The crackling of burning firewood in the furnace creates a special atmosphere of comfort in the house. But wood today is not cheap. Nevertheless, it is not worth getting rid of the stove. Brick stove With the heating boiler - an excellent alternative, economical and allowing to heat the house much faster and better.

Re-equipment of the furnace in most cases does not differ in particular complexity. You can install the boiler in the furnace with your own hands. From the heating systems of the cheapest, simple and efficient is recognized by water specialists. You can install homemade heating boilers in the oven, although there are many successful models with water contour.

Basic rules for installing a boiler in a brick stove

- If you decide to install the homemade heating boiler in the oven, the pipe for the boiler is looking for without seams and with thick walls. If found seamless pipe It does not work, make it necessary.

- Welding pipe jack can not. The welding seam should be the same thickness as the walls of the pipes.

- The distance between the boiler and the walls of the stove should not be less than 5 cm.

- In order to increase the circulation of water, the reverse line pipe must be carried out through the underground space and the foundation of the stove. For the same purpose, the battery in the furnace is installed with a slight bias.

By installing the boiler in the oven with your own hands, remember the special devices for protection. Homemade stoves Water contour boilers must be equipped with a heat exchanger that will help to avoid fluid overheating.

Brick ovens with boiler heating industrial production

Manufacturers of furnace products offer a lot of different models. Furnaces Boilers with water contour can be easily integrated into an already existing home heating system. If you have already installed the heating system, which works with a gas boiler, water to it can be built easily.

You can not call these boilers, but each nested pen is worth it. You will be able to beat off this money, saving on heating. Such modern boilers are installed in a brick stove to harmoniously embed the boiler in the overall style of the room. In fashion, there are now authentic motives, because modern heating devices are hiding in a brick furnace, decorated with tiles became very often.

What brick choose for an oven?

Have you successfully install the boiler in the furnace with your own hands, depends on the correctness of the selection of bricks. For masonry oven it is necessary to prepare two types of bricks: refractory and ordinary. The same with a solution, two types: refractory and ordinary. If you do not know how to do chimney - invite a competent specialist. If at least the slightest errors are allowed in the decreasing chimney, water heating may not act at all or create problems.

Humanity as the main source of heat, humanity uses since its most long time. Usually this type of heating system was used in rustic houses. Such heating was sufficient for heating at home with a small square. To date, many are tightening themselves private houses with a large square and not always stove heating It is capable of ensuring effective heating of the whole house. For houses with a large area, a good solution will be the installation of such devices as a furnace with a water heating boiler. Such a system is effective, and a beautiful fireplace with a water heating boiler will also serve for aesthetic purposes.

Advantages of the combined system and disadvantages

The stove with the heating boiler The traditional type heating consists of components such as grate, chimney channel, ash tank and chamber for firebox. These attributes of the classic rustic oven are familiar with any resident of the village. As for modern stoves, they are visually almost completely identical, but they have somewhat different characteristics:

- A simple rustic oven for the hour of work allocates no more than 6,500 kcal heat. This amount of heat is enough for heating at home with a small area. This method Heating is ideal for a cottage house.

- If the furnace heating is combined with water, then the performance will increase several times. You can also warm up and the large area of \u200b\u200bthe house. At the same time, the same amount will be burned solid fuel. In addition, not so many exhaust gases will be thrown into the atmosphere, which will increase the efficiency of the system.

- In order to achieve even higher efficiency, such two heating systems can be combined as convection and water. During the simultaneous operation of two systems, their performance will be summed up. In one hour of work, such a tandem will produce up to 21,000 kcal. Such a quantity of heat is enough to heat the house with an area of \u200b\u200bup to 300 square meters. meters.

- An important advantage of such a heating system can be called the availability of fuel. Usually, firewood or firewood and coal are used to work such a heating system. Such fuel is most accessible and is relatively inexpensive.

- The furnace with water heating boiler does not need a permanent firebox. So that such a system functioned, you will need to lay fuel only 2 times a day. Regardless of what temperature on the street, in the house it will be possible to create the most optimal microclimate for you.

