The design of a chimney is complex and responsible, on the correctness of which the efficiency and safety of using the heater depends. No heat generator is capable of functioning normally without a pipe that removes smoke from the room. Smoke is a mixture of gases containing residual fuel combustion products. The appearance of smoke inside the heated room is a sure sign of incorrect calculation of the chimney system, which entails the danger of fire and carbon monoxide poisoning. This article will tell you what reverse draft in a chimney is, how to prevent its occurrence.

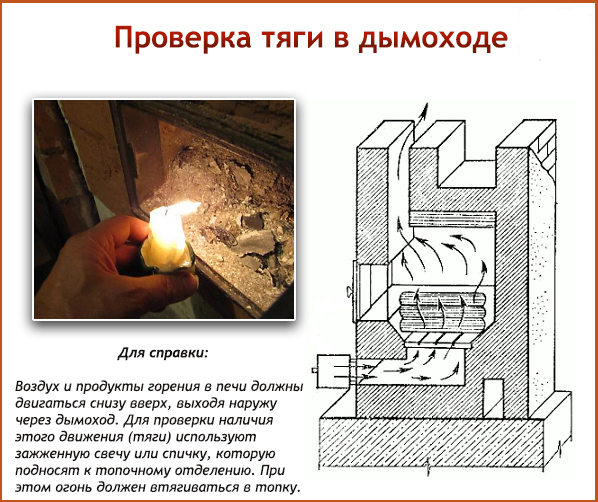

If you doubt that the draft of the chimney of a stove, fireplace or heating boiler is sufficient, you need to check. The easiest way to dispel doubts is to check with your own hands using an anemometer. If the device shows a thrust of 10-20 Pa, then it is considered normal... The problem with this method is the low measurement accuracy of inexpensive anemometers, if the thrust is less than 1 Pa, then they will show that it is not. More accurate professional devices are expensive, stove-makers use them.

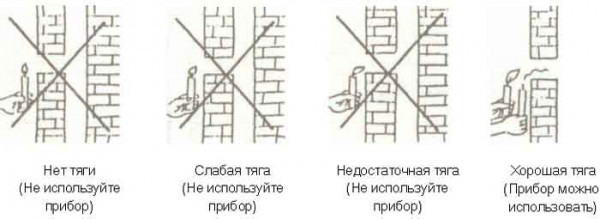

If you do not have an anemometer, use one of the folk methods determining the chimney draft force:

Note! The draft inside the chimney is created due to the difference in pressure outside and inside the building. In a heated room, the temperature is higher than outside, so the pressure is higher there. Heated air, supported from below by colder air, is squeezed out into a zone with a lower pressure, that is, into the atmosphere. If you take measurements in summer, when the temperature difference between inside and outside is minimal, you will get a smaller result than in winter.

Causes of malfunctions

After making sure that there is no sufficient draft level inside the chimney system, it is necessary to determine and eliminate the possible cause of this defect. Experienced craftsmen claim that the most frequent reasons malfunctions of the flue ducts are:

The first step in detecting problems in the chimney system is to sweep aside the most obvious causes of insufficient draft. When inspecting, make sure that the joints of all pipe segments are tight, that there are no soot blockages. Check that no moisture has entered the flue ducts and that the atmospheric pressure is correct.

Ways to increase traction

If the traction force is in the chimney duct of the heater, it is not always easy to eliminate this defect. Experienced stove makers use the following methods, ways to increase it:

If you could not find a solution to the problem of the lack of traction inside the flue duct on your own, consult an experienced stove-maker who will tell you what to do and fix the defect in the most rational way.

Video instruction

If you have a stove or fireplace in your house, then you probably know such a word as a chimney.

Most often, when using a chimney, a problem arises of how to check the thrust indicator and how to increase it (it is also worth talking about reverse thrust and how to increase it). However, first things first.

Signs of traction problems:

- Look at the color of the fire - if your fire has a dark reddish color, then you have low traction.

- If you hear the roar of fire and the white color of the flame, the thrust is excessive.

- The smell of smoke is heard in the room or smoke is entering the room.

How to check chimney draft

In general, there is a special device for this - anemoment, but is it quite expensive and it makes sense for you to buy it if you use it in an extremely row? Gas workers use such a device to check chimneys in houses and apartments.

To check traction, you can use the tools at hand:

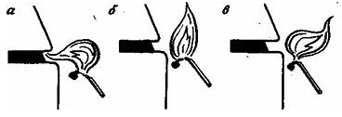

- We open the door of the stove, put a sheet of paper inside and set it on fire, watching where the smoke comes out.

- Take a piece of toilet paper and bring it to the chimney, you need to look where the paper will be deflected.

- We bring the cigarette to the chimney and watch the deflection of the smoke.

- Flame color - yellow-gold - an indicator of good traction.

a - there is thrust, b - no thrust, c - reverse thrust

a - there is thrust, b - no thrust, c - reverse thrust

Why is there no draft in the chimney

If the check showed insufficient traction force for combustion, then first you should think about it, but what could have influenced this?

Many people unknowingly say "no draft" - but this does not mean that there is none at all (there is no draft only when you do not have the chimney itself) it just means that there is no necessary draft force.

Reasons for the lack of traction:

- If there is no chimney (it is vertical pipe a certain height).

- If the channel is blocked (it may be clogged with soot, a foreign object has got there, or other debris has partially blocked the channel).

- If there is no temperature difference between the air inside the pipe and the air outside

- Sometimes another process is also taken for the lack of draft, which is called "reverse draft" (this is when air does not go out through the pipe, but rather strive through the chimney into the room).

