Modern technologies Offer different options for flooring. One of them is a floor covering on the lags. Let's find out what lags are and what their advantages are, and also get acquainted in detail with the peculiarities of working with them, starting with the selection of tools and calculating the number of materials and ending with the installation and heat insulation of the floor.

- The floor is warm.

- The noise of the neighbors does not penetrate the apartment below.

- The cost is quite acceptable.

- I can master the installation with your own hands.

- Under the floor on the lags you can hide ugly, but the necessary wires and pipes.

- The work will accompany the pleasant smell of the treated tree in the apartment.

- Paul on lags is the most environmentally friendly of existing ones.

Lags are bars used as a support for a hard floor or roofing. Lagges are made of metal, reinforced concrete, polymers, but most often from wood. The reason is simple: working with wood easier, its price is an order of magnitude lower. The difference of floors on the lags of different types - on the service life until overhaul. Under standard conditions wooden lagows designed for 40 years, iron - by 80, for concrete time is not limited.

The most practical wooden lags for the floor are made of coniferous wood.

The humidity of the bars intended for the establishment of the floor according to the standard is 18-20%. Before laying them, they are impregnated with an antiseptic from pathogens of different types of rot and covered with flame retardant, reducing the danger of fire. It can be mounted after complete drying.

Lag size and quantity calculation

The perfect size of the bar for lag is 50 x 50 mm, with a length equal to the width of the room. When using rectangular bars, the desired ratio of the width to height is 1: 2.

To simplify the work with your own hands, lags distribute 60 cm from each other, that is, the width of the insulation matte. This laying on top is sewn with a thickness of 30 mm thick.

If the upper floor covering has a different thickness, the distance between the lags changes. To calculate it, we use the following formula:

L - clearance between lags in cm,

LD - floor thickness in cm.

Now with a simple arithmetic action, we consider the number of lag required for durable sex:

room width: distance between lags +1 extreme.

Thus, with a width of a room equal to 5 m (500 cm), and the distance between lags, equal to 60 cm, the final amount will be 9 pieces.

500: 60 + 1 = 8,3 + 1 = 9,3

Pay attention to the following nuances:

- When using a bar of a rectangular section, it is put on the edge: so it will be less warmed.

- In the absence of bars of the desired length, the existing ones are spliced \u200b\u200bby connecting them to all over. When laying, it is necessary to ensure that the joints are not located on the same line.

Tools for mounting

The list of tools is very small:

- Level.

- A hammer.

- Drill or screwdriver for wrapping screws.

- Knife for cutting waterproofing or insulation.

Consumables

From materials will be required:

- Slices of plywood or chipboard of a small size (to regulate the floor in terms of level).

- Insulation. Bulk, sprayed or rolled.

- Self-tapping screws, dowels or anchor bolts.

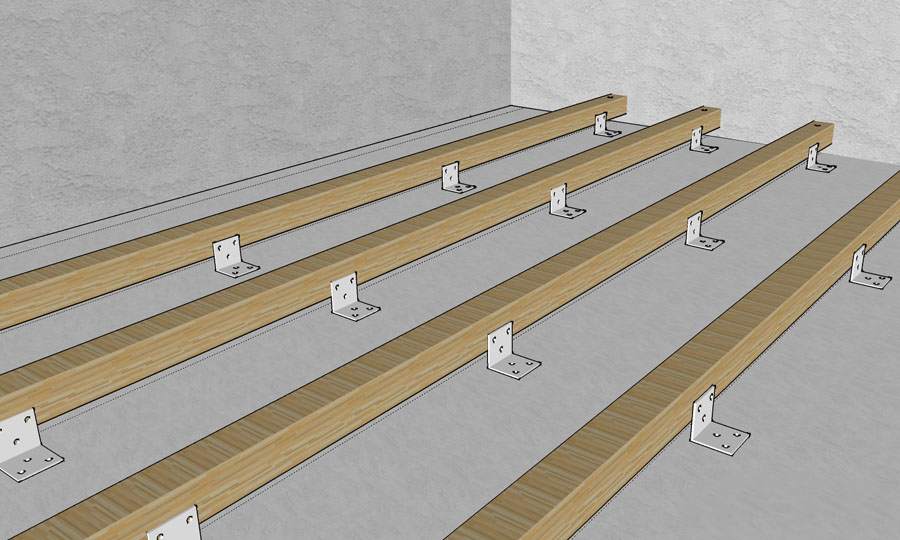

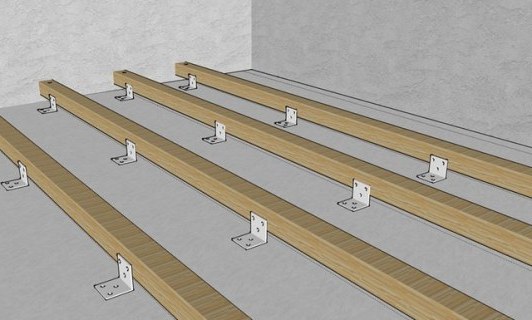

- Corners or P-shaped fasteners.

Preparation for mounting

The procedure begins with a large mess device with their own hands, that is, from dismantling the old floor.

- Fully release the entire area of \u200b\u200bthe floor.

- Check the old screed. All exhausting pieces removed, cracks will be extended. Swimming up for detecting cavities under them. Detected - open and clean up to solid monolith plates of overlapping.

- Garbage and dust carefully delete, better with the help of a vacuum cleaner. The apartment must be clean.

- Further eliminate all the found draft floor defects. First fit them and wait for the primer absorbed and dry. Cement-sandy solution Fill out the flaws with a common surface. Also suitable for the finished repair composition sold in construction stores. After burning with the ground again.

- Using the level, calculate the most high point Surfaces in the room. We make a mark - it will be a landmark for future works.

Pouring tie.

There are two options for further work.

- Make a screed, simultaneously withdrawing the surface in one level.

- Store logs into the level using plywood layers of small size.

The screed is very desirable to do in any case. The question is how much strength and money will need.

