Usually dacnishes are bored in winter, as at this time of year in country houses very cold. But so I want to just take a break from all this fuss and live in the country. Now the heating of the room is not a problem. The famous stove Buttakov will come to the rescue.

A bit of history

The creator of the famous furnace worked earlier in the Ural Polytechnic Institute, where he worked hard in the field of heat supply. Professor was well understood in the field of ventilation. This proves the books and monographs given by him. The main merit of Buttakov is an invention of a brilliant furnace, the design of which raised the efficiency (efficiency) coefficient to considerable heights. For this stove and called in honor of the inventor.

Appearance

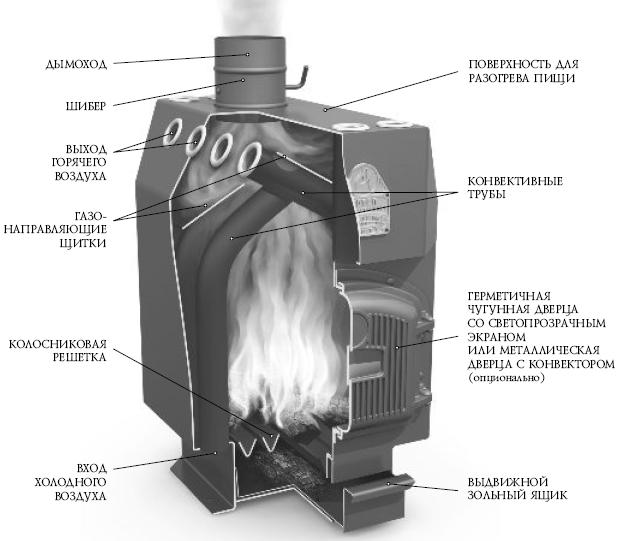

In appearance, Buttakov oven is not much different from the usual bourgear, which, by the way, is the main progenitor of this design. It looks like this is just a black box with ventilation holes on top and sides. In fact, inside - a complex network ventilation pipeswhich most heat the air around. A chimney pipe is supplied to the furnace itself.

Stove Butakova: reviews about the principles of work

The recommended application zone of the boiler is remote areas, those places where there is no electricity or gas. In remote country houses, in large warehouses and in rooms it is more profitable to install the furnace of Professor Buttakov. Reviews It is said that such a miracle design is more profitable than the usual stone oven double, and the bourgeiske at all "takes" ten times more fuel.

The economy invention works clean on solid fuel. A good plus of this stove is not additive. It can be loaded with firewood, paper, peat, chips, cardboard residues or fine coal. All this stove inside itself effectively converts to heat and distribute throughout the house.

The principle of operation itself is similar to ordinary cyclone floors, but the designer made a number of its changes. Cold air is discharged from below, then in the boiler heats up and comes out. That is why there is such a complex ventilation system. Then what is the stove of Buttakov from ordinary stoves? It is distinguished among the rest of the fuel combustion. Unlike other types of furnaces, the solid fuel is not burning in Boutakovskaya, and tweets. The design is arranged so as not to give oxygen in large quantities to penetrate the inside the boiler and not to learn fire. Heat, in turn, highlights a lot, and, as practice shows, it is necessary to change solid fuel. This is good stove Buttakov. Reviews celebrate this feature and express gratitude to manufacturers.

About model series

Professor Butakov designed a whole range of furnaces, each of which was supposed to serve for individual purposes. There were such types of furnaces: "Gymnasicist", "Student", "Engineer" and "Associate Professor", "Professor" and "Academician". The most popular of them are "student", "Engineer" and "Associate Professor".

