In any bath there should be a furnace that allows you to create a certain climatic atmosphere in the steam room. To date, there are many varieties of designs. long burningthat can be purchased in specialized stores or make it yourself. One of the most effective is metal bass furnace. To assemble such a device yourself, you should prepare or download special drawings, as well as use the instructions below or watch the video assembly video. This will save significant amount Money.

Advantages of metal Kamenka

To get a soft steam, you must collect a large, which last time saves heat in the bath. But for this reliable foundation is neededWhat leads to additional costs.

You can make it yourself. It does not need to carefully study the schemes to create a complex design. Another advantage is that the unit is already half an hour heats stear room to optimal temperature.

Disadvantages of heating equipment

Metal Kamenka not only quickly heats up, but also practically instantly cooled. Therefore, for the adoption of bath procedures, it is necessary to protrude well. It will be difficult to protrude a steam room for a group of people.

Structure

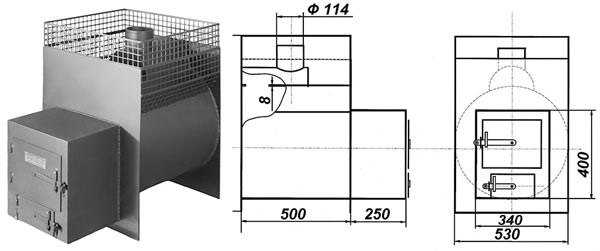

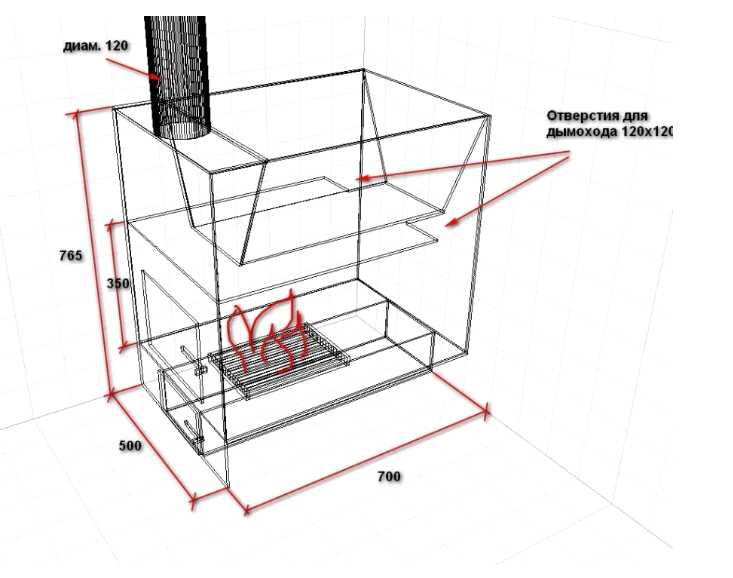

You can collect the device with your own hands in several ways. It can be made of metal tank, sheets or pipes. If there are no skills to work with the welding machine, it is recommended to assemble the unit from the pipe. Diameter construction will be 80 centimeters, and height, approximately 170 centimeters. Top is manufactured. To increase the temperature in the steam room you need to pour water.