- The efficiency of a regular rustic furnace reaches a maximum mark of 50%. If you combine two heating systems, this indicator will increase to 85%. Taking into account the fact that to organize the heating system, the furnace is used on firewood, this indicator is ideal.

Heating heating and its shortcomings. Such a furnace boiler for heating at home can be mounted not only in the country or village house, sometimes it is installed in country housesbelonging to the elite category. Sometimes such oven boilers can perform not only the role of heat source, but also a decorative task.

Security standards

Operation of wood furnaces requires compliance with some rules and safety standards:

- Furnaces with a boiler of water heating should be constantly monitored by a person. For normal operation, the system will need not only to add firewood or coal to the furnace, but also periodically clean the ash chamber.

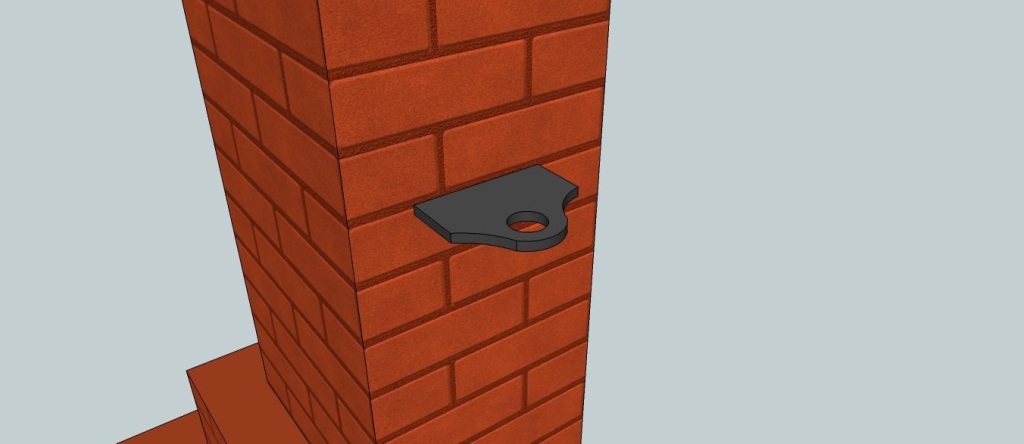

- Attention should also be given to such components of the furnace with a water boiler heating, as the gateway of the chimney channel. They need to be put in the open position until the focus will be sinking.

This heating system can only be used in the cold season. In the summer, use such a furnace for cooking will not be too appropriate. If you need to prepare food, you should search another type of heating system.

Sometimes for the organization of heating system use wood brick furnaces with a boiler heating created by folk crafts or amateurs.

Not always such stoves have good quality. Any overheating or another freelance situation may result in the repair of the furnace, sometimes serious enough. Since the flame of fire has a high temperature, it will gradually break the integrity of the stove walls. Therefore, in any case, this moment will come when the heat exchanger will be changed. In order to replace this component, you will have to disassemble part of the masonry.

If you installed the homemade heating system, it can be supplemented with a pump that will provide forced circulation, or provide a system of instruments that will control the pressure level.

Mounting boiler

During the preparation and implementation of a project to combine two heating systems, it is necessary to pay attention to some nuances. The heating boiler may vary by such parameters as manufacturing material, type of main component and others.

If you do not pay attention to the most important construction and technical requirementsYou can get a defective system. The heat exchanger must be completely in the furnace. The boiler in the oven for heating typically has a P-shaped shape, and it is made of iron sheet type.

Special attention requires such moments:

- Boiler size. Some think that for heating at the house with a large area, a massive homemade heating boiler will be required to the oven. However, the boiler has a rather modest size. Usually the boiler has such dimensions as 75x50x30. The surface of such a boiler is enough to heat the house with an area of \u200b\u200bup to 200 square meters. meters. To increase one and a half times the performance of such a boiler, you can provide it with a pump forced circulation.

- The shape of the boiler. The form of the boiler depends on how much square it can heat. Best boiler install in the center of the burning center. If it is in this way, then you can achieve the greatest efficiency of the heating system.

