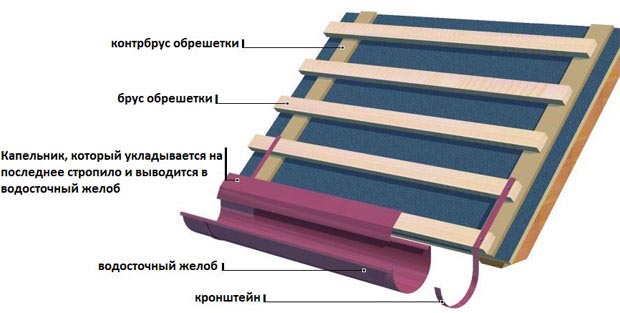

One of the important elements of the roof design is a dripper for a soft roof. Its main goal is to protect the eaves from the negative action of flowing water and moisture, as the tree in these places is particularly susceptible to rotting.

Such elements of a soft roof bent bent at an angle of 100-130 degrees, depending on the angle of inclination of the roof. Ducklings are fixed on the very edge of the roof, they are directed vertically down. Due to this, the unobstructed flow of water in the chute is ensured. In addition to its protective function, this element of the design of a soft roof ensures the creation of the completion of its appearance.

The dropper or as it is also called - for a soft roof, is made of galvanized steel sheets. To protect against corrosion, the material is covered with a special polymer layer. Such elements of the soft roof are selected under the main color of the roof, creating a completed architectural composition.

Advantages of soft roof

To the category of "soft" those roofing materials, which include bitumen. First of all, we are talking about rolled and mastic materials, bituminous tiles and polymer membrane (more detailed: "").

The advantages of such roofs include the following:

Types of soft roofs

Components for soft roofs - Installation

The base under soft roof Always done solid. To create it, mostly three types of materials are used:

- oriented chipboard (OSB);

- plywood sheets;

- edged boards with a thickness of 2-3 cm.

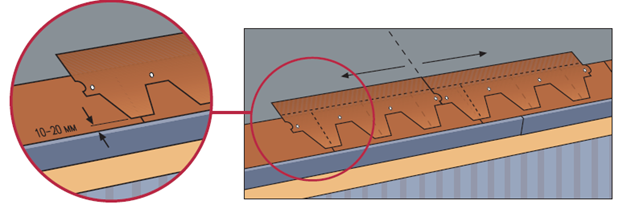

Between the individual elements of the crates, it is necessary to leave a gap of 5 mm. It is necessary for natural wood expansion. When temperature and humidity change, the elements of the crate may increase in size, and therefore if you do not leave the gap, the plane of the roof will begin to deform, for example, in places. Between OSB plates, the gap may be less (3 mm). But at the same time it should take into account the current state ambient. These gap parameters can be used under the condition of creation at temperatures up to 5 degrees of heat and 75% humidity.

Used plywood should have high moisture resistance. Even better if she is tight. The thickness of such a base should be in the range of 12-21 mm, depending on the distance between the rafyles. All items wooden base Must be well sucked and necessarily treated with antiseptic solutions. It is necessary to protect against insects and rotting.

Dropper device, look at the video:

Metal planks

Mandatory element of the roof from flexible tile. They are needed to protect wooden structures From moisture and increase the resistance of the coating to wind loads. Provide a dense fit of the material on the vertical surface. All metal strips are painted in different colors under the color of the flexible tile.

