Calculation of materials

| TOTAL: on the walls | 327749 rub. |

| FOUNDATION: | |

| rubble slopes: | |

| 10.6 m³ x 1900 rub. / M³ | 20140 rub. |

| concrete mix B15-20: | |

| 8.1 m³ x 4200 rub. / M³ | 34020 rub. |

| concrete mix B15-20: | |

| 58.4 m³ x 4200 rub. / M³ | 245280 rub. |

| hydrosotecol TPP 3.5: | |

| 17 steers. x 690 rubles / steering wheel. (10m²) | 11730 rub. |

| reinforcement rods D10, 12, 16 AIII: | |

| 3.8 t x 37500 rub. / Ton | 142500 rub. |

| edged Boards for Formwork: | |

| 1.6 m³ x 6500 rub. / M³ | 10400 rub. |

| roll waterproofing RKK-350: | |

| 4 steers. x 315 rub. / Rul. (10m²) | 1260 rub. |

| TOTAL: FOR THE FOUNDATE | 465330 rub. |

| Overlap: | |

| pine beams 150x100: | |

| 4.2 m³ x 7000 rub. / M³ | 29400 rub. |

| plasterboard KNAUF (2500x1200x10): | |

| 26 pcs. x 260 rub. / PC. | 6760 rub. |

| steel profile with fasteners: | |

| 220.1 PM x 51 rubles / pm | 11225 rub. |

| minvata (Rockwool): | |

| 19 m³ x 3700 rub. / M³ | 70300 rub. |

| waterproofing (Tyvek Soft): | |

| 183 m² x 68 rub. / M² | 12444 rub. |

| parasolation PE: | |

| 183 m² x 11 rub. / M² | 2013 rub. |

| plywood FC 1525x1525x18.: | |

| 1.4 m³ x 19000 rub. / M³ | 26600 rub. |

| cutting boards: | |

| 1.5 m³ x 6500 rub. / M³ | 9750 rub. |

| TOTAL: Overlapping | 168492 rub. |

| ROOF: | |

| wooden racks (150x50mm): | |

| 3.7 m³ x 7000 rub. / M³ | 25900 rub. |

| bibo-protein solution: | |

| 54 l x 75 rub. / Liter | 4050 rub. |

| waterproofing (Tyvek Soft): | |

| 167 m² x 68 rub. / M² | 11356 rub. |

| professional flooring SIN 35-1000: | |

| 159 m² x 347 rubles / m² | 55173 rub. |

| self-fringe roofing 4,8x35: | |

| 6 pack. x 550 rub. / pack (250 pcs.) | 3300 rubles. |

| cutting figure (2000mm): | |

| 6 pcs. x 563 rub. / PC. | 3378 rub. |

| cutting boards 100x25mm: | |

| 1 m³ x 7000 rub. / M³ | 7000 rub. |

10:0,0,0,260;0,290,260,260;290,290,260,0;290,0,0,0|5:100,100,0,260;195,195,0,260;0,100,100,100;100,195,139,139;195,290,100,100|1127:139,139|1327:75,37;75,109|1527:195,37;195,109|2244:0,33;0,157;290,157|2144:34,0;34,260;129,260;224,260|2417:290,34;290,67|2317:169,0|1927:132,-20

1 166 048.0 rub.

Only for the Moscow region!

Calculation of the cost of work

Do you want to find out how much is the work on the construction of your home and choose performers?

Place an express application and get offers from builder professionals!

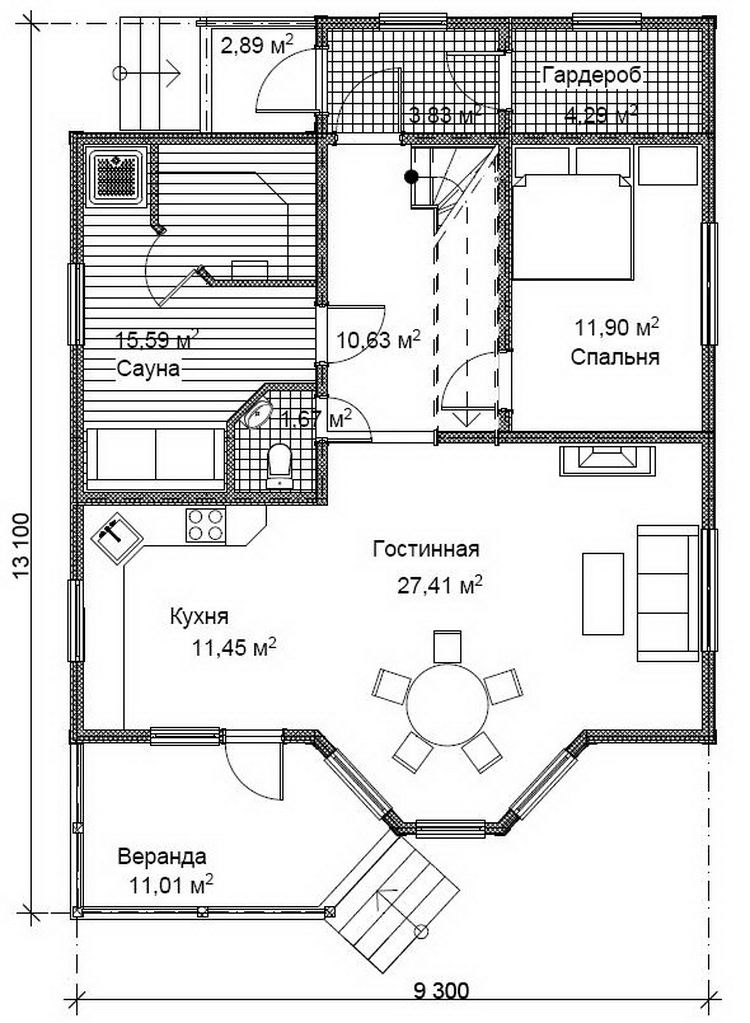

Example of planning 10x9 m for calculation |

||

|

1.

