Heating devices are a necessary attribute of any residential building, providing a comfortable temperature for life in the cold season, which lasts 9 months in most regions of Russia. However, additional comfort comes with a certain degree of fire risk. Therefore, special attention is paid to the chimney, with the help of which smoke and combustion products are removed from the heat generators and discharged outside the room. This article will tell you how to get the chimney through the roof in compliance with all safety requirements.

As a rule, in the work of a stove-operator or installer gas equipment chimney installation services are not included, the owner must ensure the passage of the chimney through the roof himself. The perceived simplicity of the task forces home craftsmen to refuse the services of professional roofing craftsmen. Nevertheless, a poor-quality pipe outlet to the roof threatens with serious consequences:

- Through a leaky pipe passage, moisture seeps into the masonry, gradually destroying it.

- The increased humidity inside stimulates the spread of mold microorganisms and fungi. Disputes of some types of fungus are dangerous to the human condition, so it is not safe to use an infected tube. In advanced cases, both the chimney and the stove masonry must be replaced

- The penetration of water into the chimney passage through the roof reduces the thermal insulation properties of the insulation by half. Moreover, after the thermal insulation layer has dried, its characteristics will never return to their previous level.

- Even the rafter system suffers from poor-quality removal of the pipe through the roof, since moisture penetrating into it through a leaky passage leads to decay and destruction.

- Slots near the pipe passage disrupt the normal air circulation inside the attic, leading to an increase in energy losses and heating costs.

By the way, not only chimneys are brought out to the roof, pipes from gas boilers and ventilation outlets are also placed there, for the installation of which they use the same methods.

The choice of the outlet of the chimney and its height

The first condition for a high-quality pipe outlet through the roof is the correct placement of the chimney on the roof. The functioning of the entire heating system depends on this factor, therefore, in order to avoid mistakes, installation is carried out in accordance with construction and fire safety requirements:

- Chimneys are placed in the immediate vicinity of the highest place of the roof, at a distance of 1-1.5 m.

- The recommended chimney height in relation to the roof ridge to ensure normal stove draft is 0.5-1.5 m.

- The greater the height of the chimney, the greater the thrust force in the furnace or gas boiler it provides.

- The lower the chimney is located on the slope, the longer its length must be in order for the recommended chimney height above the roof to meet the recommendations.

- Parameters such as the height of the chimney, the cross-sectional diameter are selected according to the recommendations of the manufacturer of the thermogenerating device or on the basis of calculation.

- The chimney consists mainly of vertical sections of pipes, the length of horizontally located segments should not exceed 1 m.

- Place the output between the elements rafter systemso as not to violate its integrity.

The main difficulty of passing the pipe through the roof is that during the passage of smoke, the wall temperature rises, which creates a danger of ignition of combustible materials of the rafter system.

Elastic penetration

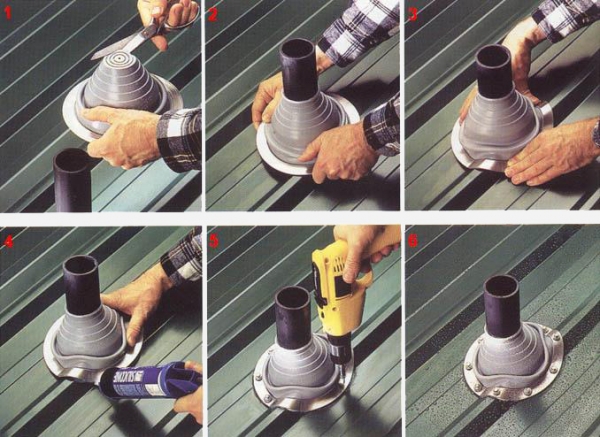

Most often in private construction they are faced with installation metal pipes round section... To ensure the tightness of the passage, a special device is used - an elastic penetration. This product is made of high-strength silicone or rubber, funnel-shaped with a wide flange in the form of a square or circle, called an apron. Due to its properties, elastic penetration takes any shape, adjusting to the slope angle. It can withstand extreme high or low temperatures, harsh chemicals and a wide range of products.