Most often this is a common blockage of the chimney, when either a layer of soot or foreign objects interfere with the passage of the air flow.

Even during the check, a metal ball is sometimes lowered from the roof through the chimney and the presence or absence of blockages is checked. With its help, they move the stuck objects, so that it is easier to get them later.

How to increase chimney draft

If, after checking, it turned out that you have insufficient traction, then you need to think and start actions to increase traction, so that later you will not freeze in bad weather and in winter.

The simplest increase in draft is to clean the chimney from foreign objects and soot.

Ideally, at the time of construction, a device is fixed in the chimney-pipe that regulates the draft in your chimney. With its help, the required pressure can be maintained (by increasing or decreasing the traction force).

And its presence significantly reduces the chance of problems with traction.

If the pipe was designed incorrectly (width and length) and because of what you have a small draft, then you can try to fix it (if possible) or attach the chimney again.

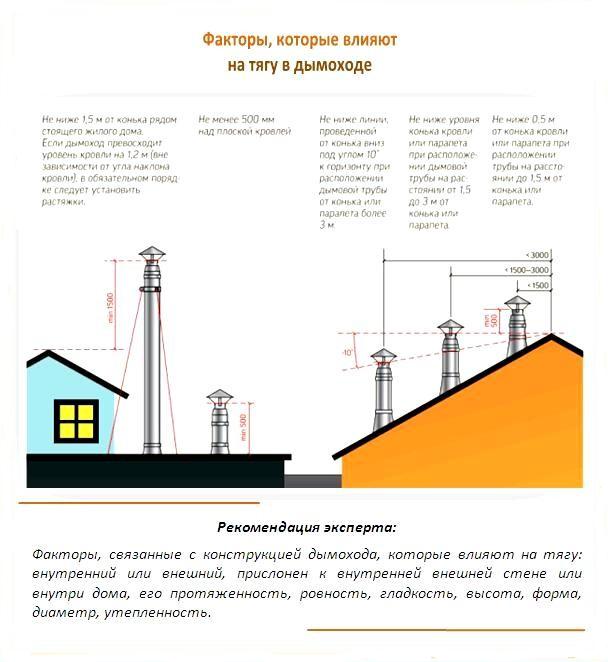

The height of the chimney depends on the slope of the roof (if it does not meet the requirements, it can be increased), although note that the higher the edge of the chimney is above the roof level, the more difficult it is to interact with the chimney (for example, cleaning).

If you want optimal work for the stove and fireplace, attach the tips - outbuildings to the top of the chimney. They prevent wind and rain from entering the chimney.

To increase traction, you can also use fans with a built-in electric motor.

Usually they work from the wind and help smoke out, but if the wind flows are not enough for normal thrust, the engine turns on and increases thrust.

Back draft in the chimney

First of all, it is worth figuring out what reverse thrust is.

Back draft is a malfunction of the chimney, that is, when the smoke returns to the room instead of going out through the chimney.

There are many reasons for the occurrence of reverse thrust, here are the main ones:

Incorrect dimensions:

- Wrong cross-sectional shape;

- Wrong choice of diameter;

- Incorrect pipe length (usually a little more than 5 meters is made).

Deviation from requirements:

- There should be no narrowing of the diameter in the pipe;

- The outer surface of the chimney must be smooth;

- There is no special wing to protect it from wind and rain.

Other reasons:

- Leaky construction;

- The pipe is clogged;

- Wrong material selected;

- Cold air inside the chimney;

- It's warmer outside than at home.

As you can see from this list of reasons, there are many, ranging from errors in the design of the pipe itself and ending with unfavorable weather conditions.

Although such an effect as reverse thrust is of a short-term nature, it still has a very detrimental effect on health, a person may simply not pay attention to a sudden onset of headache, drowsiness, go to bed and inhale combustion products ...

How to reduce chimney back draft

Before trying to fight backward thrust, you need to sit down and think about why it appears, and outline a number of reasons that need to be eliminated to reduce backward thrust.

A good way to get rid of backdraft is to use an electric fan, which will draw air (and smoke) and pipes outward.

Also, do not forget about the gate (metal damper) there are usually two of them in the chimney, one below, above the stove, the second is in the channel itself.

By simulating different positions of the gates, one can find the optimal one that solves the thrust problem.

Sometimes reverse draft is temporary, at the beginning of the season, when there is cold air in the pipe and it needs to be preheated (you can just burn a couple of sheets of paper and warm air will appear).

Draft is an inseparable part of using fireplaces and stoves, however, you need to "keep the draft in check", balancing between insufficient and excessive draft.

In this article, you learned about the main causes of thrust problems (as well as reverse thrust) and how to solve them.

Traction Test Videos

If you have a stove or fireplace, then you know what a chimney is, and if you are just going to purchase or build such a useful thing, then knowledge about the chimney and draft in it will not be superfluous for you. During the operation of the chimney, the most common problem is how to check the draft in the chimney. First, let's figure out what traction is and why it is needed.

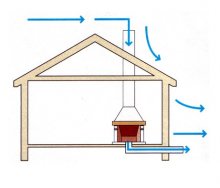

The principle of the chimney

In order to prevent even a gram of exhaust gases from entering the living space, the chimney must have a very good draft, due to which all waste gases harmful substances and fall into the pipe.

There is a special anemometer for measuring thrust. Its cost is quite high. It is usually used by gas service specialists when they start checking chimneys in apartments or private houses. For individual use, buying such a device is, frankly, expensive. In addition, you can use other methods in order to determine the presence of draft in the chimney.

