The design of any sex involves the presence of a draft coating, which in apartments of multi-storey houses is made using a screed. Screed can be made with a wet or dry way. The second way to create a draft base in the form of bulk sex is becoming increasingly popular due to the short timing of the installation of such a coating. Concrete screed requires a long time for complete drying. The leader of the modern market of this segment of building materials are German floors of Knauff. Are the bulk floors of Knauf flaws and when can such a coating be used when repaired apartments?

Main characteristics

Floors Knauf are very popular at the expense of their high technical characteristics. Dry chatting of this German brand can be applied in the most different conditions. The bulk floor is suitable as a rough layer in the design of the flooring multi-storey buildings and office structures, it can be used in cottage buildings, as well as during the reconstruction of houses-Khrushchev and buildings with floors of wood.

Dry German production screed perfectly manifests itself in non-standard conditions. It can be used at low temperatures when fill concrete screed It is inappropriate. A draft floor from the backfill of Knauff is made quite quickly, which is another of its indisputable advantage over the fill of the cement mortar. When the repair must be made to the highest possible time and time in a few weeks, which are required for complete drying of cement, no, bulk floors can save the situation. Dry tie of this brand can also be used when arranged warm floors with electrical heating elements.

The floors made on the basis of a dry screed will not creak and do not crack over time, as well as themselves are characterized by excellent sound insulation qualities. Such a coating in the summer months creates a feeling of coolness, and in winter time - Heat.

The use of bulk floors KNAUF can be considered an optimal solution for the arrangement of the floor covering in a residential apartment. The screed does not require drying, almost immediately ready for further processing, and also allows you to level the floor level between rooms. Dry floors can be made aligning any foundations of the base and easily hide the surface irregularities.

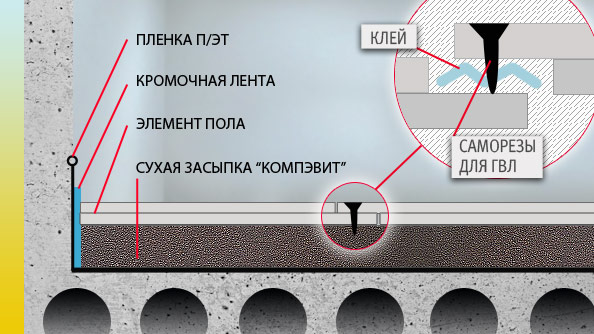

Scheme of the creation of a dry screed with a backfill of the KNAUF compavit.

Scheme of the creation of a dry screed with a backfill of the KNAUF compavit. Pros and Cons Dry Screws

Dry floor KNAUF has its advantages and disadvantages. Among the advantages of the coating, excellent heat and noise insulation characteristics should be noted. Using the German brand's dry backfilling as a draft layer, you can be confident in its quality: the floor in your apartment will correspond to all thermal insulation parameters, as well as perfectly protect against domestic and intra-quarter noises.

The bulk floor of KNAUF is mounted as soon as possible, the coating is ready to carry out further work immediately - to wait when the floor dry or takes, not required. "Wet" stages of work are absent completely, the floor can not be laid immediately throughout the apartment, but alternately. With alternately, the screed can not be afraid of the floor level drops in different rooms: the fields of Knauf are easily mounted at the same level without any additional problems.

Among the important positive qualities of the dry screed, specialists note high resistance to fire and hypoallergenicity - the quality necessary for residential premises. The advantage of the CNAUF screed is the final level, ready to install any plasterboard partitions and any outdoor decorative coating. The finished bulk floor is withstanding the distributed load of up to 500 kg per square meter, and also successfully confronts the appearance of faults and creaking sounds over the period of operation.

The coating of Knauf managed to earn positive reviews of specialists. But dry backfall has its drawbacks to which you should pay attention to the selection of the floor screed in your apartment. German floors are distinguished by low moisture resistance. Dry screed absorbs water well, so water will fall inside the coating, the floor will have to at least open for drying, as a maximum - for full replacement rough layer. This minus makes it impossible to focus from the backfill of Knauf in the basement, basement floors, rooms without heating.

