The construction of a house in German technology is characterized primarily by using high-quality materials that will serve their owner. long years. It is because of this that this construction technology is becoming increasingly popular. About the construction process of houses in German technology will be talked further.

Houses in German Technology: Production Features and Benefits

German technology The construction of the house involves the construction of a frame-type building. To carry out this process, it will take the presence of a wooden frame and insulated panels, which will easily withstand the most severe climate.

One of the advantages of using German technology is the fact that several months have enough for the construction of the house. So, for example, to build a gas-concrete house, an area of \u200b\u200b200 square meters and carry out its further finish, it will take at least three months. For the construction of a building built according to the German construction technology, a year and a half. Since it is enough to build enough ten days, and further work is related to finishing.

Among the advantages, construction of houses, using German technology, it should be noted:

1. Heat - which is to carry out the correct thermal insulation and in the safety of heat, especially in winter. Therefore, the heating of such a house should be spent twice as fewer energy resources than on the heating of stone.

2. The duration of operation is the minimum service life of this house its owner is fifty years.

3. Environmental safety - the house is performed from harmless to ambient Materials. For example, to insulate panels, it is enough to use conventional wood chips.

4. Aesthetic attractiveness - such a house is rightly suitable for minimalists, as it does not contain any unnecessary parts.

5. Easy and ease of operation - all rooms are thought out to the smallest detail, the house is convenient to use at any time of the year.

If we consider the issue of the cost of the house, erected by German technology, then construction work The arrangement of the house, with an area of \u200b\u200b60 square meters, will require about 38 thousand euros. This factor is influenced by the construction technology that happens:

- framework;

- aerated concrete type.

Besides, decoration Materials, differ in price, their choice depends on the preferences of the owners and features of the room.

Characteristics of frame houses in German technology

Low-rise construction implies several technologies for arranging a frame house. They are used in various countries and received their names from them. The most common construction technologies frame houses They are Finnish and German. The main difference of which consists in the type of materials used, the technology of construction of the frame and the quality of the work performed.

For the construction of a frame that is the main carrier design At home, wooden or metal rods are used. It is because of them that the design is solid and reliable.

For the manufacture of a skeleton house in German technology, a solid glued wooden bar is used, from which the framework is constructed. For the manufacture of such a bar, a special pre-dried and calibrated wood is used exceptionally coniferous rock. It is coniferous less susceptible to rotting and drying, as they have a high resin content.

The most common embodiment of the framework of the frame is the preliminary blockage of walls: from below and on top, installation of strides, beams and dies. In addition, additional elements are installed in the form of racks and riggers, in the space between which window and doorways are installed.

In order to fill interfraction space, the insulation is used, the main quality of which is incomplete before rotting and deformation. Therefore, most the best option The insulation is the use of basalt stone wool or plates based on polystyrene foam.

Projects of German houses:

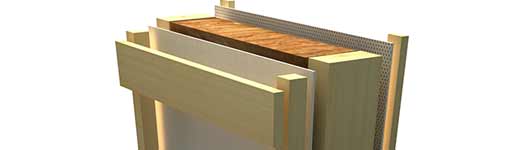

The following occurs on both sides of the framework of the OSB chipboard plates. For their manufacture, extruded wooden chips, resins and anti-grab agents are used. Possible an embodiment using cement chips. The inner part of the design is protected by using a hydro and vaporizolation membrane that passes pairs and humidity only in the outer part, so all wooden design details always remain dry.

The subsequent finishing finish includes the walls of the walls of plasterboard, and for the processing of rooms with increased level humidity, another additional waterproofing layer will be required.

Replace wooden designs quite actually with the help of light metal profile. This construction technology is the ideal option when erecting houses in the shortest possible time. With it, not only residential low-rise premises, but also offices, warehouse and production facilities are built. For their structure, materials are used higher strength than when the residential building is erected.

German houses photo:

We offer to explore the advantages of the framework of the construction technology of houses:

1. A small wall thickness, providing a high level of thermal insulation.

Insulation, which is used in the process of erection of walls in German technology, has a very low thermal conductivity, in comparison with brick or concrete. Therefore, for example, using mineral wool, it is enough to install a layer with a thickness of 15 cm. At the same time, the thickness of the whole wall will reach the mark of 25 cm. This is enough enough to make it warm and cozy even in the harsh winter in the house. In addition, the flow rate of this house, compared to the brick, will be five, or even eight times less. And in order to hide all communication elements used interetens, so the appearance of the room will not suffer.