Tools and materials

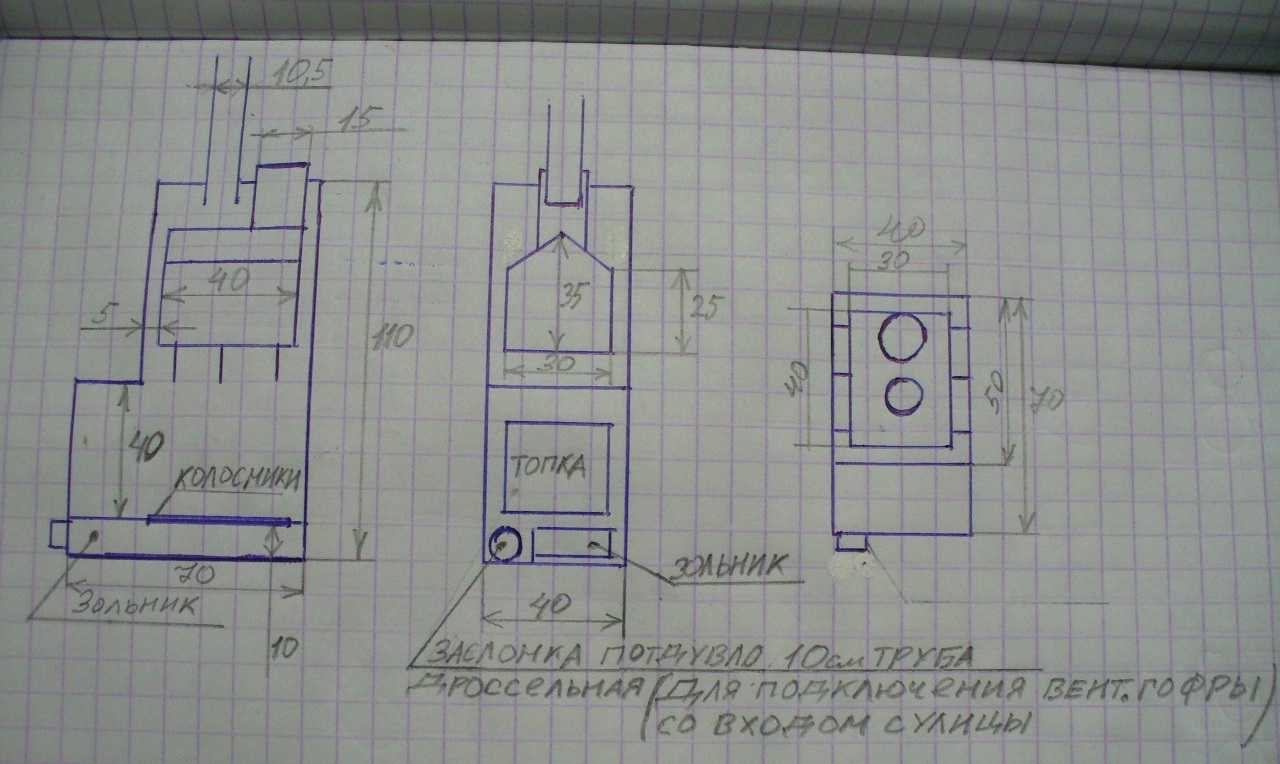

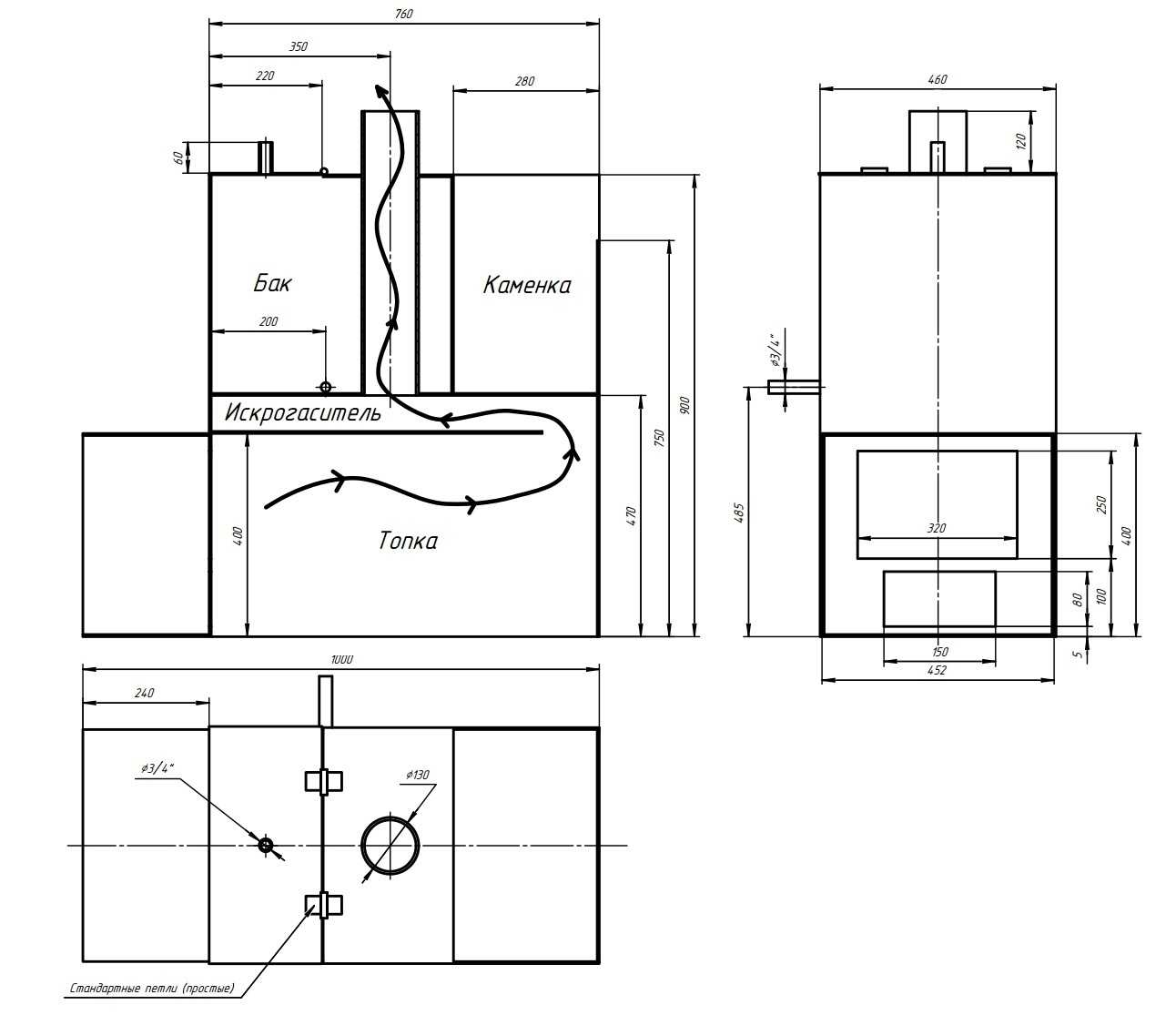

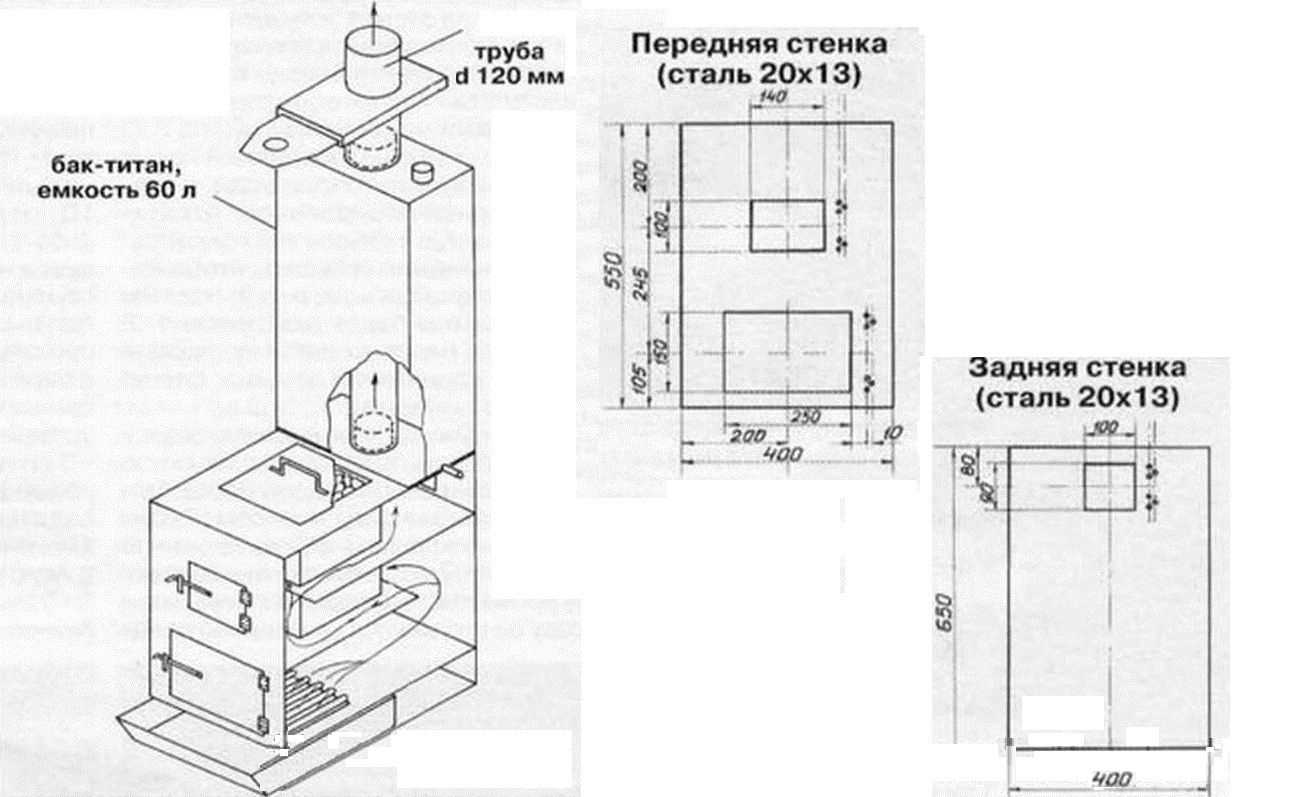

- To make the equipment with your own hands, first of all, it is necessary to prepare a drawing, the so-called sketch with precise size.

- Metal pipe with 180-centimeter height and 60-centimeter diameter. Pipe walls must have a thickness of about 10 millimeters.

- 8 mm a metal sheet.

- Steel rod with a 10-mm diameter.

- Metal doors.

- Gear.

- Crane.

- Chimney.

These materials are sold in construction stores. It is also necessary to prepare the device for welding works and Bulgarian.

Foundation for a long-burning oven

Before building the design, you must prepare for it. Some set the heating apparatus to the floor surface, but it is a rough error. For any furnace need to make foundation.

Before building the design, you must prepare for it. Some set the heating apparatus to the floor surface, but it is a rough error. For any furnace need to make foundation.

Usually, the wood-fired metal furnace weighs no more than 150 kilograms, so you can equip a fairly simple foundation. You need to dig the pit, fall asleep and tumble with rubble. Then pour cement and wait when the solution will freeze.

As a heat insulating layer you can lay out runneroid. The surface must be checked by the construction level so that it is flat enough. It is recommended to wait two months before installing the heating equipment. After that, lay out two brick rows.

After that, you can start the installation of the structure, if all the drawings are prepared. The oven must be at a distance of 1 meter from the wall of the wallwhich is covered by foil for fire safety.

Manufacturing equipment

It is made with your own hands in several stages. To qualitatively assemble the design, it is necessary to successively perform all the work.

It is made with your own hands in several stages. To qualitatively assemble the design, it is necessary to successively perform all the work.

Installation of firebox

Bulgarian need to be cut in half a pipe from a metal. The first part will be needed for the manufacture of the furnace, and the other part for heating the tank with water. From the bottom of the first pipe it is necessary to make a small hole (pushed), the dimensions of which make up 20x5 centimeters. Also from the inside it is necessary to welcome special brackets for the grate. A little higher to do another hole for the furnace: 20x25 centimeters. Then the doors are installed on the fixed loops.

