During the construction of many people, many people have a question to make the overlap, so that it is not only reliable, but also ensured good sound and thermal insulation of the premises. To solve this problem, it is best to make a choice to reinforced concrete plates or reinforced concrete monolithic overlap.

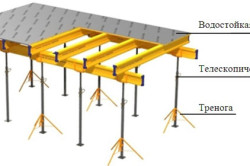

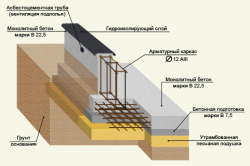

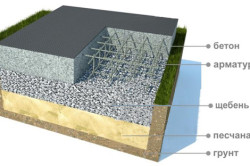

Scheme of monolithic overlap.

If you buy reinforced concrete slabs required size is not always available, then make monolithic design You can independently, the main thing is to correctly make the calculation and responsibly get to work. So that the monolithic overlap has high strength, its reinforcement is carried out. The dimensions of the reinforcement used in each case are calculated individually and depend on the magnitude of the area overlapped and from the load on the structure. Allows you to get a solid design of high quality.

One of the main advantages of the monolithic overlap before using finished designs is that in this case there is no need to apply heavy equipment that is not always available when conducting private construction.

Another advantage of the reinforced concrete monolithic overlap is that in this way it is possible to overlap any non-standard size in the size of the premises, while the movement of the reinforcement in each case is calculated separately. Construction reinforcement allows you to achieve high strength. Before wooden design Monolithic also has advantages, as it is stronger and reliable. In order to carry out the right calculation of all parts of the monolithic overlap, you can contact special design organizations or do everything yourself using available programs that allow you to calculate the placement of the reinforcement, construct the overlaps of any destination and different shapes.

Calculation of monolithic overlap

Scheme of monolithic overlap with their own hands.

The presence of special computer programs help make calculation, but they do not replace the designer itself. If you do not have major building knowledge (do not understand the characteristics of concrete and reinforcement, do not understand what fittings are B), then you cannot calculate the monolithic overlap. Some people begin to make a monolithic design without conducting a preliminary calculation. In this case, they risk, as the overlap or will have less strength, or it will be much more expensive. It is undesirable and unprofitable. It was always quite expensive to attract professionals, so many people make a decision to independently do a monolithic design. How to calculate it correctly, consider further. First you need to decide on the thickness thickness. It depends on the load on the overlap and the length of the span. In order to carry out an exemplary calculation of the overlap thickness, it is necessary to divide the largest length between the supports to 30. For example, if the rotation step is 6 m, then the plate must be a thickness of 20 cm.

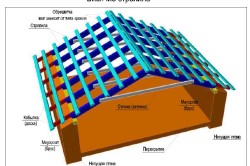

The circuit of the roof of the corrugated floor.

If the overlap thickness is 15 cm and the load on it is small, then it is possible to reinforce into one layer. If you work yourself yourself, it is better to do in two layers, in the upper and bottom of the plate. There is a choice for you, if you do everything yourself, it is better to overpay for the material and get high overlap strength. If the calculation will make specialists, then you will save on the material, but overpay for the implementation of the specified work. Professionals will help determine the desired size, pitch of cells, the cross section of the reinforcement. Often, additional reinforcement is required to enhance the strength of the structure. At the bottom of the slab, it is made in the middle of the span, and in the top - in the places of the highest load: in the technological holes, on the supports, in the installation places of heavy furniture or technology. It is necessary to take into account the pitch of the partitions, which will be at the overlap. For additional strengthening, an armature of 0.4-1.5 meters long is used. It is a solid slab, the thickness of which is usually 12-20 centimeters, which is made of concrete B15-B25 and which has reinforced with metal rods. In each case, the placement of the reinforcement is calculated individually. Such a stove relies on bearing structures and can have the most diverse shape. The device is carried out in three stages:

- mounting formwork;

- reinforcement: The framework of reinforcement is made, the diameter of which is 8-16 mm, usually the step is 15-20 cm;

- concrete concrete concrete B15-B25.

