11.04.2013

The modern panel can not be compared with panel houses of twenty years ago, since today's technologies allow you to build a house that will look like also as a monolithic brick, and its internal state in some cases will be even better.

House-building fabrics confidently declare that the modern three-layer panel in its characteristics (heat, sound insulation, etc.) corresponds to a meter brickwork. The covered sides of the panel still remain - joints and seams. But if all technologies are observed during construction: as it should be insulated, insulation, tenants panel house There will be no discomfort.

"Over the past ten-fifteen years, the technology of panel house-building has been seriously evolved," the representative of the Su-155 GK says. - They did not have problems familiar to everyone who had dubious pleasure to live in Soviet panel high-rise buildings: bad noise and thermal insulation, poorly sealed seams, etc. Now at the level of comfort, the available panel housing was equal to much more expensive analogues: for example, produced on DSC "Trokovitsa" for houses LCD "Kamenka" Wall panel 40 cm thick on insulating indicators is ahead of twice the thicker brick wall. "

How is the quality of panel walls regulate?

All modern panel houses have similar designs. For example, such popular panel series, like P-44, CAE, P-111, all three-layer and have thermal insulation.

"Outdoor panels are three-layer: There is a heater (polystyrene) between the two layers of concrete," says the existing standards of Sofya Lebedev, General Director of Miel-New Building. - Also inside the heat-reflecting metallized film is invested. In such a three-layer panel, the thermal insulation coefficient is similar to a brick wall with a thickness of 90 cm. "

Interior Walls B. panel houses different series are about the same, while the width of the outer walls in more than Depends on the design of the building. Large scatter in the thickness of different series is associated with the fact that, in contrast to monolithic structures The outer walls in the panel houses bearing, so the higher the house, the thickness of the wall on the lower floors. The thinnest outer walls in the panel buildings on the upper floors.

As for compliance with standards, then improvement construction technologies It made it possible to exclude from the list of mandatory standards that correspond to all modern housing. For example, known SNiP 23-02-03 "Thermal protection of buildings" and SNIP 52-01-03 "Concrete and reinforced concrete structures" from 2010 passed into the category of rules arches (documents, which are voluntary).

But uncontrolled panel constructionOf course, it did not. The representative of the SU-155 GK notes that the production of reinforced concrete products and the construction of buildings of them is strictly regulated by GOST. For example, the three-layer wall panels that the SU-155 GC uses available housing in the construction of the available housing, correspond to GOST 31310-2005 ("Three-layer wall-plated panels with an efficient insulation"). This standard places the requirements for the insulating properties and thickness of the concrete and insulation layers, the number and quality of the reinforcement, the ability of the panel to withstand the load, accuracy of its geometric sizes and other important parameters.

How to check the quality?

Check the quality of the walls of your future home for compliance with standards is possible. Most construction companies allow potential buyers to visit construction site His complex and inspect the wall panels ready for installation. Such an inspection allows you to make sure that there is a compulsory heat insulating layer with a thickness of 190 mm, as an external coating and metal-plastic windows (and the other is installed in the panel still in factory workshops).

In the panel houses one of the weak points - the joints between the panels that the buyer can see when inspection. "You can check out any elementary things: Does not blow from the seams, for this they light a candle and look like a flame behaves," says Sophia Lebedeva. - some moments can be revealed during repairs. If this happens, you can write a claim to the developer so that it corrected the defects. "

But to identify the marriage of the panel itself, the buyer is most likely not able. Such a marriage occurs during production at the factory, but often the technical control department discovers such violations on time and does not allow the output of panels with defects.

Is the developer savors on quality?

Developers who care about their reputation are not trying to save on quality. There are honest ways to reduce costs. For example, many companies that have large volumes of construction, most often create their own production and construction and assembly bases that are located in the area. For example, the SU-155 Group of Companies has its own production and a construction and assembly base in the SFR, which allows them to reduce the cost of the square due to the minimum share of the external order and large volumes of construction.