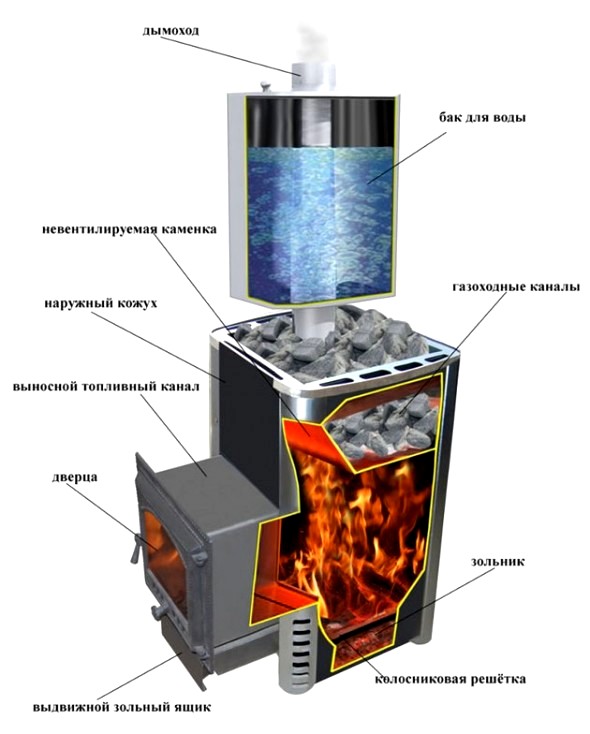

Kamenka must be above the furnace, in which the grate is installed or metal grillewhose cells should be less sizes of stones.

In Kamenka, it is necessary to make a window intended for the bay of liquid. It is recommended to be located opposite the furnace, then install the door. The chimney is installed above the grate, after which the stones are laid. From above you need to fight the circle of metal, to do a hole in it for the second pipe. It is necessary to check the seams of welding on aqueous impefeability, as the tank with liquid will be on top.

Container for water

Based on the drawing you need to privar at the bottom of the second tube crane. Then secure the cut pipe to the heater using a welding machine. Seam must be checked necessarily on water impermeability. Two halves of the lid are welded to the Baku. One should be welded, and second install on the loop.

Based on the drawing you need to privar at the bottom of the second tube crane. Then secure the cut pipe to the heater using a welding machine. Seam must be checked necessarily on water impermeability. Two halves of the lid are welded to the Baku. One should be welded, and second install on the loop.

Chimney

The pipe must be isolated using a brick or. It is important to understand that the homemade metal wood-burning furnace is heated to a high temperature, so fire safety is raised. therefore it is necessary to isolate high quality and reliably..

The surface of the near wall is also it is necessary to isolate. To do this, you can use metal sheets. Also homemade design Long burning can be covered with red brick to prevent ignition. This nuance should also be included in the drawing.

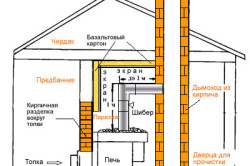

Experienced masters recommend setting equipment for long burning separately from the paired room to in the pre-tribbon it was also warm.

Experienced masters recommend setting equipment for long burning separately from the paired room to in the pre-tribbon it was also warm.

- To increase the level of fire safety, the furnace should be, which is quickly heated, so the furnace is not recommended to put in the pair room.

- Frequent bookmark solid fuel convenient do in the pre-tribbon.

- Therefore, the bath design is installed in the wall between the premises. The wall is necessary to isolate asbestos or metal sheet.

Also, experts advise to mount the supply and exhaust ventilation system so that fresh air circulates in the steam room. Compliance with these simple requirements to increase the paired room, and the metal apparatus will serve for a long time without failures.

Hybrid Kamenka and Kitchen Furnace

Heating structures for the bath can combine with kitchen stove. Such equipment of long burning is advisable to establish if there is a rest room in which you can not only relax, but also to eat. This room must be added to the drawing not to miss no details of construction.

Also, such a bath design is great for the paired room, which is attached to the kitchen room or private house. Kitchen Equipment Actuator must be combined with a kilnic stove. At the same time, the door is installed only on the heater, as it is not needed for kitchen equipment.

The steam room and the kitchen are separated by a red brick partition. To avoid burns, it is recommended to install a metal screen from the paired room.

Types of designs

Besides traditional metal furnace, There are many options for heating equipment. The video demonstrates the principle of their work. The main ones are:

Besides traditional metal furnace, There are many options for heating equipment. The video demonstrates the principle of their work. The main ones are:

- Kalorior oven.

- Vertical design.

- Equipment with open heat exchanger and Kamenka.

The latter model increases the temperature not only in the steam room, but also in other rooms. Such equipment of long burning is heated in a short time. But to avoid heat impact or burns, there should be an air layer in the walls. Water heats up in the heat exchanger, which is installed in the fuel. Through the heater passes the chimney, it allows you to increase the heat transfer.

The manufacture of any of the existing devices is possible with your own hands only with high-quality preparation, and also need to develop appropriate drawings. These furnaces are distinguished by the fact that the housing is made of metal sheets, and not from the pipe.

If you need a small model, then projects are suitable vertical furnace. Metal tank with water mounted over Kamenka. In the center of the tank, the chimney is attached using a welding machine. The calorifer is made with an open heat exchanger and camera. To do this, you need a metal sheet with a 5mm thick.

All options can be make it yourself. To do this, find the necessary schemes and prepare all the materials. It is recommended to consult with professionals for the installation of insulating materials, as safety depends on them metal aggregate works. If necessary, you can see the video instructions for assembling the device.

The modern building market offers a variety of bath stoves: both on liquid fuel, and for firewood, and gas, and with many additional features. True, the manufacturers are asked for such aggregates just a fabulous amount, and there are no guarantees that this furnace is suitable for the requirements of a particular bath and will last a long time. But the fact that they create those in whom lives the spirit of the Russian master - by century.

But it's not so difficult to make the stove for the bath - everything that will need it detailed instructions, step-by-step photos Construction and recommendations of experienced masters. All this you will find in this article. The main thing is to approach the business in slow and scrupulously comply with the safety equipment of furnace work.

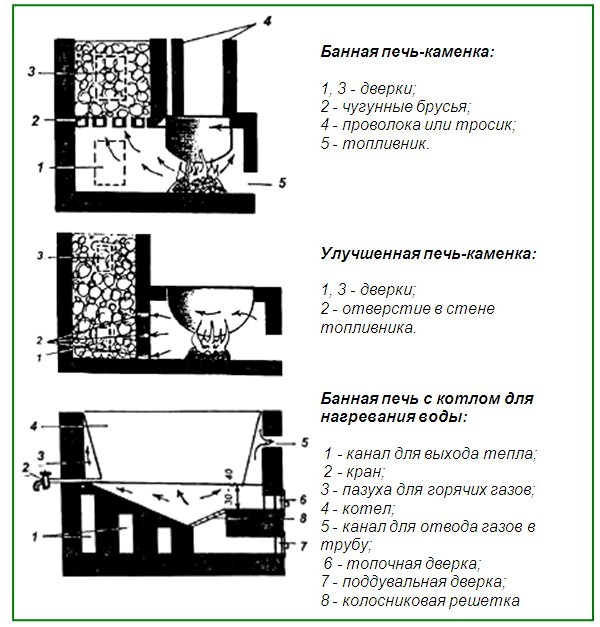

For many modern masters, self-made furnaces for baths, which were made over the centuries and until recently, cause sincere bewilderment: they were built without any chimney, and the carbon monoxide came out of the bath only through the door. That is why our ancestors spoke to "wash in black". Although, except for this disadvantage, the ancient bass furnace itself had a completely practical device, very resistant to fire. So, from an environmentally friendly clay brick, a domed focus, resembling a well, was built. In it, the prepared stones were laid on metal rods, and they were put on a water-type water container. Fire under cobblestones glowing the latter, and the boiling water falling on them fill the room with a soft and enveloping steam.

Over time, the Russian masters came out to equip what kind of chimney for such furnaces, and the baths became much more aesthetic and functional. And even more - this attribute of paired became the semantic and organizing center of its interior design, and the improved concept of their manufacture has made bath procedures not as expensive and more pleasant.