Such a floor will be an inappropriate solution for rooms with high humidity: for the bathroom and kitchen it is better to choose another version of the screed. Dry belling for the floor Knauff will not fit for the installation of warm water coatings. The flow of one of the heating elements will be unusable for the entire floor design.

Another of the shortcomings of the Floor CNAUF Specialists call the high cultivation of the work: when carrying out a clamping of clay builders will have to work in respirators not to damage airways. The finished coating of the pesticity is no different and does not constitute a threat to the health of households.

A serious problem when installing gender of the German brand can be the height of the layer of frustration. The minimum coating thickness cannot be less than 4 cm, but this value does not guarantee high quality of future floors. The bulk floors of the KNAUF will fully comply with the stated characteristics if the subference will have from 6 to 8 cm in height. In apartments with low ceilings, such a thickness of the floor can be critical because it is also required to add the thickness of the decorative top coating.

Floors Knauf cost quite expensive compared to other options for the floor screed, but when proper montage With the highest durations, it provides even and high-quality coating, ready for finishing.

Montaja technology

Knauf's floors can be mounted with their own hands, for this you need to stock tools, time and step by step instructions. Working begins with the preparation of the working surface. This requires to open and completely remove the old coating. Aligning the surface can not be done, obvious irregularities can still be removed, the main thing is to clean the floor from the construction trash. The remaining drops will be hidden by swelling.

The bulk floor requires steam and moisture insulation. The better this stage of repair work will be held, the longer the dry screed will last. A PVC or a special vapor barrier film can be used as insulating materials - laying such materials will protect the dry filling from moisture and keep the finish coating from damage. The film is placed on the surface of the mustache and is sampled by the construction scotch. The edges of the canvas should enter the walls before the level where the floor design will end - the material in these places should be consolidated efficiently.

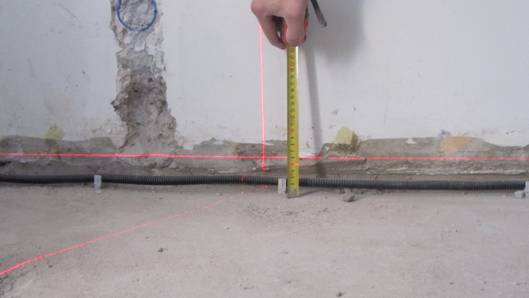

The bulk floors of Knauf fall asleep at a certain level, determine which is necessary in advance. For these purposes there are special laser levels that help install the most accurate markers on the walls. Failure of the screed can have a different depth depending on the presence of sharp drops of the working surface, but the upper coating level must be performed exactly by marks.

Additional sound insulation stacked around the perimeter of the room along the walls: For this, there are special gaps near the walls. If the insulating material does not have an adhesive layer, then it can be fixed on the usual tape. Laying the material along the walls is a mandatory procedure, as it provides a high level of noise insulation of the future floor.

How to make bulk floors Knauf? The technology of their installation is no difficulty. Ceramzit is usually used as a bulk material for a dry screed. It can be replaced by quartz sand, perlite sand or slag from particles of small fractions. Any of these materials is in bulk, good porosity and stability to the shrinkage. Ceramzite or other bulk material is stacked up to the top floor level.

Fasting thickness can be different. It will depend on the presence of drops of heights on the working surface, as well as the need for laying engineering networks. If the wires are located on the working surface, they must be pre-removed in the corrugated tubes. The presence of any communications means that you will have to trace even over a thickness of the corrugated tube - the thickness of the clamzite layer should not be less than 2 cm.

The bulk floor is mounted at 4-5 cm - such a thickness of the dry screed is most often enough. If for some reason a layer of claympsite will exceed 5-6 cm, then for the strength of the future floor it is necessary to provide an additional layer of plates.

CNAUF floors are mounted easily enough, you can make such a floor yourself without attracting qualified specialists. So that the coverage is high-quality, you should know several rules that will help you avoid the most common mistakes.

The profile installation must be started from the wall, the main thing is to observe their parallel mutual location. The optimal distance between profiles should not exceed one and a half meters, ideally - to be equal to the length of the rules that you are going to rampture.