Usually the most common paper is used for this, which is set on fire and brought to the chimney grill. If there is a draft, then the flame will deflect towards the chimney. Instead of paper, you can also use matches. (See also: )

Traction problems

In order to determine the presence of good draft in the pipe, it is not necessary to have a special device. Sometimes the problems that arise become so large that it is not difficult to determine the complete absence of gases from the premises.

As a rule, the following indicates a malfunction of the outlet pipe:

- If, while heating a stove or fireplace, you look closely at the color of the flame, then you can talk about the following. The flame in the firebox, which has a dark red color, indicates insufficient draft force.

- The bright, almost white color of the burning fuel, on the contrary, indicates a strong thrust.

- If there is a smell of smoke in the room, then this may indicate a malfunction of the chimney and the complete absence of draft, this effect is called reverse draft. In this case, all smoke and waste products of combustion do not go outside, but, on the contrary, into the room. (See also: )

Reasons for the malfunctioning of the chimney

During the ideal operation of the chimney, the flame in the furnace of a stove or fireplace usually has a golden color, there is no extraneous noise in the chimney, and there is no smell of smoke in the room. The reasons for the malfunctioning of the flue gas system are mainly the following:

- Errors in the early stages of design. Perhaps the chimney is insufficient in size and simply cannot cope with the incoming flow of waste materials.

- Perhaps the wrong pipe height has been selected, which can also significantly affect the operation of the chimney. (See also: )

The first two cases are relevant when, at the first start-up of a gas column or furnace, it shows that there is no draft in the chimney. And if before that you fired a stove or fireplace and there were no problems with the removal of exhaust gases, then the reasons that affected the draft may be as follows.

- Temperature difference too large.

- Blockages in the flue pipe.

- There is a lot of soot in the chimney.

- Weather conditions: strong, squall winds or high humidity due to prolonged precipitation.

How to fix the situation

If the check of the draft in the chimney showed its complete absence or poor quality, you will have to make a certain decision in order not to be left without heat in bad weather.

In general, ideally, a special device is installed in the chimney - a chimney draft regulator. It helps maintain the pressure required by building codes in the flue gas system. This, in turn, excludes incorrect operation of the system as a whole. If necessary, the regulator can both reduce and increase the force of exhaust gas extraction in the pipe.

So, such a device is useful for prophylaxis, but what to do when the chimney no longer cope with the load or in general, as it turned out, was designed incorrectly. Then all that remains is to correct mistakes and do it as soon as possible.

Therefore, it is simply forbidden to use a fireplace or stove if the chimney is not working properly. Carbon monoxide gases may not be noticed at all. Sometimes the head just starts to hurt and drowsiness appears, a person can lie down for a while and inhale poisonous substances.

If we talk about the height of the pipe, then in accordance with the established norms, its value directly depends on the slope of the roof. If the height of the pipe does not correspond to the given parameters, it will have to be increased. According to the established norms, it is allowed to arrange the height of the pipe somewhat higher, but in no way less than the established norms.

Just be sure to take into account the fact that sooner or later the pipe will have to be cleaned. Maybe you will do it yourself, or maybe you will use the services of a specialist, it doesn't matter. Just remember that a pipe that is too high will not be able to clean properly and well.

Strengthening traction

If checking the chimney draft showed its complete absence or a small value. You can also use a device such as a chimney draft stabilizer or a turbine. True, their use is limited only gas boilers... Excessively high flue gas temperature at the outlet of the pipe will cause the device to malfunction or fail.

