In each building during construction, the ventilation system should be thought out and designed, the main purpose of which is the removal of polluted air and the influx of external. Ventilation of the roof from metal tile and professional flooring should have the same functions and serve as aerator.The output of the ventilation channels is carried out, as a rule, through the roof of the building, forming a constructive node in the places of docking. Such a node is called a ventilation or a pass node (UE) . The passage node is mounted on the roof and for each roof ventilation scheme or the air duct has its own design and its elements. In addition, the UE works as an aerator, can be used for natural and forced air output systems.

Currently, there are many varieties of ventilation units that can be selected under the design of the air ducts. Independent publication nodes are:

- baptized;

- having air outlet valve;

- equipped with a valve control mechanism;

- with additional insulation;

Air outlet valves that perform the role of aerator and valve control mechanisms (manual or automatic) are installed on ventilation systems with a changing air output mode.

Passage knot through roof

The varieties of the aisle nodes exist depending on the type and design of the attic roof and, as well as from the type of professional flooring. On the form of the duct elements, the nodes of the passage distinguish:

- square cross section;

- oval cross section;

- round cross section;

- rectangular cross section.

Round node of ventilation passage through roof

The main constructive type of UE looks like a nozzle inserted into the hole in the folding roof to exit the ventilation air ducts. UE is mounted either in the roof itself, or in glasses made from reinforced concrete.

Square and rectangular ventilation nodes on the roof

Characteristics of UP domestic production

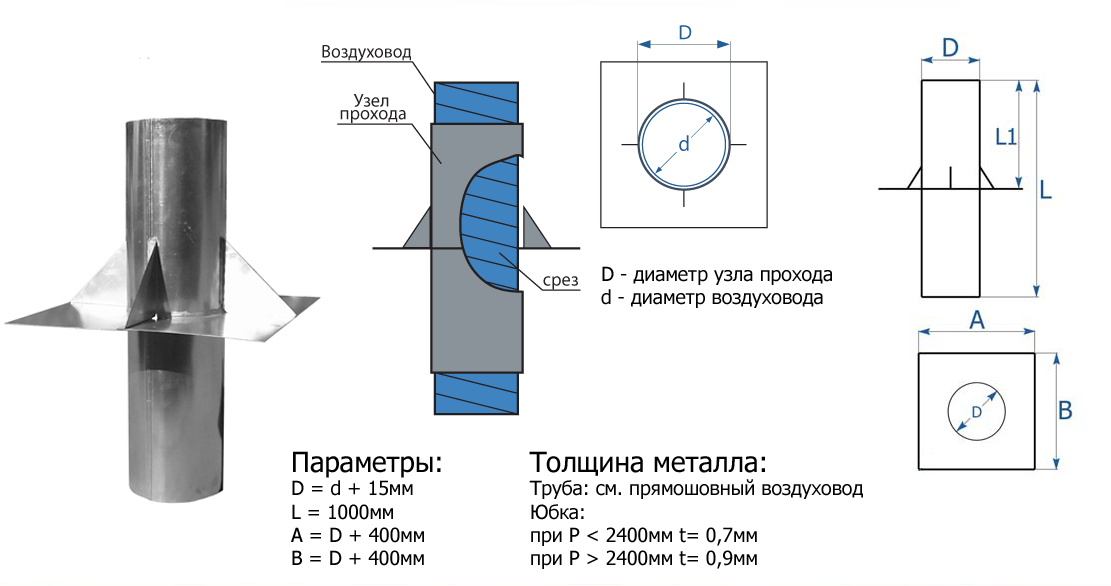

UP under ventilation channels should be made according to GOST 15150. This document shows the recommendations on the size of the UE and the gaps of elements when installing on the roof.

Sizes of the passage node

Industrial serial production produced various in size and in the form of the UE. The basic requirements that must be respected for ventilation nodes and elements are as follows:

- the node must be made of metal at least 1.19 mm thick;

- the diameter of the Round section should be within 10 - 12.5 cm.

- nodes with a rectangular cross section do not have limitations in size;

- the node must be processed by an anti-corrosion coating;

- the size of the reference ring must exceed the diameter of the nozzle by 30-40 cm;

- the total length of the design of the UE should not, as a rule, exceed 100 cm (the valve is not taken into account);

Duct passage knot through the roof

Since the ventilation system works as a aerator before selecting the type of package should be calculated by the scheme of their installation and take into account the room parameters:

- humidity level;

- the degree of gas supply;

- possible smallest and largest temperatures in the building;

- the content of dust and others.

Purpose and installation of the venation passage node

Marking UP

Today, the industry produces eleven-dimensional species of vetuzlov, including for the ventilation of the folded roof and professional flooring. For the original designs of ventilation systems and aerators, non-standard options of the UE are manufactured.