"Student"

The furnace called "Student" is the most first invention of Buttakov from a number of solid fuel furnaces. It is the smallest size. Its power is not enough for large choirs, but for little house Or the warehouse is quite suitable. The "student" can heat the room with a volume of up to 150 cubic meters. Her dimensions are rather small: only 65 centimeters in height and 37 centimeters in width. She will fit anywhere. Stove Butukova "Student" is equipped with a special combustion control mechanism so that the temperature and fuel consumption can be adjusted. Surprisingly, a small "student" can continue its burning to seven hours only on one fuel tab, which proves the effectiveness of this invention.

Among the wide variety metal stoves Special popularity was specially popular. Another name that can be found is furnace long burning. It is quite economical and easy to operate, suitable for garages and small country houses and for large private houses with permanent accommodation. On the market you can find a wide variety of stoves, but many prefer to make them independently. In this article, we learn what is the stove of slow burning, what kind of varieties they have and how to make it with their own hands.

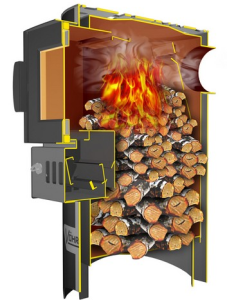

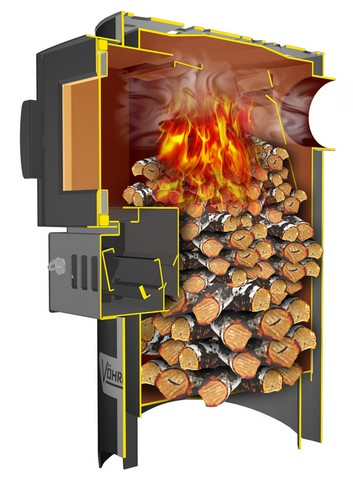

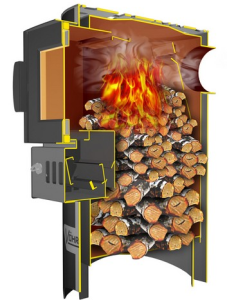

Constructive features

This heating device has such distinctive features:

- Surrounding furnace and a large door for loading firewood. This allows you to conveniently apply firewood in large parties.

- Dividing the furnace into two parts. One of them is intended for the decline of firewood, the other - for burning gas. It is thanks to this feature that the device is called "catalytic stove of slow burning."

- The presence of the so-called "tooth" - the bump of a flame from the chimney. It is a plate welded at the top of the furnace. The task of "tooth" - prevent the flame hitting the pipe.

Differences from a simple stove

The heating function of a simple stove consists in heating the stove housing and the subsequent return of heat into the room. The combustion in it passes quite intensively. If the furnace is metallic, it is uncomfortable. Fuel does not burn completely, it must be constantly added, and the temperature in the room is lowered, it rises. The furnace of slow burning is more convenient.

A simple oven is burned down from below. The flame in it can spread up and to the side. It develops rapidly and dials the maximum value, as a result of which the firewood will quickly go and remain a lot of coal. The power of the flame in the standard stove is due to the fact that the air flow is constantly undergoing. In the oven long burning, the other vice versa - firewood is mounted on top, and the fire applies down. Air comes only to the place of fire. As a result, the slow burning of firewood in the furnace is obtained, which will even more correctly name. The heat stands out less, and the air temperature in the room is saved at one level.

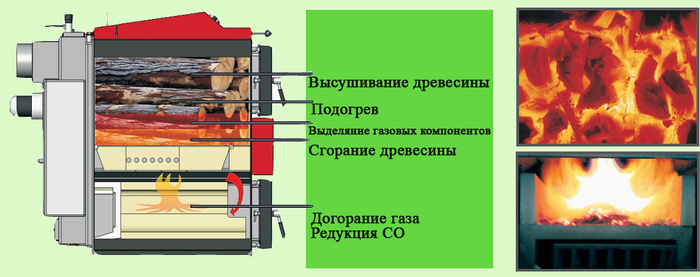

In addition to mannings, pyrolysis gas burns in the stove of long burning. It is formed by the decline of firewood and moves to the second combustion chamber where it is mixed with air. As a result, the products of final combustion almost do not contain substances harmful to humans, the efficiency increases, and heating costs are reduced.