Farmery Planck (Dweller) |

|

|

The cornice bar is designed to enhance the cornis of the roof and ensures efficient water removal. Its use to preserve your roof is extremely important: it protects the roofing flooring from atmospheric precipitation - prevents the process of rotting the roof in the cornice zone of the roof. |

Planck adjoining |

|

|

Planck adjoining is designed to enhance the places of the adjunct and ensures efficient water removal. It provides a dense fit of the waterproofing (omene) carpet to the vertical surface of the elements of the building or structure. Geometric dimensions: Length: 2 m, thickness 0.45 mm. |

Fronton (Fantasy) Planck |

|

|

Fronton plank is designed to enhance the frontal soles. Its use for the preservation of your roof is extremely important: it protects the roofing flooring from atmospheric precipitation and exposure - prevents the process of rotting the roof in the frontal roof zone. Geometric dimensions: Length: 2 m, thickness 0.45 mm. |

Flexible

OSP - 3 (chipboard oriented) |

|

|

Material for a solid base under flexible tile. Unlike the crate of the boards, it forms a perfectly smooth, smooth surface and does not breed from moisture. OSP is easily sawing, facilitating the fitting of the sizes on the object, which greatly simplifies the installation of complex roofs. The thickness of the sheet depends on the step of lag clamps and the calculated snow loads. As solid flooring, there is a better sheet geometry, rigidity, homogeneity and durability, which is confirmed by the regulatory construction organizations of the leading countries of the world. |

Plywood of high moisture resistance (FSF) |

|

|

It is often used as a solid base under flexible tile. FSF plywood sheets have increased moisture resistance, so they have a high resistance to break and bending, and these characteristics do not depend on temperature drops and humidity. Coniferous plywood has high resistance to rotting and infection with fungi. This material will serve the entire service life of the "soft" roof. |

Ventilation and air exchange elements

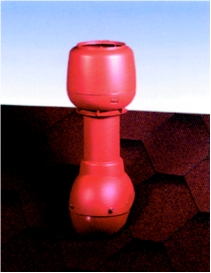

In order for the roof to prevent us with any surprises in a few years and served the entire service life, it must be built in all the rules. One of the most important elements her proper device is the creation . It is clear that this system requires additional costs, but it is justified by the fact that the service life of the roof is much extended. Today, modern high-tech systems of the undercase appeared on the market. TechnoNikol is also not lagging behind this issue and can offer you a wide range of materials of this system.

|

|

|

Aerator KTV.and deflector Allows you to ensure efficient ventilation of the underproof space, that is, it is used to remove moisture from the roofing structures of the attic and attic rooms. | |

A feature of challenges for a soft roof is that they are made of material other than the main coating. The Internet hypermarket "1Platform" offers an end bar for flexible tiles of painted galvanized steel at low prices.

Characteristics of the proposed end slats

Facial planka for soft tile Used to decorate the frontal roofs. The element is mounted over the finished roofing and performs several functions:

- prevents water from entering, snow under the soft roof;

- protects the edges of the sheets from the gap under the action of wind (therefore, another product name is);

- it gives the roof decorated and finished view.

The planks implemented in the "1Platform" are made of metal with a thickness of 0.5 mm, protected from corrosion of zinc layer. A synthetic polymer coating based on plastisole or polyester is applied to the elements.