Types of Elements of Ventilation Outputs

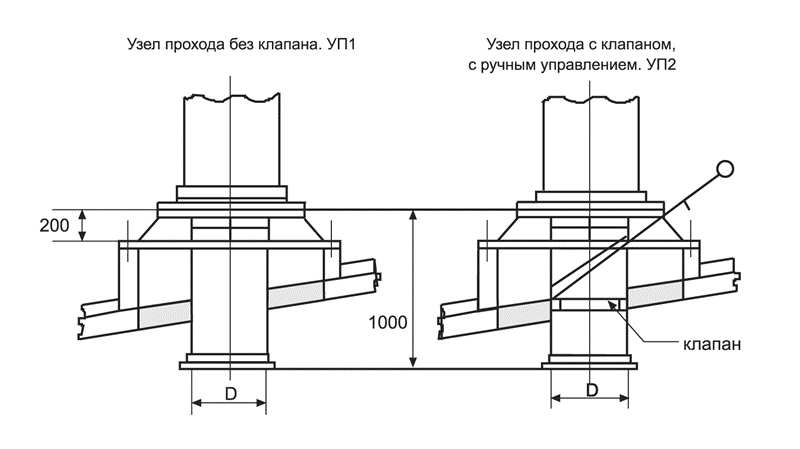

Typical designs of nodes are marked with letterpress and digital designations that determine their characteristics and elements:

- An alphabet combination of UE denotes a passage node.

- Figures 1 and Next 01-10 denote the sizes of nodes without a condensate ring and valve (for example, UP1-01).

- Figures 2 and Next 01-10 denote the typical dimensions of nodes with a valve, but not having a condensate ring (for example, UE2-01).

- Figures 3 and Next, 11-20 denote the typical dimensions of the nodes equipped with a valve and a condensate ring (for example, UE3-22).

Important!

The selection of ventilation nodes to exit ventilation in one or another version is carried out by designers.

Type UP directly associated with climate ambient, the need to install aerator, the design of the folded roof and professional flooring.

Nodal passages on the roof of the house

Installation of UP

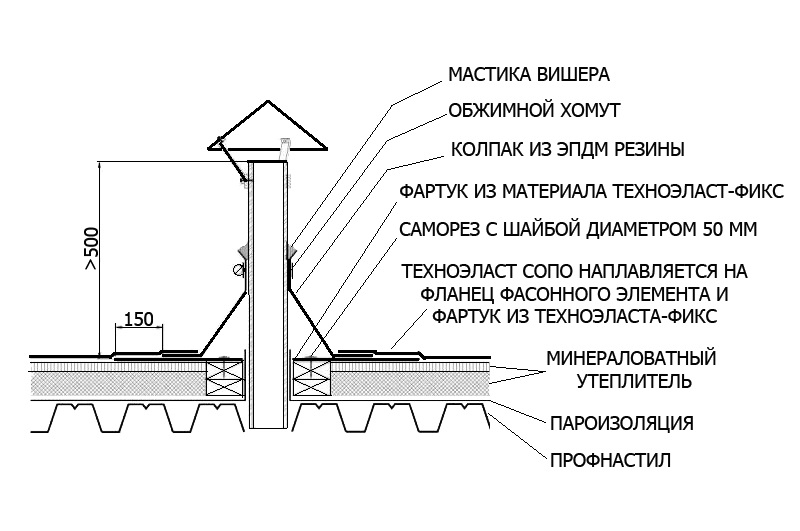

The design of the roof with the built-in UE to exit Ventkanal is often referred to . The passage node is fixed on the roof using braces fixed with brackets and clamps. The pipe unit is connected to the flange, as a support fixed on a concrete glass anchor fastening. Often on the roofing penetment the "skirt", protecting the joints from the fall of water inside.

Installation of roofing penetration

Ventkanal and ventilation soft roof (Unlike Faltseva) has some features in the installation of UE. It is made from a galvanized sheet with a mineral wool that serves thermal insulator. Inside are mounted deflectors (also from galvanized) or umbrellas that are protected from moisture.

Tip!

The power output is placed in plastic covers. The design of the ventilation unit on mansard roof This variant will perform a noise absorbing function.

Ventilation nodes pass through the soft roof

For reinforced concrete structures, roofs at the point of the penetrations are installed concrete plates With finished holes for the exit of ventilation channels. When the size of a similar hole cannot provide the required characteristics of the reliability of the ceiling slab, the roofing penetration and ventilation output should be constructed in a monolithic concrete.

Installation ventilation exit on roofing

Adjustable valve

Unlike the UP, mounted in reinforced concrete glasses, and fastening anchors, on the roof with metal design Glasses must be metallic. The roofing bearing for the output of standard ventilation channels, as a rule, has rectangular pack. In cases where buildings have large areas of roofing and professional flooring, the location of the output of the ventilation must be calculated at the project creation stage.

Nodes of passage through the roof of metal tile

A node of passage with adjustable valves serving a aerator is also installed in glasses, and the calculation should be carried out with the following parameters:

- The angle of inclination of the folding roof.

- Distance from the installation site to the skate.

- The thickness of the roof and professional flooring.

- Material making roof.

- Parameters of subsecutive rooms.

Ventilation nodes of the passage with aerator

Important!

A passage node equipped with a control valve must have a mechanism that operates and closing the valve.

Such mechanisms work as good aerators and often have manual control, and the mode switch has two positions - "closed", "openly". The design of this pack includes the following items:

- spray canvas;

- cable management;

- counterweight;

- managing sector.