2. High bearing ability walls and low weight of the building itself. It is than these qualities, to build a house, it will not be necessary to equip too powerful and expensive foundation. Quite fine-breeded columnar or tape types of foundation. Thus, it is possible to save the means on their arrangement. Due to the high bearing ability of the walls, a huge selection of the roof finishes, as almost any materials are applied.

3. High levels of seismic resistance and immunity before seasonal movements of soils. The house for the construction of which was used by German frame technology Withstand earthquake from 7.5 to 9.2 points.

4. The design is non-shrum, so it is not necessary to expect a certain period of time for finishing works.

5. The ability to build a house of any form and configuration. This construction technology is able to implement any ideas of architects, designers and owners of the house. In addition, there is an opportunity to arrange additional attacks located near the house.

6. The velocity of houses is the highest. All construction work is carried out directly at the construction facility and takes this process for no more than two months. Houses built in German technology are based on a large-sized panel assembly, the degree of readiness of which is 91%, as they are pre-prepared by the manufacturer, and it remains only to connect them on the spot using a small workforce in the form of four or five people. All elements made at the factory have high quality, therefore the probability of errors in the process of connecting parts is practically absent.

7. Availability of opportunity in a dilvenous construction work. Houses built in German technology are equipped both in summer and in winter time of the year. Installation work does not depend on ambient temperature. The main condition is the lack of precipitation and high humidity.

8. Health care is ensured by using exclusively environmentally friendly materials. In this case, not only a person, but also the environment.

9. Low level of labor costs at home. In the process of construction, there is no need to attract special technical equipment. Houses are mounted on both small narrow streets and spacious sites. In addition, five people are enough for the installation of such a house.

10. Low price On the built house is determined by all the above advantages.

11. High level of durability. Houses performed on German construction technology will serve their owners from fifty to eighty years.

Panel houses in German technology

Life time panel house In Germany is about 100 years. This is due to the presence of such qualities of the panel house as:

- the use of dry materials and the manufacture of parts on the factories;

- sending to the object of finished walls, plates of overlaps, elements rafter system and frontal;

- high speed in carrying out installation work.

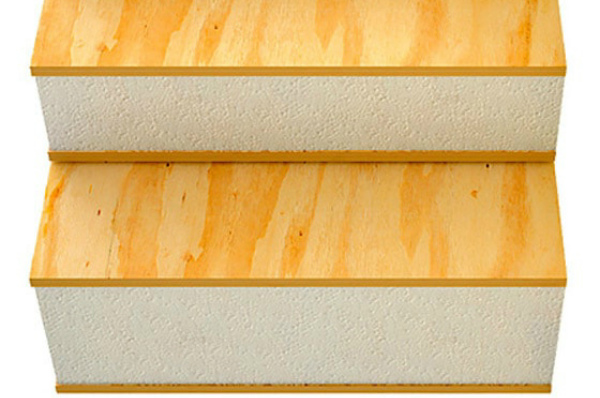

The wall design consists of:

- dry planed timber;

- non-combustible basalt insulation;

- internal covering of the cement-chipboard;

- vapor insulation film;

- outdoor CSP covering.

Cement-chip plates are non-combustible durable moisture-resistant and frost-resistant fireproof material used for construction, structural or repair work.

For the manufacture of frame structures, pine is used, passing strict control, automatic calibration work, sorting in a ratio with quality and drying procedure.

The most optimal type of insulation is the basalt mineral wool. Since it has a good density preventing its shrinkage. If the house is located in the northern region, then the recommended wall thickness is more than 25 cm.

Construction in German technology involves the arrangement of fireproof houses, which belong to the fourth category of fire-resistant. Plates of cement chip type are referred to as a reflare and unprofitable fire materials. Mineral wool is an absolutely non-combustible substance. In addition, during fire, there is no toxic or poisonous vapor and gases in the house.

Video german houses:

It is the framework of house construction that is German technology.

She is flawless for construction as country house or the cottage and the main house in which you can live all year. After all, this technology is the technology of prefabricated houses, with its economy, high precision In the production, environmental purity and thoughtfulness of absolutely all engineering systems. And thanks to relatively low periods during construction, quality and small cost, this technology has become increasingly more and more popular in recent decades. different countries World.