Mounting

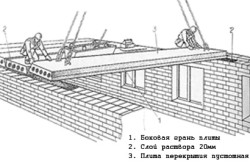

Mounting diagram of reinforced concrete slabs.

In order to make a monolithic design, you must first form a formwork. The forming surface in it is the waterproof plywood. As the calculation shows the calculation, its thickness must be 18-21 mm. After pouring the plate, Phane will be removed and reused. If the installation is performed, the edged boards can be used. But in this case, be prepared for the fact that the concrete will leak through the slot. Boards can be fed, the rusts that spoil will appear in these places. appearance Coatings. In the future, they need to either be shot down, or align with plaster. Especially thoroughly, it is necessary to check the reliability of the installation of the racks and the absence of cracks in the formwork, if the slots are more than 3 mm, then they must be attached. Otherwise, the concrete milk will be seamless to them, and this leads to a decrease in concrete strength.

Formation of reinforcement carcass

Scheme of the monolithic slab overlap.

After the installation of the formwork was carried out, it is possible to begin reinforcement (with the help of metal rods form a frame of monolithic overlap). Between itself, the reinforcement is tied up into the grid with a knitting wire, as the calculation shows, sufficiently wire with a diameter of 0.8-1.2 mm. Usually, the cell pitch is 15-20 cm, respectively, their size is 15 × 15 cm or 20 × 20 cm. For the main reinforcement, fittings are used with a diameter of 8-12 mm, for seats where it is necessary to strengthen the design (support on the walls, columns and spans), Third-thick fittings with a diameter of 12-20 mm are used. The thickness of the reinforcement in the monolithic overlap in each case is calculated individually. The thickness of the protective layer of the reinforcement should be at least 2 cm, for this, the locking layer locks are put on it onto the formwork. After reinforcement, the entire frame must be carefully checked.

Conducting concreting slabs

House construction scheme.

After a formwork is made along all surfaces of the overlap and reinforcement, it is starting to concrete. Concrete mix It can be delivered to the place of work or prepare directly on the site. Cement is used as the main binder material, as a small aggregate - sand, and crushed stone as a large aggregate. As the calculation showed, on average, the weight of the square meter of the monolithic overlap with a thickness of 20 cm is 480-500 kg. Best of all, the finished concrete mixture is predicted immediately to the entire thickness of the plate, while one direction of work is withstanding. These works should be carried out continuously and well compact the mixture with a vibrator. Most often, deep vibrators are used to seal the concrete mix. When carrying out the free laying of concrete, the height of the drop may be up to 0.7 meters. If the base is flat, then control of the thickness of the overlap can be carried out using the probe. When it is uneven, then with the help of a level. The surface of the slab must be covered from wind exposure and direct sunlight. You can not expose hard concrete and mechanical impacts, such as shocks or concussions. In order for the hardening process most effectively, it is necessary to periodically water the monolithic overlap of water, in dry weather it is necessary to make it at a minimum for the first 7 days. If temperature ambient Above 15 ° C, the first three days concrete watered every 3 hours during the daytime and once at night, and then no less than three times a day. At the air temperature of about 5 ° C, it is necessary, on the contrary, provide additional heating of concrete. The calculation showed that the most optimal parameters for hardening concrete are air temperature + 15 ° C and the humidity of about 90-100%. Only after 28 days, concrete will acquire estimated strength. You can move to the dismantling of the formwork after the concrete acquires 70% of the calculated strength.

What is the foundation to choose? This question concerns all developers, regardless of the characteristics of the soil in the site and financial capabilities. Types of monolithic foundations are quite very different at cost and complexity, so it is not possible to choose the appropriate work.

Why the choice most often falls on monolithic optionDespite the higher price?

The house is built "for centuries," and I do not want to constantly fight for its preservation. Monolithic foundations are durable, reliable and durable. There are no problems with the choice of materials for walls - timber, blocks, brick, frame design - monolithic foundation All "Sorpit". The reserve of reliability is that monoliths often build with their own hands and without project.