Passage node diagram with insulated valve

Nodes of the passage of chimneys

For houses having stove heating Or fireplaces on folding roofs from the professional flooring are constructed a passage of the passage for the tube and chimney. Such designs have their own characteristics. So, when the chimney is created, create an additional slinge system on the mansard constructionSo that snow pockets are not formed on top of the chimney channel.

Types of nodes of the passage of chimney

Additional strengthening of the rafter and professional flooring is necessary in cases of the location of the roofing penetration through the lip of the roof. Such a scheme makes it difficult to make a devices of the attic roof in the attic space.

Important!

UP for chimneys require severe compliance with fire measures, especially for wooden structures Roof.

Protective anti-aggravated materials should be used to avoid heating and roof fire. Also, it is also necessary to withstand standards for lowering gaps between the pipe and the wooden element in the UE.

Roof chimney pipe location scheme

The common design of UE to protect from heating from the chimney looks like a box around the pipe. The box is filled non-combustible materials Type glass gambled.

Device of chimney box

Special umbrellas are arranged over chimney, preventing rain from entering and reducing the blown of wind on the attic roof. Since the tightness of the junction of the folding roof and the apron around the chimney can be violated, it is not recommended to install the UE in Under.

Pipe of chimney pipe through roof

According to experts, the most optimal option is the smoke-feeding device near the skate. Due to this, it will be possible to ensure the minimum accumulation of snow around the chimney pipe and completely eliminate the leakage in the adjustment zone.

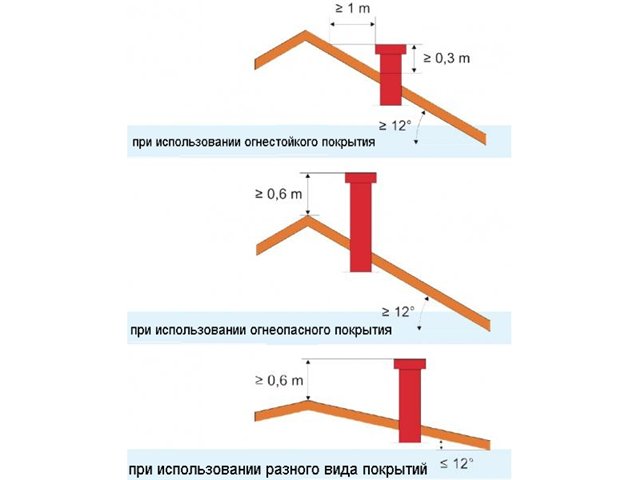

In addition, the height of the chimney in this case is small, which leads to a decrease in the effect on the design of the device of negative external factors. According to construction regulations, the height of the chimney over the roof depends on the height of the smoke-sinking pipe.

It is not recommended to organize the passage of chimney pipe through the roof in such places:

- near mansard windowsSince even a weak wind will enter carbon monoxide;

- at the junction of two slopes, where it is almost impossible to provide high-quality adjacent to the pipe.

Features of the output of the chimney through the roof

For the correct and qualitative conclusion of the chimney, it is necessary to comply with the basic requirements of SNiP. Of course, some parts of the document could be outdated, however, according to its provisions, inspecting services will check you.

In which cases is required to pass the chimney through the roof? This may be required when erecting a new home or roof reconstruction. In addition, the rocking of the chimney through the roof is an indispensable part of the installation autonomous System Heating.

When erecting a new house you will know the type of roof used. It is possible that it will have to organize a complex conclusion when it is necessary to carry out a chimney through the roof covered with metal tiles or usually tiles. To date, it is easier to ensure the flow of the chimney through the sandwich-roof.

If we are talking about the usual reconstruction, then there is already a chimney and the place allotted for it. Of course, during the construction of a new house, it is much easier to arrange a chimney, as it is possible to see the kind of roof and place, where it is better to remove the chimney.

Methods of mounting chimneh

Deciding to bring the chimney to the roof with their own hands, remember that this is a very responsible business. The most important task is to create a good traction. Otherwise, the efficiency of the chimney will fully depend on atmospheric phenomena: sometimes the furnace will work without problems, and sometimes smoke will go to the room itself, and not in the pipe.

But the most dangerous thing is that the error can cause fire.

In order to provide a device for a long period of use, the chimney should differ in good thermal insulation.

Such chimney will be in less degree depend on changes in air temperature, and most likely will not be subjected to condensate.

If the roof is flat, then enough pipes with a height of 500 mm. If your home has a skating roof, then the length of the pipe will depend on the distance to the skate:

- if the distance is not more than 1.5 m, then you need to choose a pipe with a height of +500 mm to the length of the skate;

- if the distance is up to 3 m, then the pipe must be at the same level;

- when the distance is greater than 3 m, the length of the pipe should be determined on the basis of an inclined line, at an angle of 10 degrees.

Inside the room, the chimney must be placed along the walls or partitions. The fixtures of the device must be performed in such a way that its horizontal sites do not exceed 1 m. In addition, the chimney should not be in contact with the electrical wiring and pipelines. Correct installation It starts from the boiler so that each pipe is included in the previous one. The joints are best bonded with a clamp. Ensuring the tightness of the joints is one of the most important tasks. For sealing, it is necessary to use a sealant that does not lose its properties even at a very high temperature.