Building this kind of house has become possible on time to fifty days, due to the high quality of the finished structural elements, which is the advantage of German technology. These elements (panels) are essentially a frame created from. The timber is protected from deformation by high-quality drying. At the plant for the manufacture of such panels, all possible communications, thermal insulation materials are mounted.

Walls from these panels have excellent soundproofing, thermal insulation and very resistant to moisture. When building a house in German technology use monolithic foundation. Such foundation is rather durable and unsatisfying deformation. At the construction site with already prepared, the panels are delivered unchanged. They have a ready-made outdoor finish in the form of basalt wool and plaster, as well as interior decoration From.

Among the technologies of prefabricated houses, at the moment, it is the construction of houses in German technology that is one of the leaders. And due to the fact that it meets all the requirements for strength, security, durability and sustainability, this technology has been approved by builders around the world.

Manufacturers of such houses in German technology can be offered a lot of different ready projectsthat may be remade under their own taste and its financial capabilities. But there is a small complexity in the construction of a similar house.

Repair of cottages that are built on this technology is very low-cost and fast. Since shipping and installation is carried out using special equipment, it may entail additional financial expenses, thereby increasing the cost of construction. But positive moments are still much more. For example, the positive side is economy in heating. After all wooden house It is enough to warm up and expenses are reduced at times.

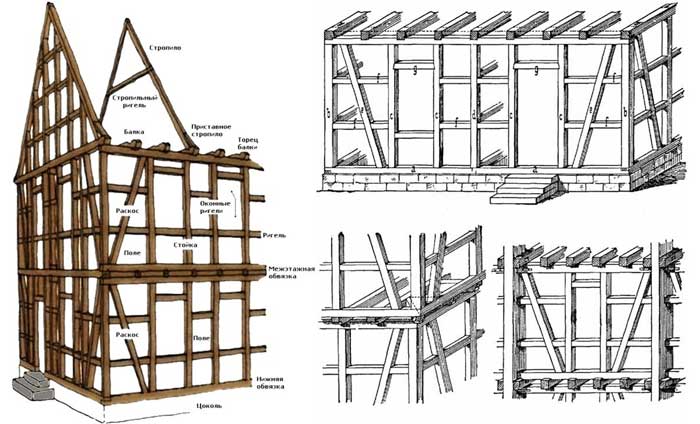

Fakhverk - The technology originated in Germany in the XV century, was distributed not only in the homeland, but also throughout Europe. Today, half-timbered houses are building not only Germans, but also in Russia. They are quite popular and received a lot of positive feedback. How to build this magnificent home yourself?

What is a half-timber? Let's deal with

it frame house And this type building construction It is a lot of durable beams interconnected at right angles and strengthened oblique crossing (backups and disclosures). These backups (discharge) give the designs greater stability, and the entire building is reliability and durability.

The space between beams and crossings, which, as a rule, leave visible outside, is filled various materials, That's what it is frame houses, It does not matter whether it is or a board, in the header use.

In ancient times in Germany, the Germans were used to use clay mixed with. There is even a house built in the 13th century, which the German builder built in 1347.

In ancient times in Germany, the Germans were used to use clay mixed with. There is even a house built in the 13th century, which the German builder built in 1347.

Beams from the bar for such time, did not rot, and the wood became durable as a stone. This house, just just one century. Europeans have long been aware of the reliability of these houses, gradually they begin to appear in Russia. And all this was done by hand, without the use of power tools.

It is surprising that the half-timbered house can stand more than 500 years, it proves the reliability of this type of construction.

Today, technological solutions can be the most diverse, in half-timbered construction, instead of walls panoramic windows, brick, wood, natural stone, etc. apply instead of walls.

Feature of German frame houses in Germany

A characteristic feature of the house in the style of Fakhverk is the speech of each top floor over the previous one. This historically existing feature is not related to the desire to increase the area of \u200b\u200bthe upper floor. This was done to protect the facade of the house, which is also carrier carcass Total buildings, precipitation and extra moisture. Thanks to such an indent, water flowing along the walls of the upper floors is flowing directly to the ground, and the facade of the lower floor remains dry.