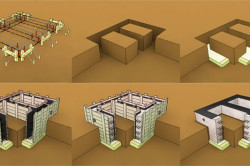

There are several types of monolithic foundations:

- Ribbon. This type includes bellied and small-breeding options. They are distinguished by the depth of the embedding (depending on the characteristics of the soil) and the cost. For such a foundation dig a trench, make a sand pillow, install a formwork and armature carcass. Then poured concrete.

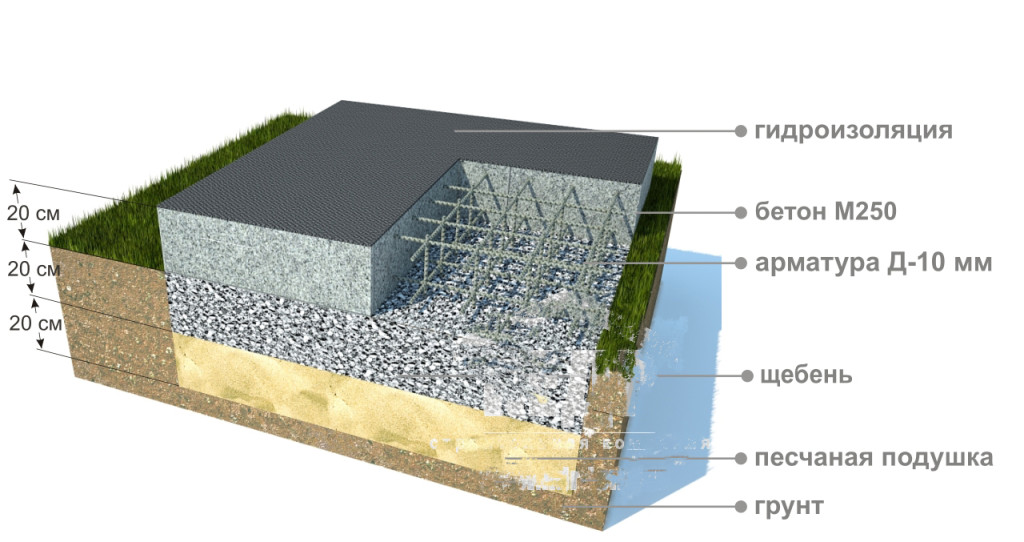

- Foundation monolithic plate Also has options: it can be laid on the surface of the Earth or in the pit. In the second case, we will get a house with a basement floor, but at a higher price. Make monolithic slab foundation It is easy: a plate of reinforced concrete is placed on a flat rammed pad from a sandy-gravel mixture. If necessary, insulate and make drainage.

- Insulated Swedish plate - a more perfect variety. All engineering communications, including warm floors, laid strictly on the project and poured concrete.

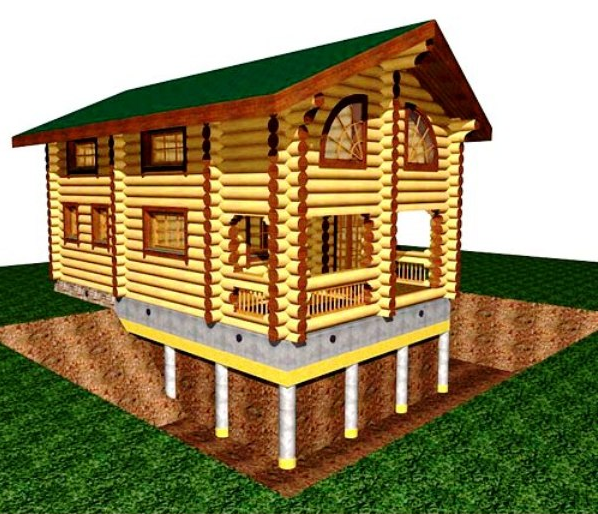

- To monolithic foundations with some amendments, a collection-monolithic foundation and foundation columnal According to tees technology with painter. In the first case, they pour out the usual finely breeding tape and the base of the factory blocks are laid out on it. In a good ground, a reverse option is also possible - first blocks, then the reinforced concrete belt.

Tees technology is designed to save at cost earthworks. The pits under the poles are drill with the expansion below (the support area increases), and the top of the pillars are associated with concrete woodwork. It turns out an intermediate version between the column and tape foundation.

