lid, a ten-centimeter pipe is welded.

Next, the top cover for a homemade boiler is made from an ordinary metal sheet. Using a chisel, a special hole is prepared for a pipe with a diameter of 10 cm. Then the boiler is connected to the chimney through a clamp. Before this, insulation with fiberglass or asbestos is mandatory.

After that, you can put about 1/3 of the volume of wood into the boiler - this amount is quite enough for the first check. A pipe with a securely welded lid is installed on top, immediately on the wood - it must be aligned in the center of the unit so that when moving down, nothing clings to the walls of the boiler. The top cover is put on top of the pipe.

It remains only to splash a small amount of kerosene into the pipe and throw a lighted match. There will be no smell or smoke - everything is drawn through the pipe. To prevent the wood from burning out too quickly, you need to cover the blower.

How to make a long burning boiler?

In a simple wood-burning boiler, the fuel burns out quite quickly - in about 2-3 hours. But bath procedures, as a rule, are delayed for a longer time. Therefore, it is much more convenient and more rational to install a long-burning boiler. The same volume of firewood will be consumed in 20-30 hours due to the restriction of air intake.

The boiler works according to the following principle: firewood comes in through the loading hole located above the middle of the unit body and is ignited in its upper part. Above the fuel is a limiter, which is supported by a tapered shank. In the process of burning firewood, this air supply limiter is lowered into the lower part of the stove and acts as a kind of signaling device for the need to reload the next batch of firewood. You can get acquainted with the structure of such a unit.

To make a long-burning boiler, you need a thick-walled steel pipe. A product 85 cm long and 30 cm in diameter is suitable.A branch is welded in the upper part of the pipe, which is used as another pipe - up to 40 cm long and 10 cm in diameter.

The upper part of the boiler is closed by a round removable cover with a hole in the center. The hole diameter should slightly exceed outside diameter stopper stem. In the lower part of the body, you need to prepare a rectangular hole and install a door - for periodic removal of combustion products. During the operation of such a boiler, much less soot and ash is formed. The heat generated by the combustion of wood is immediately used to heat the coolant with the liquid. For this, a pipe is installed in the tank and welded to the stove chimney. Also, pipelines are connected to the tank through which water supply and drainage will be carried out.