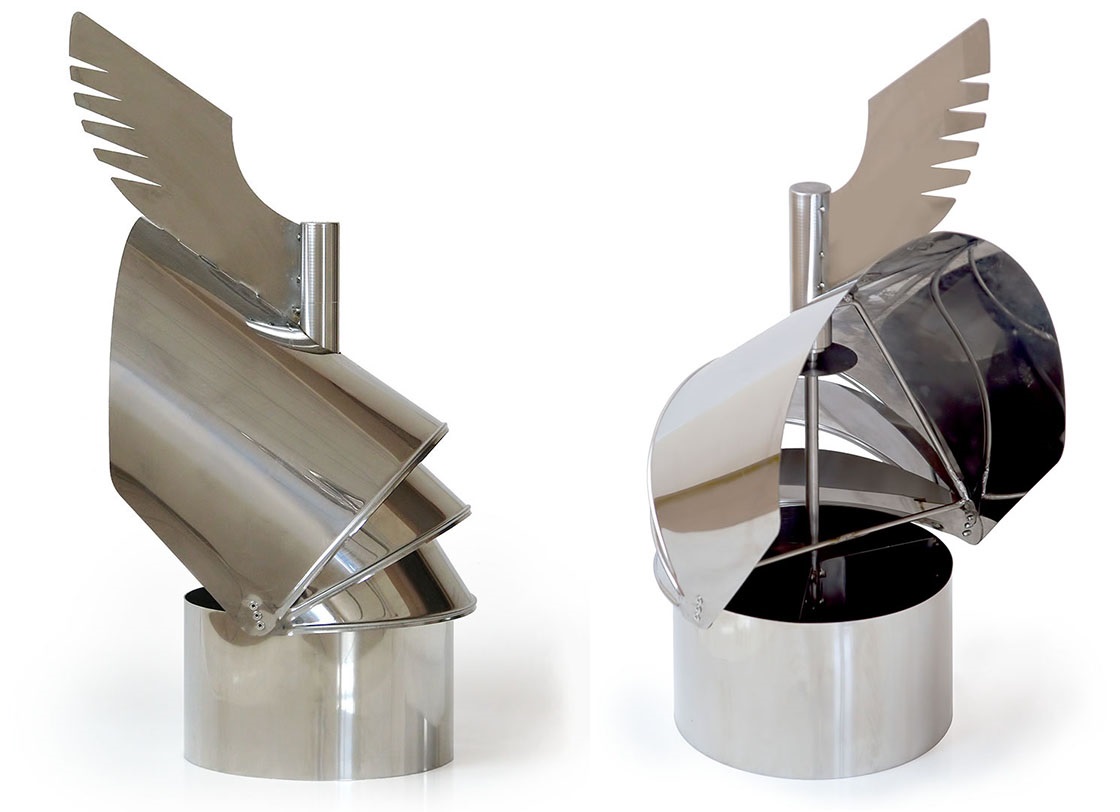

If we talk about stoves or fireplaces, then in order for the chimney to work correctly during not very good weather conditions. Special tips are installed on the pipe - wings. This device rotates freely so that its rear is always upwind. This position prevents wind or rain from entering the chimney directly.

Special fans can also be used. Such devices have a built-in electric motor. Their principle of operation is as follows. Basically, they work from the wind, with strong gusts, the fan rotates, increasing the exit of exhaust gases from the pipe, if the wind flows are not strong enough, the electric motor turns on, which forces the fan to work forcibly and all harmful substances also end up on the street.

A small disclaimer, you should not immediately after reading the article run to the store and buy a new device. Before you are going to install it, you should make calculations. And already, based on the results obtained, it will be clear whether this device can be installed on your chimney.

If there is no draft in the chimney, it will be useful to check the operation of the dampers. For stoves and fireplaces, this is a kind of regulator of the force of exhaust gases removal.

Let's sum up

If you have a question: why there is no draft in the chimney, then first of all you should check the following. If problems with the removal of waste materials arose during the first use of the stove or fireplace, then pay all your attention to the project documentation. Check the correct calculations and dimensions of the flue pipe.

If until now you have used the stove and everything was in order, then you should first check for a blockage in the pipe. It is possible that after a long stagnation, the chimney was clogged with various types of dirt. Sometimes birds can make a nest in the pipe.

Perhaps, over time, the chimney pipe collapsed. In this regard, the normal sealing has disappeared, the outflow of the exhaust gases has become not so strong. First of all, it is worth checking the chimney, part of which is located above the roof. A pipe constantly exposed to atmospheric precipitation can easily collapse. This can happen if a mortar with a low cement content was used for brickwork.

Another reason that very often leads to the problem of poor draft is a large amount of draft accumulated in the chimney. In this case, the chimney must be cleaned. After removing soot, it is imperative to check the return flow in the chimney. If your chimney has not been cleaned of soot for many years, then after cleaning it, be sure to use products that prevent excessive settling of soot on the walls of the chimney.

Helpful advice. If you have not used the stove or fireplace for a long time, and the weather turned out to be with a lot of precipitation, then it is recommended to check the efficiency of the chimney before heating. Otherwise, it may turn out that all the smoke goes directly into the room, and not into the chimney.

If you find that there is a back draft in the chimney, what can you do to eliminate it? Try to remove excess moisture accumulated in the pipe. To do this, before kindling a stove or fireplace with wood or peat, be sure to burn a couple of newspapers. Such actions will dry out the walls of the pipe somewhat and eliminate the increased humidity, so the furnace will melt easier and faster, and the smoke from the burning fuel will begin to go into the pipe.

The use of materials is permitted only if there is an indexed link to the page with the material.

The operation of heating systems directly depends on how well the chimney is made. Competent calculation of the chimney draft plays a decisive role in this. It takes into account the differences between the internal and external air temperatures, as well as the density of the gases formed. It should be remembered that poor cravings affects the health and lives of people. When it is insufficient, and even worse, reverse, toxic products of fuel combustion do not come out, but poison the living quarters. For what reasons this happens and how to prevent such a danger, this article will tell.

Reasons for the formation of reverse thrust

The thrust indicator is considered normal if it is 10-20 Pa. At lower values, the waste products remain in the room. This happens for several reasons:

In addition to the main reasons, there are other negative factors.

Note! Often little is needed to fix the problem - just clean the chimney channel.

The quality of heating depends on the correct calculation of chimneys.

Determination of the amount of thrust

To determine the indicator of draft in the chimney, there is a special device - an anemometer. It works under the condition that the air flow has a speed of more than 1 m / s.

On a note! If measurements are taken during the off-season, the anemometer may be wrong. At this time, the difference in temperature between the air and the room is minimal, so the air currents are hardly noticeable. For accurate measurements, it is better to invite a specialist who has a highly sensitive device.

There are folk ways thrust estimates, for example:

- See if there is smoke in the house. When seen with the naked eye, it indicates a lack of thrust.

- Analyze the color of the flame. If it is white in color and a hum is heard at the same time, this indicates increased traction. Dark orange flames confirm its lack. A symptom of a normal outflow of smoke is a golden yellow fire.

- Observe whether the flames of a burning match or a lit sheet of paper are deflected to the side as they are brought to the chimney.

- Install a mirror in the smoke hood and turn it towards the channel. If everything is ok, it won't fog up. Condensation indicates problems with fume extraction.

Deflectors are effective during windy weather

Methods for enhancing the outflow of smoke

After identifying the problems that led to poor smoke removal, it is necessary to increase the chimney draft. Exists different ways strengthening the outflow of gases in the chimney.

As you understood, safe and effective work heating devices directly depends on the quality of traction. At the first signs of its decrease, urgently fix the malfunctions so that carbon dioxide does not enter the room. If the repair is beyond your strength, contact the specialists. Be healthy!