- Features. It is necessary to leave a small gap between the surface of the boiler and the walls of the oven. The most ideal will be the distance of 0.5 cm.

Masonry and brick

Pechists have always enjoyed great demand. All specialists and masters in this area must comply with some important rules:

- For the manufacture of the furnace chamber, it is necessary to use only those materials that have high refractory. Open fire can harm even such material as a stone or brick. This may noticeably reduce the stability and strength of the entire design.

- Do not save on a masonry of a brick wall.

- Special attention should be paid to the sealing of seams. Even a small gap is dangerous to health people, as a carbon black gas can pass through it.

You can equip two cameras, one intended for heating, and the other for cooking. Such a cunning will allow the use of a brick boiler heating and in the summer.

In rural areas, difficulties with heating have always arose. This applies not so much type of fuel as its use. Of course, there are options for home heating on firewood, coal, even designed heating boilers Under a certain type of fuel. But how to make inexpensive and efficient with water contour, using the already existing chimney design, without damaging the furnace itself? Are there other options in the economy furnaces?

Types of furnace heating

In our case, this is the use of an existing stove. The simplest and most affordable option of heating is the installation of a special water tank, in which a separate wood-burning oven is not needed. Make a stove with water heating is quite forces to any owner, the costs are minimal, special preparatory work not required.

Brick oven must be installed in rooms with good air access, well ventilated.

Water Buck

The water tank is preparing in advance. The main requirement for its manufacture is the quality of sheet steel, which should not only withstand the thermal effects, the aggressiveness of the coolant, but also to heat it well, transmit it from the stove of water.

The thickness of the walls of the tank eco-furnace should be 3-4 mm, it provides faster heating at home. Standard sizes The tank does not exist, they are selected individually from the width of the chimney of the cast iron plate, or the slab itself, it will be a long tank.

The width can be 20-30 cm, the main thing is that the stove remains convenient access, the height is at least 400 mm. In the lower and upper corner, opposite each other, which will ensure the circulation of the coolant, for further installation works, the strapping pipes are boiled two nozzles, you can two threads.

The finished tank can be painted with silver, it will prolong the service life, will make its appearance.

Optimal places of installing tank in rooms inside the house only two. This is the edge of the cast-iron furnace slab, closer to chimney or installing in the place of transition of combustion products from the oven in the chimney.

It turns out a stove with a boiler. But many registers will not use any registers with such heating, due to the low efficiency of the system, they are usually installed in the far room, where the flow of warm air is difficult. The ease of installation is considered to be worthwhile, the stove with water heating does not require the alteration of the existing system, it is convenient to serve such a heating scheme, because it is all in sight.

Water boiler

For better indicators, specially designed heating and cooking furnaces are used. In such furnaces, heating occurs from below, and at the top of the stove at the toproom installed water heating.

Water heating furnaces have a number of advantages over other ways of heating at home. Even when strong frost To warm up the premises, the slab is enough to protrude twice.

Principle of operation

Warming up the premises of the house with heating-cooking furnaces occurs in the break between the fireboxs, the radiators are cooled at this time and give heat for several hours. The efficiency at the same time increases noticeably, reaching 80-85%. Improvements are achieved due to the best removal of heat, changes in the design of the boiler, it made it possible to significantly develop the area of \u200b\u200bits working surface, although the overall dimensions themselves remain unchanged.

Exhaust flue gases have a larger temperature. Passing through the boiler, they warmly envelop its surface from all sides, not interfering to warm the inner walls of the lower heating chamber. The walls accumulate heat, and when a break is formed between the fireboxes, about six / eight hours, start to maintain the temperature of the water boiler.

This type of heating is optimally suitable for heating the house of small sizes, the comfortable temperature is achieved by two-sized furnace.

Then wood heating Significantly saves fuel than with the usual use of the stove long burningsometimes twice. It is even more efficient than the heating by the factory water boilers of continuous action.

Brick oven with water heating circuit

Brick furnaces of this type do not imply a particularly complex masonry. The oven with a water heating boiler has enough simple design: cast iron frying stove, cooking chamber, exhaust canal, water-heating box, oven.