Installation of bulk floors KNAUF requires accurate markup of profile points. The guide profile after the end of the work on the surface markup is mandatoryly checked by the level for the deflection. Ceramzite is poured according to the installed guides and is thoroughly resurrected by the rule. Instead of the rule, you can use a wide spatula - as comfortable. Before holding a backfill, experts recommend to protect themselves with a respirator.

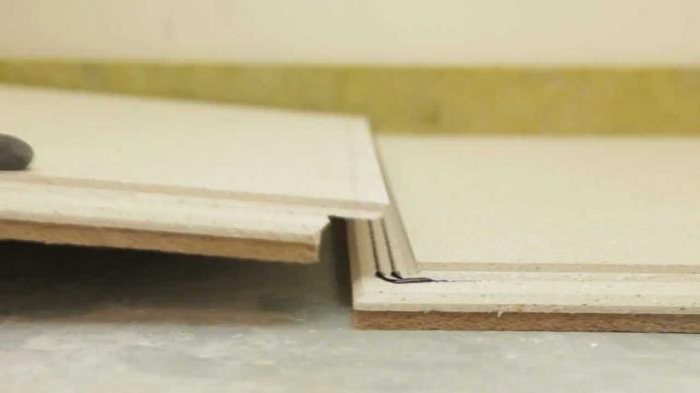

The finished bulk floor is cleaned from profiles and backups. The voids remaining after them are filled with the same clay, after which the surface is rambling. Then the installation of gypsum fiber sheets begins. Their styling should be started from the door, so that it is not necessary to go through the finished dry tie, disturbing its structure.

Installation of sheets is convenient to exercise together. The GVL sheets must smoothly go to the surface and do not delve into the screed when they are on them: For this, it is better to cut off their folds on the first sheets. The bulk Paul Knauf should have the top layer assembled according to the principle brick masonry. GWL sheets are mounted with some displacement, thanks to which the quality of the final coating increases and a place for installation of the following parts is formed.

The final stages of work is to sample all the junctions between the sheets of PVA glue. Such a measure will increase the strength of the assembled gender and will ensure its readiness for further decorative decoration.

Dry fridge Knauff.

The cost of dry backfills Knauf (KNAUF) price - 289 rubles 40 liters.

Dry Floating for Floor Knauff Original

Probably everyone knows that it can not be warm in the house in the house, if the floor is not insulated. For, by definition, the house will not be cozy when the cold rises from the bottom of the legs. And then they will not be saved from him the inhabitants of the dwelling neither the most insulated windows, no walls. The experienced builders, so perfectly understood that the heat insulation of the floor should be treated with great attention. And firmly know that the best assistant in this business is a ceramzite, or a mixture based on it. With their help, a dry screed is formed - one of the most inexpensive modern insulation, which can be used for insulation wooden housesand serve to create sustainable noise insulation

Dry filling for Paul Knauf You can purchase in our store at a low price, both in retail and wholesale. At the same time, we deliver in Moscow and to all regions of Russia.

How to make ceramzit

The word clamp itself in the Russian language came from Greece. In the literal translation, it means "baked clay", which fully corresponds to its essence. Claimed rocks are brought to high temperatures to obtain clay. Under their influence, foaming occurs, and porous cellular cavities appear inside. After cooling, the mixture is frozen and the final product is obtained.

The heat insulation for the floor of the ceramisite has a number of indisputable advantages. It does not rot, does not burn, does not destroy under the influence of external physical Loads. It costs quite inexpensively.

Features, high-quality guarantees and spending standards

Specialists affirm - the most appropriate material for the insulation of prefabricated floors and leveling surfaces, is dry powder Knauff

Its structure is radically different from the structure of the clamzit without any additives. After all, the ceramzite is crushed to bring to the necessary faction and therefore over time, he can begin to see. At the same time, it will inevitably begin to suffer and flooring. Unlike him, dry backfills Knauf have the desired round fraction without any crushing. Their composition is placed on the basis of almost an unlimited period and in the future does not change its position. So that dry backfills of Knauff Possess a number of benefits:

- Easy use

- High level of thermal and sound insulation

- Durability in operation

- Unconscious shrinkage (2-3 mm on 2 m / n) leveling layer

- Good ramp, porosity, hygroscopicity

KNAUF has worldwide fame in its industry, mainly due to the multilateral approach to the quality of products. In many countries of the world, this concern has created its training centers only to ensure that the quality of the source material is always at the highest level. Conducts KNAUF and comprehensive laboratory tests of each product manufactured in the introduction of new technologies. Not an exception in this regard and dry fridge Knauff For team floors. It can not be afraid for the quality of it, since this material has passed the most strict verification for compliance with European quality standards.

