Cosmoplast - russian manufacturer polypropylene pipes and fittings for indoor and outdoor water supply and sewerage systems. We deliver plastic pipes and fittings for building engineering systems.

IN modern world the growth rates of urban and industrial construction impose new, more stringent requirements for the laying of communications both inside and outside the facility being built. Every day, new projects are created that involve the use of lightweight and durable materials, which allow not only to reduce the labor intensity of work, but also to significantly reduce the cost of sewerage and water supply systems.

Such materials today are polypropylene (PP), polyvinyl chloride (PVC) and polyethylene (PE). Sewer and plumbing systems made of these materials have a number of advantages:

- ease of installation, carried out according to the "constructor" principle,

- resistance to chemical compounds and corrosion,

- the presence of smooth internal surfaces that provide a good flow rate of liquids and contribute to the complete removal of waste from pipelines.

The indisputable advantage of the use and fittings made of these materials is also the durability of operation, which ensures the uninterrupted operation of the system for 50 years (provided correct installation designs). Modern construction organizations and private developers have already been able to evaluate sewerage and water supply systems made of polypropylene, polyethylene and PVC. Widely used today, drainage system, etc.

Cosmoplast - manufacturer of polypropylene pipes and fittings

Every modern polypropylene pipe manufacturer uses a consistent policy of improving product quality, focuses on the latest technological solutions. Thanks to a quick response to changing consumer demands and a constant expansion of the range, we can offer universal sewerage and water supply systems that meet the highest standards.

PVC pipe manufacturer Cosmoplast offers self-made goods, as well as products from the world's best manufacturers - PVC pipes for external sewerage, PP pipes and fittings for internal, sewerage, casing pipes, pressure polypropylene. All sold products are of high quality and reliability. A huge range of products of the company allows you to reduce the time of search and selection necessary materials... If any product is out of stock, you can order it from the catalogs of our partners. Deliveries are made directly from Europe, so our prices are affordable for every consumer.

Currently russian market saturated with components for water supply and sewerage communications. However, their quality in most cases leaves much to be desired. Manufacturer polyethylene pipes Cosmoplast offers reliable and other products from leading manufacturers that have won a long-term competition in the price-quality category. is carried out in accordance with the norms and standards established by the enterprise and the state.

Employees of the company will provide you with comprehensive information about any sold product, will assist on any issue related to the application and installation. Each client will find an individual approach with us. Regular customers are provided with optimal conditions for long and fruitful cooperation. We make every effort to provide a convenient and profitable service to our customers and strive to establish long-term business relationships.

Heating is a complete system in which radiators and a heat source are interconnected by a network of pipes. The conditions and service life depend on their strength, durability, tightness of the connection. What pipes for heating are best purchased to ensure a long and reliable service of the heating system? The choice depends on the type of installation (hidden or external), the location of the pipes, temperature, type of coolant, design working pressure and many other factors that can affect the operating conditions of the system.

Schematic representation of the types of heating pipes

What pipes are needed for heating

Durable. The reliability of the pipes determines how long they will last without repair and replacement. It is highly undesirable to save on materials, because a burst pipe is quite capable of causing a "flood", damage to things, furniture, finishing materials... When choosing, you should pay attention to specifications products - working pressure and temperature.

Corrosion resistant. The inner surface of the products must be protected with a reliable anti-corrosion coating. Otherwise, the integrity of the material will quickly be destroyed due to rust.

Low noise. The noise figure during the operation of the system directly depends on the material. The quieter the coolant flows, the cozier atmosphere in home.

Aesthetic. If you are planning an outdoor, not a hidden gasket, then you need to think about how the system will look in the interior.

Appearance heating pipes plays an important role when choosing

Selection of pipes for centralized and autonomous heating systems

In a centralized heating network, the working pressure and quality of the heat carrier differ markedly from individual systems. Private homeowners usually monitor the purity of the water circulating through the pipes, and the pressure rarely exceeds 2-3 atmospheres. In a centralized network, the pressure can reach 16 atmospheres, and the coolant is often contaminated and chemically active, capable of corroding and damaging the inner walls of pipes. Therefore, for apartments in multi-storey buildings, it is worth choosing the most durable and reliable elements of the heating system.

Materials and scope of pipes

As a rule, products of the following main types are used for heating:

- metal;

- polypropylene;

- metal-plastic;

- steel;

- copper;

- made of cross-linked polyethylene.