Constructions adjoining

Chimney pipes are made of different materials: fireproof bricks, metal or asbestos-cement pipe. The presence of a certain material requires a special design of the passage through the roof and a different isolation system. Also, the effect on the choice of design is the type of fuel in the fireplace or oven. The fact is that every type of fuel is distinguished by its combustion temperature, so first it is necessary to choose a fuel correctly.

Smoke Pipe Pass through roofing system No accident recognize the most complex designation node. It is necessary to equip it so that the tightness is ensured and the probability of fires is eliminated. To achieve the goal, an impressive number of actions were carried out, the work was trusted only by experienced roofers. To problem areas were fardial, asbestos, rubberoid, seams poured cement solutions and bitumen compositions. The result of labor-intensive operations served shortly due to atmospheric and temperature influences. A new type of roofing seal - the wizard for chimney provides an opportunity to abandon exhausting procedures. With it, a reliable penetration can be arranged with their own hands, spending the minimum of time and effort with the means.

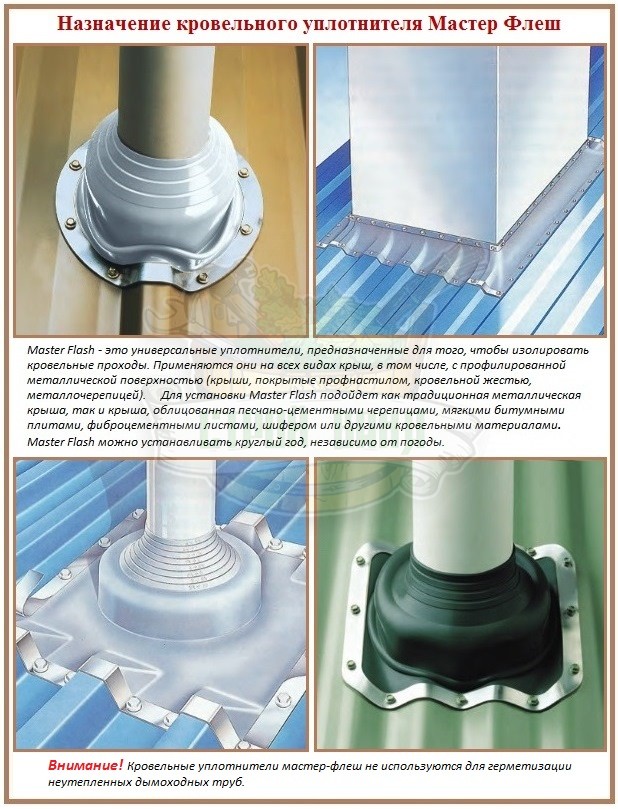

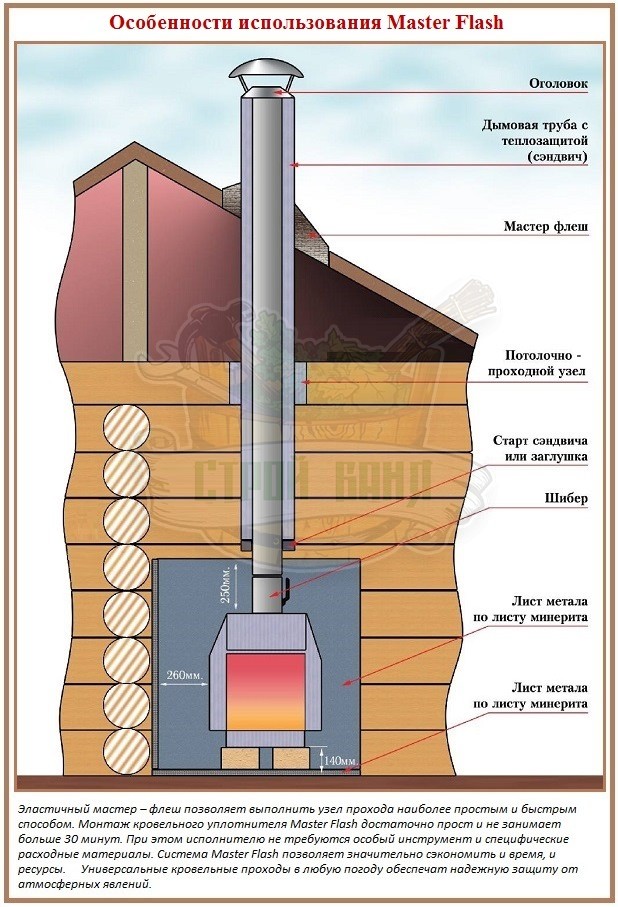

Master Flash - Meet the device

Master Flash is a series of elastic sealing systems intended for sealing areas of roofing pipes. They are used in the organization of penetrations of chimneys, sewer and ventilation risers and other communications.