Advantages and disadvantages

Before the stove of slow burning will be released on the normal operation, it must be melt to raise the room temperature to the desired level. Then you can reduce cravings and translate the furnace to slow burning. At the same time, the air temperature in the room will be kept at one level.

So, consider the benefits of such stoves:

- High efficiency - 80-85%.

- Small dimensions.

- If there is no electricity and gas indoors, such a stove is the only heating option.

- Absolute non-volatility.

- Ease of operation. By loading the fuel, you just need to adjust the thrust level. One download is enough for 5-6 hours of full heating.

- The combustion products are practically harmless.

- The heating devices of this design are suitable for different areas and the method of use of the premises.

Without flaws, it also did not cost:

- Chimney must be as high as possible.

- Raw firewood are not suitable for burning in this mode.

- Due to the fact that the smoke enters the chimney at low speed, deposits accumulate in it.

Now consider the process of independent manufacture of the stove. The main difference between the ovens of long burning is two combustion chambers, which are connected simply with grille or grate. In the download zone, firewood occurs. This process proceeds with small amounts of oxygen. After the flow of firewood decompose on the coke and pyrolysis gas. Gas goes to the second chamber, where his burning occurs. Side products go into chimney.

To make a simple furnace of this type, you will need:

- Sheet metal with a thickness of 3-4 mm.

- Metal corners.

- Steel fittings.

- Pipe for chimney (steel or cast iron).

- Bulgarian.

- Apparatus for welding.

- Measuring tools.

Manufacture

The stove is divided into three zones: the loading area of \u200b\u200bfirewood with a grate from below, a collection of ash, a gas combustion area, separated by a bump of a flame from the pipe.

First you need to cut out of a metal corner of 4 legs, about a meter long, and the crossbar (their length depends on the sizes of the furnace that you plan to get). Next, from the crossbar you need to weld the frame of the stove, to which metal sheets will be attached. Then the legs are welded to the frame.

To increase the heat transfer of the stove and extend its service life, you should not take too thin metal for the walls. Metal sheets are cut in size sizes and welded to it. On the front wall you need to make a hole for two doors (one for loading, and the other for the ash bar).

Even before the final assembly on the front, it is necessary to fight the veils and drills for doors. Next, you need to make the doors themselves and attach them. So that the gap between the doors and the wall is minimal, it will be worthwhile to weld the bus. On one of the side surfaces you need to make an air distributor. To do this, it is necessary to do the hole in the wall, as well as to weld a circle to it with a pipe and a damper. It is necessary to regulate the flow intensity. To the wood of the treli, and not burning, the hole should not be more than 20 mm in diameter.

On the inner surface of the side walls in advance to make fasteners for the partition between the two stove compartments. As a partition, a lattice of reinforcement or grate can be performed. On the cover of the stove, you need to cut a hole for the chimney and install a flame bump.

Safe operation

The surface on which the stove of slow burning for the house should be perfectly even and horizontal. On the floor and walls near the heating device you need to impose any Metal pipe The chimney needs to be treated with a non-flammable composition, and between the pipe and the wall put the non-combustible thermal insulation.

Before melting the stove for the first time, it is necessary to check its tightness. To do this, the material is mounted in the furnace, which there is a lot of smoke during combustion. If you find the seam through which smoke seeps, this problem must be eliminated.

Cleaning

So that the furnace worked smoothly, the chimney must be cleaned periodically, and from the ash bar, choose ash. If there are hard-to-reach space in the system, at the beginning of the season, it is recommended to burn aspen in it. It has the ability to clean the walls of the chimney. This is the simplest version of the furnace - the burzhuyka of slow burning. But there are more technological and aesthetic species. They will be discussed below.