What should there be a furnace - requirements for aggregates

Modern furnaces for baths with their own hands are practically not inferior to the factory - they are no less aesthetic, just provide economical fuel consumption, as little space occupy a pair and do not require any difficult care.

The furnace itself can be made to the bath and for firewood, and for liquid fuel, and for other energy sources. The choice of its type depends on the characteristics of the bath itself, but in any case, it must meet certain requirements:

- The presence of sufficient thermal power and a wide range of its regulation. Thus, the thermal power of the same furnace can be quite sufficient for brous bath and insufficient for frame.

- The presence of a heat accumulator and steam generator so that heat and moisture can be changed.

- The presence of means of regulating convection.

- Almost complete absence of surfaces, the temperature of which exceeds 150? P.

In addition to the listed, according to the rules of furnace work, the bath furnace has more of its own requirements for the size of the firebox, fire safety and other important parameters.

Features of the design of a modern factory oven

"Hot" or "cold" design options

Depending on what the temperature of the exterior walls of the bath furnace is called "cold" or "hot". So, the "hot" walls can warm up to 100 degrees, so that in the steam room and heat. Such a bath is easy to melt in a short time, which is indispensable for those pairs, in which there are no constant heating - these are the baths that are used from time to time. And the "cold" furnaces are not suitable for them. But there are deficiencies in such furnaces: a pair can be easily overlay, turning into a real sauna - and not for each person such a mode is safe.

"Cold" stoves, to make it necessary for a long time, have and their advantages - it is impossible to burn their walls, because the temperature of their maximum reaches 50 degrees. But the heating of the baths themselves occurs through the special channels of the furnace, which are absorbed by the cold air of the floor, passed through the fire and give through the top is already warm, soft and not burning. That is why only with the help of "cold" furnaces it is possible to effectively adjust the moisture mode and temperature in the bath.

Some examples of stove structures

Brick option - chimney classic

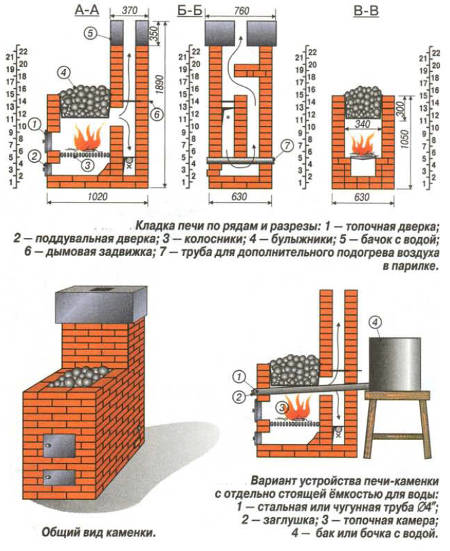

Good, but quite simple brick design Furnaces for the bath looks like this: the furnace laid out of refractory bricks, the roller below the furnace, cast iron or steel grid. for stones, chimney, snake for hot water and doors.

Weight self-made oven for a brick bath is solid, and therefore it will have to arrange a foundation in advance. Instead of a solution for masonry bricks, it will be necessary to use only clay and sand, because Cement is not racks to high temperature and is able to sprinkle a bathing stove literally for the year. And for the strength of the entire design, the madding is done by its special scheme.

Metal stove and its features

Compared to brick furnaces, cast-iron and steel are more compact, have high heat transfer and excellent warm-up speed. Plus, that such a bathing stoves are easy to produce at the factory, while bricks can only be laid directly on the spot.

It will not be difficult for anyone to weld and good metal furnaces for baths do it yourself: for this, steel sheets or a large pipe will go into the course that it will be necessary to cut. And in its design, such a stove is not far from the brick: the same nodes and blocks, the same elements, only another design and other performance. For example, a square bath furnace is made from thick steel or pig iron, from steel thick-walled pipes - round.

But today the firebox of such an oven today is made a little differently than a couple of decades ago: now there are two cameras in it, one of which serves to burn fuel, and the second for the surving of the fact that he has not burned, due to which less is less emitted harmful products Combustion and KPD itself oven increases by 20%.

The only significant disadvantage of metal furnaces is a large surface area that is capable of burning. Although this minus is not difficult to fix - it's enough to put such a stove beautiful refractory brickOr hang on the body itself the steel screen - convector, which will dispense hot air streams throughout the bath and make it warm up more uniform. On the other hand, cooling the furnaces due to the natural circulation of air, its service life is significantly increased.

But the gas or electric furnace is not recommended independently: even the factory models are extremely fire hazard and even able to explode.

The most simple homemade options

Those who have never come across a chicken business, you can try for the first couple of years to study the device of the furnace for the baths of the most simple design and build the one that will sculpt the bath, warm the water and produce a pleasant couple.

Also, you can make the furnace from ordinary or butt stone, or carefully buried bricks. The wall thickness must be from 13 to 25 cm, and the stones - weighing 1-5 kg. As stones for the furnace, you can take granite, boot or naked, but not flint, which is scattered from heating into pieces. And in order for the healer for the bath with his own hands, the heat has accumulated heat, it is possible to add cast-iron rolls so that they accounted for 20% of 80% of the stones.

Boilers and water tanks in homemade stoves They can rely either on the walls of the masonry, or on special columns inside the furnace, or hang on the cable. But the lattices for furnaces are made of thick steel, or already become standard cast-iron.

An integral attribute of any bath is a furnace. It should be treated with special care and caution. Do not forget that the furnace is not only the source of all heat for the bath, but also the source of increased danger.

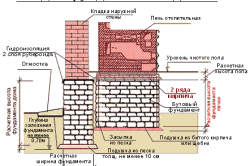

For brick oven It is necessary to prepare a qualitative foundation, pre-sow a pit and the tampering by the bottom of sand and gravel.

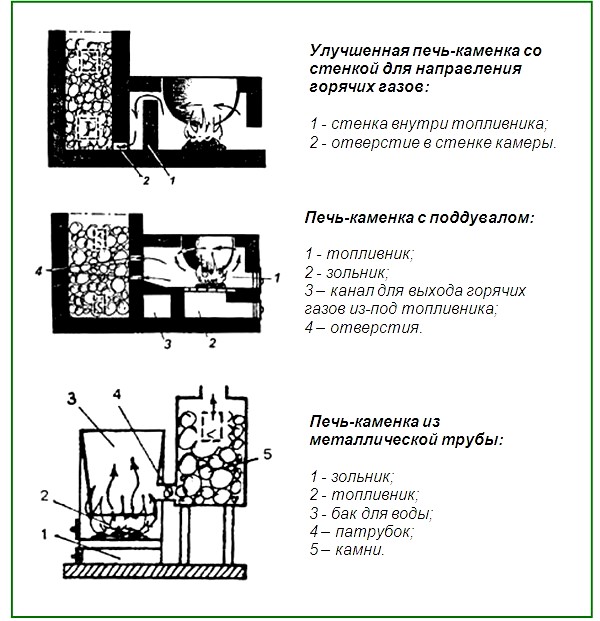

Previously, in the baths there was a furnace of one species - Kamenka. It was made, as a rule, from brick. It received its name at the expense of the principle of operation: water poured on the heated stones, as a result of which hot steam is formed. To this day in the baths, this furnace remains the most popular.

Now they make such a furnace not only from brick, but also from metal or cast iron, but the principle of operation remains the same.

Brick furnace device

The device of the furnace, like any other structure, begins with the bookmark of the foundation. It is worth noting that the foundation for the furnace should be done at the stage of the foundation device under the bath itself, that is, until the walls are erected.

To do this, often in the Bani project immediately indicates the location of the furnace and its geometric dimensions.

It is noteworthy that make the foundation with your own hands is not so difficult, as it seems at first glance.

First boils the pit. Its depth should be approximately 50-70 cm, and the length and width must be 20 cm more than the corresponding sizes of the furnace.