Opinion:

Vladimir Sparak, Deputy general Director An "Arin:

About 70% of buyers prefer apartments in brick and brick-monolithic houses. The preference of the brick panel can be called a peculiar tradition of the Soviet era, when brick houses were considered better and more comfortable for living. Nevertheless, the modern panel, especially the Scandinavian developers, allows you to build houses that externally look almost the same as brick-monolith, and the inner state of the house in some cases will even better. In particular, modern technologies The seamless panel allows you to avoid complaints about the flowing seams, as well as improve the noise and thermal insulation.

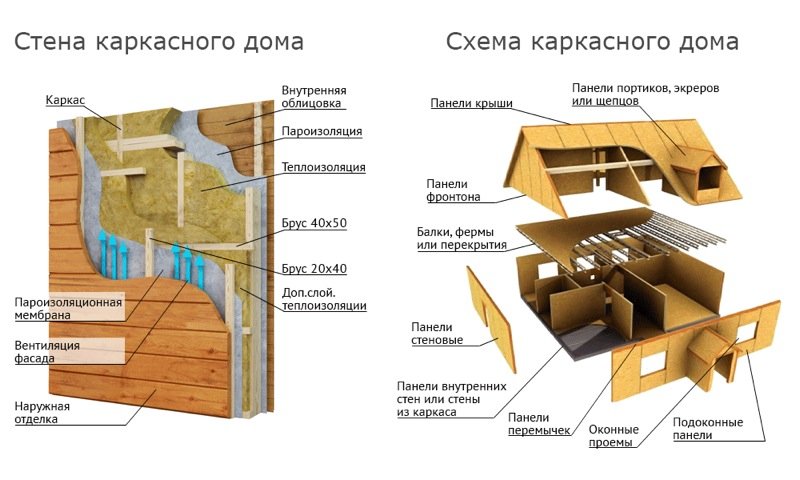

Principle frame technology It is that the framework, which is, anterorant-beam design, is erected from durable material - metal or wood, and the walls are filled with thermal efficient and inexpensive materials.

Previously, saman, clay, porous stone used in the walls, and today apply new materials that allow you to make the house even easier and warmer. At the same time, the main advantages of such a building remain unchanged: economy, heat efficiency, the speed of construction, the savings of the area due to the smaller wall thickness.

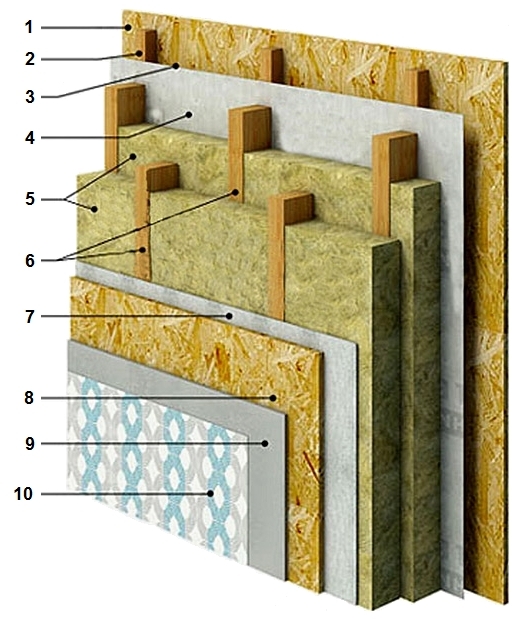

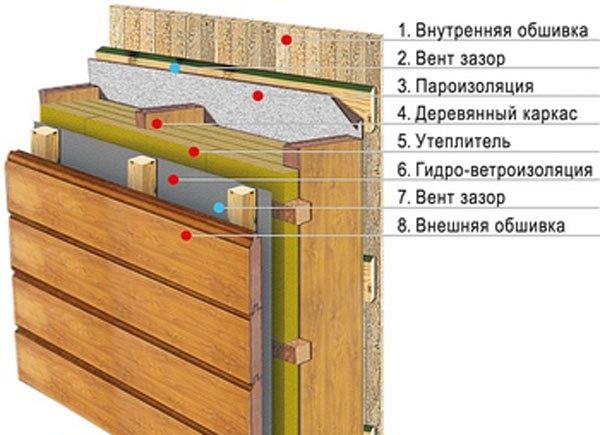

1. OSB plate (OSP), base for outdoor decoration; 2. Controlling, forming ventilation gap; 3. Ventilation clearance; 4. Windproof in the form of a vapor-permeable membrane; 5. Fiberation insulation (basalt insulation); 6. Independent dual frame racks; 7. Parosolation; 8. Internal OSB plate (OSP); 9. Glk, base for interior decoration; 10. Layer of interior decoration.