When purchasing elastic penetration, they are guided by the pipe diameter and color roofing material... Versatile stepped pyramid models suitable for all sizes, adjustments are made by cutting the penetration to the right level... It is very easy to install an elastic apron on the roof, you need to put it on the chimney passage, apply a metal circle with holes for fasteners, treat the joint with a fire-resistant sealant and fix it with a screwdriver. For roofs with steep slopes, a special type of plastic penetration is used with a given flange mounting angle.

Metal feedthrough

In hardware stores, you can find another type of passages for round pipes - a metal lead-through pipe. It is used to make a chimney passage through a non-relief roof. The finished alloy steel pipes have standard angle roofs, which are selected to match the roof slope. To complete the installation, you must:

Cut a hole in the roof to a suitable shape. To do this, using a marker, markings are applied to the roof surface. Depending on the roofing material, cutting is performed with a grinder or sharp scissors, stepping back 1-2 cm into the circle.

- Remove the waterproofing and heat-insulating material from the hole made, leaving the passage for the chimney. If necessary, remove the battens by carefully sawing them off.

- On the underside of the roof, fix a sheet of fire-resistant material with a hole of the required diameter of such an area that there is a margin of 15-20 cm on each side of the chimney.

- Push the pipe module into the hole, dock it with the laid chimney, tightening the connection point with a clamp.

- Put the outlet on the pipe, fixing it on the surface of the ramp with a fire-resistant sealant and self-tapping screws with a rubber cap.

- Extend the pipe with new segments so that the chimney height exceeds the ridge level by 0.5-1.5 m.

Some craftsmen prefer to use another method - they pre-solder the chimney into the passage pipe, cover it with thermal insulating material, for example, stone wool, and only then this structure is mounted in the passage.

Output of rectangular and square pipes

They are made of bricks, most often of a square or rectangular shape, therefore, other methods are used to bring it to the roof. This task is for an experienced stove master, not a home craftsman, because a special masonry technique is used in the process. When the chimney approaches the roof, a hole of the appropriate size is cut out in it with an allowance of 2-5 cm, through which the stove-maker takes out. Although heat-resistant brick perfectly retains heat inside the pipe, from the inside the passage is cut with asbestos sheets to protect the rafters from fire.

A soft waterproofing tape on a lead or aluminum base is attached to a brick pipe using a metal profile, the lower edge of which is fixed on the roof with a sealant. After that, the unsightly waterproofing is closed with a special decorative apron. It consists of four additional parts and is installed under the roofing material, making the passage neat and well protected.

Installation of the outlet box

The roofing device consists of layers of several materials, the refractory qualities of which are expressed in different ways. While most roofing materials are non-combustible and non-combustible, roofing systems traditionally made from wood do not. In order to safely remove the chimney through any material, a passage box is mounted:

- The first step is to purchase or make a box from refractory material, for example, metal or asbestos. The size of the box is selected in accordance with the section of the pipe, so that there is at least 15 cm between their walls.

- After making the hole, a box is installed in it, the upper edge is aligned to the level of the roof slope.

- The chimney is taken out through a hole in the duct. The edges of the waterproofing film and vapor barrier are glued to the pipe with a flame retardant sealant and reinforced tape.

- Expanded clay is poured inside the box or stone wool is laid for thermal insulation of the chimney. Thermal insulating materials are placed taking into account that they should not impede air circulation.

- Outside, the chimney pipe, depending on the shape and the roofing material, is finished using an elastic penetration, a decorative apron or a metal pipe.

A well-made chimney outlet does not spoil the appearance of the roof, does not allow moisture to pass through and is safe from the point of view of fire safety standards. Observe the right technology passage of tubes through ceilings to protect yourself and your property.

Video instruction

One of the most difficult elements of a roof structure is the passage of a pipe through the roof. It creates a lot of problems with the device.

The mouth of the umbrella, which protects the chimney from rainfall, is made of roof covering material.

Boiler room and fireplace installation experts say that the stove should be located as close to the ridge as possible. This allows most of the chimney to remain out of the cold and prevents condensation from entering the flue system.