Choosing the foundation, first of all take into account the conditions on the site: the composition of the soil, the depth of frozen and the saturation of water. It should be understood that there are no bad foundations. There are foundations that do not correspond to the characteristics of the soil. Therefore, in difficult cases, the consultation of a specialist is necessary. On the basis of engineering and geological surveys, it will offer an optimal option at cost and reliability.

What are the good monolithic foundations?

- With its reliability. This is a single structure (poured in one approach) without seams and emptiness.

- The reinforcement frame distributes the load evenly throughout the foundation.

- "Holds" shape even in the conditions of uneven effects of powered forces (compare with a column foundation!).

- Does not limit the developer in choosing a material for walls, both by weight and size.

It should be noted that the device of the monolithic foundation does not depend on its type. Each foundation is padded with sand and rubble pillow, fittings, rocked, formwork and portion of concrete. The whole question is how to put it all.

Consider the main options for "laying".

Ribbon foundation with your own hands

Searches and the emergence of new options for the foundation did not lead to anything: the usual ribbon foundation It remains the most popular. What is attractive in it? You can answer in three words: reliably, inexpensive, simple. So simple that most developers are taken to pour this monolithic foundation with their own hands without having special construction skills.

Consider the construction of the foundation tape gradually and in more detail.

- Project development. Right say, it's not cheap. Therefore, planning is charged by specialists in two cases: difficult conditions on the plot and there are nowhere to go money. In the situation, it is easier to pay for their own - forums, where Samosters share experiences and knowledge at least debug.

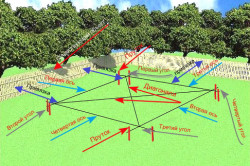

- Plant marking. The resulting project (its own or specialists developed) is transferred to construction site Maximum exactly. Pay special attention to the construction of direct angles and the observance of linear dimensions.

- Earthworks start with the removal of a vegetable layer: it is not taken into account in the calculations in depth and nothing but the decisions of the plants under the house will not give us.

- Ground removal can be done manually or technique. More precisely, but slower - need extra workforce. After the excavator, it will still have to lifted. Therefore, the method of preparing the trench at your discretion.

The depth of the trench depends on the soil: for a finely blurred foundation - 0.6 -1.0 m, for a 20-30 cm blown below below the soil freezing level. The usual thickness of the monolithic foundation is 30 -40 cm.

- The trench is covered with a layer of sand Santimeters 15-20, shed water and trambet. The sand pillow will be high quality and durable if it is put on a geotextile layer: it prevents the shears of sand.

- Next, the walls and the bottom of the trench are waterproined the rubberoid or polyethylene film. So prevent rapid dehydration of laid concrete.

- Over the surface of the Earth is collected formwork and the walls are fixed well.

- Knit a frame from the reinforcement. There must be no less than two rows of longitudinal rods (at the top and bottom of the ribbon) connected by transverse and vertical segments. The diameter of the reinforcement, connection methods, the armature location depends on the specific conditions. It is advisable to have a directory at hand, and not trust the blind items on the Internet.

- The last time you check the correctness of the formwork (sizes and reliability).

- The fill of the monolithic foundation is made in one approach, the concrete is compacted by a vibrator. it the best way achieve monolithic.

- For the period of solidification, the concrete is covered with a layer of sawdust and periodically watered with water. After 3-4 weeks you can start building walls.

How to make a foundation monolithic stove

Not always a ribbon foundation, even fulfilled in full profile, will be able to guarantee 100% reliability. Peatlands, clay soils, saturated with water, completely unpredictably behave when freezing. The foundation is experiencing colossal loads and can be deformed. Otherwise, a monolithic stove behaves: it is not for nothing that is called a floating foundation. It rests on the sand layer and rubble and perceives the pressure of the soil during freezing. The rigid frame evenly distributes the load and from below and on top (building weight), compensating for the powers.

The technology of the monolithic foundation of the stove type and the warmed Swedish plate is not much more complicated by others, and the pros is much more.

Construction passes the same stages: design, earthworks, pillow, waterproofing, reinforcement, formwork, concrete laying.