Reinforced-plastic pipes are universal. They are great for setting up systems in private and apartment buildingssince are able to withstand a pressure of 25 atmospheres, are distinguished by high indicators of resistance to corrosion and mechanical damage. Polypropylene products are more often used in autonomous systems, since they cannot be mounted if the pressure exceeds 6-10 atmospheres.

Steel is strong, but the tightness of the pipeline largely depends on the type of connections. Welding is less reliable than threads. Copper is extremely durable, but the cost often scares off potential buyers. Cross-linked polyethylene is a novelty on the construction market, products from it are applicable in any type of system. The disadvantage is the limited number of standard sizes. Manufacturers have so far established the manufacture of products of small diameters. In addition, the material is afraid of direct sunlight, and this must be taken into account during installation.

How to calculate the required diameter

To determine the diameter of the pipes, you should know the diameter of the fittings, the main characteristics of the heating devices, the type, method of circulation of the coolant, and the pressure in the system. You can calculate the diameter using a special table. Also, many specialized sites have online calculators.

To use the table, you need to calculate the area of \u200b\u200bthe room and take into account that for heating 10 sq.m. 1 kW of thermal power is needed (if the ceilings are not higher than 3 m). Having calculated the power, add 20% "in reserve" to the figure obtained. If necessary, you can increase the power indicator, but you should not decrease it. The resulting power value (in W) must be found from the table, the speed of the heat flow and the cross-section of the pipe must be determined.

Note! The optimum flow rate of the coolant flow is indicated in the table in blue.

Heating pipe diameter calculation table

Rating of the best manufacturers

The list of manufacturers of the highest quality pipes is headed by manufacturers from Germany. The advertised German quality fully justifies its reputation. The products are not cheap, but the costs are justified. Among the most famous brands are:

- Wefatherm;

- Banninger;

- Aquatherm;

- "Rehau".

Turkish pipes are somewhat inferior to Czech ones. The best producers are Vesbo, Valtek, Pilsa, Tebo, Kalde and some others are also in demand.

Of the relatively cheap products, Chinese and Russian should be named. On the domestic market, these are the brands Polytek, Heisskraft, Santrade, Pro Aqua, RVK, and among the Chinese ones one can name Dyzain and Blue Ocean.

Heating pipes of the "Rehau" trademark

Conclusion

Which pipes to choose for heating is up to the owner of the house. This largely depends on the cost of the products, because the heating system is always expensive and many of our compatriots are guided primarily by the budget. In our market, the most popular are metal-plastic and polypropylene pipes. They look neat, durable, smooth inside and out, gas tight. The materials can last for several decades. The main thing is not to skimp on quality and choose products from firms worthy of trust.

Metal-plastic is good for both centralized and individual heating systems, and it is better to choose polypropylene for an autonomous one. Otherwise, there are no restrictions. Consider what the pipes in your home will “have to endure”, decide on a brand, read the technical documentation and go to choose. If possible, be sure to consult with a specialist!

The very concept of "German quality" sounds like the name of a solid brand. Any product made in Germany meets the highest requirements for it, be it a car or the simplest piece of household appliances.

In this article we will talk about the high quality of German plastic pipes, take a closer look at the products of three leading manufacturers of German polypropylene pipes for heating and water supply and conclude that the leader in this segment:

Aquatherm

Aquatherm (Germany) products are the undisputed leader in the European market. It has a number of international certificates and is approved by the Ministry of Health of the Russian Federation.

German polypropylene pipes and fittings Aquatherm are used in drinking water supply systems, hot and cold water supply systems, heating systems, various engineering systems, in pipelines for transporting liquids under pressure.

The manufacturing company produces pipes of different diameters. The general list of products consists of more than 450 items.

Aquatherm products have significant advantages.

- All pipes can serve up to half a century without intermediate repairs, and the manufacturer gives a 10-year warranty on them.

- Aquatherm products occupy a leading place among competitors in terms of technical indicators: linear expansion, temperature exposure, impact strength, retained pressure, durability.

- Aquatherm has set a liability limit for its products at € 8,000,000.

- Pipes have high resistance to corrosion, do not allow oxygen and light to pass through, as a result of which no pathogenic environment, mucus and deposits are formed inside.

- Aquatherm products are easy to install. The elements are soldered into a single whole without the use of adhesives, seals, etc. The joints are crimped. The pipeline can be used immediately after installation. The soldering time takes a few seconds.

- The pipes are resistant to mechanical stress, shock-resistant.

- A complete set of accessories can be ordered directly from the supplier.

- Aquatherm pipes are hygienic and safe for drinking water systems.

- Due to the absolute smoothness of the inner surfaces, the same speed of water passage is constantly maintained inside and, therefore, a good head.