Water contour

The stove of slow burning with water circuit, unlike a simple stove, can heat several rooms at once. In addition to high heating efficiency, such furnaces tend to have an interesting modern design, which can be selected for the interior of the house. This is another feature that distinguishes them from products that put in garages, basements, boiler rooms, or, in the extreme case, on small, rarely visited dachas. For proper choice The wood-burning stove with water contour can become a true interior decoration and an alternative to the fireplace. Models are particularly popular with a transparent front wall. The visual effect here plays a crucial role. After all, the fire creates a cozy peace-loving atmosphere in the house. It turns out not just a furnace, but a kind of oven-fireplace of slow burning.

Through the use of the pipe system and radiators, the oven greatly warms the whole house. At the same time, it allows you to significantly save on firewood, not to mention the savings of gas and electricity. If in very coldy It is not necessary to regularly protect the furnace, then the likelihood is very high that water in the pipes will freeze. Therefore, experts offer when using a slow burning oven for giving, add special additives into water. They will increase the water crystallization temperature.

Automatic loading of wood

The most technological stove of slow burning is the oven with automatic loading of firewood. She, as can be understood from the name, allows you to warm up the house without permanent person participation. And it can do it for several days.

The principle of such a stove is simultaneously simple and complicated. Due to the fact that the firewood is fed into the furnace automatically, constant burning is ensured. The complexity is that the flow of firewood should be organized accordingly. For these purposes, special racks are installed inside the stove, which are stacked by firewood. In order for the temperature of the temperature in the firework, a new portion of firewood was served, a heat sensor is needed.

Another important nuance is a new approach to cutting wood. If usually firewood is being seen on the hemp, and then squeeze the ax, then it is necessary to drink a tree round "pancakes". This form is needed so that the fuel is most conveniently falling into the furnace. Harvested wooden circles are put into the stove with a rib on the inclined rack. When the sensor is triggered, they roll to the right place. An independent manufacture of such a furnace is rather problematic because the process requires extreme calculations, as well as compliance with all the requirements.

Benefits of wood heating

Choosing a boiler for heating at home, people compare the strengths and weaknesses of those or other options. Having considered several types of heat burning stoves, get acquainted with the benefits wood heating generally. Compared to other types of heating, it has quite a lot of strengths:

- Ecology. Wood-burning oven does not harm environment, In this regard, she simply does not have equal. Burning, wood highlights no more carbon dioxide than when rotting in a natural environment. And compared with the harm, which is applied by the other types of fuel, it's just a trifle.

- Efficiency. Unfortunately, many people think primarily about financial benefits, and then ecology. But in this regard woodstocks succeeded. Firewood is less than other types of fuel.

- This unit can be applied not only for the purpose of housing heating, but also for cooking. This is especially true for those whose house is far from the gas pipeline.

- With all the efficiency of wood heating, it is not difficult at all. If everything is done correctly, the stove even without radiators will warm the house well.

- The oven thrust creates heat exchange between the street and the house, due to which the optimal temperature level is achieved and the humidity is normalized.

- A wood boiler gives a pleasant fragrance, creates cozy atmosphere And reminds us of our roots.

Conclusion

Today we learned that they represent the furnaces of slow burning. Of course, it is a perspective version of the heating of residential premises, because in lately The issue of conservation of ecology and fuel economy has become particularly relevant, and the design of the catalytic furnace allows it to get rid of the shortcomings of other, obsolete species of wood stoves.

Any furnace or fireplace used to heat the premises effectively perform their function only when constant and active fuel combustion occurs. Plus, an additional heat transfer takes place by the walls of the heating device at that time when the fuel burned down and the device cools. This method of heating the premises is not effective enough, since the efficiency of most such devices is too low. In cases where the heating device is required, first of all, high efficiency with low fuel consumption, long burning furnaces are used.