Roofers advise making the passage of the pipe through the roof directly in the ridge. This design maximally facilitates the work associated with the implementation of the pipe contact unit with the overlap. In addition, such a knot avoids the appearance in winter time pockets made of snow, which significantly reduces the possibility of leakage at the points of abutment to the roof.

To protect the chimney from rainfall, it is recommended to cover its mouth with an umbrella. It is made of roof covering material.

Advice: in cases where the chimney is installed in houses with boiler equipment, it is impractical to use an umbrella. This is due to the fact that the combustion products have a relatively low temperature. Low temperature prevents gases from escaping.

The passage for a pipe through a roof with layer-by-layer insulation ("layer cake") is the most difficult in terms of execution. Such a roof structure requires the use of a special box for the pipe outlet.

The area around the chimney must be insulated with a non-combustible insulating material such as stone wool.

The rafters and beams of the roof frame must be installed in strict accordance with building codes and regulations. The space around the chimney must be insulated with non-combustible insulating materials. Rock wool is a good sealant for roof passages.

Chimney cross-sections vary depending on the materials from which they are made, and can have the following shapes:

- rectangular;

- round;

- square;

- oval.

When bringing the pipe through the ceiling, it is very important to do all the waterproofing work with high quality.

Usually, an apron is mounted around the entire chimney through the roof. Pipes with brick walls, having a square or rectangular cross-section, are equipped with an apron made of roofing material or aluminum or lead tape with a layer of glue along the edges.

One end of the tape is glued to the roof, and the other to the pipe. After that, the tape is clamped with a metal bar and fastened with heat-resistant dowels.

Exiting the pipe through the roof

After installing the lower apron, you can start installing the tie, which is a sheet of waterproofing material, wound under the elements of the inner apron from below. The main function of the tie is to drain the water.

After finishing work on the arrangement of the tie and apron, which protect the joints, the roofing material is laid. Then the outer apron is mounted. To do this, use the upper abutment strips.

The installation of the apron from the outside is similar to the installation of the apron inside. The difference is the absence of a groove and the upper edge is fixed directly to the chimney wall.

Important: the market today building materials offers products that are specially designed for chimneys with a circular cross section. They are roof passages which consist of a base (flat steel sheet) and an apron cover. A round chimney is laid inside the passage.

Passage for pipes with circular cross section

Having bought or made an apron yourself, you need to secure it to the roof structure. It is not recommended to tightly connect the apron to the chimney. Otherwise, due to temperature differences or shrinkage of the roof, the structure may be damaged.

At the joints of the apron and the pipe, you can make a skirt (a steel clamp, secured with a heat-resistant elastic gasket). The skirt increases the waterproofing properties of the apron.

When designing and building a private house, special attention must be paid to future passages through the roof. The passage of the pipe through the metal tile is the most important unit, since the tightness and fire safety of the entire roof depend on its quality and correct installation.

The standards and requirements that the chimney must meet are specified in the corresponding regulatory documents... Often, the planning of the chimney passage is designed along with the construction of the house itself. But there are times when the passage of the chimney through the metal tile must be carried out through the roof of an already built house. This need can be caused by two options:

- if there is a change of roofing structure or major repairs;

- if the heating source itself is being installed or replaced.

The place where the chimney exits through the metal tile is determined at the initial stage of its design. It is not recommended to install a chimney through the valleys due to the lack of a guarantee of complete tightness at the points of contact with the roof. In addition, the largest amount of snow is collected in the valleys, which can put a heavy load on the joints of the pipe with the roof and disrupt the integrity of the entire structure unit.

It is also irrational when the pipe on the roof is made of metal tiles, laid near the windows of the attic. Carbon monoxide or smoke can be blown into the room by a slight gust of wind.

The optimal location of the chimney is to install it near the ridge. In winter, the least accumulation of snow occurs in this place, which means that the possibility of leakage is minimized. The pipe near the ridge has the smallest height, which favorably affects the possible impact of atmospheric phenomena. In the cold season, the least condensation occurs here, since the main part of the pipe is not located in the cold zone.

This option also has some disadvantages. In the rafter system, the installation of a ridge beam is not provided, or the beam is made with a gap, which affects the strength of the entire structure. We have to install additional support nodes under the rafters, which is not always beneficial if you plan to use the attic as an attic room. Therefore, a rational solution would be to pass the chimney near the ridge run.