- If the difference in the base level is small, then the fill with a solution is more profitable. With the right hand, the lags are placed directly on the floor.

- If the difference reaches 5 cm and more, then the coupling makes the three-stage and the installation of the lag is made on the substrates from the chipboard or even on the bars.

When the screed has surrendered and drew strength, we continue the arrangement of the floor. On top of it, we spread the polyethylene film or waterproofing material. The joints of the joints glue the scotch.

The smell of the basement often penetrates the apartment on the first floor. To prevent such an attack in the future, the screed is additionally processed by bitumen, diluted diesel. Three days will have to wait until the smell is weathered. But on long years You will forget what smells from under the floor. By the way, this solution is a powerful antiseptic.

Stage Installation Lag.

We proceed with the installation of lag for the floor with your own hands.

- One-piece or connected bars lay out the width of the room. The first and the latter are located at 20-25 cm from the wall. The distance between the lags was calculated before.

- Now the most responsible moment is the removal of the floor level with their own hands. The quality of the finishing coating depends on it. All bars must be in one, strictly horizontal plane. To raise, we use linings from cropping boards, plywood or bars of the desired size.

- Need reliable. To do this, use powerful self-tapping screws or anchor bolts. The length of the mounting step is 60-80 cm. We select the drill, in size, the corresponding screw diameter. Drill the timber, capturing the concrete base. Spin self-tapping.

There is another way to achieve perfectly smooth floor - setting the lag on adjustable bolts. Turning them, we achieve the desired result.

If the floor coating for the floor will be used ceramic tile Little size, the distance between the bars must be reduced to 30 cm. In this case, transverse lags will also need at the same distance. Their attitudes in one level with the longitudinal bar of the corner, apply and the P-shaped profile. Such an increase in the design is caused by a small tile size.

Insulation

The next step is the laying of the insulation, which is also. There are several types of insulation on sale:

- Bulk insulation for gender. It may be clay, wood sawdust, eco-tree, vermiculitis. Low price, thermal conductivity and environmental friendliness provide him with great popularity. But it requires a good rambling when installing.

- Spray insulation. The process of applying such a insulation is quite complex. Special equipment will be required, expensive components. But if you have the necessary skills, you can carry out this operation with your own hands, while at the same time removing the problem of noise, hydro and vaporizolation. Such a heater penetrates the most hard-to-reach places, forming a solid mass.

- Rolled insulation. Mineral wool, foam, polystyrene foam. Such material is convenient when heating the floor. It is unfolded or rolled right at the overlap, adjusting the size so that it fill in the entire space between the lags.

If we talk about building buildings, it is already more often used by foam concrete, gas-silicate blocks, bricks and a stone, in the field of floors of floors, as before the most popular wood materials remain. Most often, lags for floor are used for the device of multilayer systems from wood, they are made of durable wood, there are also plastic options on the market.

Why are the lags so popular?

This material is really very popular, and all with such properties:

- Lags have high thermal insulation characteristics. Under such a design, you can even install an additional heat insulating layer;

- Affordable price. Compared to other materials for the design of the floor, lags are considered a budget option;

- A light weight. Thanks to this characteristic, the load on the foundation, beams or concrete slabs will be low. When installing lags under the floor, a free place is formed, in which you can pave communication;

- Lags allow you to raise the plane on any required level. This material quality fell in love with designers, because it allows you to create multi-level floors;

- Simple and fast installation. If we compare the installation of lags and laying a mixture of cement and sand, where you need time to dry out the material, then the time difference will be several times. Also, the installation of lags can be made independently, which will help to save not only time, but also money;

- Thanks wooden semi, Inside the construction you can create an optimal microclimate.

The material of this type allows to significantly save on leveling work. The fact is that the lags themselves perform leveling functions. Free space under the floor will be an excellent ventilation channel, which increases the service life of materials. In order for the floor from the lags to serve even longer, the masters recommend treating wood materials with special antiseptic means.

LAVA design

It is worth noting that you can make the floor on the lags with any place indoors. It may be a simple land, the beams of overlapping or concrete plates. The design in all these cases will be almost the same only with minor changes that mainly relate to the elements of the attachment.

If we talk about the design of the lags and their manufacturing materials, these are peculiar materials on which the finish flooring From wood. Most often, the lags are also produced from wood, but there are plastic materials on the market. Less popular, but no less functional are lags from concrete or metal. But wooden and plastic materials are still more convenient in the installation and are less.

Some craftsmen instead wooden bar For lag, dual boards are used, and these elements are placed on the edge. In terms of reliability, such boards will be no worse than the usual timber, but if we use the wood of a large cross section, the quality of the design will be very high.

Before those who want to build a private house, It is a very important question of the strength of such a design. You need to find out how to choose a cross section of a bar and other nuances. Experts argue that for right choice It is necessary to take into account the characteristics that relate to the structure of the floor as a whole. Here it is necessary to take into account the span, so the area of \u200b\u200bconstruction, the thickness of the boards and other factors are of great importance. But what should be exactly in standard values \u200b\u200b- the ratio of height and width of a wooden bar. It should be 2 to 1.5.

It is also necessary to pay attention to the location of the ventilation gap. An indicator The distance between the clean floor and the heat insulation layer between the lags should be at least 2 centimeters. Specialists say that this indicator ideally should be 3-4 centimeters. Therefore, buying lags should be taken into account this characteristic. If the floor covering is installed on lags, under which only the soil, then it is necessary to take into account the dimensions of the cranial bar, which is installed below and provides the desired rolling.

Some experts say that you need to buy a timber with a secting reserve, this will reduce it if necessary. But it should be understood that it is very difficult to reduce the section yourself, only the master can cope with this, so it's better to buy materials exactly in size, and to align the lining.

In the case when the lag construction is suitable for the soil, specials can be used for alignment in the plane brick columns. It is best to use a red brick M100. Silicate brands can be used only if the groundwater is at the level below 2 meters.

When installing lag in columns, the most important nuance is to determine the distance from one row to another. Also, each column of bricks need to make a small foundation for 40 square centimeters.