The principle of operation of this type of heating devices

In most heating devices, the heating function is implemented due to the heating of the device itself, heating the surround air and the subsequent heat transfer with its walls. This is due to the rapid and intensive combustion of fuel. This method is not too convenient for several reasons: these are "jumps" of temperature in the room, incomplete combustion of fuel, resulting in a lot of soot and soot, the need to constantly add coal or firewood to the furnace and adjust the thrust. In the crops of long burning, everything happens somewhat differently.

When we burn a fire or finish the furnace, we set fire to the cut from below, after which the fire gradually spreads upwards and sides. As a result, we get a large flame in which the fuel combines quickly, forming coals. While they are not dead finally, there is an opportunity to inflate them, directing the flow of air into the bottom layer of coal, where they are most hot - so often come when cooking kebabs. Such intensive combustion of fuel occurs because the oxygen access to the furnace is open. In the crops of long burning, the fire moves on the contrary - from top to bottom, due to which it is possible to load the firebox completely, and use the fuel gradually, as the previous, top layer is combustion. The air enters the furnace directly to the place where there is a fire, contributing to the gradual promotion of it down. The combustion process itself is not so intense, as in conventional furnaces: the fuel is rather tweet, and not burns. As a result, the combustion occurs significantly slower and stands out. less heatwhich is enough to maintain optimal temperature in room.

When we burn a fire or finish the furnace, we set fire to the cut from below, after which the fire gradually spreads upwards and sides. As a result, we get a large flame in which the fuel combines quickly, forming coals. While they are not dead finally, there is an opportunity to inflate them, directing the flow of air into the bottom layer of coal, where they are most hot - so often come when cooking kebabs. Such intensive combustion of fuel occurs because the oxygen access to the furnace is open. In the crops of long burning, the fire moves on the contrary - from top to bottom, due to which it is possible to load the firebox completely, and use the fuel gradually, as the previous, top layer is combustion. The air enters the furnace directly to the place where there is a fire, contributing to the gradual promotion of it down. The combustion process itself is not so intense, as in conventional furnaces: the fuel is rather tweet, and not burns. As a result, the combustion occurs significantly slower and stands out. less heatwhich is enough to maintain optimal temperature in room.

Pyrolysis boilers are particularly economical: in addition to the principle of slow combustion of fuel, the burning of gases formed as a result of combustion is also being implemented. Thus, the efficiency of such a heating device increases significantly, reducing costs.

"Pros and cons"

Undoubtedly, high efficiency (up to 85%!) And small sizes of such aggregates have gained great popularity, especially where there are no other heating resources - natural gas, electricity. Attracts the ability to load the fuel once, after which it is enough just to adjust the thrust in the furnace when the desired room temperature has been reached. It remains stable enough long period of time - depending on the model of the device - and can reach 30 or more hours.

The cost is another positive moment: the oven of long burning can be purchased at a very modest price, compared with "pathos" fireplaces, and get a much greater heating effect. Therefore, these devices are most often used to heat the premises of small country houses, production workshops that do not have a centralized heating system, houses of rural residents, etc. Buildings.

The cost is another positive moment: the oven of long burning can be purchased at a very modest price, compared with "pathos" fireplaces, and get a much greater heating effect. Therefore, these devices are most often used to heat the premises of small country houses, production workshops that do not have a centralized heating system, houses of rural residents, etc. Buildings.

A variety of models allows you to organize both air and water heating at home - in this case, a water circuit is connected to the furnace. To such an oven, it is possible to connect a container for heating water for household needs, it can be even cooked and disperse and disperse - in a word, this device is truly multifunctional.

The relative disadvantage of this device can be called utilitarian appearance: Such a stub is unlikely to decorate the interior, but it is not required of it. It can be called "workhorse" among heating stoves with full right.

Gases emerging from the furnace in chimney have a low temperature (compared to conventional furnaces) - about 2000, which leads to the formation of condensate in the chimney. Such a furnace cannot be connected to the curved, a multi-part pipe, since the thrust in it is very small, and the combustion products will not be output.