Next you need to make several pillows. The first is poured a layer of sand of a large fraction. The layer thickness should be about 10-15 cm. This sandy pillow is compacted and smoothes, then abundantly wetted with clean water.

The second layer should be made of construction debris, that is, from the broken brick, slate, glass, foam blocks, and so on. Its thickness - about 20 cm. Finally, the third layer consists of a pure gravel or the crushed stone of the middle fraction. Its thickness should be about 10 cm.

It should be noted that each of the three layers need to be ragged and spinning. After the foundation for the foundation is ready, it is necessary to install a formwork. Formwork can be made with your own hands, but you can buy ready.

The formwork of industrial manufacture is made of plastic or aluminum. It is smooth and smooth, which makes a very easy process of platforms. If it is not possible to purchase finished formwork, you can make it with your own hands.

As a rule, it is made of wood, because it is more convenient to work with this material, and costs are significantly less. The height of the formwork should be about 25 centimeters, equal to the remaining height of the dumped pit.

The walls of the formwork are placed at a distance of 10 centimeters from the edge of the pit. Such a stock is needed in the case when the soil begins to shift under the influence of any external forces.

The walls of the formwork fasten with each other with the help of P-shaped brackets or ordinary nails.

Important! So that the formwork does not shift under pressure cement mortarOutside on each wall put slopes.

After the device, the formwork proceeds to the manufacture of the reinforcement frame. Its main goal is to make a cement solution more elastic and movable. The thing is that the cement itself has low elasticity, so when heated is bursting.

The armature takes on tensile stresses arising in cement during heating, thereby cracking it.

The frame is a grid made of reinforcing rods with a cross section of 8-10 mm. Rods with each other can be associated with a special knitting wire, but you can weld. Most often armature carcass It has 2 reinforcement belts.

Each belt is a grid of rods, which has a square section cells. The side of such a cell must be about 10-15 cm.

The belt between them is attached with the help of vertical racks, which are also manufactured from the reinforcement. Racks must be from each other at a distance equal to the length of the cell side.

It should be noted that the edges of the reinforcement should not touch the walls of the formwork, and even more so to go beyond their plane.

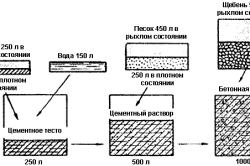

So, after the framework of the frame, you need to start the pouring of concrete. Since the metal frame was used, the crushed stone can not be added to the cement solution.

In this case, the following proportion is ideal for the preparation of cement mortar:

- 3 pieces of sand;

- 1 part of the cement brand is not lower than M400;

- water.

Concrete is poured and smoothed. After that, it sprinkles on top of a pure cement, which, with the help of a grater and water rubs into the surface of the solution. After soaring, this layer of cement forms a sufficiently durable crust that will protect the entire foundation from minor mechanical damage.

After the layer of cement mortar is freezing, you can begin to build directly the stove itself.

First, lay a layer of rubberoid, and then with the help of a cement solution completely along the entire surface of the foundation, the first row of brick is laid out. Further, the masonry should be carried out by clay solution.

The first three rows of bricks are stacked by ordinary masonry, that is, with the overlap of the joints to the Polkirpich. Next, in the middle of the walls install the door pissed, the lower fasteners of which you need to put on the surface of the brick. For mounting the door, it is best to use galvanized wire.

So that it does not interfere in the masonry process, the wire should be laid in special grooves that must be done in the brick surface. The top fasteners will be fixed in the same way, which will be attached on the sixth row.

After laying the first three-dimensions and installation of the doors, you should start equipping a grate and an ash well.

As a support for a grate grid, you can use two rows of bricks that are in confusion. Such a support should be prepared for laying the lattice.

For this purpose, brick is cut by a grinder along in half. These half of the cut side are stacked up. First, the bricks are applied a thick layer of the solution, and then the crazy halves themselves. At the same time, they are aligned with wooden or rubber hammer.

After that, the walls of the stove are stacked until the sixth row, that is, to the very top of the door pissed. The seventh row begins the installation of the grate and the furnaces of the furnace. The furnace door is mounted similarly to the reinforcement process of the door pondered.

On the eighth row it is necessary to make a transverse partition. It is from this partition that the chimney takes the beginning.

Now you need to make a fastening for the tank, in which water will be heated. To do this, the fasteners are installed between the rows of bricks, which must be sufficiently strong.

As a container for hot water, ready-made tanks that have a rectangular cross section are often used.

It should be noted that an empty space should remain between the wall of the furnace and the wall of the tank. Such an air gap will be the reason that the water in the tank will be barely warm.

After the preparation of the fasteners for the tank, you can lay all the rows of bricks to the eleventh, that is, to the top edge of the furnace of the furnace.

At the same time, it is impossible to allow the fittings to overlap the chimney walls. It should end on the walls of the partition, which was manufactured during the masonry of the eighth row.

Stones are stacked on this fittings. In their center there must be a pipe. The pipe itself can be made with their own bricks or to be industrial production.

It is better to make a pipe with your own hands, since in the already finished pipe you will have to cut a hole to set the damper. The flap is needed in order to adjust the power of the exhaust.

At the level of the upper stone you need to do the door in the furnace. It is required in order to water stones with water.

After the top layer of the brick will be posted, you can start the pipe output. It can also be made with your own hands. The pipe should pass through the ceiling and the attic and go out about 30-70 cm outside.

All places where the pipe comes into contact with wooden elements, it is necessary to isolate with any fire-resistant material.

The pipe must have, as already mentioned, the hole with the damper. Make a damper need at the head level to be comfortable to use it.

When the pipe is derived, you need to stack all the stove.

Bath Metal Furnace Device

Metal oven for the bath can be made with their own hands. Such furnaces are made by welding sheet iron or cast iron. At the same time, the iron sheet is not thinner than 5 mm - a lens lesser thickness very quickly.

The whole process begins with the fact that they do the foundation. It does not differ from its device from that foundation, which is used in the manufacture of a brick furnace.

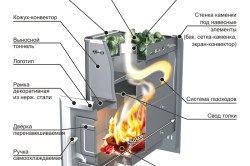

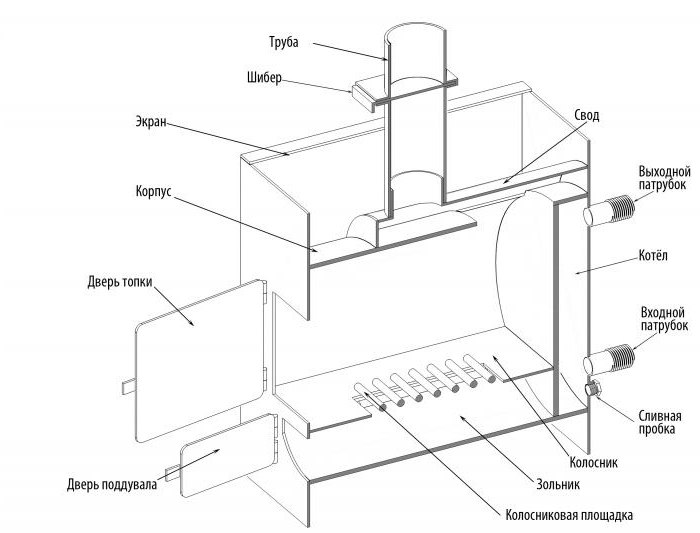

Important! The furnace itself has two compartments. The first is intended for firebox, second - for stones.

The separation of the furnace has a door in which the through holes are drilled below. They serve as a confusion. Inside the branch of the furnace, it is advisable to lay out the brick to increase the service life of the stove for the bath. Between the furnace and the stones separation, you need to establish a solid partition on which stones will be lying. The wall of the department with stones is also required to make the door so that water can be pouring.

From the partition originates and pipe. Stones are located around it and due to this are additionally heated.

It will be best to take a metal pipe. The height of the pipe should be 20-30 cm greeting the height of the stones. Metal tube is facing brick. At the level of its top slice, a hole with a damper is made.