Wooden bars150x150mm; 2. Cladding siding; 3. insulation mineral wool d \u003d 100mm; 4. Air channel d \u003d 20-50mm; 7. Wooden-beam overlap D \u003d 150-250mm; 8. Sheets of professional flooring; 9. The foundation of the slab monolithic H \u003d 1.8m; |

|

Wall of wooden bars with a facade of siding panels and interlayer insulation

Wood-timber wall

The obvious attractiveness of the brusco-log architecture in Russia is explained by the traditional, accessibility and ecology of the housing of the forest tree.

The properties of wooden-log housing are proved to automatically normalize the magnitude of the humidity of 45-55%, to provide a pacifying effect on the psyche of people, as well as neutralizing carcinogenic compounds. On the building bases really find brusade products sections 140x140, 150x150, 200x150, 100x100, 180x180, 150x100, 120x120, Among which the type of 150x150 mm is the most purchased, because it is an acceptable combination of thermal insulating properties and available cost, as well as the processability of the assembly, a pronounced number of legitimate suture joints.

It can be mentioned that with recently the number of supplies of the profiled, mainly collection-glued brusade material is clearly growing, which is released (compared to a conventional lumber), 10 times reduced lurcinity, as well as increased, due to tipped joints, heat-saving and strength properties . There is only one negative aspect that prevents the massive use of said material - this is its tangible high cost, which, nevertheless, is justified by its long exploitation.

Approximate rules for mounting walls from a bar:

- First, on the foundation, covered bituminous waterproofing, along the walls, laid the lower brusade series, which is bonded by "in the floor tree" in the nodes of the docking of interroom walls and at the corners.

- During the installation of walls, the brusade rows are covered with a suture insulation (linen, pacles, jute, hemp, shine, felt), which in 9-12 months (or, when the humidity indicator will reach 12-15 percent) will need to repel again to reduce Heat carrier through inter-row slots.

- In order to dock the bars with each other, it is used by the boiling fastener (round oak or birch dowels with a cross section Ø30 ÷ 40 mm), which are inserted without effort into the holes performed through three rows, with an interval of 300-400 mm. Often, the boost fasteners are replaced by large nails - 250 ... 300 mm, with a mandatory drilling in the upper log hole, a depth of 30 ÷ 40 mm, where the nail with the nail helper is to neutralize the vertical deformation of the wooden material while drying.

- In order to in the process of shrinking a wooden log cabin, door and window boxes do not breed, door and light niches are framed by the ends of the crowns by the "Clock" - profiled bars. At the same time, the trapezacious spits are cut on the ends of the crowns, through which "drive", by means of an appropriate cutout, these are the most profiled bars. At the top of the doors and windows perform technological gaps, laid by hemp or glass-fibrous material.

- When choosing interior decorations, it should be borne in view of the periodic movements of wooden structures and, while fixing urgent facing plates, such as plasterboard sheets, refuse direct bonds with a brusade wall, due to the device of free-suspended buffer frameworks.

PVC Siding finish

If all-season accommodation is foreseen, the wooden-brusade log house will still heat insulating. Typically, outside, in a vertical position, nailed wooden lagows, dimensional 40-50x90-100 mm, every 40-60 cm, between which there are insulating plates (for example, brands: PPH-200, Isover, P-125, URSA, isomer, Rockwool, grinding, Knauf, P-175) The next step is stretched by windproof membrane (Yutaplek, Izospan, Tyvek), bobbed by the rails, a thickness of 2.5 ... 5.0 cm, which establishes facing material (CSP sheets, painted lining or PVC siding).

The vinyl profile during the fire is only melted, starting to burn when heated over 390 ° C (for wood: 230-260 ° C), quickly catching with the elimination of the heating focus, while the amount of carcinogenic discharge is no more than when combustion of wooden structures.

However, it is important to remember that PVC siding profile will keep an attractive exterior and serve for many years, only with a clear execution of the installation rules.

Siding polyvinyl chloride does not corrosive, characterized by self-filing in a fire, stable to borrowed, physical, atmospheric influences.

Now dealers of plastic siding profile (companies such as: Orto, Tecos, AltaProofil, Gentek, Varitek, Fineber, Docke, Mitten, Holzplast, Georgia Pacific, Nordside, Vytec, Snowbird) announce a variety of colors and shades palette, which gives any dwelling different from the rest.

Since PVC, the siding profile varies quite significantly in size at various temperature modes, then free fixation of PVC plates should be provided.

Additional rules for using PVC profile:

- Fastening PVC profiles It is produced from the Earth, while the first-case is fixed by a hidden initial rail.

- The installation of vinyl profiles is more correct to maintain, starting from the back of the house, moving to the front side, and each subsequent siding panel will go to the already attached in the current row, with a flystone 20 ... 30 mm, - this method allows you to hide the seams for the same reason , arising articulations, for the nearest rows, should be shifted to each other.

- The suspended siding panels must be shifted in the longitudinal direction without effort, as a result, it is forbidden to highly twist the screws in the fasteners.

- You should leave cut, 5-10 mm, in the fields of external networks (cables, brackets, wires, pipes), as well as in the docking nodes of the siding panel and additional parts ( inner corner, N-profile, outer angle, platband, etc.), in order to compensate for thermal extensions and compression of the siding profile.