When designing, the overall load, the thickness of the plate, the amount and dimensions of the reinforcement, the brand of concrete and its quantity are calculated. Do not forget about drainage drangies and insulation with foam (in the northern regions).

Plate marking does not cause difficulties: a rectangular platform for the size of the structure - that's all the markings.

Earthwork works are conveniently and quickly carried out by a bulldozer. For a few hours of operation, move the fertile land to the side (maybe it's useful?) And align the site.

The platform is littered with geotextiles and pour sand and crushed stone layers. It is also convenient to rub, you can use the technique.

For waterproofing laid any rolled materials Two layers with sealing of joints and release from all sides half meter. These excessions cover the ends of the plate.

The next layer is thermal insulation sheets of foam. Optional stage for southern regions.

The formwork consists of one wall installed around the perimeter of the foundation.

Reinforcement of monolithic foundation is a mandatory process. For the slab, the frame is performed in the form of two lattices with a square cell 20 cm. Each of them is placed at 5 cm from the plates surfaces.

Comparative value of monolithic foundations

The cost of construction of each type of foundation has long been calculated construction firms. Let's ask and we will ask.

Of the monolithic foundations considered by us the cheapest small-breeding belt. It is clear: a small amount of earthworks, consumption of materials and concrete.

A bit more expensive monolithic stove. Moreover, its cost will increase in proportion to the area, not only the consumption of concrete increases. But reinforcement, sand and rubble.

The following is the foundation of the TISE. It follows hop prices. Collected-monolithic is already twice as expensive, a broken belt - in three.

The price of your foundation may not fit into this grid. Maybe you have your excavator - minus the cost of earthworks. Many relatives and friends are saving on labor. The more parameters you take into account when drawing up the estimate, the more accurate it will be.

- Types of foundations

- Preparatory stage

- Ribbon foundation

- Monolithic plate

- Materials and tools

- Stages of work

- Advantages of slaughter foundation

It is not difficult to perform a monolithic foundation with your own hands, it, like other types of foundation, has its advantages and disadvantages. For independent erection Houses the main and most difficult task is to arrange a quality foundation. Before buying everything you need for the foundation, you need to decide on its type.

Types of foundations

To choose the type of foundation for the construction, you must first examine the soil on the construction site. To do this, you must dig a deepening in the ground of about 1.5 m and clarify, looking at the cut, what is the composition of the soil. In the event that the soil consists of wet and fine sand or he is peat, its bearing the worst. In areas with such a type of soil, the foundation of the pile-screw or more stable foundation of the monolithic plate is erected.

It is allowed to use, but it is necessary that it is not separate blocks, namely monolithic. With the construction of the foundation under construction on dense, stony soil, you can use almost any type of foundation. But remember that the type of houses will depend on the foundation, the construction on each type of foundation will last for quite a long time.

The monolithic foundation is divided into several types:

- monolithic ribbon;

- monolithic pile;

- monolithic slab.

For the construction of any type of foundation only high quality construction Materials. This is due to the high demands imposed on the monolithic foundation.

Based on the specific sizes of the future structure and the depth of the foundation, the calculation of the material is calculated. The depth of the embedding, in turn, depends on such parameters as:

- the full weight of the design that will be built;

- underground water level;

- the depth on which the soil is freezing.

Back to the category

Preparatory stage

First you must choose a place for your construction. As a basis, it is better to choose a practically even, clean pad. In the case of a segment with vegetation, it must be pre-cleaned. For these purposes, you can resort to the help of a bulldozer, which easily melts the soil on the site. The order of work is:

- the selected area must be cleaned, spilling trees, removing bushes, garbage and stumps;

- remove the top layer of the Earth to a depth of about 20 cm and align the construction site;

- decide and designate with the help of clutching pegs and pulling the rope of the outlines of the future base;

- measure the aspect ratio and necessarily compare the diagonal using the roulette, a corner and a construction level for this.