Long burning mode starts to work not immediately - first the temperature in the room should be brought to the desired level, only after that the thrust is reduced and translated the furnace to the economical mode. In this case, the temperature does not increase anymore, but only supported at a given level.

Types of fuel used in the furnaces of this type

Another advantage that has a durable burning furnace - the ability to use different species Fuel - solid, liquid and gaseous. True, for each of them the device model is intended here - there is no universalism. Featuring a model that works on the most accessible and advantageous fuel in this area, you can fully ensure efficient and economical heating of your private house, cottage, industrial premises.

May 14, 2014.  Alexei

Alexei

Depletion natural resourcesUsed as fuel makes humanity think about finding alternatives. But so far there are no replacement, you have to develop equipment that can work in economy mode.

One of these devices is a durable burning furnace. Its work is based on the principle of pyrolysis. What is this process and is it profitable for the purchase of such aggregates?

Answers to these questions will help choose a furnace, which can cope with the function of heating is not worse than the most modern boiler equipment.

What is the secretion of gas generator equipment?

Many know the heating units of long burning, but that they are not known to everyone. Therefore, before buying such a model does not prevent the basic information about it.

Many know the heating units of long burning, but that they are not known to everyone. Therefore, before buying such a model does not prevent the basic information about it.

So, the oven operating on the principle of long burning is a heating unit capable of maintaining a comfortable room in the room during at least 4 hours. Its structural features are designed for the most complete consumption of energy of burning of any fuel.

Such equipment has a rather high efficiency, thanks to high quality heat transfer. The market for long-term combustion devices are represented by three varieties:

- Furnaces - fireplaces

- Bourgehogs

- Heat generators

The first, except for heating the room, are designed to review the live flame languages. Their design will fit into any interior and can be performed both in classical old form and in modern.

Bourgeisters are the most simple from this class. They are a metal container equipped with a doors to load firewood. In the oven built into the nozzle, allowing you to connect the unit to the chimney.

Bourgeisters are the most simple from this class. They are a metal container equipped with a doors to load firewood. In the oven built into the nozzle, allowing you to connect the unit to the chimney.

The third type of equipment is considered the most efficient. Its feature is the ability to maintain a special combustion regime, in which a gaseous product is formed with a high specific heat capacity. Such efficiency models can reach 80%.

The essence of pyrolysis is what fuel is the best for him?

How does a long burning device work? Its principle of operation is based on the ability of wood under the influence of high temperatures and with a limited oxygen supply to highlight the combustion gases during combustion. Previously, they came out with smoke into the atmosphere, and in modern models they enter the download zone, where the mixture burns with high heat release. This made it possible to significantly increase the efficiency of the equipment.

The work of such an aggregate occurs in the following order. At first, with a large concentration of air in the firewood, the firewood is intensively lit. Gradually, oxygen burns out and the combustion goes into the process of tension. This becomes possible due to the effect of high temperature.

The work of such an aggregate occurs in the following order. At first, with a large concentration of air in the firewood, the firewood is intensively lit. Gradually, oxygen burns out and the combustion goes into the process of tension. This becomes possible due to the effect of high temperature.

Long burning heating furnaces can work almost on any kind solid fuel, But the maximum effect is achieved only when burning dry wood. Therefore, deciding to buy this equipment as an additional heat source, choose models in which the main fuel is wood.

A variety of modifications of long-burning furnaces, their main advantages

A variety of modifications of long-burning furnaces, their main advantages

The difference of aggregates consists in several parameters:

- The type of material (from which equipment is manufactured)

- Room heating time

- Functional features

Based on the parameters of the first point, pyrolysis furnaces of long burning are divided into:

- Steel

- Cast iron

- Brick

Depending on the dimensions and some technical features they have different time Heating (minimum - 3 hours, maximum - more than 10 hours). Different designs of units allow them to use them for heating rooms with an area of \u200b\u200b80 to 250 m²

There are models for heating, as well as heating and cooking, intended for cooking and warming up food.