- When installing the subsequent siding panel, clutch it into the lock with the previous one and, without pulling, fasten the screwdriver;

- In order not to prevent thermal cells and, thus, do not cause a point blocking of polyvinyl chloride material, drive carnations and twist the screws in the siding profile recommended on the central point of the available factory spaces.

Foundation from reinforced concrete plate and monolithic ribbon

The whole-slab base is arranged along the contour of the exterior walls of the house in the form of a whole railway plate and is practiced in an unloved or blown design.

In the breakout variant, the foundation plate serves as a constructive element on which the vertical walls of the foundation are arranged, which are set by an underground tier. At the upper arrangement of groundwater, it is advisable for the side walls of the foundation to arrange the method of continuous concreting, using waterproofing coatings (impregnation, strokes, coating).

Overhead slab foundation It is used in individual development, on moving lands and at the close level of groundwater. Such foundation is advisable when erecting compact buildings that do not contain high above-ground part of the foundation and basement.

According to the existing experience, when the foundation plate is located above the depth of the landscape of the Earth, and it means the upper side foundation Plate It is conceived, as a meaning for the outdoor design of the 1st floor, a task appears in the heat-stash under the stove of the foundation and around, on the width to 150 cm.

It is advisable to laying the sheets of extrusion foam plastic (type: Primaplex, Penopelex, Teplex, Styrodur, Ursa XPS, TEPLEX, STYROFOAM, POLISHAN), as the other heat saving means: polystyrene foam, glass gamble, clamzite - soon soaked in moisture, which leads to a rapid fall of them Thermal insulation characteristics in wet soil.

Brief sequence of the device of a single-lined foundation with side parts in the form of a solid concrete perimeter:

- First of all, the layer of land is taken out on a specified project mark.

- crushed stone, fraction 20-40, 150-200 mm thick, and tightly rolled with rollers.

- A sand-cement screed is produced, layer up to 4 cm.

- The moisture protective film with removal at the edges of up to 200 cm, for further moisture protection, the sidewalls of the foundation foundation.

- To save the moisture insulation membrane from possible breaks in the reinforcement process, on top of the waterproofing is made another layer of cement-sandy solution, up to 5 cm high, along the contour of which the formwork walls are fixed in the thickness of the foundation plate.

- The manufactured plate is enhanced by two layers of welded iron rods with a diameter of the D12-D16 AII-AIII grade with a step of 200x200mm.

- In the variant of the whole pylon foundation, only a high-quality concrete, a class, not less than B22.5 (M300 Magnaya), brought by a car.

- With offset to 25 cm from the edge of the foundation plate, the formwork is mounted in the height of the side walls in the form of an incident reinforced concrete perimeter,

- The prepared shape for the fill is located an armo-construct, cooked from the iron grilles of the AII number (A300), AIII (A400) Ø10-Ø14, and a concrete solution is performed.

- Duration of hardening concrete mixWhen you need to remove the formwork, takes at least 1 month in the warm season.

Woodside overlap

Woodley flooded floors are traditionally in demand in individual house-building, due to the cheapness and simplicity of their erection.

As a beam, brushes of coniferous trees are usually used: larchs, spruce, pines, with voluminous humidity no more than 14 percent. The richest lag is a bar with a sectional proportions 7/5 (for example, 0.14x0.10 m).

When planning overlap, you should use diagrams that give the dependence of the parameters of the beam from the weight of cargo and the size of the span between carriage structures; It is also permissible to repel from the approximate rule that the wide side of the beam timber must be about 1/24 of the length of the span, and the thickness is 5 ÷ 10 cm, with a step of alternation of beam boards 500 and 1000 mm and loading 150 kgf / m².

With a shortage of the beams of sufficient size, you can use the boards with a bolted bolts, with the mandatory observance of the general section.

Some moments of laying wooden beams:

- The beams are installed in this order: first finite, and after, with adjustment by level, intermediate. Lags must be described on the laying at least by 150-200 mm.

- The gap between the bars and the furnace canal is obliged to with more than 0.40 m, and from the walls of the lags are made no closer than 5 centimeters.

- in wooden srubach The end parts of the beams are handled to the cone manner, and then insert into the finished opening of the upper log on the entire depth of the wall.

- IN brick houses The end parts of the lag are installed masonry sockets, in which moisture is condensed, for this reason, between the wall and cuts of the ends of the bars, create a blank interval, and with a niche depth, it is still a thermally insulating insertion.

- Brook Brojev's ends trimged at an angle of 60-70 °, failed with antiseptic (Biospt, Biofa, CDS, potatoeside, Tikkurila, Tex, Kofadex, Teknos, Aquatex, Pinotex, Holzplast, Dulux, Senezhen) and robbed back Ruberoid, leaving the ends uncovered moldy that can happen when wetting in brick niche.

The oversight overlap is thermally insulated with the placement of a vaporizolation film from above the heat shields, the intergenerational overlap is not insulated, and the overlapping of the top level is heat insulated with the execution of a booster membrane from the bottom of the heat shield.

However, if the problem of the carrying ability of the brusal inter-level overlaps is generally removed by the usual increase in the cross section of the brusons and their number, then everything is not so simple with the fire protection and sound protection.

Possible increase in flame retardant and sound insulation characteristics of wooden inter-storey overlaps looks like that:

- Below carriers Lag.Perpendicular to them, on elastic brackets, after 300-400 mm, the ray-lamp is fixed, on which the plasterboard ceiling is reduced below.

