When building a house from a bar, an inherent attribute are windows that can be made of wood, different kinds of polymers and metal structures. Despite the fact that the installation of the window to the house from the bar seems simple, it can bring a lot of restrictions, if you do not take into account some patterns when working with wooden products. And below, we will consider in detail this process by providing useful videos and photos.

Installing a window to a house from a bar

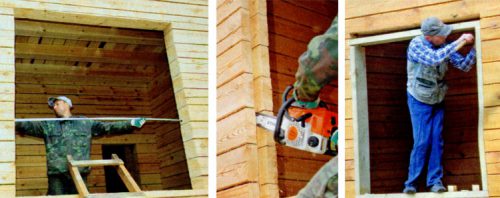

Window opening should be placed with a plumb. In this case, one building level will not be enough. To cut the window opening, we recommend using a chain saw that is being offered today. big choice. It is necessary to cut the opening so that the hole captures at least half the lower and the top log in the litigation.

Using a circular or chain saw, and even better milling, select a groove in a depth of 50 mm and a width of 50 mm in the end of the wall. The chisel and chisel to clean the ends of the groove and buy a bit of 50 mm. It is necessary to take into account the humidity of the church. Whether it is a stoken-sitting or fresh log house. In the presence of a hand-made out of fresh wood, the length of the bar must be 5 cm less from the long groove. If the log cabin is 2 cm, take the boards, 50 mm wide, then reconnect it to the bar.

It is important that the boards width correspond to the log thickness in a litter. Buy boards forming window opening to the bottom and top log. To do this, it is better to use special nails, which are then drowning, and the holes must be treated with putty.

For greater accuracy of the definition of the angles when installing the box, use the square. The window needs to be installed on the mounting foam. Applying the clamping board, close the window around the perimeter. From the inside it is necessary to close the layout. Window opening to separate the board. The board is nourished to the bottom log so that it does not form obstacles during the shrinkage of the cut.

The window itself is attached to the mounting foam and self-tapping screw. Mounting foam is most convenient to choose with weather conditions. It is important to remember that ultraviolet rays negatively affect the mounting foam. All wooden components are impregnate with an antiseptic that is sold in stores in a wide range. Holding to this technology and steps to install the window to the house from the log house, you yourself cope with this task.

Installation of plastic windows to a house from a log house

To date, the PVC windows are increasingly installed in wooden buildings - there is no point in installing simple structures wooden windowswhich have low properties of thermal insulation. Specialists involved in the implementation of new construction technologies, argue that the use of modern plastic windows a much more practical solution.

Plastic windows consist of several main elements:

- a hermetic glass, which possesses two conversions of the seal between the frame and the sash;

- plastic frame from PVC profile;

- accessories that allows you to conveniently open and close the window.

It is important that the installation of all components occurred in accordance with the process technology - the installation of plastic windows in the houses from the bar has many features that, unfortunately, take into account not all companies. Incorrectly made installation negatively appears on the service life of the structure, and therefore it makes sense to consider step by step, as this process will pass.

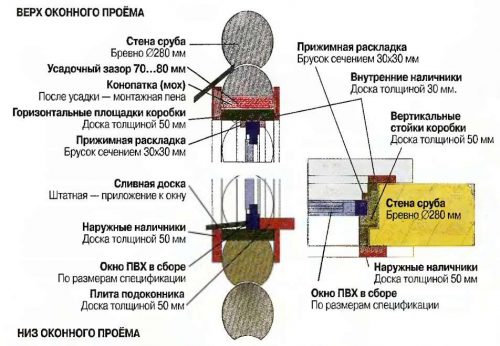

In the first year after the construction, due to the drying of the tree, the log house is noticeably settled, losing up to 10% of height. For this reason, the PVC windows cannot be installed in the openings. Slowing logs to the profile, which makes it difficult to open and be able to damage the frame. As a result, the owner will need urgent repairs.

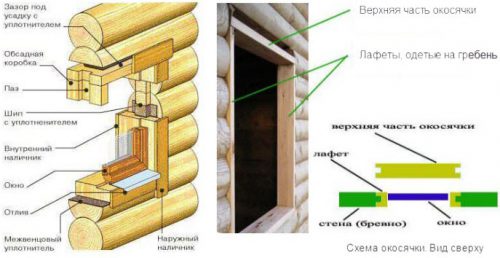

To prevent such an unpleasant incident, the window needs to be installed in the "Okosyachka" or "Planning", that is, a frame is collected from the bar, which compensates for the shrinkage of the walls. The frame provides a vertical unhindered movement of window blocks, and also enhances the strength of the whole house. Casual boxes are not rigidly attached to the walls, but through sliding bars. Therefore, it is important to perform a device of vertical groove in advance.

Unfortunately, when working on this item draws attention to a small number of repair and construction organizations, which often leads to the need for repair in the future - if only the master of the "sowing" will not follow the owner itself.

Moreover, for giving the windows of a traditional appearance it is worth using false options. They are a thin decorative profile that is glued on both sides.