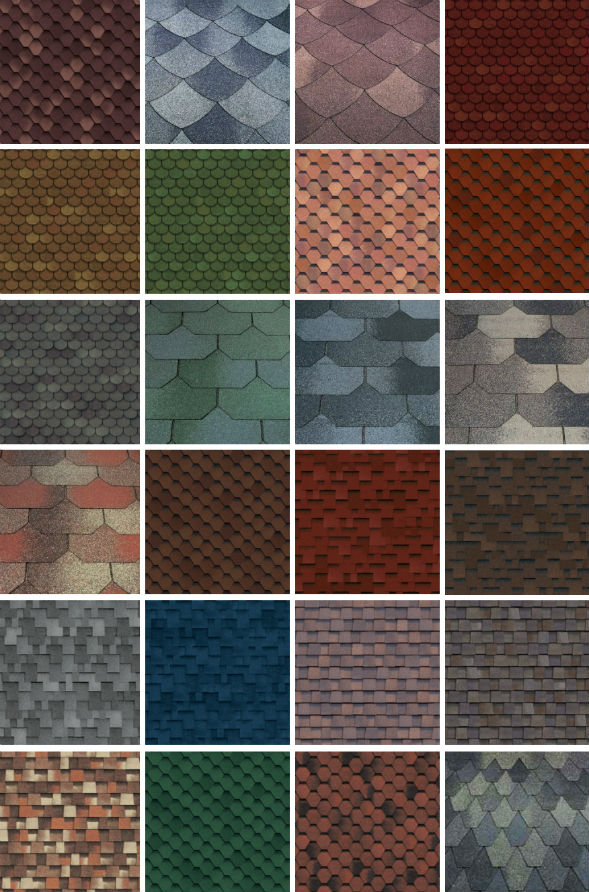

Varieties of planks in the category

The main requirement to the selection of the end plank under bitumen tiles is its color matching the main coating. The site offers a wide range of products of popular colors.

RAL coloring classification The RAL scale helps to choose the color of the bituminous roof of the shade. The dimensions of the planks are listed next to the photo and in the product description, the standard length of the element - 2 m. The prices of wind slats for flexible tile depend on the brand and polymer coating: polyester cheaper, plastisol is stronger and more expensive.

Advantages of buying goods in "1Platform"

By purchasing goods in our online store, you can be confident in his quality. Our assortment presents the best products from Russian and European manufacturers. Order with our soft roof and the whole set of components for it, including end elements - we will deliver your order to any region of Russia.

A fairly simple installation of flexible tiles is considered to be one of the obvious advantages of this material: elastic panels are easily fixed on the crate, forming a dense coating, impenetrable for moisture. Naturally, it is possible to achieve such a result only if all the rules of installation are observed, because if you plan to deal with roofing works yourself - carefully reread the article proposed by me.

Structure and advantages of flexible tile

Flexible tile is a relatively inexpensive, lightweight and elastic material that is used in roofing work Basically in private construction.

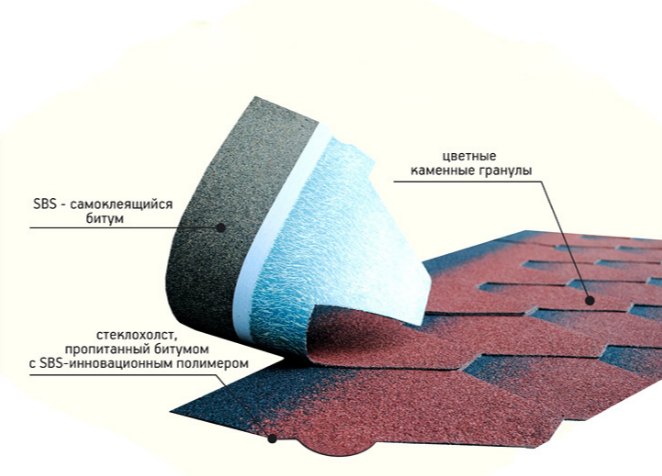

The structure of this material provides high roof resistance to moisturizing and other factors:

- The tile base is a canvas of fiberglass or polyester. The better quality (and more expensive!) The material, the more durable there will be a base, and the higher the mechanical stability of the tiles will be. It is very important that the products are well resistant to tearing efforts - this is at times increasing their service life.

- Fissure base of tiled plates impregnates modified. This component is responsible for ensuring moisture resistance, in addition, as a result of modification, bitumen is losing fluidity at high temperatures. Also, the use of a modified impregnation gives the roof a significant fire resistance.

- A stone fine-grained crumb is applied on top of the bitumen layer. In addition to the aesthetic functions, mineral granules also provide additional mechanical strength.

Despite a fairly simple structure, the tiles of this type have a number of obvious advantages:

- Relatively low weight (from 8 to 12 kg / m2), which allows you to mount roofing material On light slinge system, due to which the burden on the basis and bearing structures building.

- Good resistance to temperature drops, heating, freezing and other adverse factors.

- Almost unchanged coloring even with prolonged exposure to UV radiation.