- On the upper surface of the obtained lattice design, a synthetic tissue is filled with brackets to the bars, for which basalt fiberboard plates are tightly unfolded, for example: isover, grinding, ursa, knauf, rockwool, isom, a thickness of 50 mm, with an occasion of the lateral sides of the lag of overlapping.

- On the side of the next floor, chipboard sheets (16 ... 25 mm) are nourished, then, with an increased density of the basaltoloconde noise absorber (25 ... 30 mm), and again, the slabs of the floor chipboard are laid.

Rope of profiled metal

Compared to a metal tire, the main trumps of the professional flooring consist in lightness of installation and a minimum cost.

The professional flooring is a cloth of corrugated metal trapezidal metal rolling, with a polymer color coating, which label code, type H57, NS44, B-45, H44, NS35, MP-35, C-21, NS18, H60, where numbers determine the size of the wave cross section Profile.

For roofing purposes, professional flooring is used with the corrugations of at least 18 mm, to obtain sufficient stiffness and economical use of the root. At the same time, the working tilt of the roof is accepted more than 1: 7.

The roof is placed on a solid foundation made from rapid-beam farms and a drying filling.

For low-rise buildings, a two or three-span system with medium supporting walls and inclined rapid beams is traditionally designed.

The interval between the rafter farms is usually performed about 600 ÷ 900 mm at a cross section of 5x15 ÷ 10x15 cm; The lower ends of the rafter are fixed on a fixing agent of 10x10 ÷ 15x15 cm in size.

Standard procedure for installing corrugated steel corrugated rolling:

- In cases of the construction of residential attic, the roof based on the corrugated metal corrugated metal, as well as every other roofing surface of the metal, predetermines the use of the underlined waterproofing material, type: TYVEK, SD130, TECHNONICK, IOSPAN, YUTAVEK 115,135, which closes the interconnection insulating layer from the penetration of condensate water.

- The waterproof cloth is decayed with horizontal stripes, from the eaves to the skate, with the inter-high-flyer of 10-15 cm and the sagging between the rafters is about 20 mm, with a further tongue of the junction line of the tape.

- The long side of the profiled sheet is determined by the transverse size of the scope surface, with adding 200 ... 300 mm, for the superstar ride, for removing unnecessary inter-row docks.

- The gap between the pests is set to the thickness of the profile relief and the roofing slot angle: if the slope is more than 15-17 degrees, and the NS-8-NC-25 profile type, the gap between the boards of the dry-cutting structure is made 400 mm, and for C-35 ÷ S- profiles 44 - reaches 70 ÷ 100 cm.

- In order to exclude the lifting of the corrugated hopes of the profiled, with wind gusts, it is better to produce them from the bottom zone of the roof, opposing the main direction of the wind stream.

- The corrugated corrugations are recorded in galvanized self-refining screws, size 30x4.8 mm, with neoprene washers, through the lower part of the corrugations, and skate corners, on the contrary, into the raised corrugation zone. On the eaves, the screwing is made on all the progress of the corrugated person, and the consumption of self-sustaining screws is taken 6 ÷ 8 pieces per 1 m² of professional flooring.

- The vertical trafficking of nesting cubs must be carried out in one wave, however, when the roofing slope slope is less than 11-12 degrees - 2 waves.

To build a house from a bar you can do the forces of two strong men. Although the bar is a relatively light material, but in some types of work, for example, the construction of the roof, not only the physical force, but also the coordination of joint actions. Building a house from a bar do it yourself Significantly save costs, because in construction firms Services to assemble a log of costs are approximately 50% of the cost of materials. Additional expenses will bring the root construction using builders - 10-15% of the cost of the finished log.

To calculate the number of cubes of the profiled bar, for the construction of the house you can use the bar calculator.

As weight wooden house It is much easier than a similar structure of bricks, then there is no need for a deep base bookmark. Perfectly suitable ribbon, screw or buried foundation. In order not to make a mistake in this important issue of choosing the type of foundation and quantity required materialIt is necessary to make a calculation, taking into account the nature of the soil at the construction site. The weight of the house is calculated on the basis of the number of cubic meters of lumber, which is necessary for its construction. When the foundation is dismissed and will become strong enough, go to the bookmark of the first crown.

The first crown is a very important element, it is the contour, which accounts for the main weight and which is the first to be rotting due to the delayed humidity. To avoid this trouble in the future, under the first crown put a wedding board (not less than 50 mm) made of coniferous wood (more often than larch), impregnated with antiseptic for better safety from dampness. The main purpose of this boards is an additional gasket between the foundation and the first crown, which the first will be relevant. This element is easier and cheaper to replace than a whole crown of the house.

Technology construction houses from Bruus called pita, i.e. Each next crown is stacked after complete installation of the crown below. A jute joint seal is laid between the crowns, it is an excellent insulator for bruschers. When using a lumber of natural humidity, it is necessary to take measures to preserve the correct geometry and increase the rigidity after sandbumps at home. For this, every two crowns of the house in checkers are fastened by special brazers from the bar. Depending on the material used, choose different kinds angular connection "In the bowl", "in the paw" or a warm angle.

Special attention is paid to the walls where the cutting of door and window openings is planned, here sizes of BRUSEV Choose based on the size of the outlook. During the construction of a natural humidity bar to avoid breaks and bends of lumber, such a reception is applied. In the walls, where the plan will be windows and doors, part of the bar are layered by the walls, which fragmentary closes the passages, creating a form of a lattice. When the house is completely dry, extra details are cut off.

Paul and ceiling in a house from a bar.

In a new house from a bar The primary floor covering is performed in the form of draft flooring on beams and lags. Later, they fill the draft and finishing floor. For thermal insulation, the attic and the first floor use mineral wool.