Installing wooden windows in a house from a bar: installation rules

Many people do not represent country wooden houses without wooden windows. They do not violate a favorable climate and are harmoniously combined with nature. With shrinkage of the house design and walls, they behave equally. It must be understood that the installation of windows in wooden house It is very different from the installation of windows in buildings built on other technologies.

A bit of theory

When installing windows in a wooden house, it is worth considering some of the features of natural material - shrinkage design and drying of wood. In houses from a chopped or rounded log, profiled or planed timber in the first three to five years, shrinkage can be from 6 to 15% of the height of the building. Houses made of glued timber give a much smaller shrinkage - only 2%, but this will affect the integrity of doors and windows, if they are installed in a simple way.

If window designs are deformed, the flaps began to close and open the flaps, the double-glazed windows cracked, the inter-walled gaps were formed - it means the installation of the windows was performed with a violation of technology. For this reason, it is worth considering several important rules.

- In chopped houses, houses from a profiled, planed log or profiled timber, windows boilers are better installed, after the construction will give the main shrinkage, namely after 1-1.5 years. I do not recommend installing the doors and windows immediately after assembly, because in this case, it is impossible to calculate the installation of wall structures. The magnitude of the shrinkage directly depends on the moisture of wood: what it will be more, that respectively there is more shrinkage at home. Windows and doors in houses from glued timber can be installed immediately upon completion of the assembly of wall structures, as well as roofing devices. All because the percentage of shrinkage in them is much easier to calculate.

- Installing the doors and windows in any wooden houses can be exclusively using sliding compounds (shocking boards and sliding bars). Fastening the casing and window blocks to Brus and logs are unacceptable. Hard mount during shrinkage will cause deformations of door (window) and wall structures. In fact, the design of the window should move separately from the walls. Therefore B. window noise In the ends, the logs are made by 50x50 mm, where the sliding bar is inserted. To him on the tape seal or passing the casing is mounted, and to it - window block. Moreover, screws, by means of which the window unit is mounted, must be screwed into the sliding bar. This technology will allow the walls to be placed free, without putting pressure on window structures and without deforming them. On the same principle, installation of doors is carried out.

- From above over the boxes of doors (windows), stock for shrinkage - gaps of about 6-7 cm. They are also filled with insulation (for example, pacles). Often incorrectly calculated gaps are caused by unclipping doors and windows, and a timing of a bar or logs entails the formation of slots in the walls between the crowns.

- Calcarions (both with outdoor and on the inside) should be fixed with cloves not to the wall of the house, but to the casing. Finally, various companies provide warranties for installation of windows for a period of 1 to 5 years. Be extremely attentive: according to the requirements of GOST, the warranty should be at least 3 years.

- If the factory did not make the grooves under the sliding bar, then before making it propyl, install the guide bars. The grooves are cut into the center.

- In the groove you need to drive the sliding bar. At the same time, the shrinkage on the shrinkage of the walls should remain from below.

- Before installing the casing, launch the insulation (between the casing and the log cabin).

- Casual boards are fixed with nails into the sliding bar. Moreover, the nail must enter the sliding bar, but not to enter the end of the log.

- The upper casing is assembled and fixed so that the gap remains between the log and the upper casing, approximately 6-7 cm, so that during the shrinkage of the walls the upper logs did not put pressure on the casing.

- The window block is installed in the male salary.

- The space between the vapor insulation film and the casing of the perimeter is filled with the mounting foam. The distance between the log and the upper casing is filled with insulation, after which it is covered with a platband.

- The platbands are fixed to the casing. IN log walls It is impossible to drive the nails, it will hurt the natural shrinkage of the walls, which will cause the deformation of the platbands. During the shrinkage of the house, the platband must move with the design of the window and the casing salary, regardless of the walls of the house.

- Further install metal fits.

- Upon completion of their installation, the lower component of the platband is fixed.

- Window is ready.

High-quality repair and painting of windows in the house of the log

As you know, there are no trifles in repair, since each of the details, as a result, it develops in a common, from which it depends on how the house will look like after repair. An important stage is the repair of windows, as well as their painting. Let's consider this process in detail. This type of work requires essential financial and labor costs, but the result will delight the eye over the years.

In the case of independent windows repair, you need to adhere to five main stages:

- removal from the old paint window;

- grinding window profiles;

- putty windows;

- priming surfaces for further painting;

- painting windows.

Observing all the steps, you can get an excellent result. We do not recommend passing any of the above stages, as each of them is important in its own way and to a certain extent affects the final result. To assess the possibility of all stages and understand the subtleties, we recommend you to familiarize yourself with them more detailed.

- Removing old paint from the window surface.

When repairing windows with your own hands, this stage is the most time consuming and significant. It may take a long time to remove the old coating, but it is important to do. Moreover, it is necessary to do carefully, without regretting the strength and spent time. To do this, you need a set of different tools, ranging from abrasive paper to complex electrical equipment. The choice of a method for removing the solar paint depends on the type, there are three options: a chemical method, a mechanical method and thermal removal.

The mechanical method implies the use of "common" nozzles for straight-lifted and orbital machines, as well as an corner grinding machine. This method will be the fastest and economical among all. The only drawback is a fine dust formed during the work. However, if the tool has a system of dust collectors and dust read, such a problem will be not so acute.