The operation of heating devices depends on the draft in the chimney, as well as the safety of residents of houses with stove heating... Elimination of possible problems will help you feel comfortable and confident in your home. You can increase or adjust the pressure indicator with your own hands.

Useful information about chimney draft

All residents of suburban or private city houses are familiar with such a concept as chimney draft. Do they know the essence of this term?

If we deviate a little from dry scientific terminology, then thrust can be defined as a natural phenomenon in which air moves from one area to another, namely, from the air zone with high blood pressure to the area with reduced pressure. All this happens with the help of a ventilation device - a special channel in the chimney.

Using this aerodynamic process, mankind began to use fireplaces, stoves, boilers, heating their homes with different types of fuel - coal, wood, peat, etc.

With good draft, the stove ignites quickly and the room is filled with pleasant warmth

From a properly designed and built chimney and, accordingly, a good draft depends on:

- the quality of room heating;

- reduced fuel costs;

- safety of being in buildings with their own heating.

What affects the value

There are three groups of factors that must be taken into account when constructing and checking a chimney.

Intra-house moments

A number of factors, indoors, can significantly affect the presence / absence of traction and its strength:

- The material from which the building was erected.

- Average room temperature.

- The maximum amount of airspace in a dwelling.

- The number of people permanently inside the housing.

- The presence of internal sources that additionally consume oxygen (air heaters, heaters, stoves, etc.).

- Regularity of fresh air supply (ventilation, ventilation).

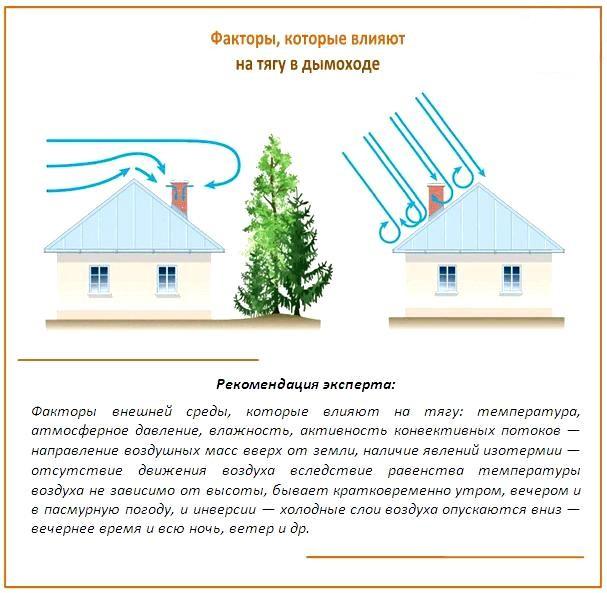

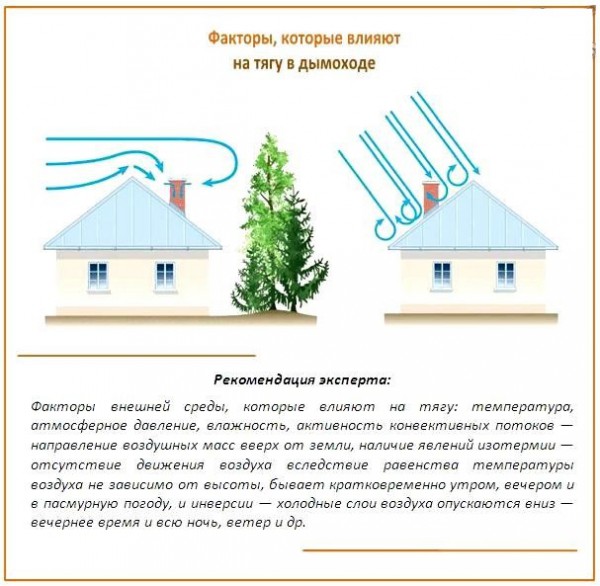

External factors

There are other factors that determine the draft of the chimney, and they are located outside the heated room. We are talking about ambient temperature, atmospheric pressure, humidity, wind direction. The phenomenon of changing temperatures throughout the day can also affect traction - due to the movement of cold and warm layers of air.

Difficulties with cravings appear for various reasons, some may simply not be noticed. For example, problems with air outlet through a chimney can arise if the chimney is much lower than the ridge of a building or tall trees nearby.

Chimney design features

The draft can be different depending on the design characteristics of the chimney:

- height;

- the presence of insulation;

- tightness;

- location (internal / external);

- length;

- presence / absence of irregularities or roughness, etc.

It is necessary and possible to control traction in a room using the "levers" of the first and third factors (in-house and design). Natural changes, naturally, do not depend on a person.

Keeping the chimney draft under control is a prerequisite for safe and comfortable living in your own premises. If the draft is very weak, then it is almost impossible to light the stove and heat the home.

In reverse thrust, combustion gases are “thrown” into the living space, and not into the air through the chimney. It is very dangerous for human health and life!

It is impossible not to notice such atypical behavior of smoke

With a very strong draft, all the heat is rapidly drawn out through the channels of the chimney, without having time to warm up the heated room to the required temperature.

Why does reverse thrust appear?

Weak traction can be the basis for reverse thrust formation. How can you tell if you're not doing well with your cravings?

This is "said" by moments that can be ascertained with the naked eye: a lot of smoke in the stove, soot on the door, the incoming movement of smoke inside the house. In other words, smoke, fumes from the combustible fuel does not go into the chimney through the chimney, but tends to get into the living room with the door open and through the cracks.