Select flooring You can already on the basis of your sketch of the internal design of the premises, their appointments and budget (floor board, linoleum, tile, laminate, etc.). At the stage of finishing work, they are moving to the ceiling.

There are various types of finishes, the most popular option for today is considered to design a ceiling by clap, leaving the massive beams open open decorative element. It looks like this very stylish, and it makes it easy to zonate the premises. Other materials can also be used as a coating: falchbus, plywood, fiberboard, laminated chipboard, plasterboard, stretch ceilings, decorative foam or PVC panels, laminate, etc.

Traditional is the option simple duscal roof with hard mount rafter system and a device of frame filons. Architects are often offered to customers to consider the options for roofs with complex geometry. By choosing in favor of such a roof, you need to remember that after 2-3 years of operation may have a need for repair work.

Features the construction of the roof in the house from the bar This is a separate topic that you need to learn.

Warming houses from a bar and finishing work.

Before starting finishing work, you must give wooden house stand out Even during construction from glued bar It is better not to start the finish immediately after the construction of a church, but let's get dry 3-6 months. When using the lumber of natural humidity, the shrinkage term of the house can be up to 1.5 years. If your home thought how housing for year-round accommodation, it is worth carefully and responsibly treat the question of the insulation of the house outside and from the inside. It will be the key to your comfortable stay in the country house and absence extra cost on heating.

During the shrinkage of the house, the density between the crowns can change and even there is a possibility of the appearance of the gaps. If during the time not to take action, then the house does not avoid heat loss through these weaknesses at home. The correct solution before finishing will be a thorough caulkite with jute fiber. The seal slot process is very long, manually is performed from the outside and inside the house. Hygroscopic thermal insulation must be shielded from the heat of the warm room with a steamproof material.

If you give preference in construction profiled bruusThe internal finish will be enough to paint the walls with a layer of LKM, which will not only fit your design project, but also protects the walls from the effects of sun rays and moisture.

During the destruction, the characteristics of lumber will undergo significant changes that will have to be considered when finishing the house. The changed humidity of the upper layers will also change the condition of the surface of the bar. Before carrying out finishing works, careful grinding will be needed. This is a long process, it may take a few days to several weeks. Only after that you can start the color.

Installing windows and doors to a house from a bar.

Door I. window Operas in a house from a bar It is recommended to fire not earlier a year after the end of construction: it will give time to dry out wood, and the main shrinkage will be completed. To avoid in the future door distortions in the house, in doorway An attic design is installed, called a tag or a soup. In the opening, a box of timber or boards without fixed fastening is installed.

For the installation of the sinks, the Schip-Groove system uses the grooves in the vertical parts of the ends into which the bar is laying. The length of the bar must be less than the height of the opening to ensure natural shrinkage at home. The box is mounted in which the door or window is mounted.

The casing is an effective design for fastening and plays the role of auxiliary enhancement element, fixing the opening in a given plane, helps to avoid deformation of Bruus When changing the moisture content of the sawn timber. Always above top The souls should remain a gap equal to the intended shrinkage value.

Exemplary shrinkage indicators (percentage of total height):

- Natural Humidity Bar 7%

- Dried profiled timber - from 3 to 5%,

- Glue timber - 1%

Do not be attached in the brusade entrance door tightly to the walls. It is important to perform the installation of doors and windows neatly, avoiding the compounds of the mounting foam of the souls with the wall.

First of all, you need to evaluate the cost of buying a turnkey house so that you can understand how much save, engaged in construction yourself. Also in the calculation, take into account that you will need to buy a land plot under ILS (prices can be viewed), that is, already with the documents decorated.

Why exactly a bar?

The reasons why decide to build a house from a bar:

- Inside such a house will always be warm, as the design is high.

- Screw moisture, and then give, if the air becomes dry, which provides a healthy microclimate.

- Bar is resistant to rotting, insect damage and thanks to a special antiseptic impregnation.

What bar is used in housing construction?

Solving how much it costs to build a house from a bar, a type is necessarily taken into account building material:

- Not glued profiled. Products are provided in products that provide hermetic junctions. For this bar is also characterized by a low shrinkage rate. In the house, collecting from the finished elements on the principle of the designer, provides natural ventilation. This type of material is considered the most budget.

- Glued bar profiled. How much does it cost to build a house from glued bar? Twice more expensive than no glued - due to the fact that the material in the preparation process passes more technological operations, including drying, profiling, flame and antiseptic preparation. Such a house is going quickly, because all parts are fitted with maximum geometric accuracy. In addition, it does not need additional finishing work. However, most of the projects made of glued timber - typical. You will also need a device forced ventilation.

- Thermobrus.. This glued profiled timber, supplemented by expanded polystyrene - insulation. It is characterized by a minimum shrinkage and can be operated in the temperature range to -50 ° C. The material is not considered to be "breathable" and more expensive than the glued bar by 20%.

As the elements of the construction affect the cost

Naturally, you will not be able to calculate how much it stands to build a house from a bar, if you do not have a project. Cheaper to purchase a typical project, already tested by developers. The project requires such aspects as the area of \u200b\u200bthe house, the structure of the structure, the location of the rooms and engineering networks. Next, the works are conducted in series:

- analysis of soils on the plot, the choice of a suitable type of foundation;

- the construction of the foundation;

- contour device, first crown;

- grab assembly;

- installation of rough floor;

- the construction of the roof;

- outdoor insulation;

- ceiling device;

- installation of doors and windows;

- laying engineering networks.