The chemical method is reduced to the use of special skills based on trinitochloromethane or potent acids.

The thermal method is excellent for residential premises. To remove the paintwork, use the construction hairdryer. This method is quite expensive.

- Grinding window profiles.

Upon completion of the first stage, residual defects may remain on the surfaces. This is usually small pieces of old paint. Also on wooden structures May form "Vault" wood fibers. Of course, these defects need to be removed, which can be done by the finish grinding. After grinding the surface window profiles They become smooth, which is positively displayed in the operation of the paint coating.

- Putty windows.

At the current stage of the repair of windows, surface putty should be performed. Such a process allows you to achieve an almost even separated surface, hide defects. First you need to remove pollution and perform a clean surface putty. After drying, the putty is worth losing excess abrasive paper or small grain net.

- Printing the surface of the window.

The penultimate stage of repair is the priming of surfaces. This is done, in order for the new paint and varnish the coating perfectly on the surface of the window. Please note that before starting the primer you need to clean and degrease the surface.

- Painting windows.

The last stage of repair is the applying paintwork. The paint should be distributed evenly, painting with a spacing or roller. Performing a free repair, remember that the paint should be applied in two or three layers. Before applying a new layer, you must wait until the past dry well.

After reading the main stages, you were convinced that the repair of windows with their own hands requires a large number of time defined skills and is distinguished by many features. For this reason, it is better to seek help from specialists.

Installing plastic windows in a log house

It would seem that simply mount Ready plastic window? But if you are going to put it in a wooden house, then you need to take into account the features of wooden buildings. The most unpleasant and main of them are shrinkage of a bar or logs. If this property take into account, the installation of plastic windows in a wooden house will lead to numerous breakdowns of window structures. Of course, they will start to break not immediately, but still correct mistakes will be spent and complicated than to do everything right, observing technology.

It is necessary to properly prepare the opening of the window and create a casing. It is used, in order for the window that stands in the opening, it was secure in it fixed and did not "feel" the shrinkage of the shrink (in this case, the window from the cut is isolated).

Why does the usual casing design not suitable for the PVC window? All because special fasteners are used when installing the plastic window. If you fulfill the first option of the cluster, then they will not be attached to what. Accordingly, the placade should be such to make the window opening more reliable and take into account the features of the installation of the plastic window.

Then we do the following: In the ends, the windows opening windows are cut no groove, and the comb. Then we dress a special faft with a groove. In this case, the logs having a crest on the ends will be removed along the window frame, but inside the faucet. In this case, no pressure on the window will not, which means you will avoid curvature. Then we will look in detail how to install the PVC windows in the house from the log house, namely about the end stage of this process - the installation of the window into the window opening with a casing.

Preparation for the installation of a plastic window

When the cabin box is ready, you can install the window in it. Simplening everything again, check the plunder and level the correct location of the vertical and horizontal details of the casing. As for the measurements of the window opening with a planting structure, it is important here to take into account the "stock" on the shrinkage - approximately 5 cm in height, for a fudge - approximately 2 cm in height and width, as well as the distance that is left to the windowsill - 4 cm.

Making sure that all sizes will be clearly observed, start mounting the window. It must be done technically correctly. Usually, when buying a window, special attachments are bought, refueling into the end of the frame, where there are technical sleds for them. Unable to use only fastenings, since, screwing the PVC window through the frame, you will reduce all the advantages of the plastic window to no: thermal insulation and tightness. To install the window did not take you too much time and effort, remove the shutters with the glass packages. Thus, you will install an empty frame that will be easier than the collected window. Yes, and keep it much more convenient. To do this, you will have to remove the pin from the loops, which holds the sash. It is important to insert correctly!

First, when installing the window, the level will need a level. Without it, the window will be inserted with the slope, which will lead to its uncontrollability during operation - the spontaneously opening or closing window is not very convenient. At the same time, do not forget about the marking - in order not to lose the required distance, we recommend that you make a flick under the frame. Just do not forget to remove it later.

After alignment, the frame can be started to secure in the casing. It is important to maintain the functionality of the whole structure, namely, screw the screws. Do not screw them into the ridge of the window opening. On the boat in advance, mark the "forbidden zone".

Then we take a sliver from under the frame, we set the sash and melt the mounting foam window throughout the perimeter.

Detailed instructions for installing windows with your own hands

Mainly, this instruction is designed to install windows at dachas or in wooden houses. It is advisory and can be adjusted to the individual features of the house. We do not recommend performing the installation without having experience and due qualifications.

The plastic window you purchased represents the finished product, which consists of a box (frame), double-glazing, and for swivel-folding and swivel - still accessories and sash. And since you are going to install windows yourself, it is important to understand that from proper technology Depends on how long it will last. Carefully learn our advice.

Before buying the window, you need to make sure that the window openings are suitable. Otherwise, you need to select another size window or resize the opening. If both options are not suitable, you need to order windows, pushing out of individual sizes, based on the dimensions of your window opening. Depending on whether you install a window with a suboolent profile or without it, the tables are given to the recommended maximum and minimum window opening size, taking into account the expansion of the foam.