Reasons for reverse thrust:

- Chimney design flaws. Low pipe - increased risk of back draft. The higher the chimney, the better the process of extracting exhaust gases and smoke goes. The optimal pipe height is about five meters.

- Correspondence of the pipe diameter to the parameters of the furnace device. A powerful stove requires a chimney with a rather large pipe. But here the measure is very important, since the use of a pipe that is too wide will make the combustion process unprofitable (all the warm air will literally fly into the pipe). It is unacceptable to use several pipes with different cross-sections in the chimney!

- Use of non-smooth pipes. Irregularities, chips, roughness, etc. are an obstacle to good traction. Over time, the chimney opening can narrow due to soot deposits and other combustion elements and hinder the process of kindling the stove and its normal functioning.

- Violation / lack of ventilation. Drafts, open windows in rooms above the firebox do not help the fuel combustion process, but distort it, making it useless and unsafe.

Chimney ducts made of metal are in many ways inferior to brick pipes. Rapid heating and the same rapid cooling do not benefit the heating system as a whole and the chimney in particular.

Brick pipes are much more efficient at extracting smoke

Reverse thrust can also appear for objective reasons beyond the control of a person. Strong gusts of wind, rainy, cloudy weather with high humidity are unfavorable moments in terms of the formation of problems with traction.

There is such a term as temporary reverse thrust. What is it? In this case, it is worth talking about temporary traction violations, for several days. After a certain period, cravings return to normal.

Temporary backdraft can occur due to a cold room that has not been heated for a long time. The very cold air trapped in the chimney prevents the fuel from burning quickly. Therefore, smoke can be “pushed out” of the chimney into a dwelling, bathhouse or other room with a stove or fireplace.

It is very easy to eliminate cold air in the chimney - warm up the pipes by burning ordinary newspapers, wallpaper, paper in the oven. The main thing is that these materials are well dried.

If traction problems can be fixed constantly or at regular intervals, then it is necessary to take measures to eliminate bad traction.

Strength test

Before throwing your energy into a bad deadlift, make sure the deadlift really leaves a lot to be desired.

You can check the traction using special devices or yourself. Simple ways fixing thrust:

- Light a piece of paper, let it burn a little. Bringing it to the stove or fireplace, put out the paper and observe the direction of the smoke. If it goes to the pipe - good traction, deviates in the opposite direction - reverse thrust, if it maintains "straightness" - there is no thrust. Similar manipulations can be done with thin tissue or toilet paper without setting it on fire.

- If there are smokers in the house, then observe the direction from the smoke of cigarettes or from the flame of a match, lighter near the fireplace or stove. Draw your conclusions in the same way as in the first point.

- The flame of an ordinary candle can also help in determining the draft in the home.

- A pocket mirror, brought to the firebox and covered with condensation, may indicate problems with removing smoke from the stove.

- The presence of too much draft, which carries away the useful heat from the room, is evidenced by an audible hum in the stove - a loud hum.

- The color of the fire in the firebox can be an indicator of different draft. Gold tint - good traction, white flame - excessive traction, red color and black smoke - poor traction, high probability of reverse thrust.

A regular lighter can help check traction

The anemometer is a device familiar to many people of the Soviet period. With this device it was possible to measure the draft of the chimney. Readings in the range of 10–20 Pa were considered normal. The disadvantages of the device are in its low accuracy with a wind force of less than one meter per second.

Such a simple device will help to secure your life in a house with stove heating.

Modern industry offers a sufficient number of devices for measuring the draft, there are devices that fix the draft at the inlet and outlet of the chimney.

Troubleshooting methods

If you have identified problems with traction, then, of course, they need to be eliminated as soon as possible.

The choice of means to combat bad or reverse draft depends on the reasons that led to the abnormal operation of the chimney.

Pipe cleaning

One of the common methods for improving traction is pipe cleaning. Fuel, burning in the stove, releases various substances that settle on the inner surface of the chimney. Soot adheres well to pipes if they are uneven or bent.

When carrying out work, do not forget about safety measures

How to clean the chimney so that there is good draft?

First of all, acting purely mechanically. The chimney channels can be made wider, getting rid of plaque, in the following ways:

- After preparing about one bucket of potatoes, peel and chop. Potato peelings are also suitable. Throw a little into the firebox and wait. When burned, potatoes will release starch, which will become a means that can soften carbon deposits. Soft pieces of soot will fall off on their own, while those that are firmly adhered will have to be removed mechanically.

- Aspen firewood. Heat the oven with two or three logs. They will very much heat up the chimney pipes and help get rid of carbon deposits. But this method requires special care, since the likelihood of a fire will be very high (soot can catch fire).

- Rock salt. This method is more suitable for prevention. The salt added at the time of burning improves the condition of the chimneys.

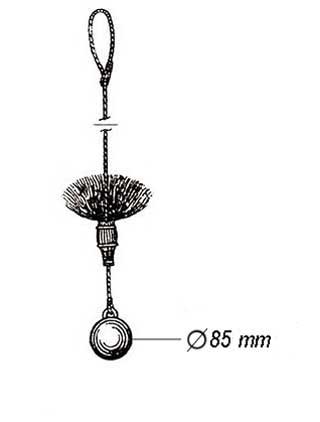

- Pipe brush. A heavy load is attached to a brush suspended from a steel rope and lowered into the chimney holes. By lowering and raising this structure, it is possible to force soot formations to fly off the walls of the pipes and fall into the furnace. These fragments are then removed from the firebox.