For flat roofs the sufficient chimney height is 500 mm. In the case of a ridge roof, the chimney is laid through the metal tile to a height that depends on the distance to the ridge:

Chimney outlet through metal roofing

In conditions of an insulated roof, materials for thermal insulation, waterproofing and vapor barrier are possible sources the occurrence of a fire. The wood sheathing can also catch on fire. In this regard, all these elements must be at a distance of at least 130 mm from brick, ceramic and concrete pipes. If a ceramic pipe without thermal insulation is used, then the distance is increased to 250 mm.

In the place where the chimney passes through the metal tile and the roofing cake, an opening is formed in which heat loss and condensation occurs in the insulation. To prevent this from happening, the chimney is equipped with its own rafter system, and the gap between the pipe and the roof is insulated with non-combustible mineral basalt wool. If the output of the pipe through the metal tile is carried out in an operated house, then the hydro and vapor barrier materials are cut out like an envelope and, turning the edges, they are fixed to the rafter system. For pipes of rectangular and square cross-section, an internal and external aprons are equipped, which ensure the abutment of the pipe to the metal tile without the possibility of leakage.

The use of pipes made of stainless steel and asbestos cement is unacceptable for furnaces fired by coal or peat!

Passage of a square or rectangular pipe through a metal tile

To ensure the tightness of the joints of the pipe to the metal tile, an internal and external apron is equipped on the roof slope. Installation begins with the inner apron by installing the bottom and top trims and side elements. The lower plank is applied to the walls and a line is drawn with a pencil. All other elements are also used as templates for marking the rest of the lines. Having measured the line along the entire perimeter of the pipe, it is necessary to make grooves. They are carried out with a grinder with a depth of at least 15 mm. After that, they are washed with water from brick dust and allowed to dry well.

It is unacceptable that the strobe passes through the place of the seam of the brickwork. The correct passage of the groove must be carried out on the surface of the brick!

The installation of the strips starts from the bottom wall of the chimney, then two side and top strips. The overlap of the planks should be about 150 mm, thus excluding the possibility of leaks. The edges of the additional elements are inserted into the groove and filled with sealant. The strips are attached to the pipe with roofing screws. A "tie" is installed under the bottom of the apron, which is necessary for water to drain and can be directed into the valley or to the eaves overhang. A side is made along the edge of the roof with pliers and a hammer.

When the inner apron is made and the roof chimney cutting is completed, the laying of metal sheets around the chimney continues. Next, equip an external apron, which plays a decorative role. Attach the outer apron abutment strips in the same manner as the inner apron strips. The edges of the slats are no longer inserted into the strobe, but are attached to the walls of the chimney.

Passage of a round pipe through a metal tile

If the roof pass-through unit must be made of a circular cross-section, then a roof penetration is used, which provides the necessary tightness at the junction of the chimney with the roof. Roof penetrations are used for arranging the passage of antennas, masts, ventilation, chimneys and electrical outlets and are applicable for many types of roofing materials. The base of the roof penetration is made of a sheet of steel, to which the hood is hermetically connected. Through the hole in the cap, the sandwich pipe passes through the metal tile.

Transits are made of silicone or EPDM rubber. These materials have a wide operating temperature range from -74 to +260 degrees.

To install the pipe through the roof penetration, a hole is made in it 20% less than the pipe diameter. Pull the penetration onto the pipe using, for example, a solution of laundry soap. The sealant is pressed against the roofing material, and it takes the required shape of the roof surface. A sealant is applied under the flange and fixed with roofing screws with an approximate pitch of 35 mm.

In many cases, a sandwich pipe is a good alternative to a brick chimney. It consists of two pipes of different diameters, between which there is a heat-insulating material made of basalt wool. Installation, performance and service life make the use of a sandwich pipe for the waste of combustible substances a profitable enterprise today. The pipe is protected from strong overheating of the outer wall and the accumulation of condensation.

It should be borne in mind that when arranging a chimney, the roof cutting done by your own hands must be performed in accordance with all building codes and regulations. If you are not confident in your abilities or you do not have enough skills and experience in this type of work, entrust the work to professionals.