Homes in the style of Fakhverk

Despite the fact that the widespread freight household houses was associated with a certain extent with the desire to save wood, this technology perfectly showed itself and has a number of advantages.

It is pretty inexpensive and environmentally friendly construction, which you can afford to build with your own hands. Homes in the style of Fakhverk are unusual and beautiful.

For modern construction More often used glued timber from coniferous rocks, which provides buildings strength and durability, but you can also use the usual bar, the main thing is to choose a dry-quality dryer.

Modern houses for half-timbered technology

Thanks to the use of modern, the modern Fakhverk style house will not only be aesthetically attractive, but also warm and cozy.

Choosing a material to fill the space between the beams, you can show fantasy and use, along with traditional construction materials, glass, carved wood, clay mixtures, etc. It will be favorably played and protects the staining of beams or filler with modern paint and varnishes.

Having all these advantages, half-timbered at home are built today, many are ready to build similar designs with their own hands. In addition, fairly lungs in their essence, half-timbered homes do not require the construction. It is perfect for them, which will allow you to put such a house at least on the slope and on the purchase of land.

Video about modern glass frames Facing houses

The frame house is a structure that the framework of the framework. The value of the term "frame" is the base, the backbone, the skeleton of the future object. The frame is installed on the foundation, it is trimmed with special panels, it is insulated, the roof is erected - the house is ready.

Frame houses first appeared in Germany, then in America and Canada. That is why there are several erection technologies - German, Scandinavian, Canadian. In Russia, the first houses of this type were built in the 50s, now interest in them considerably increased.

This article will introduce you to the main types of frame houses from the tree.

- frame-panel (panel);

- frame-frame ("Canadian");

- celestial-beam design (half-timbered);

- frame-racking;

- frame with continuous racks.

Other options for frame houses are either combinations of listed species, or small modifications of the above-mentioned frames. Consider each of them in more detail.

Frame-shield (panel) houses

![]()

Such houses are produced at the factory. In accordance with the project, the framework is made, panels (shields), inter-storey overlaps and even roofing. Each element is marked, has the necessary holes. A complete set of home is delivered to the construction site where it is carried out. Construction technology frame-shield house It is quite simple, but in order for the house to be durable, warm and reliable, the norms and rules should be clearly followed.

The main advantages of frame-shield houses are:

- high construction rate - all parts are made and marked, materials are processed by the compositions that prevent rotting and reproduction of harmful microorganisms, flame retardant impregnation;

- the affordable cost of construction - materials from which the whole design consists is much cheaper than a stone or brick. Savings also occurs at the expense of the total weight of the house - it does not require a complex, expensive foundation for him;

- the incompetence of the shrinkage - immediately after the construction of the walls and the roof can be processed to the inner and exterior decoration.

The advantages of frame-shield houses can also be attributed to a greater heating rate of the room under the condition of high-quality insulation. The insulation materials presented today in the building market can make the house as warm as the laying of 5 bricks.

The minuses of frame-shield houses are the lack of ability to redecessing, as well as the need for special technique (crane) for loading and unloading. The panels have a weight that does not allow them to raise them.

Technology "Platform"

It is one of the varieties of frame-shield technology, its other name is pallet or platform. This method of construction implies an assembly of frame elements on a platform representing a draft floor from itself on the first floor, or on the inter-storey overlap.

The walls of the future house consist of shields that are insulated and squeezed by plates. For this purpose, plates of two types are used: OSB and GVL. OSB plate (Russian translation - oriented PCP stove) - glued and compressed wood chips laid in different areas. GVL is a gypsum fiber leaf, which includes high quality gypsum and fiber from recycled waste paper. Both types of plates have increased strength and are not exposed to strain.

Prepared walls are set to a permanent place, and the new platform is installed on top, where the walls of the second floor are prepared.

The skeleton house from OSB is characterized by good moisture resistance and ability to maintain a comfortable microclimate even under adverse conditions of the external environment.

Building on this technology can be mounted from structures made both in production and on construction site.

How to collect prefabricated frame houses in Canada, watch in the video:

Canadian technology SIP.