The second group of anti-soot measures is based on the use of chemicals. The most demanded chemicals for chimney cleaning are "Log-chimney sweep", "Kominichek". Chemical agents are added to the coals formed during the heating of a stove or fireplace according to the instructions and continue to heat. After all the fuel has burned out, it is advisable to leave the coals, since they continue to "work" in terms of cleaning the chimney (at least, this is what the manufacturers advise).

Do not believe spiteful critics who talk about the mandatory ignition of soot when using the chemical method. This method does not pose any danger, since the beneficial action comes at the expense of chemical reactions, and not due to the extremely high combustion temperatures of the reagent.

It should be especially said about the observance of safety measures during all work related to the chimney. Do not fix chimney problems in windy weather! Try to use fall arrest devices when working at height!

Elimination of structural problems

When identifying certain features of the chimney design that negatively affect the thrust force, adjustments should be made to eliminate them. These actions include:

- dismantling several scattered pipes and installing a single chimney channel;

- roof chimney superstructure to the required height;

- insulation of chimney elements, etc.

Ventilation arrangement

In some cases, cravings can improve by avoiding drafts in the house or bath. You can help with problems with traction by installing ventilation devices on the windows.

In the absence of the desired effect after all the above methods, modern devices should be adopted to improve the draft in the chimney.

Installation of devices

To improve the operation of the chimney, it is best to use special devices that allow you to adjust and control the draft. Such devices can be bought in a store or made by hand.

Special devices for regulation

Modern instrument makers have taken care of the release of special devices that regulate the draft in the chimney:

- Regulators. They are installed on the chimney outlet to normalize the draft in the heating system, as well as as a means of influencing the efficiency of heating.

- Deflectors. Such devices are fixed on the chimney from the outside. An improvement in the draft speed is carried out due to the fact that the diameter of this device is much larger than the chimney pipe, and, therefore, a low pressure area arises in it when air flows around it.

- Chimney weather vane. It is a special design that performs several functions at once: improves traction, protects the pipe from raindrops and snow whirlwinds. The operation of the device is similar to the operation of the deflector, the thrust speed is normalized by reducing the external air resistance.

- Smoke fan. It is very popular among owners of houses with a heating system. An artificial air vortex is created inside the chimney due to the operation of the ventilation system, which requires electricity to connect. Compliance with all necessary safety measures is a prerequisite for the installation and operation of such a device to improve chimney draft.

All devices installed on the chimney pipe to improve draft require mandatory control, especially in winter. This is due to the fact that additional devices attached to the chimney from the outside can become clogged, icy (in winter) and thus prevent the chimney from working properly. Blockage caused by “assisted” devices can cause backdraft and carbon monoxide penetration into living quarters.

Do not forget to regularly inspect along with the chimney and appliances that help increase draft.

Photo gallery: traction control devices

The most common device among stove heating users

The most common device among stove heating users  Such a device is especially relevant for improving the operation of stoves and fireplaces.

Such a device is especially relevant for improving the operation of stoves and fireplaces.  A useful and beautiful device

A useful and beautiful device  By installing such a device, you can improve the performance of the entire heating system.

By installing such a device, you can improve the performance of the entire heating system.

Troubleshoot problems yourself

Let's try with our own hands to make the heating process safe and efficient. The most common way to combat soot build-up in pipes is with a sinker brush.

We clean the pipe with a brush

First, let's prepare everything you need:

- Hard bristle brush. The diameter of this device is selected taking into account the section of the pipe (from fifty to three hundred millimeters).

- Thin metal cable (can be replaced with a very strong rope or rope).

- Weight for hanging from the brush.

This is what the chimney pipe cleaning device looks like

Do not start work if there is strong wind or too much humidity outside. Try to think over and use reliable insurance to protect yourself from unforeseen events.

The ruff is weighted with a sinker, attaching it to the bottom of the device. The brush itself is hung on a cable. All fasteners must be especially reliable, otherwise the structure will disintegrate and you will have to perform additional actions - to "fish" them out of the pipe.

First, they clean all the revision holes of the chimney, and then proceed to cleaning the pipe itself. By moving up and down a few times, you can get rid of the soot that will fall from the pipe into the oven. It is best if someone else is around the stove to signal efficiency and when to shut down.

Pipe cleaning should be completed when the soot stops pouring.

You can also clean the pipe with the help of improvised means, as many videos have been filmed about.

Video: we clean the pipe with improvised means

Selection of devices for regulation

Let's consider some of the characteristic features and methods of using instruments for traction control and adjustment.

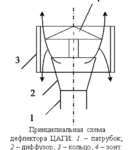

Such structures are installed on chimney (in her very upper part) to obstruct air flow. The intensity of the wind force drops noticeably when meeting with such devices placed on the pipe. The smoke comes out through the channel "at will" due to the ingress of weak air flows into the pipe. These streams "catch" the exhaust gases and "push" them out.

Deflectors eliminate the possibility of pipe clogging, as well as tasteful, significantly improve the appearance of the entire building.

There are several types of deflectors:

- TsAGI;

- round Volperta;

- Grigorovich;

- in the form of a plate;

- in the form of the letter H;

- rotating;

- vane.

Almost all these devices are made of stainless steel, in rare situations - of copper. Using brackets, clamps, bolts, sealing tape, the deflector is attached to the chimney pipe. Some devices are also equipped with additional functions: for extinguishing sparks (to eliminate a possible ignition of the roof), for controlling the temperature of the outgoing air (in this case, the sensor is triggered if hot air does not come out and there is a possibility of reverse draft).

The disadvantages of using deflectors are their minimal efficiency in calm weather.

Photo gallery: types of deflectors

The most common traction device

The most common traction device  Such a device can be purchased at specialized stores.