- Good moisture resistance.

In addition, as I have already noted, the advantages include a moderate price (from 200 rubles per square you can find a budget coating, for 300 - 350, the medium-sized material is selected without any special problems) and a fairly simple installation.

It is on the last aspect - the technology of laying flexible tiles - I will stop in more detail.

Preparation for work

Materials and tools

Laying the flexible tile on the roof involves the use of a whole list of materials.

To fulfill such work, I usually buy:

- Material for crate - OSP slabs, moisture-proof fane or boards.

- Lining bitumen material.

- Lining ribbons for funds - with their help they are protected from the flow of the joints of the planes, as well as the place of adjoining ventilation pipes, chimneys, etc.

- Bitumen tile sheets themselves in the package (the material strips are called trimming).

- Facial and cornice strips for flexible tiles.

- Mechanical fasteners are galvanized self-tapping screws, nails or staples for construction stamp.

- Glue on a bitumen basis for fixing trimming and lining material to the base.

As for the tools, the set must include the following positions:

- saw on a tree for fitting the details of the root;

- screwdriver;

- drill;

- a hammer;

- level;

- roulette;

- marker;

- knife cutting knife;

- stepter construction;

- putty knife.

Do not forget that the installation of soft tiles on the roof refers to high-rise worksSo, conjugate with increased risk to life. Consequently, it is necessary to work with insurance (mounting belt + cable), and keep the tools in a special spoil. Also, it will not be superfluous to freeze the site near the house - to avoid injury to households with falling tools, cropping material, etc.

Diselet roof

Instructions for laying flexible tile begins with the description of the process of preparing the base.

This material is best laid on a solid crate, which is built from:

- edged board (planed, and best - tipped);

- moisture-resistant plywood;

- oriented chipboard (OSP).

It is important that the moisture content of the material used for the crate device was no more than 20%.

For the selection of material for strength, it is worth using a table that demonstrates the dependence between the rafted step and the thickness of the lap:

The elements of the crates are attached to rafters with nails or screws.

When installing the base, it is worth putting all the wooden parts with a gap of at least 5 mm - this distance will allow to compensate for the expansion of wood when moisture change and temperature drops, preventing the deformation of the crate.

Lining layer and additional elements

The lining layer performs the most important function: it prevents the roof of the roof if the moisture is still leaving through the flexible tile itself.

To arrange a lining layer, either bitumen materials are used (the same runner and its analogs), or special roofing membranes.

- If the inclination of the roof is equal to or exceeds 1: 3 (i.e., 18 degrees and more), then the waterproofing materials are placed along the edges of the roof along the ends and cornices, since it is the most likely places of leakage that are located.

- In this case, the waterproofing material of 40-50 cm wide with a width of 40 - 50 cm. We laid along the cornese edge and along the end edges. Also, 25 cm of waterproofing should be on each side of the roof of the roof.

- In the endowes - the inner joints of the planes of the roof of a complex form - be sure to deploy the omene carpet. Instead of a special material, a moisture protection membrane or bitumen coating can be laid here.

Such stripes surround the outputs of ventilation pipes, chimneys, etc. - It is very important to lay a lining without gaps, because otherwise the leakage will be inevitable. On top of the place of adjoins can be covered with special metal caps, which are installed after the installation of the ordinary tiles will be completed.

- With a smaller bias, the lining material is located throughout the plane of the skates. This reduces the likelihood of the appearance of leaks, which occur due to the insufficiently fast drainage of water by a gentle roof. Solid lining roll off horizontal rolls, bottom-up, with false time at least 10 cm .

- Over the lining layer on the end is set facial Planck For flexible tile, and on the cornice part - respectively, a cornice bar. Metal parts are fastened with roofing galvanized nails in increments of 10 - 12 cm. Nails are clogged with zigzag, and at the place of the joint, we make a latter at least 30 mm.