SIP - panels

SIP - panels

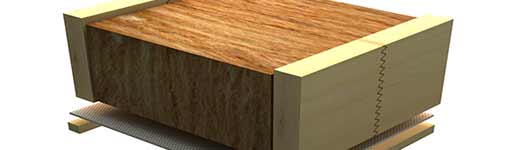

SIP is a structural insulating panel, which represents the structure from the insulation, framed by sheets of OSP. This is a reinforced version of panels for frame-shield houses. The structure of this type is erected by the "platform" technology.

Three layers of the panel (OSP - insulation - OSP) are interconnected by a bar of a spike-groove with the use of polyurethane glue. Polystyrene foam (foamed plastic) is a highly efficient insulation used in the production of sip-panels. To increase the strength of the fitting of the layers to each other, the prepared "Pie" is pressed.

High-quality sip-shields can be manufactured only in factory conditions. They have small sizes, which allows the walls of the builders forces from 2-3 people to mount the walls by the builders brigade.

The heat-insulating and strength properties of the Sip-panels are such that only 14 cm of their thickness may well be replaced by a semi-a-one-meter wall of brick or meter - from aerated concrete.

German technologies

Frame houses in German technology - another option to use the platform method.

This technology provides styling in the shields of communications and thermal insulation. In addition, windows are installed, the primary wall decoration and the floor assembly are carried out. All these operations are made exclusively under production conditions. The need to use lifting mechanisms significantly increases the cost of construction.

Summing up, it should be noted several negative moments.

A truly durable and warm frame-panel house can only be obtained by high-quality assembly and insulation of the shields, but the ability to control the course of work is completely absent. In such a situation, only one option is possible - the choice of the manufacturer with a good reputation. Compared to houses built on other technologies (we will tell about below), the frame-panel houses are less reliable.

Frame-frame houses

The framework construction method has a significant difference from the panel: the framework of the house is assembled at the construction site in the form of a unwanted framework. Only when the entire design is installed, proceed to its insulation and trim.

Houses on frame-framework technology - the most suitable option for female on their own. Their advantage is also in the fact that the owner of the future at home sees, from which it is built, how to be held necessary work And the assembly is carried out.

The frame of the house (frame) can be made not only of wood, but also from metal, in particular, the frames of the LSTK (light steel thin-walled structures) are popular. Frame houses from LSTK are energged if the climate is wet or there is a high-quality construction forest.

LSTK is a new promising construction technology from a solid, sustainable, convenient in the work of a stainless steel profile. The estimated service life of the house with such a frame reaches two hundred years, but frame houses are built from the LSTK not so long ago, and it is impossible to confirm this in practice.

Framework technology allows you to maintain construction at any time of the year. The absence of shrinkage is also significant plus.

When using this technology, it is possible to carry out the most original architectural projects at the initial stage, as well as later, if you suddenly need redevelopment.

The frame-and-frame house is very attractive and in terms of cost, especially if the frame house is erected from the LSTK.

The minuses are the elongated deadline for the construction and the need for wood processing at the construction site.

Ceiling-beam (half-timbered) frame

German (cement-beam) frame type - amazing, one of the most ancient types of frame houses. It originated in Germany, so called "German", but later received distribution in Europe, and today and Russia carefully looks at him. We will try to understand what denotes the name.

"Famverk" translated from German means "Section, Reta". The sections are formed from horizontal beams, vertical racks and windows, the latter can be located at any angle.

The feature of the Stammerk style is that the beams and racks (frame) are not hiding behind the trim, but, on the contrary, allocate them from the outside of the wall in all possible ways, which gives the house that characteristic appearance.

The frame is performed from thick bars having a cross section from 100 × 100 to 200 × 200 mm. The space between racks and beams is filled with various materials. Previously, these were clairger blocks, but now brick, global material, OSP slabs, and even glass is used. Houses with glass walls look just amazing!

For a warm house device in our difficult climatic conditions, the half-timbling type of houses is not suitable, as it requires significant insulation. But the frame house in the style of Fakhverk has such an original form that architects often offer such a way as imitation. That is, the frame is used by another, and outdoor finish Fully corresponds to the style of the step.

Frame houses with continuous racks are differently called Finnish. One-piece vertical racks passing through two floors is the main element of the frame. To ensure the high strength of the design requires perfect vertical installation Racks. Inter-storey overlap Install the supporting boards embedded in the beams. The continuous racks are tightened by lags of overlaps, due to which the design acquires the desired rigidity.