The side of the furnace is welded a boiler that should have one common wall with the stubble for the bath.

So, the stove-heater for the bath is enough to make it yourself. Both furnaces have positive and negative sides. The main negative point can be called that such bantas furnaces have a greater risk of fire, unless to take appropriate measures.

Metal furnaces for the bath on sale a lot, but good worth a lot of money. If there is a sufficient experience of metal welding, you can make the furnace for yourself, according to its size. About how to make a stove for a bath from metal (sheet), drawings and photos - on.

There is a significant difference between the steering modes in the bath and sauna. In the sauna, the air temperature is very high - from 85C and much higher. At such a temperature, the humidity is high just can not - immediately get a burn, and turns out in five minutes. And it is really small, about 5-15%. In the Russian steam room, the temperature is held in the range of 55-65 ° C, occasionally rising to 70 ° C. At such temperatures, the humidity "cattons" is large - 50-60%.

To ensure such different tasks, different approaches are required to build a furnace. The sauna requires the largest area of \u200b\u200bthe contact of the furnace housing with the surrounding air and the acceleration of the passage of air flows along the walls. Everything is subordinated to the task as soon as possible heat the air in the steam room. Kamenka is, but it is small, open, is usually above the furnace. Stones in it are warmed up to a maximum of 200-250 ° C, since a lot of heat gives to the surrounding air. With such a heater, you can get some steam. But in the sauna there is no need - one / two bucket will give 15% humidity. More just not to suffer.

In the Russian pair task, the other is not to overload the room and achieve a large number of steam. Moreover, steam must be a definite condition - it should consist of very small droplets. It is also called "dry" and has a high temperature - about 130-150 ° C. With this condition, after the harvest in the body there is a lightness and tide of strength. Such pairs are obtained only with hot stones, the temperature of which is at least 500 ° C. To achieve her stones "pack" inside the furnace - it is placed in it - a closed heater.

As you can see, there are solid constructive differences. They need to be borne.

Homemade ovens for the Russian bath

What else do you need to keep in mind when designing a furnace for a Russian steam room? The fact that having heated metal walls to keep the temperature within the required 60-65 ° C is unrealistic. Be sure to overpose. At the same time, the stove walls are tight IR radiation and there is hard. The problem is solved in two ways:

Still worth talking about the seams. IN homemade furnaces Of the metal (in the factory, in principle, too), the extension begins precisely from the seams. In production, this problem is bypass using bent structures. At the top are trying to avoid the seams. In the manufacture of a furnace for a bath with your own hands, you are unlikely to bend a metal sheet with a thickness of 6-10 mm, so that only one thing remains - to make the seams as high quality.

Kamenka: What size and where

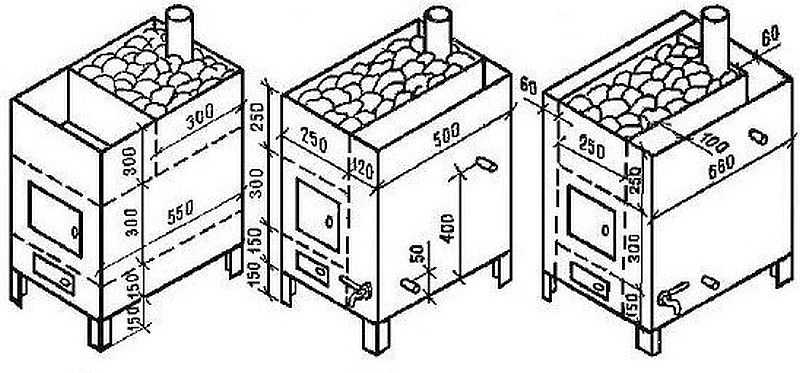

The required number of stones depends on the volume of steam room (provided that normally). In different sources there are different recommendations with a large or smaller number - from 20 to 40 kg per 1 m 3. In principle, the more stones, the easier it is to get the required amount of steam, but provided that the stove has enough power to heat them.

The problem is that the stones of different breed have different density, and, consequently, the same mass occupies a different volume. In principle, for the average steam room of 12-14 m 3, the size of the heater is approximately the following: 30 * 40 * 30 mm. Parameters can be changed a bit, make wider / already / above - see the furnace design.

The ratio of the volume of the furnace to the volume of the heater is a complex heat engineering calculation, which is not even all heat engineer to clamp. It is much easier to use ready-made drawings or experimentally defined proportions. At a minimum, the volume of "free" from the firebox should not be less. Better, even more about 30-50%.

A little about which part of the furnace is best to have a box for stones. All have long come to the conclusion that the highest temperature is in the upper part and at the rear wall. Here in this place and it makes sense to position the container. First, part of the thermal load from the furnace of the furnace will take off, and secondly, the stones are warm well.

Not for the service of the Kamenka and that the water should somehow go there. The service hatch must be positioned in such a way that you can reach with your hand to the far edge without any special problems. And the water supply is deeply organized so as not to burn. Usually insert the tube or system of tubes, which diverge throughout the plane of the stones containers. From the side of the room, this tube ends with a funnel. The tube is folded by stones. When the water is filled into it, it is distributed over the surface of the heater / stones and evaporates.

Drawings of self-made bath furnaces made of metal

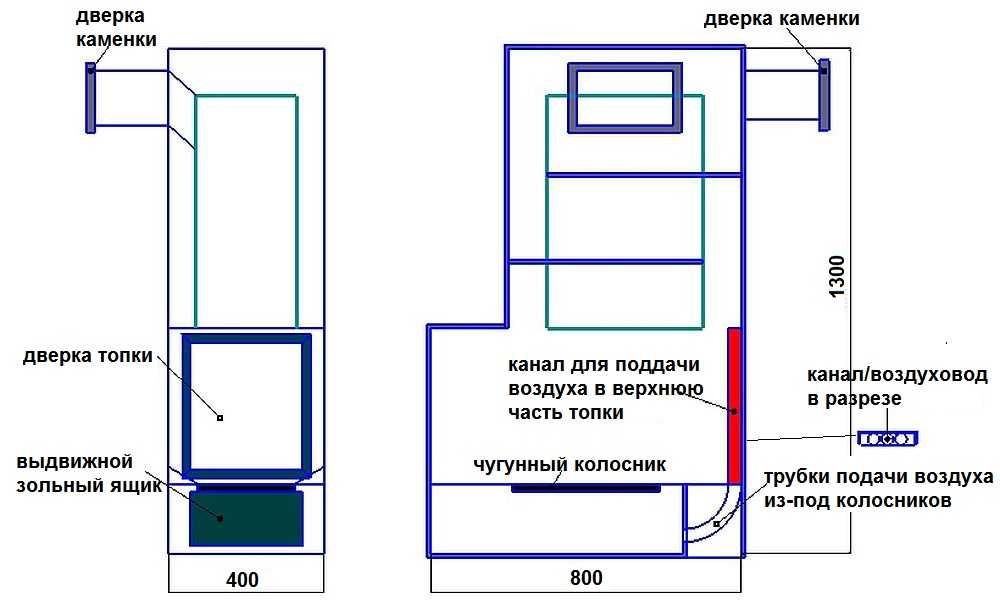

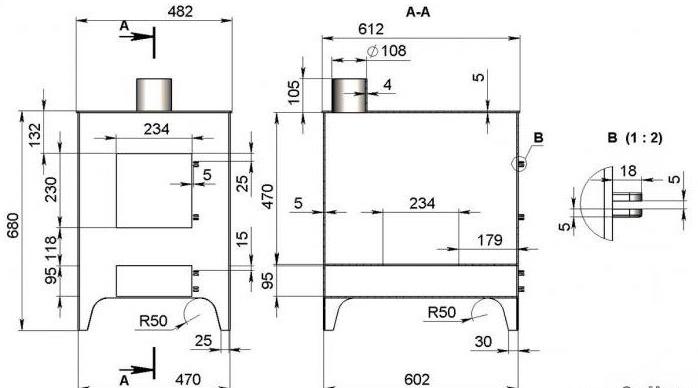

This furnace is designed for steam room 2 * 3 * 2.3 m. Cooked from sheet metal Thick 3 mm.