The accuracy of the markup is very important, it will affect the appearance of your structure in the future, strength and quality of installation. Back to the category

Ribbon foundation

For a lightweight structure with an acceptable load on the base, the foundation of the belt type is quite suitable. To improve such a reason, it will be necessary to perform the same preparatory workwhich are described above. The difference between the installation of such a base consists only in the last stage of the work, when you need to pull out the trench for the fill of the concrete and set the formwork from plywood or boards.

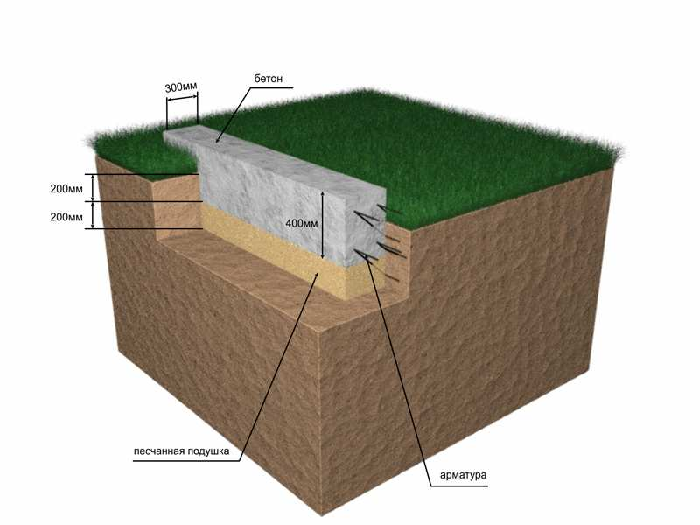

Figure 1. Drawing of a ribbon foundation.

- At the bottom of the trench, it is necessary to lay a sandy pillow with sand. Small sand for these purposes do not apply.

- Over the sand pillows you need to put waterproofing.

- Mount the reinforcement belt and pour concrete.

- After the concrete solution solids, the formwork needs to be disassembled.

- After the concrete finally freezes and the foundation will take place, you can start eating walls.

Ribbon foundation, the drawing of which is presented in Fig. 1, suitable only for buildings built of lightweight materials, such as a tree or foam block. Building a building from a brick should be on a deeply laid tape foundation. Back to the category

Monolithic plate

When the ground on the plot is very soft or swampy, it can be used as a base concrete foundation Monolithic plate (scheme 1). The thickness of such a plate is 20-40 cm depending on the load. Before starting work, it is also necessary to thoroughly calculate all materials. Back to the category

Materials and tools

To perform work on the arrangement of tiled foundation, the following tools and materials will be required:

- roulette;

- level building and hydroelectory;

- vibration plate;

- rule;

- shovel bayonge and soviet;

- bulgarian;

- welding machine;

- gas or gasoline burner;

- marker;

- sand;

- waterproofing;

- technical and drinking water;

- hammer, nails;

- boards or sheets of plywood;

- saw on wood and metal.

http://www.youtube.com/watch?v\u003dwiecv1ndkpg Back to the category

Stages of work

The following steps of arrangement of tiled foundation are distinguished:

Scheme 1. Device of a monolithic plate.

- Marking of the site. After aligning the parties and check all sizes and levels with hand tool It is necessary to re-check everything with a level and theodolite. The site prepared for construction should exceed the area of \u200b\u200bthe built house, it is necessary for the qualitative performance of construction work.

- Preparation of pita. With the help of a shovel or special equipment digging the required cutting with a strictly horizontal bottom. Check are carried out using a level or using a water level.

- Falloon of sand. Before this stage, the bottom of the pit is placed by a geotextile layer that prevents the penetration of sand into the ground. Then pumped the sand layer thickness of about 20 cm and tram it with a vibratory stove.

- Perform the laying of communications and sewage.

- Put the preparatory concrete layer with a thickness of about 10 cm, this layer is covered with a bitumen-based primer.

- Perform waterproofing. Rolled materials are usually used as waterproofing, such as runner. The layers are placed in the mustache, saving them with each other with the help of gas or gasoline burner. At the edges, there is a reserve of about 30-50 cm, which is necessary to later wrap the edges of the waterproofing up, overlapping the ends of the monolithic plate.