Working temperature of Aquatherm pipes is 95 ° С, pressure - 10 bar. With pain low temperatures the pressure indicator rises to 20. The coefficient of linear expansion is 0.15-0.35 mm / mK, which corresponds to the coefficient of expansion of metal pipes.

Banninger

The company's products have been holding leading positions in the European market for several decades. Banninger polypropylene pipes from Germany are made from first-class raw materials and meet the highest quality standards. This allows the manufacturer to provide a ten-year warranty for the entire product range, with a guarantee of 5,000,000 € for each event.

Benninger products are distinguished by a number of undoubted advantages.

- The pipes are able to withstand high pressure and do not burst even when water freezes inside them.

- They do not clog, corrode and corrosive environments.

- Vibration and noise caused by the movement of water pressure are completely absent.

- The pipes do not need to be painted.

- They can be laid in concrete or ground. durable and serve without repair for 50 years.

- The smoothness of the inner surface ensures faster water movement and, accordingly, a higher head.

- The pipes are durable, wear-resistant, heat- and shock-resistant, do not conduct electricity.

- The pipes are easy to install.

Benninger pipes can be used in hot and cold water supply systems, heating systems, process pipelines, etc. Reinforced polypropylene pipes can withstand operating temperatures up to 95 ° C and pressures up to 20 bar. Their linear expansion coefficient is extremely small, 4-5 times lower than that of unreinforced pipes.

Wefatherm

Company WefaPlastic, the German manufacturer of high quality Wefatherm piping systems, is widely known in Europe. Its products are very popular. Wefatherm pipes have the widest range of applications and have undoubted advantages.

- The pipes are resistant to corrosion, friction and aggressive environmental influences.

- Hygienic and quiet.

- Capable of withstanding high pressure.

- The pipes are lightweight, 9 times lower than metal ones.

- They have high heat-saving qualities.

- Well weldable.

- No deposits form inside the pipes. The smooth inner surface ensures high water permeability and constant good pressure.

- The pipes are easy to install.

Wefatherm are used in plumbing systems, in shipbuilding, in agriculture, horticulture and food industry, ventilation systems, etc. High performance allows the manufacturer to provide a ten-year warranty. The pipes are designed for a maximum operating temperature of 95 ° C and pressures up to 20 bar. The coefficient of linear expansion is 0.15 mm / mK.

Output:

As follows from all of the above, Aquatherm occupies the first place among the three leaders in the production of plastic pipes for a number of indicators.

Russian market of plastic pipes in last years has expanded significantly. The reason for this is the high demand for such a product, as well as a simple production technology. The production of polypropylene pipes in Russia attracts many start-up entrepreneurs. We will talk about how to organize such a business in this article.

Product advantages

The wide range of applications for plastic pipes is due to their positive properties:

- The products are highly durable. They do not rust or rot;

- Withstand temperature extremes;

- Do not affect the taste of water;

- They have a long service life;

- Low weight compared to metal pipes.

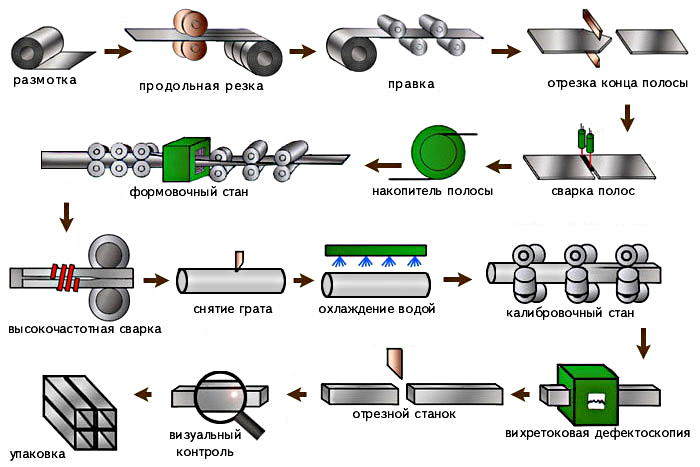

Technological process

The main machine in which raw materials are processed and turned into a pipe is an extruder. If we consider in more detail the technology for the production of polypropylene pipes, it is necessary to highlight the following stages:- Raw materials are poured into the chamber, which are chips or granules. For the production of polypropylene pipes, you can use recycled material, which should be mixed with the main raw material;

- The granules melt under the influence of gas or electric heaters at a temperature of 230-250 degrees. Plastic gradually turns into a kind of viscous substance. Inside the walls of the machine for the production of polypropylene pipes are covered with Teflon, so the material does not stick to them;

- From the molten plastic, the extruder extrudes products of the desired diameter, 2.5 meters long. This is a completely autonomous process that takes place at an accelerated rate. The operator only monitors the operation of the equipment for the production of polypropylene pipes and sets the required parameters. The best models of machine tools produce up to 200 kg of products per hour;

- The workpieces are cooled in a special bath, after which they keep their shape perfectly;

- At the last stage, marking is applied to the pipe - the batch number and the date of its release. After that, the products are packed and sent to the warehouse.