To activate the combustion, an additional air duct has been connected from the street. From other solutions - the ribs of stiffness (corners) welded to the sides of the furnace in the upper part of the furnace so that the metal does not be flexing with strong heating.

Next scheme metal oven For the bath is made with air supply to the top of the furnace. These are the so-called ovens with gases. On the back wall welded a plate of metal. In the slot between this plate and the rear wall of the furnace with the help of tubes-air ducts serves air from under grip. It is a simple, kind of device solves two tasks at once. First, it cools the rear wall, reducing the likelihood of its exercise. Secondly, the air is fed to the upper part heated. There are focused flue gases heated to high temperatures, most of which are combustible (up to 80%). When these gases are mixed with heated air, combustible substances are flammable, the temperature at the top of the furnace becomes even higher, the stones are heated to higher temperatures. At the same time (when using dry wood), fuel is needed much less. In this principle, many ovens of long burning are built, but in bathing furnaces it began to be used recently.

Approximately the same model, but without surviving, is made in another format. The dimensions are not listed here, but it is easier to understand the proportions and the location of various elements.

Volume model of a homemade stove of metal from metal

In this case, the volume of the furnace is about 130% of the volume of the heater. Normal ratio. Chimney is shifted back, which is not always good - there may be difficulties in the device of the chimney - it may reside into ceiling beam - You have to smoke bending, which is undesirable. So about the location of the pipe - think.

Even in the environment of fans of the bath, disputes are constantly being conducted: the water heating tank in the steam room is good or bad ... one regulates the humidity opening / closing the tank cover. They are satisfied with this option. Others say that this couple is "heavy," and bring the tank to the washing office, and the water in it is warm, by building a heat exchanger in the furnace and connecting it with the tank tubes. Next scheme - a furnace in a metal bath with a water tank.

The design is competent - with the help of a "sparking" the path of the flue gases is longer, it remains longer in the furnace, it is better heats up the wall. If you do not want a tank, you can put stones in its place.

An interesting option with a tank, which is located in the back of the furnace. Chimney shifted back, and passes through the tank. The height of the tank is large, the heat power will be effective - the temperature of the chimney at the outlet of the tank will not be exactly.

Interestingly arranged Kamenka. It is not very big, but for small and medium pylons of its volume is enough. It closes the lid that on the one hand is not very convenient: to close the lid after the supply of water on the stones will be problematic. On the other hand, it is convenient to maintain.

![]()

How to make a sauna oven

As already mentioned, the main task of this type of heating devices is to quickly "catch up" the desired temperature and be able to support it. There is a simple solution - put a fan that will blow the walls of the furnace, accelerating the heating.

Approximately the same function is performed by the cover-convector. This casing around the furnace housing. Between it and the wall of the furnace remains a gap of 1.5-2 cm. In this slit, the air is suused below. It passes along the walls, heats up, at the same time the oven. Next rises up, spreading heat in a steam room.

If the furnace housing is made of thick metal, then the housing can be from thin. It rarely heats up to high temperatures, and the brave does not threaten it. If in the stove for the sauna stoves will be at the top, above the furnace, as in the photo, then in the case you can make holes for the ventilation of the heater. Then part of the air that rises along the walls will fall into the heaters, blow the stones and warm up even stronger. Such a healer is called ventilated. It is good for dry saunas.

Drawings and schemes

Design furnaces for sauna is easier. Need a furnace of a normal size, in which large lamps are placed. At the top of top The fireboxes are welded the side of the heater, the volume of which is usually 20-25 liters. Variations can be in width / height / depth, but there are no special tricks.

Installing a tank for heating the water in the sauna steam room - the idea is not the best. You will not be able to control the humidity, and at high temperatures it is easy to get a burn. However, several options for installing tanks in the photo above.

Another type of heater is inside the furnace. If you wish, you can make a lid and such a furnace can be used in two modes - with an open lid for dry steam, with an open - to get more steam.

Bath is extremely popular in Russia. Today it is a mandatory attribute of the cottage, a private house or a country manor. The furnace equipment can be classified by different parameters: someone builds brick stones, someone prefers metal ovens collected by their own hands. The last option in practice turns out to be more economical, because such a model can be made of submitted materials.

Why it is worth choosing a metal furnace

Metal furnace for the bath with their own hands is going today by many domestic masters. This is due to a variety of factors, for example:

- compact;

- lack of need to build a massive foundation;

- the ability to maintain a permanent combustion process;

- the ability to build construction from available materials.

Such furnaces are really quite compact, and therefore, it will be possible to install them even in a small room. The massive foundation does not require the design, for this it will be possible to build a lightweight basis. This will not only simplify the process of mounting the furnace equipment, but also save time. Due to the fact that the combustion process can be maintained constantly, the temperature will be kept at the required level.

Cons Metal Furnace

Despite the fact that the metal furnace for the bath can be collected, many refuse such a design in favor of expensive brick structures, which are only an experienced specialist. This is explained by some minuses of metal stoves, among them:

- fast cooling;

- low room heating capacity with a large area;

- the need to ensure fire protection.

Metal furnaces are quickly heated quite quickly, but they are quickly cooled. Accumulate thermal energy Such structures do not work. In order to achieve normal temperature in the bath for procedures, it will be necessary to maintain the combustion process. Some owners of the bath abandon metal stoves also for the reason that such structures need to be protected to ensure a normal level of fire safety. Some, for example, use additional enclosures.

Metal furnace device

A simple metal furnace for a bath usually has two parts, one is intended for the firebox, the second is for a tank with water. It was confused at the bottom of the pipe, there is a round steel plate above it. The heater should be above the furnace, from the top to the bottom should be 10 cm or more. A hole for hot water is done in the hot water tank chimney. It is important to ensure the tightness of the seams. The metal furnace for the Russian bath has advantages over the brick that it is pretty quickly heated, and there is no probability of carbon monoxide poisoning. In addition, it is quite easy to make such a design.

If you are making a metal stove for a bath, you can make it in your drawing. However, if it is not desire to create it, you can make a box from the billets of the following sizes:

- two plates with dimensions of 600x1400 mm;

- one plate with dimensions 270x600 mm;

- one plate with dimensions 270x140 mm.

In order to perform a niche for stones, two blanks with the following parameters should be cut from the sheet 5 mm: 270x300 mm. Two more billets must have other dimensions: 270x250 mm. One sheet of steel must have the following dimensions: 25x300 mm. However, quite often metal furnaces for a bath from the pipe are manufactured. In this case, the workpiece with the parameters mentioned in the article.

Independent manufacture of metal furnace: Case shape selection

If a metal furnace is governed for a bath with your own hands, then at the first stage to choose the shape of the case. This parameter will affect the performance of the equipment and the convenience of its operation. The furnace can be:

- cylindrical;

- figured;

- horizontal;

- rectangular.

The last variety is more popular and convenient. If the furnace will have such a configuration, the form will continue the longest time. And about the angles will be quite difficult to burn, because these zones are subjected to minimal heat. The uniformity of the heating of the structure and the room will depend on the shape of the furnace. You must also take into account the need to ensure the stability of the structure. For example, a cylindrical or round hull has low stability. In addition, such equipment requires more dense walls, as it will heat up stronger.

Selection of structural features and preparation of materials

Metal bath furnaces It is known for a long time ago, during this time, the craftsmen developed many varieties and performances of such devices. Most simple decision Stove a stove, which can be made from barrel. For this, the capacitance is cut off the lid and bottom. As a result, it will be possible to get a cylinder, which up to half is filled with bricks installed on the edge.