What are the advantages of dry floors

1. Saving time for laying. In order to produce it on an area of \u200b\u200b50 square meters. m. You will need only 2 employees and 8 hours of working time.

2. The finish coating is allowed to lay straight on the dry tie without a break in operation.

3. The inability to form faults and cracks, due to the special specifics of the material.

4. Lack of excess load on overlapping and foundation due to the ease of the leveling layer.

5. Absolutely smooth base withstands the load of a uniform nature (up to 1000kg. Per 1 m.kv.) and point (up to 360 kg. Per 1 m.kv.).

6. Allows you to use in floor structures with heated.

7. The heat insulating layer allows you to mouncing various communications.

8. Allows the floor repair without removal of coatings.

9. Allows you to carry out work in operating conditions.

Dry screed "Knauf", negative feedback About which is intermitted with positive, is a system stacked by technology that eliminates wet processes. If you still can't decide what method is to equip the floor, you can compare the described screed with the one that is made of concrete. In the latter case, the operation of the room will be possible only after 28 days, if we are talking about a dry type screed, then you can move on such a surface in two days.

Features

Quite common among consumers dry screed "Knauf". Features, reviews, laying scheme This system will be covered in the article. These floors are easy to assemble the surplus designs of dry assemblies that are most often used in residential and public buildings. The need to arrange this system may occur when there is no possibility of wet finishing processes. The design data is relevant and with a large lifting of the floor level, as well as with increased overlap sound insulation requirements.

If the timing of work is limited, then it is best to use the dry tie "Knauf". It is possible to carry out work on wooden and concrete floors, however, it is important to verify that the room fit the normal moisture regime, there was no restrictions on fire resistance and floors, as well as climatic and engineering and geological conditions. The effect of aggressive substances is not allowed, and mechanical loads should be characterized by weak intensity.

Dry screed "Knauf", negative feedback about which may make you refuse it, can be equipped in rooms with high humidity on the type of bathrooms, as well as shower. But the correct waterproofing system should be present. At the scene of the floor with walls, it is necessary to put a waterproofing tape of the same manufacturer, while the entire surface is covered with waterproofing.

Stacking technology

Reviews about the dry tie for the floor "Knauf" can help the consumer make right choice. So, if we consider the prefabricated bases of the floors, which are equipped using the "KNAUF" technology, they can be divided into the following types: "Alpha", "Beta", "Vega" and "Gamma". The first type is a construction stacked at even overlaps. The second is a system on a substrate from porous fibrous insulation materials, which should fit in smooth overlaps. "Vega" is a design based on the substrate, which is represented by the leveling layer of dry fridge. The last species is the design of a combined substrate of heat and soundproofing fibrous materials, which are stacked according to the leveling layer of backfills.

For reference

Super-floor "Knauf" (dry screed) should be used in rooms, the temperature in which does not fall below +10 degrees. Then how humidity may vary in the range from 60 to 70%.

Main advantages

Before you acquired the described system, it is necessary to read reviews about the dry screed "Knauf", the opinions about it will help to decide on the choice. Thus, among the positive features, consumers allocate excellent quality and speed of work at home, as well as savings due to the fact that the building design can be made more lightweight. Among other things, there can be no restrictions in architectural solutions. The laid system will comply with world standards, it is environmentally friendly and creates a favorable microclimate. The design has the ability to breathe, give or absorb moisture with its disadvantage. There are no uncomfortable wet processes. Knauf's dry screed, the pros and cons of which are recommended to consider before visiting the store, can withstand 360 kilograms of weight on one square centimeter.