What tools will be needed to install the window?

For mounting the PVC window, you will need: level, screwdriver, drill, pliers, perforator, rubber molding or wooden hammer, plastic chisel, hexagon for adjusting windows, mounting foam, gloves, mounting plates (anchor plates), water sprouts. Installation is not recommended at a temperature of -10 degrees, as well as with strong wind and rain.

General view of the window

- Box (frame).

- Sash.

- Strapboard.

- Impost.

- Furnitura.

- Double glass.

- Suboofer profile.

Preparatory stage

- Before installing the window, carefully check the compliance of the dimensions of the window opening and the window itself. The gaps between the window and the installation opening, which remained after dismantling the former windows, must be on top, on the left, bottom and right (about 2 cm). Also, the window can be installed directly on the window opening without any gap, but it is in the most extreme case.

- Pull the old frame. If the window opening dimensions allow, dismantle the wooden box, as the installation is better to spend directly into the walls of the house.

- Remove the shutter from the window. Open the sash, then pull the pin from the top loop (the loops are removed from the bottom, and for convenience you can use the pliers or screwdriver).

- If the window or part of it is deaf, the glass will need. But first, remove the spat. First of all, long staps are removed, after which the short. As a rule, in the deaf parts, the stapper is clogged at the production not fully. This makes it easy to pull it out of the window using a plastic chisel.

- From the outside of the window, remove the protected film. Otherwise, under the influence of negative weather factors, it will become fragile and tight, and in the future it will be difficult to remove it.

Mounting window

Immediately it is worth saying that the installation of the window is carried out by two fasteners: directly through special holes in the frame, depending on the materials, anchor bolts or screws, or through the anchor plates, fixing in the frame frame. In two versions, the fasteners must be installed by following the following rules:

- the distance between the fasteners should not be more than 70 cm;

- the minimum distance from the frame to the first fastener is not more than 15 cm;

- the distance from the impost - no more than 15 cm;

- not necessarily fix the bottom of the frame;

- the top of the frame is fixed by three mounts with a frame width of 151 to 230 cm, two, if the width is from 71 to 150 cm, and on one with a width to 70 cm.

By installing the anchor plates, you need to fix the plates on the frame with the help of screws.

In the event of a window setting to long screws or anchor bolts, you need to drill holes in the windows frame. And all the holes in the frame must be done on the outside.

- Install the frame in the opening window. If it has a "quarter", press the frame at a quarter. We do not advise you to install the window on the outer wall of the construction, it is better to choose a position starting from the center of the wall to the inner edge (taking into account the method of installing the window sill and wall thickness).

Place the frame in the opening in such a way that the gaps on the right and the left are the same. Insert the window strictly by level and secure the frame in the horizontal and vertical plane. It is important to set the spacer clin next to the mounting place so that when twisting the screw or bolt, do not damage the frame.

- If you install the window in a log house, you can fix the window through the drilled holes with long screws directly into the wall. If the installation of the window is performed on the anchor bolts, then first through the holes in the frame, make a mark on the wall. Further pull the frame and make holes in the wall, then install the dowel, return the frame to the place, check again, check the level vertically and horizontally and secure the frame.

In the case of installation on the anchor plates, pull the window after the placement will not be reused. Bend the anchor plates on the place so that they can be pressed against the wall. Secure them. The method of mounting the plate is selected depending on which the wall material will be.

- Then set the windows on the frame, removed earlier windows and sash.

- Check the closing and opening of all sash. They must open freely without any obstacles. Seals should be seamless to the frame around the perimeter of the sash. If necessary, adjust the accessories by means of a hexagon.

- Then you need to put the seam along the perimeter of the frame indoors. This offers a pistol mounting foam. It is necessary to choose a brand of assembly foam depending on weather conditions and season. Well, if all work you do in gloves. Before filling the foam of the entire perimeter, moisturize the openings with water. Thus, the foam will not lag behind the wall and slide. It is necessary to fill out carefully, a small layer (approximately 2/3 of the thickness of the entire frame). It is important to take into account that foam expands in different ways (depending on different temperatures). Instructions can be read on the balloon itself. If you get a foam on the frame, wait until it dry, and only then delete, using a thin knife.

- Do not forget to install on the windows of waterproof, fixing them to the support profile of the outdoor side with screws. Well, if the width allows you to fit the space under a waterproof, otherwise "tin ringing" will be heard during the rain. Therefore, we recommend ordering a width of a minimum width window. The presence of waterfront eliminates the likelihood of water from entering the window, and also protects the outer wall from the wet.

- After drying the mounting foam, you need to install the windowsill. It is installed in the recess in the sub-formal (stacked) profile, which is the bottom of the frame. After installing the window to the spacer wedges, fill the space under the windowsill foam. If the house has a narrow wall, then the windowsill must be consolidated with corners (consoles).

- We recommend not to open the windows of 16 hours after they are edited. Minor movement can cause a violation of the mounting seam.

- The separation of external slopes is not larger than three days after installing the window. Be sure to close the mounting seam from the street side, because under the influence of moisture and the sun, the mounting foam is destroyed.