How to choose lags

People who have not previously worked with such structures can experience difficulties already at the selection and purchase of materials. To make a choice correctly, you must take into account several factors at once:

- Room dimensions, boards thickness and span size. There is one important rule - the wider step between the beams, the more the cross section of the bars is necessary.

- Standard for which the ratio of height and width of the bar is determined. The height should be 2, and the width is 1.5. So, if you use a ram with a height of 100, then its width should be 70.

- To make the ventilation gap, between the floor and the thermal insulation layer should be a bit of place. We have already talked about the fact that experts advise to make a gap for 3-4 centimeters.

- When buying a bar, special attention should be paid to its size, because it is very difficult to correct the secession.

We choose the material lags

In this question, it is necessary to be guided by its own preferences and a combination of materials with one or another basis. Today, floors from the board, plywood or OSB are usually used.

If you apply to Paneur, it should be at least 12 millimeters wide, and the distance between the lags should be around 30 centimeters. When using OSB, the width of the material should be 18 millimeters, and the step should also be equal to 30 centimeters.

The most popular material is a tipped board. Coniferous trees are usually used, because they have excellent performance characteristics. In general, it all depends on the purpose of the room, and now there is even a special classification:

- Coniferous woods are used for premises with low load;

- Aspen and Olha applied in a children's room and a bedroom;

- For rooms with high load on the floor, it is best to apply oak boards;

- The Siberian larch is applied in bathrooms, because it is durable, and does not rot from elevated temperatures and high humidity level;

- The universal option will be pine, with proper laying and proper care it is suitable for any premises.

Base

An important point is the type of base for lag structures. Materials are stacked directly on the ground, wood, reinforced concrete or bricks.

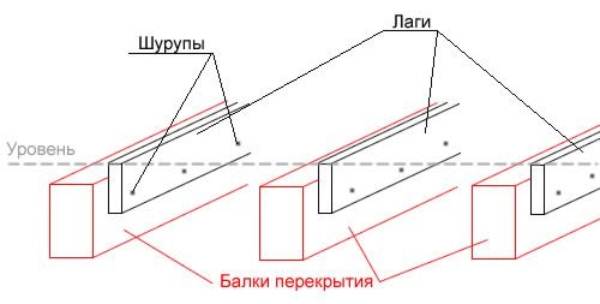

Wood

It is difficult to count on the fact that the beams will be smooth, therefore the surface is unlikely to succeed. The timber is attached on the side of the wooden beams. Incomplete screws are used as fasteners, the length of which is 2.5 times higher than the width of lags. Specialists advise apply screws with a diameter of 6 millimeters. When the distance between the beams is too large, you can equip one more layer of lag.

Concrete floors

Before starting the installation of lags, it is necessary to provide structures waterproofing. It is also necessary to ensure protection against noise and make thermal insulation, cement screed And only after that, put lagows. At such bars, it is possible to lay a clean floor, they must be in a length of at least 2 meters. When the lags need to be allowed, the joints in the rows should be shifted by the ratio of one to another 0.5 meters. Brucks must be installed on the screed, or on the waterproofing layer. But on soft materials Stop the wooden bar is impossible.

Soil base

Choose cross section

The cross section of the materials that are used to masonry the floor by lags, looks like a rectangle (remember that the ratios of height and width are 2 to 1.5). If wooden beams are used, the size of the section will depend on the distance between the elements of the support.

If you want to equip the floor with thermal insulation material, then you should pay attention to this moment. A small ventilation clearance is left between the lower part of the finishing coating and the insulation layer. Therefore, when choosing a bar to build such a design, you must pay attention to this moment. If the floor stands on the ground, then it is also necessary to take into account the size of the russum, which is laid on the cranial bar.

Installation Step

This characteristic is very important, the expenses depend on its definition. Experts advise to draw a building plan and accurately determine how much timber, bricks, cement and other materials need, if the floor is not installed on overlapping. For this take the distance between the axes parallel pieces. The sizes of the step affect the strength and power of the finish floor. This means that when the coating is installed, which holds heavy loads, the step between the elements can be increased.

If subtle coatings are used, then the lags must be mounted after every 25-40 centimeters. But for boards of 50 millimeters, the length of the step can be even 1 meter. Usually, the buildings of 40 millimeters are used for the construction of private houses, and the length of the step between them must be observed at 70 centimeters. If you reduce the step between lags or increase the cross section, the design will be more reliable, but it will have to spend more money. It all depends on your wishes and financial opportunities.

If you were going to arrange the floor on the lags on your own, then it is necessary to consider that the indentation of the extreme element from the wall should be less than step. Most often, the retreat from the wall is 25-30 centimeters.

Types of fastening

Previously, in order to attach lags to the concrete base, ordinary nails were used. This method did not differ reliability and long service life. Now the additional fasteners of different forms are popular. There are such fastening requirements:

- For fixing wooden elements, screws should be applied;

- They penetrate the structure of the tree by 3-4 centimeters;

- If the lag connects with a brick or concrete column, then it is best to use a dowel;

- Alternative fasteners are P-shaped steel elements that are considered stronger and reliable.

Laying on geometric forms

Orientation in space is very important moment In such a process, as a floor device. All who want to learn how to install lags should be taken into account in the process of such geometrical features:

- Restroom rooms and living room boards must be installed along the direction of solar lighting. At the same time, the lag is mounted "in the cross" wooden design boards;

- In the corridor, hallway and other parts of the room with an intense movement of the board, it is necessary to install the direction of passability, but the lags need to be put in perpendicular direction to the boards themselves.

If you decide to strengthen the structure of the floor by the method of installing two beams, the upper part should be installed "into the cross" bottom.

Step-by-step installation instructions

Lagged floor can be done after raising the walls, but in this case the boards themselves are installed only after all draft and finishing actions. This means that you first need to make plaster, putty, painting works, and only after that install boards.