Such a furnace is laid out of fireproof bricks using the same fireproof solutions. Doors: Fake, confused, cleaner, cooking chamber. Pig-iron stove with burner, water-heating box, oven, drying grille, grate. Woodstocks With a water heating boiler on a brickwork have a similar design.

How to make a masonry oven yourself? Arrangement of the stove for heating at home begins with a solid masonry of the initial row, except for one crane brick, to create a slope toward the ash bar. The laying of the second row is necessarily tied up with the installation of the infidel door. The third row is installed on the first row. The fourth row is more complicated, except for installing a second clean door on the right furnace wall, and from halves of bricks prepare support under the oven, where two grate grilles are installed.

Fifth

On the fifth row, the cleft holes are left, and if there are clean doors, they are fixed to the masonry, with the simultaneous installation of the water heating boiler, the highest point of which is the place of the pipe, "feed" hot water. This will avoid bringing the system, and the boiler itself and wood heating will work well.

Sixth - tenth

The sixth row is similar to the previous masonry, the rebirth of the seams is required. When laying this row to masonry fasten the flue door. Seventh nearby overlapping the clean doors. The eighth row, according to the coach, with alternating the seams of masonry. This is nearby two chims behind the boiler. The two next rows are placed equally, with suture dressing.

Eleventh - twentieth

As can be seen from the masonry, the water boiler does not touch the brickwork from behind, the front, the left clearance compensates for the expansion of the water boiler during heating. At the eleventh, the twelve row continues the previous masonry, the seams must be tied up.

The thirteenth begins to spread out of refractory brick, it is the beginning of the overlapping of the heating chamber. The fourteenth continues it. The overlap of the heating chamber completes the fifteenth row. The sixteenth row additionally overlaps the heating chamber.

On the seventeenth row, the horizontal channels of the upper heating chamber are determined, their dimensions. Also on this row, the cleft doors are installed, only four. The horizontal channel is overlapped by the eighteenth nearby, the next row is the cleft doors, the sutures are continued when laying.

The nineteenth closes the cleaner doors. On the twentieth row, the dimensions of the chimneys are determined.

Final rows

Further rows are put in orders, taking the seams. Next, up to the thirty-third row - laying on the orders, according to the rules of dressing of seams. Thirty-seventh, thirty-eighth row on brick furnaces set smoke valve.

37-38 row set smoke valve.

A smoke trumpet begins with a thirty-ninth row.

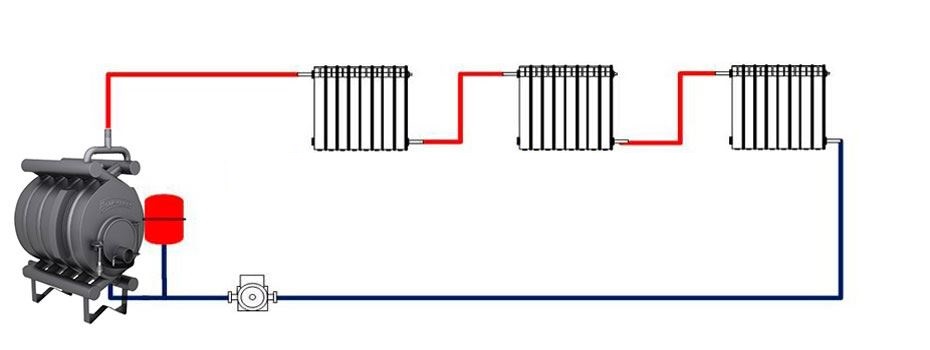

The best indicators of water heating are achieved when using a two-pipe heating system, in addition, at the top point, an expansion tank is installed, which, when the coolant temperature drops, compensates for its increase in its volume. The height of the riser on the supply is maximum, it improves circulation inside the system.

Traditional furnace heating does not provide uniform heat distribution by room. The main heat is concentrated near the heat generator, and when removing it it becomes colder. The organization of furnace water heating will allow to solve not only the problem of uniform heat distribution on the room, but also the possibility of heating several rooms at the same time.

The heating with water heating boiler is most often used in rural areas in the absence of centralized gas supply.