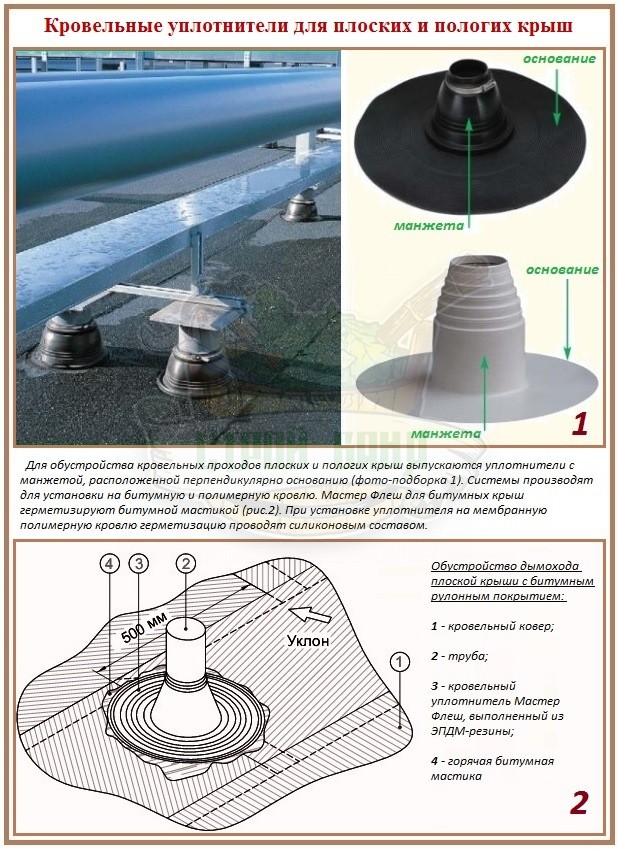

Release in formats suitable for arranging roofs from all known species of materials. Compactors are produced for flat and scanty roofs With profiled coatings and for fellows without relief.

Indisient Benefits of Master Flash Seals:

- Elasticity that allows you to create a dense adjacent to the walls of chimneys.

- Resistance to sharp temperature differences, trouble-free operation in a wide temperature range.

- Inertness to ozone, resistance to oxidative processes.

- Ultra-low porosity, providing excellent sealing.

- Fire resistance.

- The ability to take former sizes and shape after thermal linear expansion.

- Guarantees from manufacturers of about 30 years.

- For fastening sealing systems, special tools and equipment are not needed.

- Weather restrictions during the installation period is not.

A good plus of elastic seals consists in a tangible reduction in the consumption of materials used in the organization of the peaks. When used, it disappears the need to lay additional waterproofing around the penetration.

Constructive features of seals

Roofing sealing systems came to replace the traditional pipe aprons. Structurally, they resemble precursors, but include only two main parts, it is:

- Flexible cuff made in the shape of a truncated cone from rubber with EPDM marking or silicone. It is the cuffs that makes the roof to the pipe to the pipe, eliminating the penetration of dust and atmospheric water. In the operating position, the upper part of the cone framed tightly. The lower part is connected to the base of the sealing system - with the flange made in the form of a rounded or square skirt.

- The flange is the base of the system made of Rubber EPDM, silicone, galvanized tin, lead or aluminum. Silicone and rubber base for installation on a roof with large embossed corrugations is equipped with aluminum strips around the perimeter. Aluminum inserts help to give the flange the profile form for the maximum dense adjustment.

Cuffs of roofing seals for pitched roofs are arranged at an angle to the base. On the cone-shaped element there are corrugations, denoting circuits of round holes with a clear gradation in diameter.

The corrugations are also necessary to increase the accuracy of the tubular cutting: they allow you to change the angle of inclination of the seal within the limits specified by the manufacturer.

If the imaginary central axis of the cone is located strictly perpendicular to the surface of the base, the Flash wizard is designed for arrangement flat roofs.

General principles of installation

Flexible seals are significantly ahead of obsolete ways to arrange roofing penetrations according to specifications. Without loss of quality indicators, they maintain a significantly larger range of temperatures, longer serve, less often need repair.

According to the criteria for ease of installation, too, undoubtedly, the master flush for the chimney is leading - installing the system to be made in the most elementary way. To carry out the work, the Contractor will not require theoretical knowledge, no practice in roofing.

The top of the cone-shaped cuff is appropriate so that the diameter of the obtained opening was less than the diameter of the chimney of 20%. A closed cone is trite for a round in cross section of the pipe and gently moves down down to the attachment point. To facilitate the advancement of promotion, manufacturers are recommended to make or pour the surface of the chimney.

Flange fixation method determines the type roofing materialDepending on which the model of the sealing system is selected:

- To the flat roof with rolled coating, the flange is glued on bitumen mastic or silicone glue.

- To the pitched roof, the flange base is first glued with a silicone agent, then fastened with self-drawers and is fixed with rivets. If the back of the flange is equipped with a sealing porous gasket, it is screwed without prior gluing silicone.

After installing the upper cut cone and the lower edge of the flange for reliability are treated with silicone sealant. For fixing the upper edge can be used metallic clamp.

The firmly fixed passing device remains mobile. Those. In the case of thermal expansion, the fasteners and points will allow the pipe to move relative to the penetration location without loss of tightness. Similarly, the cuff behaves in the event of a shrinkage of walls and foundation.

How to correctly choose the wizard flash

Size information is insufficient to accurately pick up the roofing seal to seal the chimney, although this is an important aspect. To purchase a suitable system to take into account that:

- For the arrangement of pitched roofs with a bias from 10º to 40-45º, coated with profiled metal, irreversible roofing steel, bituminous Tiled, polymer membrane, plastic, flat shale and ceramic tiles Suitable seals with flexible square and rounded base. Their installation is performed with pre-gluing on silicone and subsequent fixation by self-draws.