This type of construction is characterized by the fact that the vertical racks perform the role of piles to which the main load is laid. Stiffness enhance horizontal beams. This design is good on swampy or subloping territories.

Other types of frame houses

Double frame (Technology dock)

The technology of double bulk frame (doc) is one of the most promising construction of frame houses. The essence of the double frame is that the bearing racks are located in a checker order, which contributes to the elimination of cold bridges. The line of racks in this case is not single, but double. The gap between the racks is filled with insulation, the double support of which provides improved thermal insulation.

Frame Bruce Houses

The frame of the house from the bar is almost the half-timber with a frame base filled with a wooden bar. Lupates can also be used as a placeholder (logs, dying only from two sides). The house is obtained by alive, breathable, environmentally friendly, that is, truly wooden.

Frame-log houses (frame-crushed houses)

The walls of the frame-log house are logs laid horizontally between vertical wooden racks forming a frame. The external charm of this house is that the frame - outside, it can be seen. It gives the construction at the same time lightness and elegance. Frame houses from wood are perhaps the most beautiful and eco-friendly houses.

Norwegian frame house

The main difference between Norwegian frame houses - carved reference pillars. Columns from powerful logs to make the work of art can only professional rubbing. It is the columns that are becoming decoration that attracts the attention of others.

The frame from the pillars with the strapping from the bar is going on the foundation earlier. Walls and partitions on wooden frame Mounted between columns. Modern thermal insulation materials that they are filled with natural and eco-friendly. Norwegian skewed houses are shed with wide boards - or glued, or planed unedged.

Scandinavian technology

Scandinavian frame houses are collected from the finished household complex produced at the factory.

Frame base - dry planed board. The peculiarity of these houses is the presence of a brigade. Bolshoe is cut in a rack on top of a board that performs the role of strapping. As a bolt in Scandinavian houses use a bar. With such a frame device, there is no need for horizontal wooden jumpers near door and window openings, as well as dual racks, which, with a different design, support these jumpers.

The heat exchange between the two sides of the rack is reduced by applying frame racks with thermal insulation mounted inside with a special way.

OSP plates when building houses on the Scandinavian technology are used, as a rule, only to enhance the corners of the construction. The problem of stiffness here is solved with soft wood-fibrous plates or special facade drywall.

Another feature of the Scandinavian technology is that all sorts of pipes and cables are located in the walls.

Swedish technology

Swedish frame houses - houses built with a harsh climate. The main thing in Swedish technology is a high degree of energy saving. The effect is achieved by applying a special galvanized steel profile. The profile design is such that its thermal conductivity is lower than that wooden bar The same size.

The advantage of the metal profile is also its good moisture resistance. On metal elements of the design, mushrooms and bacteria, damage to the tree, this material is unavailable for rodents.

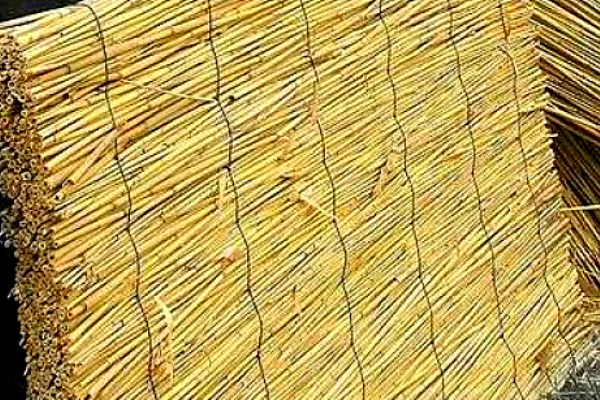

Frame coat houses

As a variant of the insulation material for frame houses, the reeds sometimes use. Cheap, low-conditioned, light reed insulation in optimal humidity conditions can serve no less than wood. From a well-dried root, dense mats are manufactured, which are placed inside the frame. Flashing the frame of the reeds is recommended after the roof of the house is erected.

Frameless house

This is an ordinary panel house in which bulk materials are used as insulation, such as sawdust. In the feasibility of using sawdust, it can be doubted, however, there are methods for their processing, allowing you to allow such a solution.

A feature of the American houses is a large area of \u200b\u200bglazing, which gives the structure lightness and transparency. It is characterized by an extensive zone, which combines the kitchen, dining room and living room.