Such a device can be purchased at specialized stores.  The choice of the device depends on the design features of the pipes and your preferences.

The choice of the device depends on the design features of the pipes and your preferences.

The turbines installed in the chimney head use the energy potential of the wind. The air currents set in motion a rotary nozzle (it always moves in one direction), and thus the air is rarefied near the chimney. It is completely excluded from entering the chimney with a rotary tube of any foreign objects and precipitation.

Rotary tubes have a big disadvantage, similar to the work of a deflector. Their use on a windless day is ineffective.

If you do not have great abilities, buying such devices is not a problem.

Draft regulators

Such devices are a real find for residents of country houses, lovers of baths and fireplace gatherings. These devices are attached to the boiler chimney. They are equipped with a metal plate with a weight that balances it on one side. When the draft is good, the metal plate does not impede the free access of air into the chimney. With weak or reverse thrust, the metal plate serves as a kind of stupor.

The range limits for thrust are set by the consumer himself, the usual parameters are 10–35 Pa.

The device works completely autonomously, it does not need an electric current supply.

How to increase cravings with your own hands: homemade appliances

Before you start building a deflector yourself, weigh your strength, review the available materials and only then get down to business.

Drawings and diagrams

To create a deflector with your own hands, you must use diagrams and drawings. You can use ready-made ones, presented in large quantities on the Internet, or you can do it yourself, relying on the data of ready-made diagrams and drawings.

Photo gallery: ready-made traction instrument circuits

On the Internet, you can find a good help for the construction of the device

On the Internet, you can find a good help for the construction of the device  Carefully study the instrument diagrams and choose the one that suits you

Carefully study the instrument diagrams and choose the one that suits you  The diagram shows the device for improving traction

The diagram shows the device for improving traction  The diagram shows the components of this device

The diagram shows the components of this device

If you decide to test yourself and at the same time save money, arm yourself with measuring instruments to determine the inner diameter of the chimney. Depending on this value, you can, focusing on the table, determine the required parameters for the height of the deflector and the width of the diffuser.

With an inner diameter of 120 mm, these parameters are respectively 144/240, for a diameter of 140 mm - 168/280; if the internal section is 200, then 240/400; for a section of 400 mm, a deflector height of -480 mm is required, and a diffuser width of 800 mm.

You can calculate the necessary parameters (for a specific pipe diameter) yourself, using simple calculations. To determine the width of the diffuser, the inner pipe diameter must be multiplied by 1.2; the width of the umbrella for protection is considered to be -1.7 x d; We find out the total height of the structure if we multiply the size of the inner section by 1.7.

Having received all the dimensions, we build drawings for more accurate cutting. We draw diagrams on a sheet of Whatman paper or on the back of the remaining pieces of wallpaper.

It is best to build a full-size drawing. So that during cutting it is easy to attach the cut paper parts to the steel sheet and not to recalculate the data taking into account the scale of the drawing.

We stock up on materials and tools

Everything must be prepared in advance so as not to be distracted during work.

We need to make a deflector:

- galvanized sheet with a thickness of at least half a millimeter, you can also use stainless steel;

- scissors for metal;

- drill with different drills;

- riveting device;

- a hammer;

- pliers;

- clamps, nuts, bolts;

- marker (for transferring the drawing to a metal sheet).

Preliminary stage

The preparatory work consists not only in drawing the details of the device, but also in cutting them out and trying them on. All paper elements are fastened with paper clips or a stapler and applied to each other. If all fits, then you can carefully remove the bartacks and straighten the templates.

Do not be negligent in the process of creating a deflector, try to think about your safety. In order not to injure your hands and to protect your eyes, use the prepared gloves and special glasses.

Getting started

So, everything is in place, you can start!

A step-by-step description of the sequence of actions will help you:

- We transfer the parts cut out of paper to a galvanized sheet. We should have a sweep of the following elements: a cap, a diffuser, an outer cylinder and a rack.

- Using scissors for metal, carefully cut out all the components of the deflector. In places of cuts, the metal is bent with pliers to a half-millimeter thickness and "passed" with a hammer.

- The blanks of the diffuser, cap and cylinder are folded and drilled holes for fasteners (if bolts are used). Connections are made using rivets or bolts; in exceptional cases, welding (semi-automatic) can be used.

- To fix the cap, we prepare 3-4 metal strips. The dimensions of the strips are 6 by 20 cm. The strips bent at the edges and knocked out with a hammer must be bent in the shape of the letter P. Drill 3-4 holes on the cap, five centimeters from the edge, and fasten the metal strips with bolts.

- The other ends of the galvanized strips must be attached to the diffuser, thereby "looping" the dome and diffuser.

- We insert the resulting structure into the shell.

You can watch the video about the construction of the TsAGI deflector with your own hands.

Video: do-it-yourself TsAGI deflector

Deflector installation

The first way is to climb onto the roof and, observing safety precautions, attach the made device to the chimney pipe.

You can make your work a little easier - attach the deflector to an additional pipe, which is then raised to the roof and inserted into the main pipe.

We put the homemade device in place in a second, safer and more convenient way. We need a piece of pipe with a slightly larger diameter than that of the chimney. Having departed from the edge of the cut pipe about fifteen centimeters, mark and make holes, perform the same manipulations on the wide part of the diffuser.

Large buildings also need traction control devices

Process self adjustment traction is necessary in order to comfortably and safely live and relax in a house with stove heating. To do this, you can use different wayswhich are suitable for your chimney design: pipe cleaning with a brush, "chemical cleaning furnace", installation of special devices. Traction control devices can be purchased or made yourself.