Negative moments

It is impossible to use in the garage of the floor in the garage, since the hard moving technique will break and move the sheets. In addition, you must be prepared for a sufficiently low moisture resistance. When moisture gets, the surface will need to be opened for a long drying or a complete replacement. Therefore, such structures are not recommended to be applied on the ground floors, in unheated rooms, basements and when installing warm water floors.

Considering the subtleties and nuances of the dry screed "Knauf", you will understand that when installing do not have to use wet processes. However, this does not exclude some inconveniences that are in high propagation of dust during the frustration of the clay. That is why the masters should work in respirators and glasses. When comparing costs with other methods of laying floors, it can be noted that the KNAUF system costs much more expensive.

Negative feedback

Consumers sometimes abandon the dry screed "Knauf" for the reason that it provides for the need to use additional materials, which is accompanied by costs. This is explained by the fear of moisture, while leaks have simply catastrophic consequences. On the overlap, it will be necessary to put a vapor insulation layer, which will protect the filling from moisture located on it, which occurs when contacting with overlapping. Moisture pairs can penetrate out the following premises or concrete, as well as through the walls. To ensure steam and moisture protection, it is recommended to use a polyethylene film, the thickness of which can vary in the range from 200 to 250 microns. This is true for reinforced concrete overlap. If we are talking about wood, it is best to use bituminized paper or parchment. Do not give up from modern vaporizolation.

Dry screed "Knauf", negative feedback about which also exist, according to users, provides for the need for a sufficiently impressive backfill thickness. This affects the decrease in the height of the ceilings. The thickness of the layer may vary from 30 to 50 millimeters, but the final layer will depend on the magnitude of the irregularities. That is why it is advisable to align the surface of the floor before carrying out work. The thickness of the backfill will also affect other equipment. Consumers argue that the dry screed system can become a place of formation of fungus or mold under unsuitable conditions. It does not avoid repairs, which will be accompanied by costs. This indicates significant restrictions in application. Buyers argue that during the operation of such a floor, it is necessary to constantly monitor the microclimate, and in the room there should be no sharp drops of temperature and humidity.

Preparatory work

Initially, it will be necessary to prepare a draft base. Under the elements of dry backfills, plumbing communications can be laid, but only before using the clay. Before the floor, it is necessary to prepare a concrete surface, while all the gaps and gaps between the plates are closed cement mortar Marks M 500. After that, the entire area is cleaned from garbage and foreign objects. If there are minor irregularities to 5 millimeters, then such floors can be aligned with corrugated cardboard. Then how to deal with local irregularities up to 20 millimeters is recommended using repair mix. Excellent proven itself, for example, vetonit 4000. If there are more impressive potholes, then they are recommended to fall asleep fine ceramzite. With it, the ground slope is aligned if it is.

If you need insulation of floors before laying a dry screed, it is necessary to initially align the putty, which can be replaced by a sand-cement mixture. Polystyrene foam plates for thermal insulation are stacked on such a surface. After preparing the base, the waterproofing layer is placed, since the ceramzite does not tolerate contact with humidity. Dry screed "Knauf", reviews, pros and cons of which are considered in detail in the article, should fit on the polyethylene film, covered with the allen in 20 centimeters. In the walls of the waterproofing edge should be higher than the collection floor by 2 centimeters. It is necessary to provide vapor barrier. Instead of film, you can apply parafined or corrugated paper, Modern vaporizoation "LTRPOL" or pergamine.