Author Pavlov Yuri

Nikolaevich

Metal roofing - reliable and durable protection houses from precipitation, wind and winter cold. The material is convenient to work with, has a fairly big choice options - by manufacturer, by color and type of metal. it is simple and quite accessible for independent implementation, but it requires taking into account some of the features of the material and preliminary familiarization with the rules for its installation and use.

To address this issue, you must pay the utmost attention the quality of pipe sealing on the ridge side... It is recommended to equip the furnace passage as close to the ridge as possible, this will exclude the possibility of accumulation of large masses of snow.

NOTE!

All elements of the pipe in the place of passage through the roof must be solid, without joints. All connections are made either before or after the passage.

To ensure fire safety, it is necessary to manufacture (or purchase if the pipe on the roof made of metal tiles has a standard shape) special metal box providing the necessary clearance and cutting off hot sections of the pipe from the material roofing cake and rafter system. The space between the box and the roof is filled non-combustible material, glass wool or mineral wool. This will provide insulation of the passage section and avoid the appearance of foci of condensation formation.

chimney on the roof of metal

So, how to get around the pipe with metal tiles? We will talk about this further.

Passage of a square pipe through a metal tile

- The passage of the chimney through the metal roof begins with the installation of the inner apron... To do this, mark the contact points of the abutment strips on the pipe (elements of the inner apron), use the grinder to go through the groove into which the upper edge of the strips will be inserted.

- Install the abutment strips. They are attached to roofing screws with a pitch of no more than 25 cm... Start from the bottom of the pipe, the strips are installed with an overlap with an overlap of at least 15 cm. Joints and gaps (especially the encircling groove where the edge of the abutment strips is inserted) are filled with sealant.

- A sheet of metal is installed under the lower bar - bottom tie, providing water flow into the gutter or valley.

- An additional waterproofing shell of the inner part of the unit is equipped. You can do without it if all the work is done quite reliably, but in this case, additional insurance against leaks will not be superfluous. Its upper edge should overlap the cut of the abutment strips at least 5 cm.

- Then they start to the installation of metal tiles.

- On top of the finished roof, the place where the chimney exits through the metal tile must be girded with an upper apron. This will be the first layer of protection against rain or melt water. Fastening is done without a groove, therefore the joint between the pipe and the apron must be sealed.

abutting metal tiles to the pipe

CAUTION!

Install the apron carefully, avoid deformation of the metal and cracking (peeling) of the polymer layer. This will help prevent corrosion of the elements and ensure maximum service life.

Round chimney passage

If a circular pipe is used, the best output option would be application of roof penetration of circular cross-section.

They are made of rubber or thermosilicone, which ensures the elasticity of the material and the ability to tightly connect it to any roof relief.

Installed over the existing roof, tightly stretched over the pipe and attached to the metal tile.

Thus, an elastic "cap" is obtained, tightly fitting the pipe and smoothly turning into the roof plane.

For reliability, you need to pour the joints with sealant... Such a system reliably provides protection from rain, is not afraid of temperature changes and deformations.

The inner part of the passage is filled with a non-combustible insulation and covered with a sheet of metal.

round pipe installation

All places where the pipe adjoins to the metal roofing must be insulated with silicone sealant. This applies to both the bottom and top aprons. Do not neglect installing a layer of insulator between the aprons. After installing the upper apron, all existing joints and connections of elements must be carefully insulated.

Useful video

And now we invite you to watch the video on self-assembly chimney:

Conclusion

In general, aisle equipment chimney requires accuracy and full understanding of the essence of the operations performed. Failure to comply with the rules entails the formation of leaks and destruction of the roofing cake, threatens with fire. Compliance with the rules is the key to a long and reliable roof service.

- Choosing a place for a chimney

- Required tool

- Removing the chimney to the roof

- Round chimney

- Passage through rigid roofing material

The passage of the chimney through the roof is an important unit of the roof arrangement. This area is the most fire hazardous in the entire chimney system. Its design is regulated by the special requirements of SNiP. Only the unconditional fulfillment of all safety requirements will allow you to sleep peacefully or take bath procedures without worrying about the state of the stove. The passage of the chimney pipe through the roof can be done by hand, but in full compliance with all norms and requirements.