From above, you should lay a grate grid. The remaining half of the barrel must be filled with stones on 2/3. The design should be supplemented with chimney and install the cover on the furnace. Such technology is quite simple, but the design is not easy to use. If the metal furnace is performed for the bath with your own hands, then for the work you can use leaf steel, which will also be based on the base of the Kamenka stove.

The inner surface of the design should be lined with brick. Whatever execution option you choose, some materials should be prepared, among them:

- sheet steel;

- 10-mm rod;

- cheeks;

- pipes;

- metal pipe;

- cooper

- water crane.

Sheet steel should have a thickness of 8 mm or more. Concerning metal pipe, the thickness of its walls should be 10 mm, while the diameter can vary in the range from 50 to 60 cm. For the furnace chamber, not only tapes are needed, but also doors.

Preparing the pipe, you must take care of the presence of a 90-cm segment that will go to the furnace. For a tank, you will need a 60-cm segment, whereas 50-cm pipe will go to secondary parts. When furnaces are performed for baths on firewood, quite often doors are manufactured independently. As for the tools, the welding machine should be prepared for work and a corner-melting machine.

Making a stove with a closed heater

If you need a stove with a closed heater, then you must be prepared for the fact that to supply the pair you will need to open the door. This design is manufactured according to the following technology. In a large piece of pipes, the diameter of which is 50 cm or more, it is necessary to do the opening for pushed. Its size should be equal to 5x20 cm. Inside you need to weld the mount for the installation of the grate. To do this, you can apply a metal plate with eyelashes.

Now you can begin work on the arrangement of the furnace. For it, a hole is cut with dimensions, which are equal to 25x20 cm. For Kamenka rods, you need to fight fasteners. In order to make a grate grid, you can use centimeter bar, but some homemade craftsmen prefer to acquire this element of the furnace.

On the opposite wall, a hole should be cut through, through which steam will arrive. Kamenka is filled with stones that are suitable for such a design. It is best to choose diabases or talco chlorite, but it costs to refuse silicon, droil-containing stones and granite. In the lid, a hole for the chimney pipe should be done by setting it in the next step.

By such technology, you can be performed furnaces for baths on firewood. Additionally, the design can be enhanced, for this you can use a hot water tank. For this, a segment of the tube of an impressive diameter is prepared, in which the crane must be done. For a tank with water, you should prepare the lid. It must be cut into two parts, in one of them is cut out the opening for the chimney, this part will need to be welded from above the tank. The second part of the cover will be removable, for convenience to its surface, you need to weld the handle and loops.

Metal furnace manufacture with an open stone

If you manage to prepare a stove drawing for a bath from a metal, it will greatly simplify work. Alternatively, you can use the scheme that is presented in the article. Before starting assembly, you should familiarize yourself with another technology that provides for the manufacture of an open-air furnace. If there is a metal sheet in the presence, then the unit will simply build enough.

The design will have a view of a pipe that should be divided into two compartments with a grain grid. The upper part will become a firebox, while the bottom will perform the roller function pondered. The branches must be added to the doors through which firewood can be laid and ensure air supply, as well as remove combustion products.

In the turn on the end of the pipe, it is necessary to install the flue of the chimney, the diameter of which will be 100 mm. Over the case you need to welcome metal boxFilled by stones. With the help of the knee of the chimney, you can ensure the heating of the stones, because the contacting surface will become more.

If you think about how to make a metal furnace for a bath, then the design can be performed in the form of a parallelepiped. In this case, metal sheets should be prepared, and not a pipe. For such equipment you will need a water tank. In a rectangular furnace, the tank can be placed one of several ways. It is sometimes placed on any side, fixed on top, cut pipes for feeding and water intake, perform a shirt on several sides. In order to achieve the most convenient way to produce hot water, you can install a heat exchange tank, which should be located on the chimney pipe.

Water heater can be performed independently or purchased in the store, in the latter case the design will be supplemented with a pipe standard sizes. In this case, the chimney will need to be embedded into the tank, and the vertical part is located above the furnace case. With a sufficient amount of water, the tank will perform the function of the tank or act as a heat exchanger that can be connected to the container.

Making an open-type furnace with brick walls

Quite often, homemade masters are made of a metal furnace for a bathroom with bricks. In this case, the design will have an open type. The equipment is quite difficult in execution, but it will have a great ability to accumulate heat. The design will have a metal housing, inside of which - brickwork.

Metal thickness requirements should be reduced, 2-mm sheet can be used. For masonry, you should purchase styling of the material is carried out on ready mixwhich is intended for furnace work. The damage is carried out taking into account the requirements of the instruction.

Before making a metal furnace for a bath, you need to prepare the basis. The legs and heels are welded to it, which will make the construction more stable. On this basis it is necessary to lay a solid brick series. For other types near the furnace, it is necessary to carry out masonry in the Pollipich, whereas in the field of chimney channels it is worth using a quarter of a brick.

As soon as the camera is imagined, it will be ready, you can move to the installation of a cast-iron grate. It is necessary to position it between the ashtar and the furnace. In order to arrange the opening of the boot window and pondered, the metal corners of the square cross section with a side of 20 mm should be used. It is important to ensure that the seams between the rows are as even as possible.

The metal grille from the rods must be laid above the heat chamber. The diameter of the rod can be equal to 12 mm. As soon as you achieve the level of the heater, on the left and right should be left the opening. In it you will load stones, clean and get them. In this window, during the procedures, it will be possible to spill with water to get steam.

Having considered the scheme of metal furnaces for a bath, you can take the design described herein in this section. In it, the chimney canal is better to make winding. This will contribute to the maximum heating of the hull and fuel combustion. In the place where the pipe will turn upward, you should create an audit window. In it should be a valve, which will save heat after the completion of the furnace of the furnace.

The upper rows of bricks should be done with solid, leaving the opening for as soon as the brickwork will be completed, the solution should be left until the time of grapplation. Then you can start cooking the walls of the metal case. In this case, it will remind the case. On the joints, it is necessary to put the corner of the square section with the aforementioned dimensions, which will make it easier for welding work. It is important to ensure the tightness of the seams.

When the front wall is performed, you should not forget to cut the openings in it for the boot chamber and the ash bar. The front wall after that is installed in its place, the loop for doors will need to be welded at the next stage. If you want the doors to make yourself, their width should be more than 10 mm on each side compared with the openings. It will provide tightness. Additionally, you can use the asbestos seal for this, which is paired along the perimeter of the door or on the inner surface.

You can also make the manufacture of metal furnaces for baths. If you decide to use the described technology, then in the side wall you need to make the opening for the window for the formation of steam. Metal door Need to be installed with sealing material. It is advisable to make it opening down. A hole for the chimney pipe is cut on the lid, and after the lid you can come into place. As soon as the chimney channel is installed, it should be drilled around the perimeter. The metal furnace at the next stage can be installed in place and fill with stones.

Features of the metal furnace

The dimensions of the metal furnace for the bath will be determined by the pipe or barrel, which will form the basis of the design. However, for the right and safe operation Heating equipment It is important not only to comply with the technology of assembly, but also take care that the rules for installing the design are taken into account.

The bath furnace should be removed from the walls per 1 m or more. The construction should be located close to the chimney. It is important to place a design to a special stand or foundation from fireproof materials. Steam walls, near which the furnace will be located, must be separated by refractory sheet material.

Conclusion

Prepare a drawing of a stove for a bath from a metal, you will facilitate your work. However, the scheme does not ensure success. When welding parts, it is important to make sure that the sealing of the seams, otherwise the design may be dangerous during operation. If you want to avoid mistakes, the device must be studied in more detail.

Metal stoves for baths are usually made of pipes or sheet steel. The first option will be easier, because the number of welding works can be reduced. Alleviate the furnace assembly is still in several ways. For example, by purchasing ready-made doors, grille, handles and canopies. Some homework are trying to make these elements on their own. In addition, the drawing is not necessary to draw up independently, you can use ready-made solutions. Some options are presented in the article. They will allow you to understand what sizes should have a stove, as well as which device it has.