Flipping and alignment of a dry screed

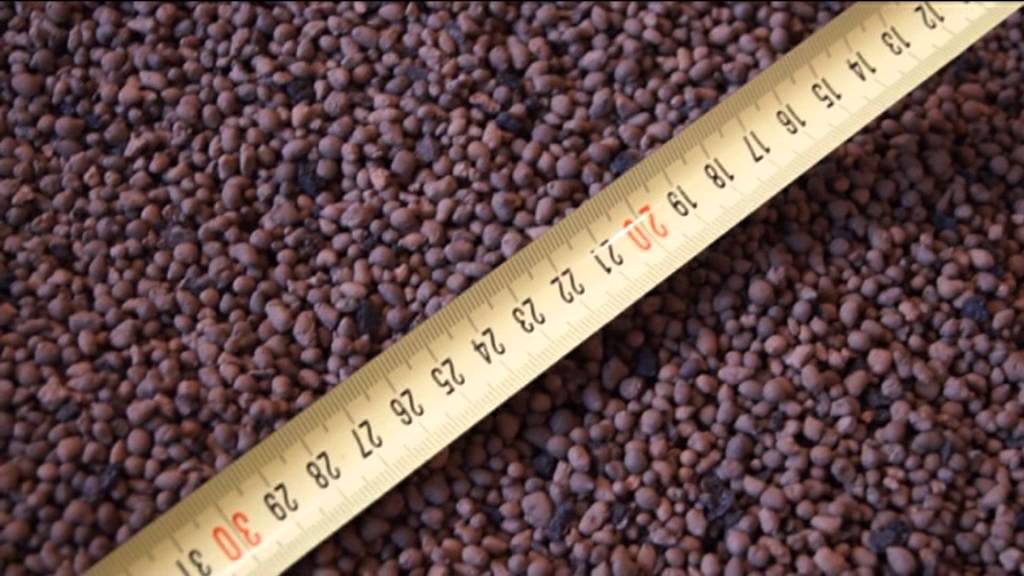

Ceramzite used in the arrangement of the team of the screed is an excellent heat insulating material. It should have a small fraction from 2 to 4 millimeters, but it is impossible to take a trim from large elements, since the floors will cover. Before laying, you need to install beacons using a laser level, and then it is recommended to apply a trapezoidal rule.

FEATURES OF STOCK SYSTEM KNAUF

Dry screed "Knauf", and against which there was an approximately equal number of users, as described in detail above, should not come into contact with the walls, since the insulating contour tape of 10 centimeters is laid around the perimeter. Its thickness should be 10 millimeters. Polymer wool can be used as a material. Using the edge ribbon, it will be possible to compensate for the deformed expansion. Fucking insulation will need to be poured into the floor and align using a rail. You should start from the wall that is opposite to the input. Tamming material is carried out manually.

What sheets are better to use as an external layer?

Dry screed "Knauf", negative feedback on which quite often make users make a choice in favor of other materials, may have a GVL or GKL sheets. These two material are successfully used today when arranging dry screeds. Glk, for example, is a plasterboard sheet, the edges of which are lined with cardboard, with the exception of the end part. In order for the material to be durable, binding components are added to the gypsum. Cardboard adhesion with plaster with special adhesive additives. Sheets are well bent and cut down, and in the collection floors are used somewhat less frequently compared to other species.

GVL is a gypsumless sheet, completely homogeneous in composition. It is stronger, compared to plasterboard, and is more suitable for the collection floor. Its manufacture is carried out not by pressing, but through reinforcement of cellulose. This material is also characterized by a higher fire resistance. In addition, GVL will cost cheaper.

Laying sheets

Dry screed "Knauf", the process of use, the study of reviews of which will exclude errors, stacked from the door, while the gap in the joints should be one millimeter. The first layer is covered with adhesive composition, and after the second is stacked. Sheets are located across with the same gap. The canvas in the second layer are fixed with screws for GWL.

Dry clay fringe for teams Knauf

Specially selected composition of the ceramic sand of a certain fraction, providing non-presidency during the operation of combined floors and improving heat and sound insulation character

Application

It is intended for leveling, sound and thermal insulation of bases, followed by the device of the combined bases of the KNAUF-Superplate of the floor elements of KNAUF or small-format KNAUF-superlists of moisture resistant (GVLV).

Benefits

"Ability to hide communications.

Improving sound and thermal insulation bases.

Reducing the weight of the structure. "

Specifications

Minimum fuse height: 20 mm

Consumption: 10 l / m2 for layer in 10 mm

Bulk density: 400-800 kg / m3

Summary strength in the cylinder: at least 2.0 MPa

Thermal conductivity coefficient: not less than 0.12 W / m ° C

Packing: Paper Bag, 40 L

Packaging: pallet

Dry fridge Knauff 40 l, claying price per bag. Buy delivery in the online store Terraramoll.