Finishing stage - Finish. If the house is from the glued bar, then it can be started immediately. In all other cases, they make a 6-month break for shrinkage at home.

Each of these stages use various building materials, from which the final estimate will depend on. By construction of the house on their own, you will save as much as work costs, but only if you can easily organize and fulfill everything.

Stages of construction and materials

For houses from a bar can be used:

- pile;

- columnar;

- ribbon foundation.

Accordingly, the costs of piles are made in the estimate, the delivery of the material is made. No matter how compulsory, the level of the foundation is taken into account - in most cases it is 500-600 mm.

As for the walls, the cost in this case depends on the complexity of the project and the type of material used. As a rule, for the manufacture of components from European raw materials take 50% more. The acquisition of a set for the construction of a typical cottage from a bar is twice as cheaper than the installation of the "turnkey" building. But not only the manufacturer of the bar is affected, but also the parameters of the material profile.

The type and height of the roof erected is also important - the number of lumber used depends on it. The cost of a suitable roofing material is also taken into account.

And one more point - in order to save, you can wait for the end of the season and profitable to purchase materials on the sale. But only you decide whether you are ready to stretch the project.

When building a house from a log house, you can not reinvent the bike and not spend a lot of time and money for the development of your own, and take advantage of the already ready, the one that will maximize all the requirements. Here are some interesting and completely different projects of houses from a bar who can accurately interest.

№1. Draft House "Family"

One of the most simple, but at the same time spectacular options Houses from Bruus. This is a project of a one-story house, which is perfect for both families in the city, and for permanent residence there. All the necessary premises are arranged here quite compactly and thought out so that in the end the construction did not take extra financial and temporary resources, and the finished house was functional and convenient.

The project provides for a small hallway, which leads to a spacious living-dining room and bathroom. Near the living room there is a small kitchen, the purpose of which consists only in cooking, and you can have breakfast, dining and dinner will be already in the dining room with large windows, it, moreover, has access to the terrace, so in the warm season of the year you can transfer lunch there. The project provides for the presence of three bedrooms, each of which can turn into a nursery. Each bedroom has a huge angular window to maximize the use of natural lighting. But that's not all. There is here place and saunaIn which you can get from the bathroom. A great .

№2. Project of the country house "Terem"

Another wonderful home option for big familywhich prefers to relax all together. The house built by such a project will be convenient and will become a real decoration of anyone. country plot. On the first floor there is an entrance hall and walk-in closetwhere not only all the necessary things, but also some accessories for the execution of garden work. The first-floor decoration is a spacious living room, which plays the role and lounge, and dining area, because it is connected to the kitchen. With good weather, you can move the scene on the veranda, the exit to which is present from the kitchen. In addition, on the first floor, the project provides for the location spacious bathroom with saunawhich will be a great place to relax. Also on the first floor there is provided the location of one bedroom.

From the first floor to the second leads. On the second floor it is proposed to arrange three bedrooms: convenient when there are always a lot of guests in the house or when the family is big. The versatility of this project is that it is well suited as for the conditions country constructionand as a permanent housing within the city.

Number 3. House project "Country"

The layout of the house for this project is great for the construction of it on cottage plot. Places he takes at least just 7.5 * 10.5 mbut its layout allows compactly arrange all the necessary zones. The entrance to the house leads to a tambour, which goes into a spacious living room. Unlike many other projects of the house from the bar, here it is provided separate kitchen with dining areathat is not combined with the living room. From the kitchen and living room there are doors to the terrace for reading in the fresh air - the perfect option for, and from the kitchen to carry ready-made meals. In addition, on the ground floor there is a bathroom and two small bedrooms.

At the attic there are two more bedrooms and a spacious balcony where you can also relax in the warm season. Excellent option for those who like to spend time in big company, because the place in this, it would seem, not so much big House, there will be everyone.

№4. Project of the house "Zhukov"

Comfortable I. economical housewhich looks more than solid. Thanks to his thoughtful layout, the house can be as permanent year-round housing and country house For seasonal stay. It provides for everything necessary for life. On the first floor there is a significant place for a dining room, which can accommodate a considerable number of people. Also, there is a bathroom and a boiler room, and the staircase leads to the second floor. There is a spacious bedroom and a living room, which at night can turn into one bedroom. On the second floor is provided spacious balconywhich can be another holiday destination.

№5. Draft House "Compact"

This project provides for the construction of the most compact and functional house, which will suit for a small family. Its area is 57 m 2, of which living area - 33 m 2. A distinctive feature of the house is a spacious covered terrace that can be used as a place of rest. In the house itself there is a small entrance hall, a spacious living room with a kitchen and a dining area. There is also a small bedroom, bathroom and sauna. Large windows make room light and cozy. Thanks to the original facade, the house will decorate the site.

№6. Draft House "Chic"

Excellent house for big familywhich can be decorated with a country site or perform the role of permanent housing. For a comfortable stay, there is everything you need, and even more. The facade of the house is stylish and attractive, and the planning is perfect. The first floor includes a spacious hallway, where all the necessary things of the whole family will fit. A huge bright living room goes into the kitchen. The area of \u200b\u200bthe kitchen allows not only to cook there food, but also dinner there. The door to the terrace comes out of the kitchen, which is very convenient, because you can very quickly bring all the cooked meals for snacking outdoors. In addition, the spacious first floor allows you to freely place there also boiler room, bath, office and garage - An excellent option for business people who value comfort in everything.

The staircase connects the first floor with the second, on which the hall is located and three very spacious bedrooms with huge windows. Project feature – the second light. Above part of the first floor premises there are no floors, and the ceiling of the second floor becomes the ceiling for them. This technique allows you to make the interior of the house more spacious, air and light.