- Remove the protective film from the inside of the plastic window. Install on the loop decorative lining and secure the window handle.

As the window opens

Through the intermediate press of the sash to the frame, a window opening is changed. Otherwise, it is possible to jump from the top hinge of the sash. To fix this position, you need to close the sash tightly and close the window.

When polluting plastic surfaces, it is necessary to wipe with a windshield with a wet fabric cloth moistened with soap solution or water. Never buy abrasive detergents for this purpose.

It is necessary once a year to carry out the lubricant of the movable parts of the fittings using machine oil. As for the sealing gum, they need to be witched from dirt and dust wet, not a soap napkin. At least 1 time per year to process a special spray based on glycerin (silicone oil).

Installation of a plastic window in a log house: the most common questions

The windows are an important part of the interior. They focus on the decoration of housing outside and inside, allow you to penetrate the light into the house, make it more comfortable and more comfortable. It is important to choose the right version of the windows and ensure their competent installation. Especially if it concerns wooden houses.

What you need to take into account when you deal with a building from a wooden log cabin?

First of all, shrinkage wood. In the first 12 months it is up to 20 cm from the height wooden house. The digit is rather big, and you can imagine what can be with a window opening. Shrinkage Building can last up to 3 years. Accordingly, the size of the window openings will change.

How to install windows into a house from a log house? How to avoid restrictions and problems caused by the shrinkage process?

It is important to adhere to a special technology that eliminates the effect of shrinkage on the windows, as well as its deformation.

Now consider the technology itself. The windows are installed in a special salary - a casing, which is installed in the log house. It allows the house to sit down, without delivering any problems to the window, holds the walls along the vertical and horizontal. The gaps between the salary and the window opening are caught, which allows the "float vertical" box, after which they are closed with wooden or other platbands. The plastic window is inserted into the casing of the house, which is not susceptible to the geometry of the window opening and changes in size.

Is it possible to cope with the installation of the window in the house from the log house?

Yes, you can do everything with your own hands. But, as practice shows, the result does not bring satisfaction. To make the windows beautifully looked, did not deform, made a log house more beautiful and more comfortable, you need to know technology, be able to use certain materials and be a true specialist. Only a professional master guarantees a good result.

The same qualified real and experienced masters are, but, of course, how and all the best, they are not so much. Moreover, the masters and specialists who know how to install windows in apartment brick and concrete houses, are not always suitable here. All because the wall of a wooden house, where the window will be installed, as if "live", it moves vertically depending on the chipped timber or log wet. The greater the humidity of the church, the topics (log) becomes more.

The walls seem to live independently, compared with windows, whether they are of plastic or dry glued timber.

But if you wish, you can set the windows by the hands of the masters, we recommend paying particular attention to their search. First of all, it concerns positive recommendations from their clients.

What materials will be needed to install the window

First of all, it is worth noting that when dismantling and installation work, you need to protect the open areas of the skin with gloves. Each of the steps requires its own tool. To dismantle, the most important - scrap is applied. With it, it is conveniently removed the sash of the old window: encourage it under the sash and upset up, after which the sash is removed from the loop. Then repeal the impost, that is, a part separating the sash (often there are several).

Further Frame should be held. We remove the windowsill and the tump, we clean the opening - it is important that he remains clean. If necessary, you can knock down the old slopes using the blade and perforator. Usually, the slopes are knocked down in the houses of the old fund (their width is approximately 50 cm). We draw attention to the fact that a qualified window installation specialist before dismantling should determine the need to knock them down, otherwise all the dirt, as well as pieces of walls will fall down, which does not correspond to safety technician.

This necessity arises if old slopes do not allow new ones. At the same time, new slopes in no way should look inside the windows and be at him at a right angle, but should be deployed. With the help of a mounting foam you need to close the distance between plastic slope and wall. The seam between the wall and slope is closed with a PVC corner (in most cases a three-chamber) is used).

Installation of a new window

First of all, to install a new window you need to have such tools such as: level (good, if there are two - big and small), pencil, roulette.

Main tool: Perforator with boots 10 and 6 - Bur for 10 required if the window is installed on the anchors. In the case of installation on the plate will be quite enough drill on 6.

Drill on 10 and drill screwdriver with bits. 10 Drill is necessary to send the window profile if it is installed on an anchor. We are screwed to the frame.

A foam gun is a convenient tool for giving, it is adjusted to the foam output rate.

Scissors for metal - it is necessary to cut off the waterproof.

The knife is construction with a hammer. They are necessary for cutting wooden mortgages for fastening the frame.

Knife Stationery with blades - to cut a foam that dried.

Finishing of slopes.

Tools for mounting slopes:

- Pistol for sealant (seam closeing between frame and slopes).

- Lobzik for the peel of slopes.

- Hoven for metal (Circumcision of PVC corners).

- Spatula - To launch the space under the windowsill and external slopes.

- Molarcotch to secure the slopes until the mounting foam does not dry.

The longer a person lives in small close apartments from an artificial material, the more often he dreams of having his own big, spacious house. Tired of everyday artificiality, I really want to be as close as possible to nature, and have your home from a natural material, which is easy to breathe, and, it means, and easily lives. It is a tree is considered the most ancient, very beloved many environmentally friendly material for the construction of your own house.