Scheme: production of polypropylene pipes

Equipment

The choice of a line for the production of polypropylene pipes largely depends on the type of end product and the scale of the enterprise. The plant can produce over 1000 m of pipes per shift.

The production line consists of the following units:

- Dispensers for raw materials supply;

- The extruder is the main equipment for the production of polypropylene pipes. In this machine, the raw material is melted and given the desired shape;

- A device that pulls the workpiece and sends it to the bathroom for subsequent cooling;

- Calibration machine;

- Device for cutting finished products to size.

The minimum price for equipment for the production of polypropylene pipes is 700 thousand rubles. The line with high performance will cost 2 million rubles.

Where to buy equipment for the enterprise?

Domestic manufacturers offer equipment at more affordable prices, but it is not as high-quality as foreign counterparts. IN recent times many entrepreneurs prefer Chinese equipment for the production of polypropylene pipes and fittings. It has decent quality and is different affordable prices... If financial opportunities allow you, it is better to immediately purchase an automated line. In this case, in the future you will not have to stop the work of the enterprise in order to carry out its modernization.Raw materials

Before organizing the production process, it is necessary to develop a competent business plan.

It must include the following items:

- Equipment list;

- Purchase of raw materials;

- Rent price.

Special attention should be paid to the choice of raw materials for the manufacture of polypropylene pipes, since the operational properties of finished products largely depend on this.

Products can be made from the following materials:

- Homopolymer is propylene. It is commonly used for the production of fittings and internal sewer pipes;

- Random copolymer propylene. This material is used for the production of heating and water pipes... Such raw materials are supplied to our country from abroad;

- Before purchasing raw materials, check their quality and expiration date. It is advisable to conclude contracts for the supply of materials with trusted suppliers who have been on the market for a long time and have an excellent reputation.

Company registration

In order to organize the production of polypropylene pipes as a business, it is necessary to formally formalize all the documents. First of all, you need to register with the tax office, as well as the pension and insurance fund.

In addition, you need to obtain permits from the fire inspection, SES, local authorities and the gas service. Special licenses for this type of activity are not provided by law.

Location

For such an enterprise, it is advisable to find premises that are outside the city. It should be of a large area, approximately 150-200 square meters. meters, so that you can equip a workshop, a spacious warehouse and a changing room for workers.

To maintain the production line, you need to hire 3 workers. In addition, you will need an experienced technologist, machine operators and movers.

Financial calculations

To open an enterprise for the production of plastic pipes, it is necessary to invest about 5 million rubles. The money will be needed to purchase expensive equipment, rent premises, purchase raw materials and wages for workers. If you find reliable sales markets, and the products are not stale in the warehouse, the enterprise will bring in 300-400 thousand rubles of net income monthly. All initial investments will return with interest literally in 2-3 years.

Establishing such a business is not so easy. For an enterprise to work legally, you need to obtain many permits and formalize everything required documents... In addition, this industry is very competitive, so you have to work hard to get your place in the market.

If you don't have your own start-up capital, you can arrange. It does not require large investments, but it brings good income. The profits made can be set aside to raise funds for the purchase of equipment to equip the pipe production shop. You can also earn good money for. Construction Materials are always in great demand, so there will be no problems with the sale of such products.

Enterprise profitability

To perform a profitability calculation, you need to determine the costs of purchasing equipment, staff salaries and renting a production facility. Divide the resulting figure by the amount of net profit, and you get a percentage of profitability.

Related Videos Related Videos

Of course, all these calculations are approximate. To achieve more accurate results, it is necessary to carefully analyze the market in your region and draw appropriate conclusions. According to experts, in order for the enterprise to bring good income, 8-9 million rubles must be invested in it. The profitability of such a business fluctuates in different regions within 20%.

Polymer pipes are used in a wide variety of areas - for transporting water, gas, various technical liquids and others. Such a great popularity of products can be explained by its environmental friendliness, durability and strength.

Recently, it has been one of the most promising areas of entrepreneurial activity, since it brings good profits in any economic environment. High profitability is provided by