№7. Project of the House "Surprise"

We have a project that will become a real find for all those who love to relax are interesting and with benefit without leaving home. It is perfect for the country area, but also for permanent residence more than it is forbidden. The total area is more than 280 m 2, and the main feature of this house consists in the presence of three floors. So, the basement includes a sauna, billiard, bath and auxiliary room.

On the ground floor there is a spacious living room, a huge dining room kitchen with access to the terrace: a project, like many others, provides for a simple and fast access from the kitchen on the air to organize dinners - with plates you will not have to go around the whole house. Also on the first floor there is a bedroom, a bathroom, a dressing room and a hall with a staircase leading to the second floor. There is two more bedrooms and a bathroom. Such a house is an excellent option for all occasions.

- square,

- floor,

- type of foundation (determined by the properties of the soil and weighing the house),

- view of the used bar (glued, natural humidity, profiled, smooth),

- the need and type of finishing works,

- the type of roofing system,

- the number of windows and doors.

It is they who have a maximum impact on the final valuable value. From the listed factors depends on the type of work performed and the building materials used. Thus, the full cost of building a house from a bar can be defined as the amount of prices for all works and materials that will have to pay for the customer. For example, on the number of window and door openings Directly depends on the total price for the acquisition and installation of the corresponding blocks.

The cost of building a house of a turnkey bar

Largely depends on the type of timber used, which can be:

- smooth

- profiled

- solid natural humidity

- glued.

They are used for the construction of non-residential facilities, such as products, non-critical to storage conditions. In the process of drying, such a timber is experiencing a multidirectional deformation forces, leading to a violation of the geometry of the walls and the expansion of interventic joints. Due to the simplicity of the design of such projects of houses from a bar and the cost of construction will have a minimum amount among other lumber.

They are used for the construction of non-residential facilities, such as products, non-critical to storage conditions. In the process of drying, such a timber is experiencing a multidirectional deformation forces, leading to a violation of the geometry of the walls and the expansion of interventic joints. Due to the simplicity of the design of such projects of houses from a bar and the cost of construction will have a minimum amount among other lumber.

Giving a section of a profile timber with elements of "spike-groove" provides an increase in the waterproof of the joint and prevents the relative shift of the crowns during shrinkage. The advantage of this building material is the excellent aesthetics of the wall of the walls, which allows you to do without the finish finish or limit ourselves to staining. As a result, the "turnkey" house from the profiled timber is suitable for permanent accommodation immediately after completion construction work - There is no need to wait for the shrinkage.

The best indicators for the aesthetic, the accuracy of the sizes and the speed of completion of the work possess profiled bars with glued structure. For their manufacture, dried wooden lamellas are used. Therefore, the shrinkage of the house from the profiled glued bar can be neglected and proceed with the finishing work "turnkey" immediately after the completion of roofing works.

The cost of materials for the construction of a house from a bar

The financial cost of acquiring materials includes the cost of a bar for the construction of the house and the price of an additional set of sawn timber and auxiliary elements:

The financial cost of acquiring materials includes the cost of a bar for the construction of the house and the price of an additional set of sawn timber and auxiliary elements:

- rafted

- copily

- seal

- roofing,

- facade and interior decoration, etc.

It will also be necessary to purchase waterproofing materials for the foundation and roof. If there are partitions, stairs and attacks in the house, it is also necessary to take into account the price of materials for their manufacture. When purchasing any material, it is necessary to consider the marriage reserve coefficient (for this, the calculated amount increases by 3-5%).

The cost of building a house from a bar do it yourself

Many are solved on an independent assembly in order to save on payment of work in the construction of a house from a bar. However, it is necessary to take into account the costs of acquiring or renting the necessary equipment or tools and the detention service of garbage. It is necessary that the foundation was fully prepared at the time of delivery of a set of Bruusyev to the construction site. Thus, it will be possible to protect the impact on atmospheric lumber.

The cost of building a house from a profiled timber will be minimal, if you carefully follow the project, comply with the technology of work and use quality materials. In this case, alterations will not be removed, in time, finance and laboriousness. In some cases, an excellent option in the ratio of quality and economy of the cost of building a wooden house from a bar for m² can be the assembly of a log cabin with their own hands and attracting specialists to finishing work, or vice versa.

Other articles

Our projects

672000

rub.

Old price: 707000 rub.

Total area: 110.9 m 2

645000

rub.

Old price: 679000 rub.

Total area: 109.5 m 2

588000

rub.

Old price: 619000 rub.

Total area: 143.7 m 2

Many are now dreaming of a comfortable house outside the city where you can spend rest in hot summer days. AND best Material For this building is considered a bar. For the benefit of this material, the small cost of brusade houses, and more environmental friendliness, durability and beautiful appearance of such buildings.

Due to the fact that building materials will now cost expensive, the desire of many household professionals to save on the construction is absolutely justified. And therefore, in this note, we calculate the cost of manufacturing brusade houses, considering the value of this material.

In two floors, a brusade house.

Houses from the logs are considered traditional in Kiev. The technologies of their construction take their own start in the old days and reached our time almost without change. Bruce walls own the same characterities as from logs, with all this cost this material is much less.

Charturing the construction of a house from a bar, you can go 2nd ways:

- Ordering the work of the company which is engaged in construction. In this embodiment, you will need to pay not only for the material, but also for the cost of assembling Bruce houses. But in this case you will get the ready-made building, the entirely cooked in the settlement. Such an option will be allowed for those who do not want to burden themselves with construction work, having finance.