- Seals with an elastic flange, reinforced aluminum strip, are used to arrange scanty roofs with a steep area of \u200b\u200b45º to 60º with similar types of coating.

- For the arrangement of gentle roofs and roofing structures steeper 60º, the model of the Flash Wizard with an enlarged flange area is used.

- Flat roofs are equipped with cuffs perpendicular to the base plane. Bituminous roofs are glued with bitumen mastic, to polymer coatings - with the help of silicone composition.

- On slate and tiled roofs, elastic systems with metallic flanges of increased area are installed. The bases of the seals are placed in accordance with the set of regulations for the installation of tin aprons: top Rent under the tiles or slate located above.

In addition, it is necessary to take into account in which temperature range will be able to work without loss without loss technical characteristics. The specified aspect is directly related to the material from which the bullet is made for the chimney.

Systems Master Flash manufactures:

- From ethylene-propylene rubber EPDM carrying the effects of temperatures in the range from -50º to + 160ºС without destruction. A number of manufacturers limits the upper limit + 140ºС.

- From silicone, absolutely "indifferent" to temperatures in the range from -60º to + 200ºС. There are silicone cuffs, in the supasport of which the upper limit is indicated + 240ºС.

The standard temperature of the flue gases at the entry level in smoky pipe Approximately 120-140ºС. Gas and liquid fuel boilers slightly lower. In principle, both options quite satisfy the conditions for equipping bath chimneys.

However, according to experts, these quantities can be recognized by valid if there is a distance of at least 1m between the fiber part and the yield from the smoke furnace. If not, then preference is better to give the products from silicone, an additional advantage of which quite reasonably recognize saturated flavor and impeccable compatibility with sealing compositions. True, the operating deadlines of the EPDM products are somewhat larger than that of silicone seals. But in the regions where occasionally or not very freezing below -50ºС, they will not be found on bath roofs. Yes, chemists assure that synthetic rubber begins to rule at Tº \u003d + 135ºС.

If a waterproofing cuff from EPDM has already been purchased for the equipment of the chimney pipe, but there were doubts in real temperature mode, it is not necessary to despair.

there is people's method Adaptation of rubber adaptation to undesirable temperature effects. Before mounting the cuff around the chimney, you need to install a sleeve that creates a small gap between it and the pipe wall. Basalt wool is stacked over the sleeve, then another sleeve is put on, the shape of which is close to the cuff configuration. In completion standard method Installed Master Flash.

Sealing systems Master Flash are available not only to equip the chimney of the house under construction. There are models in the product lineups and for installation in case the elastic fixture on the pipe is simply impossible.

The cones of such products have a side view with snap-down when connecting with clips or lock. Models with a fastener are also used to seal square in cross section of pipes with a wall size to 150mm. More solid square pipes are framed by a rubber or silicone strip on an aluminum-based basis.

How to install roofing seal?

The general principles of the organization of roofing passes using the Flash Master were given above. In addition, manufacturers make a detailed description of the assembly process. However, in the installation algorithms and fixation of different models, there are differences with which it is better to get acquainted before the acquisition.