With the choice of materials and their dimensions, we have already figured out, now it remains only to know how it is all mounted. The sequence of work on the arrangement of the lag construction (on the ground) will be like this:

- Initially, the Earth must be tightly tamped. Next to the surface, crushed stone, for 5 centimeters, it allows you to create an incompressible base.

- Under all supports, formwork is mounted, and small foundations are poured. When these foundations (40 x 40 centimeters) dry, you need to install brick columns. It is worth considering that between this element should be a layer of waterproofing material (referenced rubberoid, bitumen or only). Top part Waterproofing material finds on the columns. You can also make sound insulation gasket to suppress noise.

- Installation and fixation of lags. It is important to comply with the basic rule - lags are set in the same plane. In the lower part of the element, the cranial bar is installed, the draft floor is mounted on these details. To save, you can apply inexpensive lumber.

- Mounted layer of waterproofing and thermal insulation material. The final stage of the structure of the design will be the installation of boards from which the finishing floor will consist. It is worth considering that a tree with high humidity and a change in temperature can expand, so space in 2 centimeters should remain between the walls and boards.

If such floors are collected on beams or on a special plate, it greatly simplifies the task. In such a case, all work will be held much faster, and you will not need so many materials. In particular, it will be possible to do without brick columns.

Modern ways to solve certain tasks in construction work, including the construction of a wooden floor, forced producers to produce more modern materials. So, now on the market there are lags with special lifting devices that allow you to quickly change the position of the elements. These mechanisms are made in the form of a rod, which is equipped with a bolt-nut type. Also, the element is equipped with two support plastics that support both the floor and the bar. When the mechanism is rotated, you can lift or lower the extreme part of the lag. The masters believe that this is a very convenient solution, and it helps to significantly speed up the process of the wooden floor device.

Features of the installation of lags

First of all, you need to put two lags near the opposite parts of the building. To determine the level, you need to use the level gauge, such a device can be bought in specialized stores or order on the Internet. Between two lags, it is necessary to pull a thin thread that will help install all the bars in the same plane.

The tree can create excellent conditions for breeding all sorts of microorganisms, and so that there is no problem with this, it is necessary to treat wood with special means. Such formulations will help disinfect the tree and extend its service life. So that the lags were even more reliable, should be treated with their water repellent composition. In this case, the risk of swelling or loss of the design balance will be minimal.

The use of the design of this type has its drawbacks. The main minus lags is that it raises the floor level by 10 centimeters, and for rooms where very low ceilings, it creates big problems. It would seem that 10 centimeters are not enough, but in low buildings such a loss of height is very felt, and will have to look for other solutions in such a situation.

An important stage of work will be the insulation of the structure of the floor. To B to winter time The floor in the room was not cold, between the lags it is worth putting the insulation. Specialists advise apply basalt or mineral wool. Also excellent materials for thermal insulation are an avoever and polystyrene foam. Sometimes used and fridge clamisite.

If, when performing work, take into account all these tips, the floors in the house will be very durable and warm. The designs on the lags will not creak and do not break, they also look very nice. The main thing is to take into account all the installation rules, and everything will turn out to be the best way.

Prices

Today, many enterprises working with wood are offered lags for the floor. For one cubic meter of lags from the highest grades of the tree will have to pay about 7,500 rubles. If you are not sure that you yourself can cope with the installation, you can use the service of the masters, whose lag laying costs 350 rubles per meter square design.

The styling of them is made on the basis of any type - wooden, soil or concrete. The functions of them are to support the floorboards. The installation depends on the design of the house and the choice of floor covering. In this article we will talk about how much the distance should be between lags. But first of all, you should enter the reader in the essence of the question and become acquainted with the basic concepts.

There are different variants of the device of the genital lag. In addition, they themselves differ in density and thickness. The distance between lags from the thickness of the board, which will be laid from above, and from a number of other parameters, which are lower.

Read more about Lagas

There are, they exist in the form of a rigid timber - the bases on which the floor covering is stacked. Most often wooden. But in some cases, the material can serve metal, concrete or even plastic solid species. True, the application of these options is not yet too common.

In low-rise construction (erection of cottages and private houses), a wooden bar is used to use a floor with an outfit on top of it.

What is the dignity of the floors on the lags?

1. Provided that the distance between the floor lags is selected and is observed correctly, the coating is durable and very durable.

2. The installation process is fairly simple and can be done with your own hands. Before the start of repair, using a special calculator, you will need to make the calculation of the required amount of wood, then the floors simply are collected manually. The whole procedure will require several days of labor.

3. Put and align lags using the level. That is why the floor with supporting them is even more than that without them. Among other things, the existing concrete gender curvature panel house It can be reduced due to the laying of the lag under the tilt and eliminate the unnecessary height differences.

4. A small gap between the base and lags allows laying below the floor covering the necessary communications. It is not only about the wiring, but also about the pipes of the water supply. It is possible even a warm water floor device.

5. Even in the absence of a warming layer below the flooring wooden floor, arranged with lags, has good thermal insulation properties. If such floors are also insulated, then even in winter it is possible to completely abandon the home shoes and move around the barefoot room.

6. The flooring device at the lags further improves sound insulation, which is especially important in a multi-apartment building. If under the flooring is laid a layer of insulation, the noise from the top apartments can absolutely not to reach the ears of living.

7. If one of the elements of the entire design will randomly be damaged, it is fairly easily replaced by a similar one without disassembling.

The main thing is to prepare

Thus, without special material and temporary costs, thanks to a special calculator and a carefully spent calculation of the household, the flooring floor on the lags, receives a whole set of amenities - a wonderful warm and smooth coating with sound insulation and a guarantee of the absence in the next 10-20 years any serious problems With floor.

Sometimes the owners of the houses can be heard the complaints from the creaking coming from wooden floors. In order to avoid this unpleasant phenomenon, it follows the preparation of the foundation to pay the most thorough attention to the accurate removal of sawdust and any garbage. Used construction Materials Must be previously processed using special means that do not allow bruus to crumble. Wooden parts are bonded among themselves should also be only suitable, carefully selected dowels and nails.