The passage of the chimney through the roof is the most fire hazardous in the entire chimney system.

Features of the roof passage

A chimney in any building has an increased fire hazard due to the fact that it heats up to very high temperatures and, in the presence of direct contact with combustible materials, can cause them to ignite. This is especially dangerous in the presence of wooden elements. Based on this, the construction of the chimney is regulated by the requirements of SNiP 41-03-01-2003. This document should be looked at when building a new house, overhauling a roof or a heating system. Thus, the first requirement appears - the presence of a heat-resistant non-combustible barrier.

The second requirement is mutual temperature influence. The cold metal of the roof covering, when it comes into contact with the chimney, causes it to cool sharply, which renders the tall chimney useless and reduces draft. In turn, the heated chimney heats up the roofing material, causing its accelerated aging. To eliminate such mutual influence, it is necessary to have thermal insulation in the passage zone.

Finally, when the pipe is passed through the roof, the integrity of the coating is violated, where moisture will certainly rush during precipitation or melting snow. The joint must be waterproofed to prevent leakage.

The arrangement of the chimney passage must take into account the type of pipe and the type of roof. The chimney can be of two types - rectangular or round tube different sizes. This determines the construction of the transition. When designing, it is necessary to take into account the presence of an attic room, a wooden rafter system and the type of roofing material. Passing through metal or corrugated board is different from going through slate or other covering.

Back to the table of contents

Choosing a place for a chimney

Figure 1. Diagram of the different location of the chimney along the roof slope.

How to make a chimney on the roof correctly is shown schematically in Fig. 1. Recommended distances and heights for different locations of the pipe relative to the ridge are set based on the following conditions: snow accumulation in winter, condensation formation, wind impact. The height of the pipe increases as the drop point decreases along the roof slope. In addition, there are additional rules:

- The pipe is not placed next to roof window and on the edge of the junction of two slopes, as a wooden beam passes under it.

- If a higher structure is closely adjacent to the building, then the chimney must be higher than its roof. (Fig. 1. Diagram of the different location of the chimney along the roof slope)

Back to the table of contents

Required tool

When arranging the passage of the chimney through the roof with your own hands, you will need the following tool:

Figure 2. Passage of a rectangular chimney.

- bulgarian;

- electric drill;

- screwdriver;

- hacksaw;

- scissors;

- chisel;

- plane;

- putty knife;

- paint brush;

- hammer;

- mallet;

- metal ruler;

- construction level;

- roulette;

- the stapler is furniture.

Back to the table of contents

Removing the chimney to the roof

The chimney through the roof is equipped with roof cutting with aprons made of metal (galvanized or stainless steel, copper or lead); and with the expectation of a different slope angle. The standard design of the abutment (groove) depends on the pipe material, pipe shape and roofing material. For rectangular pipes, ready-made parts are available; and together with the roofing material.

The place of passage of the pipe is also subject to heat, hydro and vapor insulation. All these layers must be separated from each other by a non-combustible barrier. To fix such a puff pastry, a separate box is mounted around the chimney (Fig. 2) - rafters on the sides of the pipe and cross beams attached to the rafters.

The connection of the vapor barrier and waterproofing film can be made by cutting them according to the "envelope" principle, while the edges are wound onto the crossbars and secured with a stapler or nails.

Figure 3. Waterproofing of the chimney passage.

Then the waterproofing is compressed by the elements of the lathing, and the vapor barrier is closed with the lining material of the attic ceiling. To increase the tightness, the joints are glued with tape or treated with an adhesive (Fig. 2. Passage of a rectangular chimney).

Additional waterproofing to protect and drain water flowing down the walls and slope is carried out to various chimneys according to the same type of technique. Fig. 3 shows a diagram of the upper protective system. One edge of the waterproofing is glued to the roof and the other to the pipe surface. The pipe part of the insulation is pressed with a standard metal profile, which is fixed with dowels. The upper end of the profile strip is treated with a sealant (Fig. 3. Waterproofing of the chimney passage).