Left - Eaves Plank for Flexible Tile, Right - End Element

So we come to completion preparatory work. It is necessary to perform them extremely qualitatively, since the tightness of the roof depends on the lining layer: whatever high quality is flexible bituminous tile And no matter how correctly we did not put it, some kind of moisture is still leaving inside.

Technology laying

Mounting conditions

Before describing the method of laying a flexible bitumen coating, I would like to stay on some nuances that accompany this process:

- Packaging with flexible tiles It is advisable to store in a closed room protected from direct sunlight. Low temperatures Most materials are not terrible, but from sharp drops roofing It is best to secure.

- The installation of the coating is best done at a temperature of +5 to +25 degrees Celsius. Before mounting, the package is preferably opened in advance so that the tile has acquired the ambient temperature - so it will be much less deformed.

- Laying the roof of this type in the cold season is also allowed, but before the installation of the installation, open packages with tiles should be labored in the heated room at least day. To avoid cracking, it is also desirable to equip "warmly" - a frame design with a polyethylene coating over the roof section where work is underway.

- Finally, directly in the process of laying the shings need to warm the construction hairdryer - so we will reduce the fragility of the material in the cold and contribute to the rapid polymerization of adhesive base.

- Do not use the propane burner instead of a hair dryer - this can lead to irreversible damage to the material that is not designed for contact with the open flame.

- If the installation is performed in the cold or with strong wind, then the use of adhesive compositions may be necessary for additional fixation of the trunks. In this case, I prefer a bitumen mixture of KatePal K-36, providing optimal adhesion.

- When installing in the warm season, work is best done in the morning and in the evening. In order not to damage the heat-softened coating, it is desirable to use stairs, dresses and other devices evenly distributing the load to move on the roof.

Montage tiles

Works start with styling of the so-called cornice tile:

- With narrow strips of the material, we remove the protective film, put them on top farmery Plank. and secure nails in a step of 20 mm. Nails are scored at a distance of about 25 - 30 mm from the edge. Farmery tile put the jack, the slots between the individual stripes are noticed by bitumen mastic.

- After that, we select an ordinary tile on shades. In one batch, the color of the elements may slightly differ slightly, which, on the one hand, forces us to spend time on sorting, but on the other, it allows you to give the roof more efficient appearance Due to visual depth. This is especially touched by tiles with gradient color.

- An ordinary tile by mounting from the bottom edge of the skate, ranging from its central line. We remove the protective film from the tricks of the first row and point them to the adhesive side in such a way that the lower edges are at a distance of about 10 mm from the edge of the cornese tile, and the petals overlap the joints.

- Each trimming gears with 4 - 6 nails. Nails are robbed immediately above the depressions so that their caps are closed with the protrusions of the next row of flexible tiles.

- The second row of sheets lay on top of the first with displacement of the joints. When positioning, watches the protrusions (petals) of the upper row to be exactly at the level of the depression already laid down the lower rows.

Such placement of roof elements provides its maximum reliable fixation. Each sheet is nailed at least twice: first when it is laying, and then - when laying a sheet lying on top.

- In the place of adjustment to the finalons, the shonts are cutting off the jack, and their edges are definitely glued to the base with waterproofing coating. If this is not done, then the air flows will teapinate, and sooner or later the water will begin in the resulting gap. Similarly, the edges of the sheets and endowes are glued.

- Installation of the styling of the skate layer is completed: it should cover the lip of the roof and fix on both sides.

Final stage - installation. It is possible to mount the simplest metal bar, and can be fixed in the top of the roof a ventilated plastic horse. It is worth it a lot, but its installation in many ways solves the problem of air exchange in the underpants space.

Conclusion

Installation of flexible tiles is performed simply enough, but at the same time it is necessary to work carefully, given the many nuances. However, anyone who possesses at least minimal skill can successfully cope with such a task - it is enough to carefully examine the recommendations given here, view the video in this article, as well as consult all complex issues Either in the comments below, or on the forum.