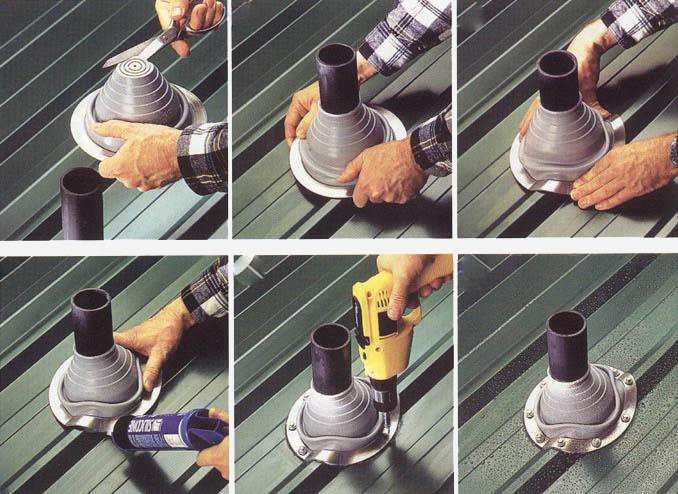

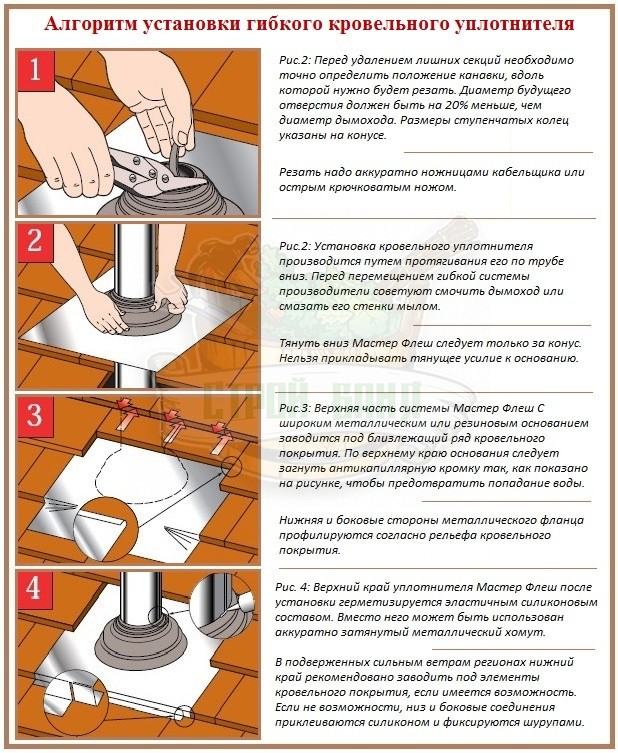

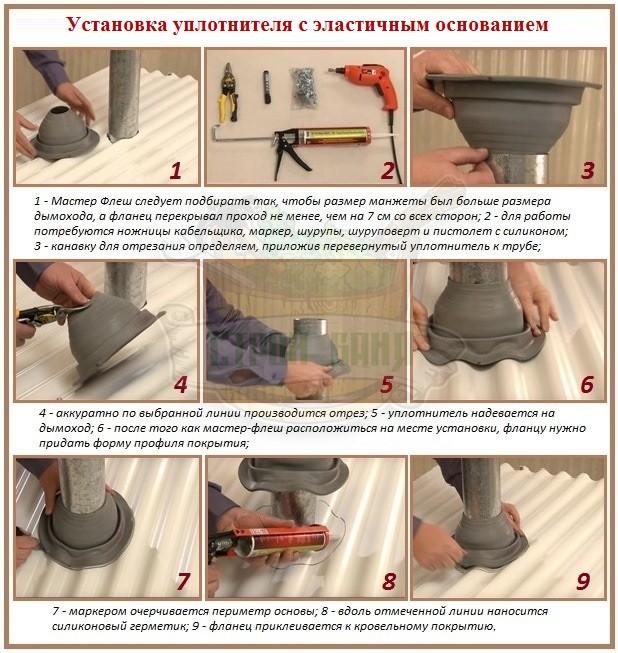

Installation of a flexible flange seal

The sealing system with an elastic base is mainly used in the arrangement of chimneys crossing the metal roofs.

Work algorithm:

- We define the location of the groove on the cone for the upcoming cut. We do not forget that the Ø of the segment of the segment must be 20% less than the pipe Ø.

- Correctly cut the cable drivers, trying to dry out the cut as much as possible.

- Moisten the surface of the pipe to optimize the slip. We put on the cuff on the chimney and pull it to the place of fixation, keeping the cone, and not for the flange.

- Reaching the seal to the place put it, outlined the line around the edge of the flange.

- Lightly raise the cuffs to apply the adhesive composition around the perimeter of the flange according to the markup.

- Install the seal in place.

- Around the top cut and the base edges are applied elastic sealant.

Adhesive substance must match the type of coating. The rules and reconciliations on the selection are indicated in the articulated briefing. For example, glued bituminous mastic Master flush to a roof with a polycarbonate coating or a polymer membrane is prohibited, because The materials will begin to collapse, and the connection will come to unsuitability.

Master Flash with hard edging

The procedure for installing a seal with an aluminum strip along the edge is performed by a similar scheme. Before the fixing stage, all work is carried out in the same order. The difference is that during the fitting before the stroke of the flange abras the flange, it must be spinled for dense adjacent to the surface of the coating.

Fastening is made with self-tested cap with a hex. Screw fasteners in low profile shelves. If you wish, for the reliability of fixation, you can buy a counter metal part installed on the back side of the roof.

On roofing passages for smokers of large size and on the roofs steeper 45º square flange is recommended to have a rhombus. In order to more effectively protect against the flow of roofs with a pronounced ribbed surface and steeply ribs, it is recommended to acquire seals with an increased base.

In the ruler of the cuff with a metal edging flange there are models with a porous seal located on the back side. To fix them, there is no need to process the surface with adhesive composition. The system is simply screwed to the roof without gluing and filling seams with silicone. The porous material provides impeccable tightness without additional manipulations.

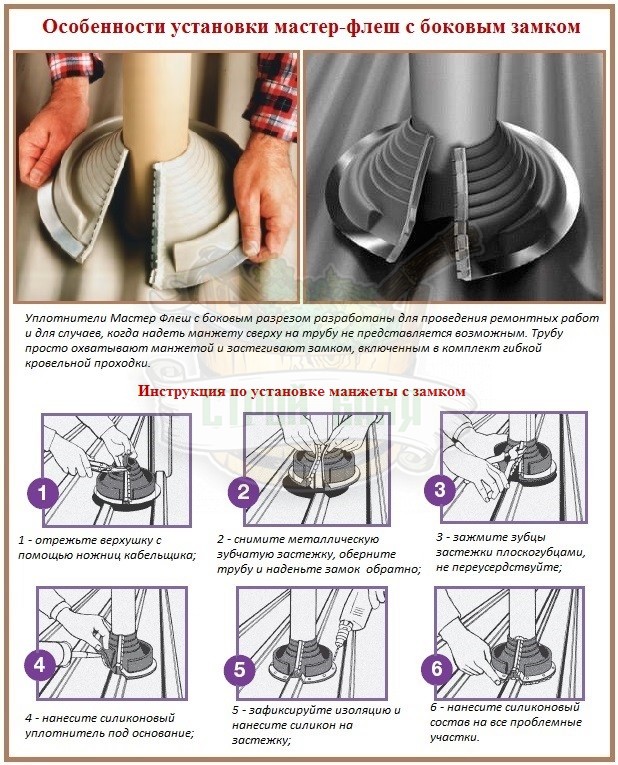

Insulation for repair operations

Roofing seals with a section are required where to wear insulation on the chimney from above is not possible. Most often, they are in demand in the repair of wear insulation of chimneys.