Where and how the floors on the lags

Such a practical and universal method of flooring device, like lags, can be used in the most different conditions And for various types of foundations. But each of the options have their own characteristic features that should be considered.

The first option of their use is laying on the base of the tree. A rough wooden coating, available or re-laid, is very often strengthened and insulated due to lags, mounted in a frame wooden house. Sometimes large beams and large durable logs are laid in its foundation, on top of which the basis of the future floor of the tree is satisfied. Possible laying of such wooden beams Even on the support columns or the foundation of the ribbon type.

Installation of floors on lags is technically rather simple, it is usually not difficult with him even in inexperienced builders, first starting to the device of such a design.

Other floors

The second of the types of installation, to which the owners of private houses are often resorted to, is to lay the lag on the concrete. Bulk concrete foundation refers to one of the simplest and rapid ways of the device with their own hands under the house. Paul N. concrete screed May take place in almost any room without restrictions on floor or appointment. Place the lags from the tree on it handled the wizard easily enough.

The third version of the floor of the floor in a private house is to lay lags on a tightly rammed primer base. Mainports when choosing this option is large enough. Usually resort to this method only in summer unheated houses and extension extensions, where it is not necessary to maintain heat all year round.

As the basis for laying the lag, a small pita is arranged, which is purified from soil and soil and poured sand and gravel for strength. Laying of wooden bars is produced directly on the crossbank layer, and on top of the stelement of a wooden floor covering. Due to immediately under the ground, the insulation of such a floor is a rather complicated task.

In addition, there is an option to lay a bar on brick or concrete column columns (piles are clogged directly to the ground). In this case, in the design of the house it is important to provide additional ribs of stiffness. The mounting of the bar should be made more reliable than the classic - with the help of dowels and screws.

Choice of Lags and Bruus

The purpose of a wooden bar or sex lags is a durable service for decades. But the wrong selection of materials or error in the calculations can violate all plans. For the purpose of repair and construction, the timber of coniferous rocks is best suited. The optimal option is made of pine. Its wood can be considered the easiest, inexpensive, but it is quite strong. Its processing is possible with their own hands.

Another breed of coniferous - larch - will require the cost of more serious. Her dignity is that the larch wood is practically no subject to rotting. It is also characterized by high rates of durability and strength. But compared with the pine bar, the larch will cost you an order of magnitude more.

Other breeds of trees (deciduous) look well in the form of decorative coatings and are often used in the production of furniture items. But how to apply them much less often.

What you need to consider

When calculating the distance between the lags and the choice of their thickness, take the material by providing the necessary reserve for strength. It is understood that the obtained values \u200b\u200bwill not only be rounded into the biggest. Requires the purchase of a bar a little more important than which is obtained as a result of the calculation. These measures are being taken as a safety patio in the event of an unpleasant situation - if the installation of the floor will be completed with errors and the distance between the lags will be more necessary.

After arranging sometimes, it is completely without a bar. If you build a small light lodge, perhaps lags will serve the thick boards set on the edge. By reducing the distance between the elements of the whole structure, you will add reliability to it. Strength as a result will be at no less than with the standard version.

The shape of the lags used during repair and flooring is rectangular. The aspect ratio should be 1: 2 or 1: 1.5. The floors can be mounted and with a lag having a square cross section, but this form involves a reduced margin of safety, and therefore they should be laid on a smaller distance relative to each other.

What distance between the lags of the floor can be considered optimal?

In order to achieve the strength and durability of stacked flooring, preventing the screenshot and deflection of the flooring, it is necessary to pre-calculate the necessary distances between all the elements of our design. Not only the service life of the coating depends on its correctness, but also the amount in which we will be repaired.

The size of the lag may be different depending on the place where they have to be laid. For example, repairing the floor in apartment house With the existing overlap of the tree or concrete, you can do for fastening the floorboats by a thin ram. If you build a frame building, the lags most often serve as necessary elements of this frame, that is, their function is carrier. Since they have to withstand the weight of the structure entirely, their size is taken much larger, the distance between the lags changes.

What factors should be taken into account by performing the calculation

1. The thickness of the material from which the floor is mounted (chipboard or boards). It is clear that the distance between the lags under Paneur is not comparable to the size when laying a heavy board.

2. Load in its maximum value per square meter of coating.

3. The approximate distance on which the lags will be located.

Deciding with these parameters, you can start the selection and size of boards, timber and all other materials necessary in the process of repair or construction. According to the optimal distances from one element to another, it is convenient to use either a table or a special calculator.

It follows, among other things, take into account that they cannot be placed further than 30 cm from each wall. Because of this, the distance between the lags should be adjusted by the necessary amendments. When the results of the calculations are the fractional number of elements, rounding is produced in a large of the parties. For example, if the calculator showed the required number of Lag - 9.5, then optimally take 10 pieces and slightly reduce the gaps.

From the table below, it can be seen how the distance between the lags should be selected depending on the initial parameters.

Not worth saveing

If you take only 9 lags in order to save money, the strength of the wooden floor will be reduced. Savings in this case will not be so significant as I would like, since the cost of materials is generally not too big.

The price of lags and floorboards can be asked not only in construction stores or on the Internet, but also on the sawmaker, where you can buy any wooden products and materials are made up cheaper.

Saving by reducing the distance between lags when installing the floor - not the most best idea. In addition, it is important to draw attention to the size of the Lag themselves and the required density. If the distance between them is increased, the floorboards may be undergoing a deflection. When the floor covering is not arranged from the boards, but, for example, from the plates, the latter can easily be unwritten or covered with a network of cracks.

Thus, the key to successful repair and guarantee of the safety of high-quality wooden floor for many years ahead is an accurate count of all the necessary sizes (including the calculator), the choice of high-quality suitable wood breeds and a competent approach to the preparation of the base.

So, we build, change or repair the floor, but the complexity is as follows: lags for the floor, the size of the bar.

What is more correct to purchase the material? About this next.

What it is

Lagas for the floor are called a timber that performs the reference properties. Even since the time of five-wall log cabins, the floors were made according to the principle of lag, but in those times, the bars of a particular diameter replaced the usual lamps.