Principle of operation of water heating oven

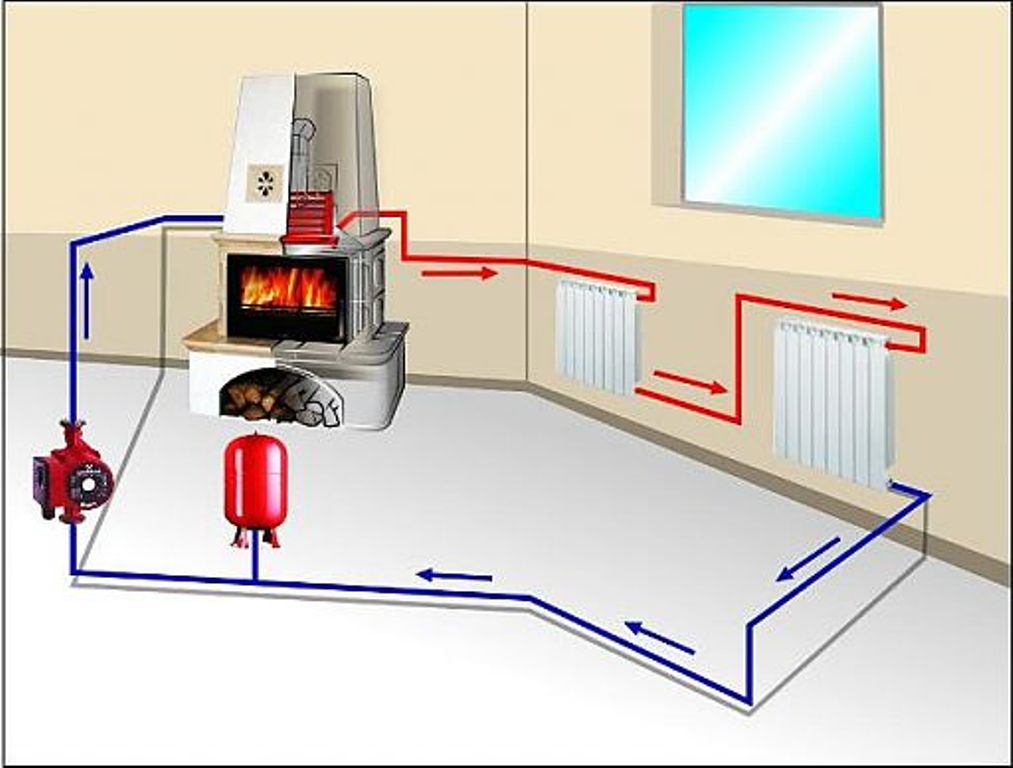

The water heating system is built on a closed cycle, where the heat carrier acts as a coolant.

The order of the furnace connected to the water heating circuit:

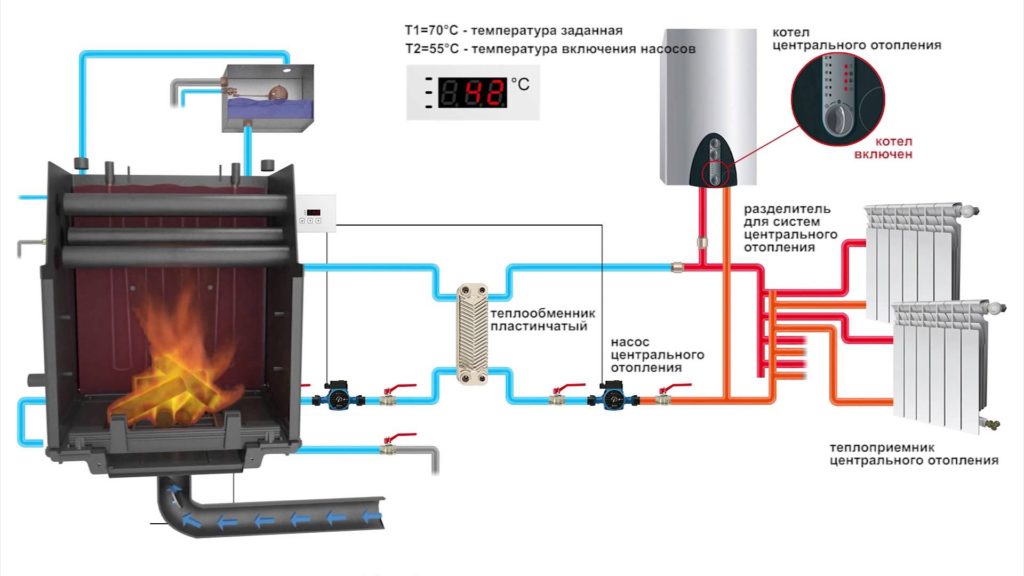

- As a result of the fuel burning, the temperature of the liquid in the boiler is heated, and through the pipeline system is transmitted to heating devices. Under the observance of the slope when laying pipes, the liquid in the system can circulate independently, under the action of gravity. However, the heating system with forced circulation is organized more often using the pump setting.

- Heating devices give their heat to the heated room.

- The cooled heat carrier enters the boiler for subsequent heating.

From the above, it can be seen that the operation of a heat generator with a water heating boiler (heat exchanger) is similar to the functioning of a traditional solid fuel boiler. However, there are also differences - in addition to heating the coolant, the heat generator with water circuit spends the heat generated heat to heating its own smoke channels and the installation walls.

Heat exchanger oven with water contour

If the problem is to connect the water circuit to the already finished brick furnace, the simplest option is to install the heat exchanger (coil) in the heat exchanger.

Attention! This option is suitable for heating, heating and cooking furnaces and fireplaces. The shape of the coil can be any, and its size is such that it does not interfere with the loading of fuel and its effective burning.

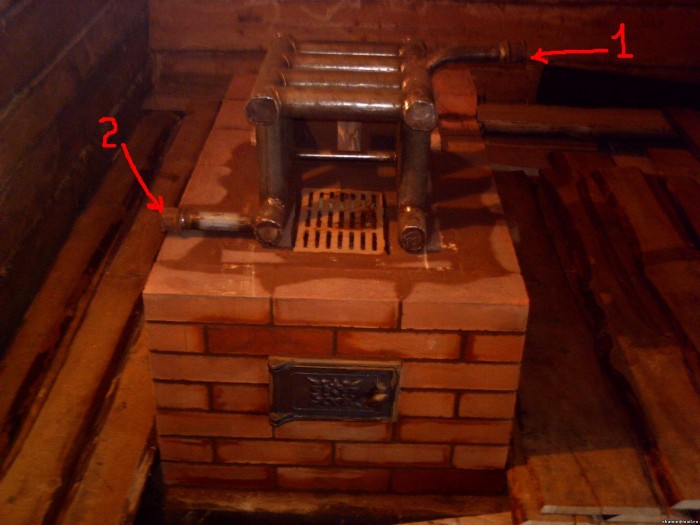

In this case, the furnace is partially disassembled, a torturenik is installed in the fifuel, then the first appearance is applied to the heating installation.

If the brick heat generator with the water circuit is constructed from scratch, then its design can be changed so that its work is as efficient as possible:

- The temperature of gases leaving the chimney must be minimal. The more heat of the combustion products will be removed inside the heat generator, the higher its efficiency.

- The heat exchanger is preferably located outside the fuel area.

Definition! The flame is the burning volatile particles. The heat exchanger that is inside the furnace takes the heat in these particles and reduces the efficiency of the heating installation.

- The coolant in the heat exchanger must be applied towards the heat flow. With this design, the heating of the coolant is most effective, and the amount of destructive steel of condensate on the heat exchanger decreases sharply.

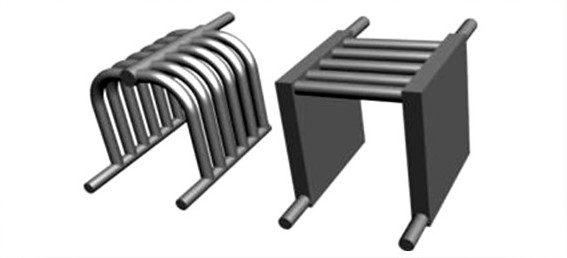

The solution of all these problems provides a device of a cap chimney with a considerable heat exchanger located in it. The simplest version of such a heat exchanger is the register. The register is welded from several pipes of a significant diameter into a single design.