Imagine how nice, leaving the whole bustle behind yourself, relax the medium of warm, natural walls of a wooden house.

Building a house from a bar is not expensive compared to stone buildings. Many construction firms Build houses from a turnkey bar. You will only have to choose a project or develop your own. And the construction of houses will take on professionals.

Brous houses are a small cost, the possibility of finishing the most various materials, affordable material, fast construction. Houses from the bar are superbly kept warm. In such a house in the heat will be cool, and in the cold - very warm.

If you have a nearly complete new home bar, do not rush to insert a quick window, doors and cope a housewarming. Only at first glance it seems that insert windows and doors - a matter of times, two, three. Not at all. Houses from the bar for this require special specifics and a special approach.

If you smell your hand to all this specific, then the joy of accommodation in a new house will be short. Already in a year or another bar, as a result of natural drying, will give a significant shrinkage. From sufficiently strong vertical pressure, door and window mounts will be shifted or, simply, will fly out. That in this case will happen to the doors themselves and the windows can guess not difficult. They are either thoroughly embarrassing, or they will come with you in the same way as Kolobok entered the grandparents in a famous fairy tale.

There is a natural question: how to be?

The first is to wait for a natural shrinkage of the house from the bar year or two. But even after this period, it is not a fact that the house will stop dying.

The second is not to wait if I do not want, but with windows and doors it is intelligently and competent.

Intelligence and literacy means: take care of the right and reliable casing. Otherwise, it is also called the soul. The opposite is a design that helps strengthen the cutting openings under the windows and doors. The casing box perfectly protects from the deformation and windows of window and door blocks. It almost completely ignores the shrinkage process of the house from the bar, without changing the form of the opening.

This design consists of a heap (upper crossbar), threshold (lower crossbar) and side risers. And in simple, it is called the usual word - a box. There are several variations of brass manufacturers. Its maintenance is to protect windows and doors in the construction of a turnkey house.

You can select three casing box functions: protective, decorative and replacement function (for windows). When mounting the windows / doors to the casing, there is a small gap in one - two centimeters. This gap can be seen by the usual mounting foam, and after close to the navigation. The foam does not interfere with the "move" to the house, and the box perfectly "holds" window and door blocks.

So you can install windows and doors only after establishing a special chip. The design of the box will save your doors and windows from the jam, and therefore they will serve you long years, pleased with its flawless work.

Technology installation of doors and windows in the house from wooden bar Differs from installation in other buildings. This is due to the shrinkage of the bar, which inevitably happens the first two or three years, and which is necessarily taken into account when designing and building wooden houses.

How to install windows?

When installing a small window with a height of three-fold logs (hearing windows in the attic or window in the bath), the shrinkage can not be taken into account. If the height of the window is eight or ten logs, the casing frame is applied to its installation. The method of manufacturing a frame depends on whether plastic or wooden windows are planned to be used in the house.

Installing a small window

When installing a small window, you need to cut the opening in a benzo-or electron bar. After that, with the help of spacer wedges and levels, we install the frame in the opening. Having achieved the right position on the vertical and horizontal, the frame is fixed with self-draws or nails. The free space between the walls and the frame is recommended to fill with the mounting foam. Sut off the surplus of foam, nail a ticket.

Installing a large window

When installing a large window, take into account the future shrinkage at home. To reduce the pressure of the bar on the window when shrinking, you need to use the casing. The casing blocks the horizontal mixing of the timber and does not interfere with the natural shrinkage. When building a house from a wooden bar, casing for doors and windows are installed at the construction stage.

Sometimes the casing is set later. Before the primary shrinkage of the house in the openings, not drinking jumpers left to eliminate the "care" of the walls horizontally.

When installing the casing key of the key point - the accuracy of measurements. If you make a gap for shrinkage too big, it will remain between the wall and the casing big gap. If the gap will be too small - the wall does not sit until the end, which will affect the strength of the whole design.

Placing the opening under the high window, you need to consider the size of the boards of the casing, the windowsill and the gap in one and a half or two centimeters, which are left to align the window on the sides. The upper gap must provide for the shrinkage of the wall.

There are two ways to manufacture a casing. Which one to use depends on which windows will later be installed in the house - plastic or wooden.

Installing a casing under wooden windows

After the window opening is cut, in the end surface of the bar along the entire length of the window, a vertical groove of 50 per 50 millimeters is powered. In the grooves insert the timing of the corresponding thickness. This timing together with the slave will distribute the pressure of the walls when the timber sees. After that, a casing is installed in the opening, to which the wooden window is subsequently mounted.

Installing a casing under plastic windows

If the house is planned to install plastic windows, a more complex design of the casing frame is used. As in the case of wooden windows, the bar is cut into the opening, taking into account the future shrinkage. At the ends of the logs cut the ridge. It dresses with a groove with a groove - a vertical ram 150 per 100 millimeters, with cuts on the ends. These cuts are installed horizontal jumpers with spike. When mounting the jumpers, it is recommended to pae the grooves insulation. Before installing the casing, the windowsill is mounted at the bottom of the opening. When shrinking, the window with a casing will slide the groove to the end of the shrinkage process, without deviating horizontally.