Lagas for the floor are called a timber that performs the reference properties. Even since the time of five-wall log cabins, the floors were made according to the principle of lag, but in those times, the bars of a particular diameter replaced the usual lamps.

Now lags for the new floor should be made of pine breed. And the best of them is a larch. It is this breed that does not rot over the years, although antiseptics on the same pine increase the service life of the material.

Buying a timber from ate or pine is important to monitor moisture. If in the material at the time of purchase this value is below 20 percent, then the tree will not definitely lead. And this is a wonderful floor guarantee even with amateur installation.

Section and dimensions

There are accurate values \u200b\u200bfor spans:

There are accurate values \u200b\u200bfor spans:

- No more than two meters, there is a cross section in 60x110 mm.

- Three meters need a size of 80x150 mm.

- Four already 100x180 mm.

- Five meters require serious material strength, so at least 150x200 mm.

- The span of six meters is a maximum, and we select the cross section, naturally, the maximum 180x200 mm.

You still need to take into account the distance when working with the floor. And for this there are the following characteristics:

Installation: Rules for different surfaces

Lags made of wood can be mounted on any types of bases, surfaces. But everyone works with a tree, concrete and soil.

Lags made of wood can be mounted on any types of bases, surfaces. But everyone works with a tree, concrete and soil.

When laying on concrete, structures contributing to the alignment of the overall plane of the lag are necessarily created. And fasten wooden products with standard anchors or self-draws. There is a chance of collapse of the whole structure, if you ignore the part of the fastener during the work.

It's important to know: When lags are placed on the concrete of the first (base) floor, then it is necessary to produce waterproofing. For this use foil polyethylene films. This is very important because there is a "neutral" between different types of materials. It will provide the best preservation of the tree, will reduce heat losses.

It's just that the tree does not fix - the support is soft. Enroll as follows:

It's just that the tree does not fix - the support is soft. Enroll as follows:

- Small pits dig out (depth in the area of \u200b\u200b10 cm).

- Then they wake up sand and shed liquid.

- From above, it is necessary to put polyethylene, and the support pads for installation are created on top of such a pillow.

- Pillows are brick columns on the size of the brick itself.

- A piece of rubberoid is placed on top of each and is already installed.

- But the lags will not attach to the brick, and it is correct to use galvanized corners for fixing common design To the walls.

And we will analyze working moments with wooden beams as the basis. It is important to find out the moment of laying: transverse or longitudinal.

When lags fall across the beams, they are easiest to fix with standard self-drawing. Once work is only with a tree, we take action: in advance drill holes under fastening to avoid cracks.

We protect against rot

Created a large number of impregnations, verses and other antiseptic tools To protect the usual wood in conditions of high humidity.

Created a large number of impregnations, verses and other antiseptic tools To protect the usual wood in conditions of high humidity.

And heave with such means you need individually every unit. It is recommended to leave a substantial protective layer (from 5 to 15 mm) and use environmentally friendly types of impregnation.

In addition, when purchasing such a bar is paying attention to dryness of wood. Now there are devices showing moisture in any lumber.

Even before the installation, it is necessary to consider a plan for ventilation - this is the third important natural condition for protection against rot, mold and rodents. Floors should be bludging at the expense of air bags.

Lags are laid "on the edge". This does not mean that bars really fix the angle to the spans.

Lags are laid "on the edge". This does not mean that bars really fix the angle to the spans.

No, ensuring the safety margin helps the section. It is invented only for this, well, and a little to save wood. So, the bar is laid on the floor with the side that thinner. This is the main recommendation.

Before working with this material, it is necessary to make calculations of length and sections. But not to forget about the distances between them. When all the values \u200b\u200bare selected, as a result, you will get a perfectly strong and smooth floor. Because the calculations are created in order not to be protected under the furniture or a viper when a person is moving.

Most private and. They are environmentally friendly, durable and easy to install. In addition, the flooring device on lags is good and thermally insulates the room.

They are environmentally friendly, durable and easy to install. In addition, the flooring device on lags is good and thermally insulates the room.

In this article we will tell you the technology of the black floor assembly on the lags.

They are environmentally friendly, durable and easy to install. In addition, the flooring device on lags is good and thermally insulates the room.

In this article we will tell you the technology of the black floor assembly on the lags.

Wooden floor in the apartment: installation features, sequence of work and subsequent processing "href \u003d" http://shkolapola.ru/derevyannie/457-derevyannyj-pol-v-kvartire "\u003e Apartment houses are used by floors from wood. They are environmentally friendly, durable and easy to install. In addition, the flooring device on lags is good and thermally insulates the room.

In this article we will tell you the technology of the black floor assembly on the lags.

I \u003d ""\u003e what are lag

Lags are bars who lie perpendicularly to the floor, and serve as a reason for him. Most often they are made of wood.

Their use gives a number of advantages:

- Noise insulation is increasing;

- It is observed correct ventilation of the tree below;

- The ability to put inside communication;

- An increase in thermal insulation and the ability to use additional insulation;

- The strength of the structure increases;

- Ease of repair and replacement of defective elements with their own hands.

Selection and purchase of material

Inexpensive wood (pine, spruce, fir) can be used as a lag. Sometimes a larch is used, since the price is high. Wood 2-3 varieties with humidity of about 20 percent.

The cross section of the bar must have a rectangular shape so that the height is more than 1.5-2 times. Dimensions will depend on the width of the spans and the thickness of the insulation. The photo shows an example of calculations if the lags will be laid in 70 cm increments.

As a flooring, cedar, aspen, pines are used. Consider that the coniferous wood species are soft enough, and they will need to be protected from damage.

Distance between lagami

Cedar, Osin, Pines. Consider that the coniferous wood species are soft enough, and they will need to be protected from damage.

The most elite materials are the array of oak and pine, they will be very durable. Larch does not rot in wet conditions, so it can be used in the bathroom, bath.