Conclusion

So, we introduced you to which there are varieties of frame houses, their features, advantages and disadvantages. Summing up, once again, we note that the distinguishing features of the frame houses are their faster-based, relative low cost, the real opportunity to build a frame house with their own hands.

What a frame house is better to choose if it is decided to build, maybe it is not always easy to determine. But the frame house building deserves attention!

Foundation

Monolithic reinforced concrete pile-screened with a bave of 1.8 meters and the fill of the insulated slab

Outdoor wall in plaster 1. Plastering system Caparol (Germany)

1. Plastering system Caparol (Germany)

2. Plate insulation density 130 kg / m2 50 mm thick

3. Caparol adhesive system, 2 mm

4. Cleaning GHSV, 12.5 mm

7. Saving GSP, 12.5 mm

8. Covering GLK, 12.5 mm

Outdoor wall with trim under the ventilated facade 1. Planed vertical wooden chamber drying case with a moisture content from 8 to 12%

1. Planed vertical wooden chamber drying case with a moisture content from 8 to 12%

2. Windproof membrane, ONDUTIS R70

3. Planed horizontal wooden chamber drying drying with 8 to 12% humidity from 8 to 12%, filled with a soaplier technobox standard 50 mm thick

4. Cleaning GHSV, 12.5 mm

5. Planed wicked wooden frame frame 144x70 (44) mm chamber drying with humidity from 8 to 12%, filled with insulation KNAUF "Framework structures TR 037 Aqua Static" thickness 150 mm

6. Parosolation membrane, ONDUTIS SA115

7. Saving GSP, 12.5 mm

8. Covering GLK, 12.5 mm

Facade

Caparol Maintenance System (Germany) / Fibrotic panels KMEW / Brusade imitation / siding

Internal partitions 1. Saving GSP, 12.5 mm

1. Saving GSP, 12.5 mm

2. Planed scrambled wooden frame frame 144 (94) x70 (44) mm chamber drying with humidity from 8 to 12%, filled with insulation KNAUF "frame structures tr 040 aqua static" thickness 150 (100) mm

3. Trying GSP, 12.5 mm

Technology building panel-frame houses. Part 2

Inter-storey overlap 1. Plywood, 18 mm

1. Plywood, 18 mm

2. Planed scrambled wooden frame frame 194x70 (44) mm chamber drying with a moisture content from 8 to 12%, filled with insulation KNAUF "Framework structures tr 040 aqua static" 100 mm thick

3. Parosolation, ONDUTIS SA115

4. Planed Wooden Disease 20x44 mm Chamber Drying Humidity from 8 to 12%

Attic overlap 1. Planed designed wooden frame frame 194 (144) x70 (44) mm chamber drying with a moisture content from 8 to 12%, filled with insulation KNAUF "Frame structures tr 040 aqua static" thickness 200 mm

1. Planed designed wooden frame frame 194 (144) x70 (44) mm chamber drying with a moisture content from 8 to 12%, filled with insulation KNAUF "Frame structures tr 040 aqua static" thickness 200 mm

2. Parosolation, ONDUTIS SA115

3. GSP, 9 mm

Roof panels 1. Wooden doom 25 (32) x100 mm chamber drying with humidity from 8 to 12%

1. Wooden doom 25 (32) x100 mm chamber drying with humidity from 8 to 12%

2. Planed Wooden Distribution 20 (44) x44 mm Chamber Drying Humidity from 8 to 12%

3. Windproof membrane, ONDUTIS R70

4. Planed designed wooden frame frame 194x70 (44) mm chamber drying with humidity from 8 to 12%

5. Planed Wooden Board 20x44mm Chamber Drying Humidity from 8 to 12%

Roof coating Metal Tie GRAND LINE (Germany)

Metal Tie GRAND LINE (Germany)

Additionally At factory B. wall panels A two-chamber double-glazed glass with a profile with a thickness of 70 mm with lowers + accessories, a gofrotrub is laid under the wiring. Installed painted porches, terraces, balconies according to the project. All outdoor entrance doors are installed.

At factory B. wall panels A two-chamber double-glazed glass with a profile with a thickness of 70 mm with lowers + accessories, a gofrotrub is laid under the wiring. Installed painted porches, terraces, balconies according to the project. All outdoor entrance doors are installed.