Installation of doors in a bar

Installation of doors in a wooden house is carried out by the same technology using casing. It should be borne in mind that the height of the doorway is greater than the height of the window, and therefore, the pressure will be higher on the door casing.

The final installation of doors and windows in the house from the bar is carried out after the end of construction. The choice of windows - plastic or wooden - depends on the preference of the owner of the house.

Summary

Installing windows in a wooden house is planned with the inevitable shrinkage of the structure. To avoid overpressure on the windows, they are mounted in casing. The casing frames are installed with the upper gaps between the frame and the wall - the admission to the shrinkage of the building. The tolerance is carefully calculated before the opening of the openings so as not to make it too big or too small. The choice of the type of casing depends on which windows will be installed in the house - wooden or plastic.

Installation of doors is made by similar technology.

The location of the windows and doors is thought out at the design stage, as in our catalog of wooden houses.

An independent installation of a plastic window in a brusade house will not submit difficulties if you follow the instructions described below. Such work is significantly reduced to the process, however, double-glazed windows should be measured in all the rules of professionals. There is a risk of mistaken in calculations. In addition, it is extremely important to prepare window peres very well.

Proper preparation of the face

Wooden houses have one significant disadvantage that affects the entire quality of construction - this is a shrinkage of natural material. Its term is individual and for solid wood, it is more than for the buildings raised by frame-shield technology. All sawn timber - log, profiled and glue bar are subject to the process.

True, the building from the last named version of the least, since initially this expensive material produced from the lamellae was already dried by chamber method. But still each object built of wood should wait for its o'clock to dry out window and door openings Without prejudice to future exploitation.

The work consists of the following steps:

After preparing the opening, proceed to the insertion of window blocks. Double-glazed windows of the corresponding sizes are ordered in advance.

Construction of the placade

This element provides the installed glass protection against shrinkage manifestations, which goes continuously throughout the operation of the building from a tree. There are several ways to assemble the cluster or, as it is called it, the souls. Consider them:- Cutting the groove along the ends and insert in them special bars. During shrinkage, the work will begin to decline without acting directly on the frame. It will be protected by a box of boards fixed on bars in the grooves. This method of the device is understood even to amateurs.

The grooves on the vertical guide ends are saved or cut down. The sealer is inserted into them as used between the crowns - Jute. Then the line of bars.In no case, they cannot be fixed by self-drawing or nails, then there will be no movement. Score them with a wooden hammer. They are installed at the bottom of the day: there they create gaps for gate between the casing and wall material. The top edge remains empty, it is laid by the seal and closed after inserting with a platband.

- The way "in a deck". The process goes on the contrary - they cut the thorns on the ends, and the casing contains a groove. It is not necessary to use bars, only their mounting along the bottom edge. We must not forget about the seal in the groove.

When the discretion is ready to take a casing, it is constructed from boards, carefully sharp and polished. It is advisable not to use any fastener, otherwise, when moving and constant moisturizing and drying wood, it will give corrosion or simply fall out of its places.

It is better to use the drinking spike-groove and thus knock down the whole championship. It is strengthened strictly along the outer edge of the bar with nails or self-drawing into movable bars. In the case of the fastener, it will not be required.

Inserting metal-plastic design

Before starting the installation of plastic windows in the house from a bar, the design itself should be disassembled into components, leaving only the frame. If the block is confusing, helpers will need, as the double-glazed glass. Further:- The design is set in a hole, focusing on the outer edge or a little blocking it inside. Align and "grab" in several places.

- Correcting with the level, the frame is screwed to the scene, acting in parallel: from one and on the other side. Thus, the package will be fixed evenly.

- The leftmost gaps are marked with the assembly composition, they do not spare it, otherwise it is possible to penetrate moisture, and where the dampness is staring, mold will quickly appear there.

Operating Rules

The warranty period of the plastic window is 5 years. The task of the owner to extend the life to him for a long time, for disregard for the care will reduce the service life of even the new design. What are the rules of operation of the glass package from PVC:If prophylaxis is regular, then the boosters will show themselves to the glazed windows from the best side. Then the independent installation of plastic windows into the house from the bar will not be in vain spending forces, time and means.

Causes of irregular use

Often independent work The installation of window blocks does not differ in quality. After some time, the owners become obvious to the owners: bad opening, fogging of the glass, skewing the entire design, the encoding of the flaps. To identify the shortcomings is easy to correct - difficult.

Therefore, when there is an opportunity, work should be entrusted with professionals, especially if the windows are installed in a wooden house from the glue bar, the material of dear and beautiful. Although it is possible to eliminate some faults yourself.

The appearance of condensate

The problem appears as a result of the penetration of cold air and mix it with warm. The question is solved like this:

Installing the vent valve is well coping with condensate. Through a small slit, the exhaust masses will leave the room. It is important to choose its optimal length so as not to make the room cold.

Window block skew

Many factors could lead to this:

Owners in the case self-mount It is necessary to be prepared for possible consequences, among which such a nuisance like a skew. Measures in this case are radical.