Installation algorithm:

- Cutting the cable top of the cone on the edge, Ø of which is 20% less than the same size of the chimney.

- Remove the gear clasp from the lock and turn the cuff pipe.

- We connect the parties of the cut of the cuff and wear a fastener back, without fanatism, pressing the tapes with pliers.

- Raising the edge of the flange, we apply a silicone seal on the roof.

- We press the system and apply silicone glue to the fastener and all the problem areas of isolation.

On the roofs with an enlarged probability of the flow, systems are installed with an increased base area.

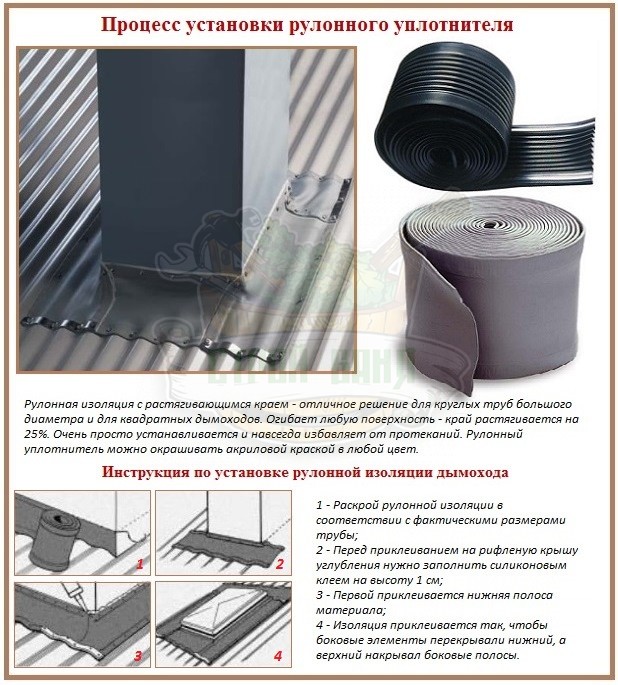

Device of rolled insulation

For the cutting of large pipes, a rolled material reinforced by an aluminum strip is produced. It allows you to seal chimneys round, square, rectangular configuration. Due to the elasticity, the parts of the tubular bypass are easily formed, thanks to the built-in aluminum, the sealing system fits flawlessly to the roofing surface. The method of installation of rolled insulation is similar to which we led to another article.

In order to seal the round chimney, it is necessary to cut off a piece of material by 30 cm larger than the circumference of the pipe. So it is necessary to make insulation fastened with the allen. Before gluing the segment, you need to bend like a metal corner so that the vertical shelf is 17cm wide. This part will be glued to the vertical surface of the chimney. Before fixing, the horizontal shelf should be given the shape of the skirt by stretching. The edge of the roll sealer can stretch by 25%. After full forming and a pair of fitting flexible roofing apron sticks to the pipe and coating.

Square chimneys are flooded in four receptions in the following sequence:

- Cut 4 parts of the apron, leaving 30cm inputs. We stretch the material before sticking, because after its form and dimensions cannot be changed.

- Fill out with a silicone or seal of the deepening of slate or coatings with a similar profile so that the cutting feet is tight. The sealing composition should be no more than 1 cm. Corners are not necessary.

- We glue the upper part of the insulation to the walls of the chimney, not the touch corners. First we glue the lower strip of the apron, then we get on it and glue two lateral parts. After we put the upper strip so that its edges overlap the top of the sideways. As a result, the atmospheric water will be dragged, not falling into the butt seams.

- Rush the apron and glue its lower part to the roof of silicone, not forgetting to glue corners. In the perimeter, we laid the metal strip, secure it with self-draws or rivets.

Rolled insulation can be painted in any combined color color.

Mounting cuffs on tile and slate

To improve the penetrations through the roofs, the coating of bitumen and ceramic tiles, slate tiles and slate sealing systems with lead or aluminum base are produced. The cone is traditionally cut to wear a chimney tightly. Its upper part of the metal flange must be coated, on the side and bottom it is placed on top of the roof.

The upper edge of the base is bent to avoid penetration of atmospheric moisture into the system. After installation, all problem compounds are poured with silicone composition.

With the details of the installation of the Master Flash Systems for chimneys will familiarize the selection of video:

Note of the root of the waterproofing of chimneys:

Installation and fastening of a split sealing cuff:

How to install a metal tile seal:

The use of roofing seals Master Flash attracts speed and convenience of installation. The important advantage of elastic penetments is tangible savings. money, in the reliability of waterproofing and long service life. However, the most convincing argument in favor of new materials for the arrangement of the penetration is the ability to establish them with your own hands without attracting workers.