There are models for heating, as well as heating and cooking, intended for cooking and warming up food.

The price range of such equipment is quite wide. The simplest models of domestic production can be bought in just 7 thousand rubles, and having a stylish design and modern equipment - within 100 thousand rubles.

However, considering various ovens of long burning, the prices of them cannot be remembered about the merits.

These include:

- Opportunity efficient work on any type of solid fuel

- Almost complete absence of harmful emissions into the atmosphere

- High efficiency

Is it possible to collect such equipment yourself?

The issue of saving funds by creating a durable burning furnace with their own hands is especially relevant in modern society. But will there be difficulties in the operation of such equipment? And the point here is not even that the collected design will be less efficient than manufactured.

We watch the video about the bunching furnace:

The question concerns the need to install electronic fillings in them, which complicates the equipment and the process of creating it with their own hands. This fact is questioned how profitable is based on the principle of long burning.

However, not everything is so bad. If the equipment is not calculated for continuous use, then you can collect one of the most simple models, the control of the operation of which is carried out in manual mode. Such ovens of long burning can be used for heating workshops and utility rooms, baths, greenhouses and garages.

Among the variety of independently manufactured equipment, two samples can be distinguished:

Among the variety of independently manufactured equipment, two samples can be distinguished:

- Long burning furnace on the spent oil (it is assembled mainly from the primary materials)

- Model navigated in the people of bubonphia (made of metal barrel)

Both aggregates are quite popular among folk craftsmen, due to the simplicity of their design and high efficiency during operation. The scheme and package of such models is quite easy to find on the network.

Whose products are more effective?

Long burning furnaces make it possible to reduce heating costs at least 4 times. In addition, they can work on waste from wood processing and even agricultural products (straw). But how much would buy a furnace based on the principle of long burning? It all depends on the type of heated room and material capabilities.

We look at the video about the products of the Bulleroin Rules of the furnace:

Here it should be borne in mind that the equipment from foreign companies is considered the most efficient and has a stylish design. It is capable not only to heat the room, but also become an decoration (fire mills). But the cost of such furnaces is several times higher than the indicators on a similar domestic product. It is necessary to navigate when choosing.

We will look at the products of local enterprises that are in demand in the domestic market of heating equipment.

We will look at the products of local enterprises that are in demand in the domestic market of heating equipment.

The cinene furnace is used to heating the premises with minimal fuel consumption. It is able to work on one download to 12 hours, which was achieved through the principle of gas generation.

As fuel in this model can be used:

- Wood waste

- Peat briquettes

- Cardboard

Machine is carried out, as in conventional furnaces, and then the unit is translated into the radiation mode. For this, the chimney valve closes and the door is covered. Adjusting the degree of movement of the flap set the highest possible combustion mode.

Some modifications of devices allow cooking food

The oven Vologda is another of the models of long-burning equipment. Since the manufacturer releases several equipment modifications, then when choosing a model, you must pay attention to their specifications. The efficiency of the furnace reaches 80%.

The oven Vologda is another of the models of long-burning equipment. Since the manufacturer releases several equipment modifications, then when choosing a model, you must pay attention to their specifications. The efficiency of the furnace reaches 80%.

All furnaces of long burning on the corner from this manufacturer are equipped with a cooking panel, and some have a coil to heat water. Constructive features allow you to connect a tank with water to it, with flexible hoses or use with water heating system.

Choose the oven not forgetting to explore the reviews

The process of buying heating equipment requires a thorough approach. After all, the oven heating long burning is not chosen for a couple of weeks, but for many years and therefore it should be paid to choosing special attention. The first to pay attention is power.

It is chosen depending on the size of the heated room. However, it is not necessary to neglect other characteristics. And so that the opinion is correct, it will not be superfluous in the network reviews on the ovens of long burning.