With these materials, it is even possible not to use the finish coating, but simply sprawling well, cover them with varnish, versal. However, in this case, you will have to buy a first-grade gender board.

Aspen and alder is well suitable for the bedroom and children, as it is good for health.

It is advisable to buy dry wood so that it will not be deformed after drying. Take into account the stock of about 15 percent for marriage and trimming.

Tip! Before stacking, it is desirable to handle wood with antiseptics and antipirens to counteract fungus, mold, fire. You can also use treatment with hydrophobic fluid so that the surface has water-repellent properties.

Distance between lagami

The lag of the floor allows them to be located at different distances, depending on the thickness of the genital board.

- If thin boards are used, the step becomes small to avoid bending (from 30 cm).

- If thick is used massive boardsThe step can be increased, up to 100 cm.

- The most commonly applied step 50-70 cm.

- Also consider such a distance so that it is convenient to lay insulation inside.

flooring board from larch, cedar, aspen, pines. Consider that the coniferous wood species are soft enough, and they will need to be protected from damage.

flooring board from larch, cedar, aspen, pines. Consider that the coniferous wood species are soft enough, and they will need to be protected from damage.

The most elite materials are the array of oak and pine, they will be very durable. Larch does not rot in wet conditions, so it can be used in the bathroom, bath.

With these materials, it is even possible not to use the finish coating, but simply sprawling well, cover them with varnish, versal. However, in this case, you will have to buy a first-grade gender board.

Aspen and alder is well suitable for the bedroom and children, as it is good for health.

It is advisable to buy dry wood so that it will not be deformed after drying. Take into account the stock of about 15 percent for marriage and trimming.

Tip! Before stacking, it is desirable to handle wood with antiseptics and antipirens to counteract fungus, mold, fire. You can also use treatment with hydrophobic fluid so that the surface has water-repellent properties.

Distance between lagami

The lag of the floor allows them to be located at different distances, depending on the thickness of the genital board.

- If thin boards are used, the step becomes small to avoid bending (from 30 cm).

- If thick massive boards are used, the step can be increased, up to 100 cm.

- The most commonly applied step 50-70 cm.

- Also consider such a distance so that it is convenient to lay insulation inside.

Batten From larch and other lumber "href \u003d" http://shkolapola.ru/derevyannie/427-polovaya-doska-iz-listvennicy "\u003e Flooring of larch, cedar, aspen, pines. Consider that the coniferous wood species are soft enough, and they will need to be protected from damage.

The most elite materials are the array of oak and pine, they will be very durable. Larch does not rot in wet conditions, so it can be used in the bathroom, bath.

With these materials, it is even possible not to use the finish coating, but simply sprawling well, cover them with varnish, versal. However, in this case, you will have to buy a first-grade gender board.

Aspen and alder is well suitable for the bedroom and children, as it is good for health.

It is advisable to buy dry wood so that it will not be deformed after drying. Take into account the stock of about 15 percent for marriage and trimming.

Tip! Before stacking, it is desirable to handle wood with antiseptics and antipirens to counteract fungus, mold, fire. You can also use treatment with hydrophobic fluid so that the surface has water-repellent properties.

Distance between lagami

The lag of the floor allows them to be located at different distances, depending on the thickness of the genital board.

- If thin boards are used, the step becomes small to avoid bending (from 30 cm).

- If thick massive boards are used, the step can be increased, up to 100 cm.

- The most commonly applied step 50-70 cm.

- Also consider such a distance so that it is convenient to lay insulation inside.

I-7 \u003d ""\u003e Installing Lag

The device of the wooden floor by lags can be done along a concrete or earth ground, overlapping or beams. The main rule that should be observed, regardless of the selected method, lagows should be thoroughly and in the same plane. This will give you a guarantee of the strength and durability of your floors without the appearance of a screens.

Installation on wooden beams

If in the house of the overlap is made of wooden beams, the lags are attached to them. Considering the fact that the beams are usually not perfectly even, it is best to mount them to the side part, exposing the level.

If simply fixes them, laying on overlappings, it will be necessary to put the gaskets to align the same level. It is better to do so if the distance between the overlaps is large. In this case, it will be necessary to mount the lags perpendicular to beams with a smaller step.

It is necessary to use clocks 6 mm and a length of 2.5 times the width of the lag. For bars do not crack during screwing, it is previously necessary to drill holes for smaller diameter.

Concrete flooring

There are several ways to make a smooth wooden floor device on lags on concrete base.

- The first method is most popular - the use of linings for bars, to level the level. Over time, they can fly, dry, deform, and the floor will begin to creak, so this option is not the best.

- The next way is more expensive, but effective - preliminary leveling of the base. This may be a self-leveling mixture, sand, depending on its condition.

Laying Lag on the soil

And self-leveling mixture, sand, depending on its condition.

Before laying, you need to sash on concrete waterproofing from a plastic film. It is also extremely desirable to put on the lags and from their ends with soundproofing substrates to reduce the transmission of vibration noise.

It is advisable to use bars to the entire width of the room so that you do not have to dock them. The insulation is laid between the lags installed.

Many ask a question whether it is necessary to hardly fix the lags to the base? The device of floors on the lags on a concrete base allows them to be fixed with the cement-sand mixture.

However, it will be necessary to protect the boards with bitumen insulation or hydrokhotloxole. The coating is placed only after drying the solution. In this case, you can set the lags into one plane, by saving the solution to them.

However, it should be borne in mind that the rigid fastening of the lag to the overlaps will strengthen the transmission of noise to the neighbors below. That is why it is more likely to make a floating mount with an anti-vibration substrate.

Tip! To enhance the strength and rigidity of the frame, it is recommended to bore the bars between themselves with crossings by cropping boards and corners of 4 * 4 cm.

Laying Lag on the soil

Paul B Floor wooden house By lags on the first floor can be installed directly on the ground.

- First of all, you need to align and tamme the soil. This can be done manually, building a device for thrombling from a large log and a wide board from below.