- Perform thermal insulation. Usually, extruded polystyrene foam is used as a material for thermal insulation, produced in sheets with special docking grooves. Thermal insulation layer is covered with a polyethylene film.

- With the help of boards or plywood sheets, the formwork is installed along the perimeter of the structure.

- Start the mounting of the frame from the reinforcement, and it can be done in place or install the prepared framework prepared elsewhere. For a frame, an armature is used with a diameter of 12-16 mm depending on the requirements for the base. The reinforcement is welded with grids with cells of 20 cm. The bottom mesh is located at a distance of 5 cm from the bottom of the plate, and the top is 5 cm from the top. Grids are welded and among themselves, this will allow you to get a reliable design, which will be able to walk in subsequent works.

- Pour the frame of concrete. Typically, it is used for this bridge brand 400. With the help of trays, the machine serves a concrete first into remote edges of the foundation, and then closer and closer. Moving the framework, it is necessary to help uniform spread of concrete mass and prevent the formation of air cavities. After filling out the entire frame of concrete, it is necessary to thoroughly align it and walk the vibration plate to remove excess air.

- After drying the mixture (complete drying occurs in 28 days) you can proceed to the dismantling of the formwork.

- With a finely breeded foundation, filling the sinuses near the stove, aligning them with the level of land.

- Plate with a layer of waterproofing, which protects the walls from capillary moisture.

The foundation for the house is ready, the entire process shows scheme 2.

Humanity is engaged in construction throughout its history, starting from the cave time. According to the evidence of scientists, the ancient civilizations showed non-cold abilities in science and crafts. Monuments of the architecture of the ancient peoples have been preserved to this day due to stone materials, including the most common today - concrete. It is widely used in monolithic construction, and it practically does not exist clear boundaries. Most foundations are made precisely from this material. But is it important to build a foundation for your home from? Why are concrete properties still study scientists? How to properly apply in the construction of the foundation? These and other questions will analyze in order.

IN modern construction The following types of monolithic foundations are produced:

There are cases when there is a technology of combined foundations. They also use monolithic technologies From reinforced concrete, for example, to strengthen the properties of the seismicity of the building.

Advantages and disadvantages of monolithic foundations

Like most technologies, the device of monolithic foundations has its advantages and cons, depending on different circumstances.

The advantages of monolithic foundation technology are as follows:

- Material strength;

- The ability to withstand large loads due to the reinforcement of metal;

- Durability;

- Frost resistance (50-1000 cycles);

- High moisture resistance;

- Great opportunities for making any shapes and sizes;

- The rationality of the application of technology is directly at the construction object;

- Efficiency.

Of the shortcomings, the following can be noted:

- Dependence on seasonality of work - in winter, the technology of the monolithic device of foundations requires high exercise costs and concrete care;

- Additional range of formwork and work with it;

- The need for control - a device of monolithic elements requires compliance with technological requirements for the properties of concrete, the assembly class, the manufacture and placement of the frame and formwork;

- With large plugs (the device underground floors, basements, technical underground) will be more rational to apply the technology of prefabricated foundations.

The device of the monolithic foundation for the house is a fundamental process of laying a base for the entire building. From how correctly its device will be correct, the integrity of the entire building structure, its durability and safety of operation for people depends. When calculating monolithic foundations, it is customary to take into account additional load ratings that can be manifested in emergency situationsFor example, with an earthquake. However, reinforced concrete today is the most reliable and advanced in the construction of not only small private low-rise houses, but also of high-rise skyscrapers, once again confirming the status of a universal building material!

The device of the monolithic foundation for the house is a fundamental process of laying a base for the entire building. From how correctly its device will be correct, the integrity of the entire building structure, its durability and safety of operation for people depends. When calculating monolithic foundations, it is customary to take into account additional load ratings that can be manifested in emergency situationsFor example, with an earthquake. However, reinforced concrete today is the most reliable and advanced in the construction of not only small private low-rise houses, but also of high-rise skyscrapers, once again confirming the status of a universal building material!

The video is dedicated to the technology of the UCH device - a warmed Swedish plate - a slab foundation based on puzzle plates from extruded polystyrene and water warm floorslaid inside the slab itself, in the upper part of it.