What advantages allows you to achieve this scheme?

- Combustion products accumulate in the cap. And the most hot gases focus in its upper part. Out of the limits of the cap get cold, already the flue gases have already gone.

- Due to the absence of foreign objects in the floating chamber, the fuel burns without interference, completely.

- Natural circulation of the coolant in the heat exchanger occurs from the bottom up. At the same time, the cold coolant, which entered the heat exchanger heats up from the lower, colder layers of flue gases. Gradually, the liquid rises upwards where it is heated by hot combustion products.

Wiring of heating from a stove-boiler for home heating

The wiring of the heating system is carried out in the same way as from a solid fuel boiler.

Attention! The main difference is the highest location of the inlet in the heat exchanger, compared with the solid fuel boiler. This moment must be taken into account when designing a pipeline laying.

Main points of installation of the heating system with a heat generator for water heating at home:

- IN higher point The pipeline is installed expansion tank. Alternatively, it can serve as a hydroaccumulating capacity.

- Pipes are mounted with the observance of the angle of the angle of the slope. To increase the efficiency of the heat generator, the circulation pump is installed in the system.

Attention! The most functional is the heating system in which the boding of pipe gaskets is combined, and installing the pump. In this case, the system works effectively and in the presence of electricity, and without it.

A brick stove with water heating is a more efficient heat generator, compared with a solid fuel boiler. Such a furnace is faster and more efficiently heats the house, it looks great in the kitchen and can serve for cooking.

Brick oven - classic option autonomous heatingwhich in Russia is used for hundreds of years. Brick can be called an eternal material, serve such a furnace will be very long, and it will not lose its effectiveness. However, the usual oven heats the house unevenly, in addition, it is suitable only for a small one-story building.

It is possible to significantly expand its capabilities due to the installation of the register - a water circuit, which will make it with the help of radiators to heat all the premises of the house and get the maximum heat with minimal costs. How is the furnace with water heating boiler?

How to combine brick oven and water heating

Built the boiler in the oven for heating throughout the house is not so difficult at all, as it may seem. To do this, it is necessary to make a heat exchanger that is usually an ordinary serpentine.

It requires the maximum surface area and such a location so that it does not interfere with the loading of fuel and the combustion process. It is most often made of pipes or metal plates, as a material with an optimal option is the heat-resistant stainless steel.

The heat exchanger is installed in the bracket chamber, and water in it is warmed due to the combustion of the fuel. After that, it enters the heating radiators, gives them a heat that enters the rooms and returns for the next heating cycle. Perhaps two installation options for such a system:

- With natural circulation. This is the easiest option that will be completely non-volatile. The movement of water in the network in this case is carried out due to the temperature expansion and increase water pressure during heating.

- For this, the pumps are not required, water is expanding under the influence of heat and rises upstairs, and then under the action of gravity it is lowered to radiators and returns back. At the top point, an open expansion tank is installed, which compensates for the temperature expansion and ensures unnecessary air from the pipeline system.

- With forced circulation. In this case, the movement of water is carried out by a circulating pump operating from electricity. This makes the system dependent and more vulnerable, but it will be more energy efficient.

Forced circulation involves the installation of a hermetic expansion tank and safety valve. The tank compensates for the expansion of water when heated, and the air from the system is removed through the valves.

A faster circulation does not allow water to cool, therefore, it takes less energy to re-heating, and the system will be more economical. In addition, the circulation pump will allow the movement of water to all rooms even in a very large house.

Advantage of water heating oven

The furnace with the boiler of water heating at home plays several roles at once: it is not only a heater, it can be used for hot water. If you equip it with a cookbook and a brass cabinet, it will also become the best place For cooking, which will additionally increase its utility. Brick ovens with a heating boiler have several important advantages:

In addition, such a furnace will not have to constantly heat, which will significantly simplify the life of the owner of the house. Enough in the morning and evening or even once a day, so that it is enough to warm the coolant and ensure a sufficient amount of heat.