- Then you need to mark the columns that will support lags. At the edges, they will have to rely on the foundation. The extreme lags must be installed almost at the wall, with a gap of 5-20 cm.

filling of floor screeds in lighthouses, and self-leveling mixture, sand, depending on its condition.

filling of floor screeds in lighthouses, and self-leveling mixture, sand, depending on its condition.

Before laying, you need to sash on concrete waterproofing from a plastic film. It is also extremely desirable to put on the lags and from their ends with soundproofing substrates to reduce the transmission of vibration noise.

It is advisable to use bars to the entire width of the room so that you do not have to dock them. The insulation is laid between the lags installed.

Many ask a question whether it is necessary to hardly fix the lags to the base? The device of floors on the lags on a concrete base allows them to be fixed with the cement-sand mixture.

However, it will be necessary to protect the boards with bitumen insulation or hydrokhotloxole. The coating is placed only after drying the solution. In this case, you can set the lags into one plane, by saving the solution to them.

However, it should be borne in mind that the rigid fastening of the lag to the overlaps will strengthen the transmission of noise to the neighbors below. That is why it is more likely to make a floating mount with an anti-vibration substrate.

Tip! To enhance the strength and rigidity of the frame, it is recommended to bore the bars between themselves with crossings by cropping boards and corners of 4 * 4 cm.

Laying Lag on the soil

The flooring device in a wooden house on lags on the first floor can be installed directly to the ground.

- First of all, you need to align and tamme the soil. This can be done manually, building a device for thrombling from a large log and a wide board from below.

- Then you need to mark the columns that will support lags. At the edges, they will have to rely on the foundation. The extreme lags must be installed almost at the wall, with a gap of 5-20 cm.

Filling a tie of the floor - how to qualitatively make a reliable basis "href \u003d" http://shkolapola.ru/ustroystvo/styazhka/560-zalivka-styazhki-pola "\u003e Filling of floor screed in lighthouses, and self-leveling mixture, sand, depending on his status.

Before laying, you need to sash on concrete waterproofing from a plastic film. It is also extremely desirable to put on the lags and from their ends with soundproofing substrates to reduce the transmission of vibration noise.

It is advisable to use bars to the entire width of the room so that you do not have to dock them. The insulation is laid between the lags installed.

Many ask a question whether it is necessary to hardly fix the lags to the base? The device of floors on the lags on a concrete base allows them to be fixed with the cement-sand mixture.

However, it will be necessary to protect the boards with bitumen insulation or hydrokhotloxole. The coating is placed only after drying the solution. In this case, you can set the lags into one plane, by saving the solution to them.

However, it should be borne in mind that the rigid fastening of the lag to the overlaps will strengthen the transmission of noise to the neighbors below. That is why it is more likely to make a floating mount with an anti-vibration substrate.

Tip! To enhance the strength and rigidity of the frame, it is recommended to bore the bars between themselves with crossings by cropping boards and corners of 4 * 4 cm.

Laying Lag on the soil

The flooring device in a wooden house on lags on the first floor can be installed directly to the ground.

- First of all, you need to align and tamme the soil. This can be done manually, building a device for thrombling from a large log and a wide board from below.

- Then you need to mark the columns that will support lags. At the edges, they will have to rely on the foundation. The extreme lags must be installed almost at the wall, with a gap of 5-20 cm.

I-14 \u003d ""\u003e insulation

Since the lag laying device allows insulation inside the design, at this stage you can fill the cells between lags insulation. Most often for this use mineral wool, extruded polystyrene foam, foamizol, sawdust. If the lags are installed on the soil, the insulation must be laid on the draft floor.

For insulation wood coating From evaporation and condensates, you can fix on the lags before the covering sheets of vapor insulation (pergamine) on the stapler. If at the bottom is dry and warm, you can do without it.

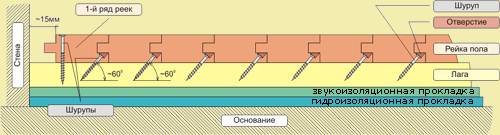

Sheathing floorboard

The floor cover is starting from the far from the corner. It is important to leave the temperature gap of 10 mm around the perimeter of the walls, which then hobs the plinth.

The casing is placed perpendicular to lagas.

- Flooring has a spike on one side, and with another groove. We put the first row with a spike to the wall and secure it on top of the self-tapping screw to the lag. Additionally, fasten this board on the side of the groove, screwing down the self-tapping screw at an angle of about 60 degrees. Boards need to be shorted so that their joints are in the center of lag.

Note! It is very important to put the first row to put exactly, as it will set the direction of all others. At the same time, it is impossible to repel from the walls (they can be curves).

- The second and the subsequent row is joined with the previous one. For dense docking, they need to be hammer through the gasket. Unlike the first row, it is necessary to fasten them only on the side of the groove so that the screws are not visible.

- Thus, the device of the adhesive floor is made along the lags throughout the rest of the area. The last row will need, most likely to cut off.

Note! Sevective rings on the boards should be alternating. In one row, they should look in one direction, and in the other - in the opposite.

- The length of the self-tapping screws should be the thickness of the genital board 2-2.5 times. For example, for a 27 mm boards, the screws of 3.8 * 55 mm will be optimally used.

- If the finish will be used to be used on top of the boards, the screws can be screwed into the usual way - on top, and not at an angle. So it will be faster, but the hats will be visible.

- Pre-drilling holes will save the splitting boards and allow them to close them.

- It's better not to use nails for this business, as they overwhelm it over time, and the boards will begin to creak. If you still decided to mount the boards with nails, then take them with a length of 70-100 mm.

Tip! During the boost of the boards, one edge will fly out of the groove. For temporary fixation, you can use the clamp, which will attract the board through the gasket, as shown in the photo.

The use of this technology will allow you to correct the significant irregularities of the overlap and will evenly distribute the load, but you will have to sacrifice 7-10 cm of the ceiling height. Instructions on the video in this article will show you in practice, how the device of the black floor is done on lags:

"width \u003d" 640 "height \u003d" 360 "frameborder \u003d" 0 "allowfullscreen \u003d" allowfullscreen "\u003e