Construction of brusade buildings.

- Do all jobs with your own hands. In this case, you only pay for the cost of the bar for the house, but the work associated with the entire construction is fully fitted with your shoulders. The construction of the house is solid, therefore, solving at such a serious step, you must be completely confident that we will manage.

It is necessary to consider two options more details.

Cost when ordering in a company that is engaged in construction

If you still wanted to trust home the construction of specialists, then you must first know about the list of services that the developer will provide you, and for which, naturally, the fee will be charged. Such works in most cases are divided into two groups: those that are included in the usual list of services and those that are not included.

The construction of a house from a bar of a professional company takes into account such services:

- Selection of material, and still shipping logs to the construction site. In most cases, the construction goes, the size of 240 to 320 mm in cross section.

- The refinement of the material that includes the cutting of logs with a manual option, and still finishing with disinfectants.

- Production of important components, such as rafyled, retaining pillars, overlap beams and subcording beams, and still becoming the holes for the electrocabylide.

- Installation of brusched walls for the prepared foundation, hydro and thermal insulation with laying material for isolation (packle, flax, jute, moss). Application of any equipment for construction work will be paid additionally.

In the photo - the initial moment of the installation of the brusal walls.

- Installation of the system of rafters and retaining columns.

- Installing door and windows.

Taking into account the services described above, the estimative price of the box of the house from the bar will be:

- When operating a simple rounded bar (with taking into account the assembly) - from 160 y. e. for 1m2.

- When operating a profbus - from 180 y. e. For meter Square Square.

- If the material is glued, then the smallest price will be within 180-190 y. e. for 1 m2.

Works that are not included in the list of ordinary services, but for which you will need to pay in the future:

- Paddle, ceilings of an unedged plank.

- Installation of draft floor and lags.

- External I. interior decoration Swiss sealants and linen oil.

- Conducting walls inside (grinding for painting).

- Konopka flane, which passes 1-2 years after the end of construction work.

Taking into account the full range of services, the cost ready projectOrdering a company that is engaged in construction will be:

- For a bath, sizes 3 by 3 meters and with a height of the walls of 2.5 meters - from 5,000 to 5500 y. e.

Bath from Brousa.

- For the house of small sizes, with the dimensions of the walls 4 by 6 meters and the ceiling height of 3 meters - 10-11 thousand y. e.

As you can see, such sums will be suitable not for any site host in the country. And therefore, many are decided to build houses at their own hands, and save with all this considerable funds, because the cost of the house from the bar in this embodiment will be an order of magnitude lower.

Calculate the price of the house with an independent construction

When selecting material for independent constructionYou should look at both the type of building material and its backstage. Further, we will take into account the cost of a bar of 200 mm in size 200 mm, which is considered an excellent option for construction works.

Consider from what indicators are the cost of brusade houses:

- View. Now there are 3 types of bar:

- Ordinary repair. The most inexpensive of these building materials, but there are enough roads in service, because it feels a shortage in a pantry, comes to construction site There is only a rough grinding, because it needs to be coated in hand. The price of such a material will cost you in 160-180 y. e. per cubic meter.

Ordinary repair bar.

Tip! Because such a bar is supplied to the construction site in a unusable form, then its drying is performed specifically in the walls. To prevent it, it should be purchased only from verified suppliers.

- Profiled bar. It has a specialized profiled structure, thanks to it, the assembly process becomes much becomes easier. In particular, such walls do not have needs in a pantry, and the building material comes to the construction site already polished and dried.

Dry (with moisture 18-20%) bar stands hardly by half an expensive than ordinary. Thus, the cost of profiled building material forms 300-350 y. e. per cubic meter.

- Cleaning ram. It is considered the most valuable, because it meets particularly great conditions. It is done by gluing several lamellas, but it does not prevent such a bruk to own all the good qualities of the real tree. With all this, the sediment is not characteristic.

In most cases, such a material is not much more expensive than the profiled, many companies recommend both building material at one cost.

Glued material with profiled composition.

- Crowded. Now the bar can be four varieties, from 0 to 3. and from quantity in most cases, it is based on the cost of the house of the tree from the bar. Zero grade is considered the most valuable, but very often the materials of the 1st and 2nd varieties can occur. Actually, they are considered suitable options for construction work.

Calculate the number of material

Let's calculate how much bar need to build a box of the house.

Instructions for calculating walls from the outside implies a couple of stages:

- We find the dimensions of the walls, a multiple length. Square walls from the outside are summed up. For example: 4 x 3 x 2 + 6 x 3 x 2 (for the house, 4 sizes 6 meters from the height of the walls of 3 meters). Acquire 60 m2.

Tip! The presence of a plan of the house will make it easier for the calculations by freeing you from the measurements of the walls.

- For accuracy of calculations, it is necessary to subtract from the area of \u200b\u200bthe walls. The area of \u200b\u200btechnical holes, in other words of the area of \u200b\u200bwindows and doors. For example, the door area is 1.8 m2, and 2 windows 1.28 m2. The whole area of \u200b\u200bthose. Holes - 3.08 m2. We subtract: 60 - 3.8 \u003d 56.2 m2.

- To translate sq.m. In cubic, it is necessary to multiply the wall dimensions on their width, finding the volume in a similar way. 56.2 x 0.2 \u003d 11.24 m3 It is necessary to build a box of the house.

Plan Bruce Houses.

Conclusion

In this article, we looked at the cost of assembling brusade houses and the price of the most building material, if you want to build the construction with your own hands. We also led an example of calculating the material to the house, so that each can understand the calculation method itself. No less useful information awaits you in the video in this article, we look at!