The water circuit will significantly increase the efficiency: in a standard Russian furnace it is no more than 50-60%, and after installing the heat exchanger, this parameter will grow to 85%. This will allow to spend the minimum of fuel to get the maximum heat.

The main disadvantages of such heating

The furnace-boiler for home heating is a nonideal solution, and cons, like any other system, he has. Even an updated oven remains a fire hazardous, so you will have to constantly take care of the requirements of the fire safety of the health of chimneys and so on. Before the furnace must lie metal sheet or other non-combustible materialprotecting the room from accidentally fallen coals.

The heating furnace with a water heating boiler will require professional construction. It is possible to build it with your own hands, but at the same time it is advisable to constantly consult with professionals, since the masonry of the furnace is the most difficult art, which is immediately difficult to master. Professional services are expensive and still will not be one hundred percent guarantee from errors and flaws.

If you want to independently build a furnace, you will need to erect an additional foundation for it: brickwork It has too high weight, so it needs strong concrete base. The area is calculated by the formula: 1 kV. m. The furnace is heated 35 square meters. Meters of housing. Accordingly, it is possible to calculate the size of the heater taking into account the installed water circuit.

Construction of an oven with a boiler heating

Construction begins with design work: It is usually first designed and a coherent heat exchanger is manufactured, and then the oven is built on its size. It is important to choose the right place: usually it is located in the sides of the kitchen, and the housing itself should go into residential premises. If the furnace is equipped with a water circuit, it can be placed where it will be convenient for maintenance.

When the place is chosen, and the foundation is ready, the coach of the furnace with a water heating boiler is drawn up: this is a brickwork planning plan, which allows you to determine the location of the fuel chamber, a cooking panel, chimney, etc. Order can be downloaded on the network in finished video: A variety of projects have already been developed, and thinking out a unique oven optional.

The oven with a boiler of water heating with their own hands is built from a refractory brick of high quality: it should not be checked or inextricated, there should not be chips and cracks on it. Construction itself after completion of preparatory work is carried out in several stages:

- It is necessary to prepare a solution from sand, water and clay, or you can buy ready construction mixture. The second option will significantly simplify the work and will save from excess work. However, experienced cooks prepare the solution only on their own.

- The finished foundation is closed by a waterproofing layer. To do this, you can take a ruleroid or other protective material.

- A solution is applied on the rubberoid layer, and the first row of bricks is laid out. Next, according to the order, the first rows are erected, and a coil is installed in the contours of the furnace chamber.

- A compartment is built for ash and furnace, work must be carried out strictly in order. Each series of bricks is necessarily checked: the deviation from a number can lead to very unpleasant consequences.

- Wired fastened fire doorThe arch of the furnace and chimney is built. For the inner surface of the heat chamber and chimney, bricks are used with rounded corners so that soot can be accumulated inside, which can lead to fire.

- When the furnace is ready, you can move to the installation of water heating. The heat exchanger is attached to the tubes of the feed and reverse contour, which are connected to the radiators. An expansion tank is installed, the system is filled with the coolant.

When the construction process is completed, you can begin the furnace furnace and a test furnace. For the outer surface you can use simple plaster or tiled decoration. Tile-tile oven decorate for a long time, it will create an interesting beautiful interior.

The chimney tube must be white: black spots will be noticeable on it, if the chimney is faulty and passes the combustion products into the room. Already a trial firing will allow you to see errors and, if possible, fix them.

Independent construction furnace and installation in her heat exchanger - not easy task, and better entrust her professionals. The skill of the liver is always highly appreciated, and should not save on the call of the master, which, indeed, knows all the secrets of construction technology. The correct construction of heating will allow reliable heating, and in your home will never be cold.

One of the main advantages of the Russian oven is complete autonomy. With sufficient firewood, you can provide home heating throughout the winter, and your home will not remain without heat due to the accident on centralized networks. The Russian oven is an eternal classic, which will not lose popularity for a long time, and new technologies will make it use more efficient.

You need to enable JavaScript or update the player!