Dry screed is one of the most promising methods of installation of floors in the premises. When using this method, the means and time of work will significantly save. This technology is very simple in its essence and does not require special knowledge and skills: the existing floor is embanked by a dry bevel of KNAUF, and then the GVL plates that give strength and ideal evenness are stacked. Top, laminate, parquet and other types of coatings are stacked on top of the GWL. The main advantages of the dry screed are the elimination of all the irregularities of the floor, the preservation of the heat indoors and good sound insulation.

KNAUF Currently - the most famous manufacturer of dry ceramzitic frustration, producing materials, easy to install, and meet all standards. The scope of application of such national flooring is extremely large: any residential and industrial premises with normal temperature and humidity level. When using waterproofing, they are used in indoors with high humidity.

KNAUF Dry fridge is an environmentally friendly ceramzite, with an ideal particle size distribution, which is excluded by the floor shrinkage subsequently. Ceramzite is particles of burnt clay having a light porous structure that are resistant to wetting and influence of fungus. The use of the usual claying that does not have exactly verified composition, and containing many small particles and dust, will lead to floor drawdown after some time, and spoil all the floor covering. The size of the granules of dry backfills of KNAUF 1-4 mm, and thanks to a properly balanced composition, its density and form is the perfect material for the device dry screed in your room!

Dry frustration KNAUF has the following technical characteristics:

The minimum backfill thickness is 20 mm;

Consumption per 1 m2 of the floor surface with a thickness of 10 mm - 10 kg;

Fusion density - 600 kg / m3;

Strength - 2.5 MPa;

The coefficient of thermal conductivity is not less than 0.12 W / m ° C.

Dry screed mounting technology using Knauff's backfills is quite simple. Works must be carried out at the end of all electrical and sanitary and technical events. First you need to clean concrete base Paul from all types of pollution. To lay on the overlap of a layer of steam insulation that protects the filling from moisturizing, with the bottom of the backfill level. Fill the material on a dry base, and align it throughout the perimeter (in the process of backfills, communications and cable wiring are hidden, which is also an indisputable advantage).

As can be seen from the description of the installation technology, when applying dry backfills, the KNAUF is not necessary to use concrete mixer, as in the production of "wet" screed, wait for several weeks to froze the concrete screed, to carry furniture and utensils out of the room (they can be simply transferred from place to place). And most importantly is the creation of an impeccable level level, ready to lay decorative coating, because laminate laminated on this surface will not creak, and ceramic tile Not crap!

Best prices in Moscow!

Prefabricated floors on dry backfill - simple and easy-to-install system. But in order to get a high-quality design, it is necessary to use the correct filler. Ceramzit that meets technological requirements should have a certain fraction, density and shape of the granules.

The usual clay sand is susceptible to the shrinkage, which leads to a time to send and damage the elements of the floor (GVL sheets) and the surface level disorders. Dry fridge for the floor of the Knauff brand is oval granules up to 5 mm. A specially selected granulometric composition ensures the insaneness of the material during operation, and also increases the heat and sound insulation features of the floor.

Dry backfilling Knauf is not available. We offer similar snowwork in our online store. Link to the product.

Properties and use of dry backfills for team floors Knauf

Keramzit is a light porous material obtained as a result of firing a special lifeline clay. It is an excellent environmentally friendly insulation.

The use of dry clay fading KNAUF allows you to create high-quality and reliable floors with a perfectly smooth surface. The mineral composition of the filler provides fireproof and low gigroscopic design.

Works on the equipment of the collection floor are beginning with the preparation of the base. The surface is purified from garbage, then a vapor insulation film is placed on it. The size of the film should be so that the walls on the walls were higher than the planned level of the dry screed. On the perimeter of the room fasten the edge ribbon.

The thickness of the backfill varies from 20 to 50 mm. Deciding with the level of the layer, control marks are applied to the walls and exhibit in the level of beacons (even guide metal rails). Between the beacons distribute ceramzite granules and tighten their surplus. As a result, it turns out an even basis for laying the prefabricated elements of the floor - KNAUF-Superlists of moisture resistant (GVLV) or KNAUF superflake.

The use of dry clawed backfill makes it possible to hide communications, as well as significantly increase the sound and thermal insulation of the room.

The consumption of material when applied by a layer with a thickness of 1 cm is 10 liters per m2.