Enchanting Folds, Bad Opening

Before mounting the window in the opening, the design should be carefully calculated in size. Double glazed windows, even standard size, severe, their weight affects operation. It is also worth carefully considering the options for opening mechanisms - large packages are better to make axes, then the wedge will not happen.

Naturally, shrinkage will affect poor operation. As already written above, the measures in this case are necessary radical: dismantling, inserting a new clusade and the installation of plastic windows in the house in a new way. Hide

A wooden house from a bar or logs inevitably gives shrinkage in the first years of operation. Wood dries, the height of the walls is reduced - with the huge load turns out to be on the window frames. So that the window structures of PVC are not damaged due to this natural process, the installation of plastic windows in the brusade house should be made with accurate observance of instructions.

The windows are put in 1-2 years after the completion of construction, if the material used is a log or a regular bar. It is for this period that the most active shrinkage is held. If the glued bar is applied, it is allowed to start at once, since there is little moisture in this material, and it practically does not give a shrinkage. But in any case, the installation of the window will have a number of features, and the main one is not directly in the opening, but in a special plug-in box. So how to install in a log or brusade house right?

Preparation of window opening

Drinking opening

The main thing in the formation of the opening is the observance of the evenness of all its faces. For this you need to use not only a plumb, but also a water level.

It begins with the measurement of the distance from the floor to the lower edge of the opening. It can be any, but the optimal parameter is 80-90 cm, so the windowsill does not interfere with neither the radiator or a written table or other furniture.

The size of the windows in the brusade house is selected as follows:

- height - 13 cm more plastic design;

- width - by 12-14 cm more;

- additionally, 3 cm is taken into account in both planes for mounting foam.

The opening is muffled with a chain saw so that it is captured by half the logs from below and from above. Spiles must be treated with protective impregnations.

The main stage is the installation of double-glazed windows in a wooden house - fixing the stacks in the window opening.

Planning (Okosyachka)

The most responsible stage of work is an installation. It is made from a bar that is not just nailed to the walls, but attached through the Schip-Paz system. You need this box to make windows in a bar independent of the walls and protect the designs from a private house shrinkage - the use of fasteners instead of the grooves would not make this task.

The second protective barrier is a compensation gap above the box. Its height is calculated based on the maximum shrinkage, which is usually 15 mm for each meter of wall height. The windows in the log house is usually done using a mortgage or monolithic timber:

- In the lateral edges of the opening with a chain saw or cutters, the grooves width and a depth of 50 mm are done.

- Inside the groove is investing jute.

- The lower board is stacked, which will not only be the element of the cluster, but also the windowsill. There is a heater between it and the wall timber.

- In the grooves inserted spike - a lump of 50 mm thick. It is impossible to fix it with fasteners - the wall will slide on it, as on the rail.

- A well-dried board with a thickness of 50 mm and a width equal to the thickness of the wall timber is screwed to the bar.

- The upper board is inserted into the grooves, placing on the vertical elements and becoming a strut for them. The gap is top filled with a seal (moss, packle).

- Boxing elements are bonded with self-draws.

- The gaps are filled with sealant.

The seal in the upper gap must be hidden from moisture and pair using a special film, since in the brusade house put plastic windows for a long time you can only provide them with full protection.

It is impossible to use a mounting foam as a seal, since it turns into a rigid material during polymerization, which will transmit the entire shrinkage of the frame.

There is another way to install plastic windows in a log house - "in a deck". Instead of boards and bars, boilers are used with grooves, and the spike is cut on the logs themselves. In this case, the fasteners will not need at all. It is important not to forget about the compound of the jute compound.

Installing the window

Actually in the brusade house with their own hands consists of several stages:

- installation of a metal plastic frame inside the prepared casing;

- inserting double-glazed windows;

- installation of fittings and additional elements.

The window can align on the front surface of the wall or a little to delve into the opening. The size of the windows in a wooden house from a bar must be 15 mm less than the opening with a drop on each side so that the place to blame is left.

Installation is carried out as follows:

- Double-glazed windows and sash are disconnected from the frame.

- The frame is inserted into the window opening in a brusade house and is temporarily fixed in several places with wedges.

- Using the level of the frame, aligns and fixed with self-draws. They should be such a length to attach the frame to the bulk, without passing through it.

- The gaps of 15 mm on each side left in advance are filled with the mounting foam for thermal insulation and protection against water. While the cock could not be rigidly fixed to the wall, the window itself can be fixed - the shrinkage does not affect it if there were no errors in the initial stages of installation of windows in the log.

After the frame is installed, you can mount the sump and slopes. Domestic and external platbands should be attached to the sowing boards, but not to the wall bruus. Double-glazed windows are inserted into the frame and aligned with strokes. After that, the hinge hangs on the loop, the work of the fittings is checked. Installing windows in the brusade house is over.

Thus, in a wooden house is not so difficult, as it seems at first glance. If you observe the procedure for installing the placade, the rules for fixing the design and keep all the necessary shrinkage gaps, it will be reliable and durable. So that the gaps do not affect the thermal insulation properties of the structure, modern high-quality rolled insulation should be applied.