Modern skeleton design - Multi-storey, if it is erected, knowledge, experience and care, which far from always inherent in builders are required. As a result, since the frame houses are very sensitive to the quality of construction, an incredulous attitude has been formed. Myths about their negative qualities do not consider.

Myth 1. Frame house is short-lived

Different types frame houses List from 30 to 100 years. This indicator depends on the quality of the frame and the insulation and their safety in the design.

To ensure the durability of materials, it is important to prevent moisture from entering the wall. The durability of the tree and metal under conditions of normal atmospheric humidity and with proper processing exceeds 100 years.

Weak link - insulation. The house with polystyrene foam insulation will serve at least 30 years. The use of a rigid mineral wool material will increase the service life of the building without repairing the wall to 60 years and more. However, these deadlines are justified with high-quality implementation of the house, when fasteners and protective films have a high degree of reliability, providing tightness of the structure for long years.

Significantly reduces the durability of the structure. Use for a raw wood frame. As the tree in the constructed house dries up, racks and beams change their geometry, the casing is disturbed, the slots appear on the joints, so it is necessary to carefully monitor the moisture content of the material for the frame (for this you can use a special device - moisture meter). The tree should be dried natural or artificial (vacuum drying) in the way.

Myth 2. Frame house cold, he will not stand frost

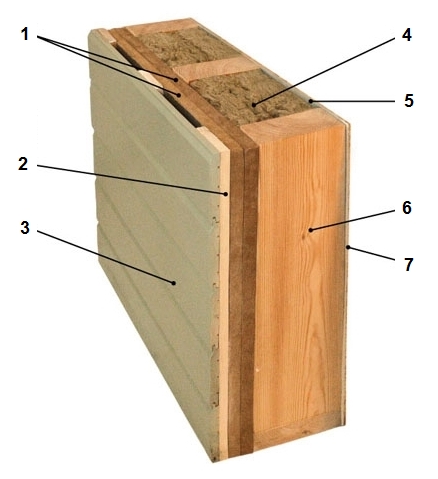

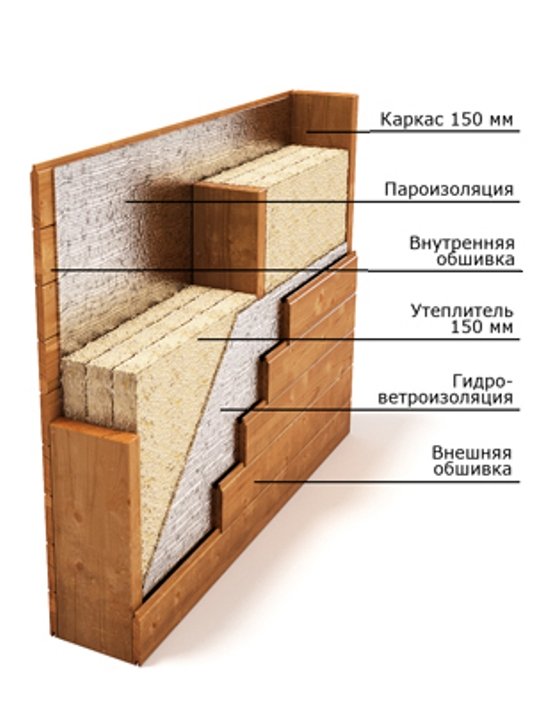

On the contrary, one of the most important merchandise of frame houses is the high energy-saving quality of the walls. They provide a layer of insulation with a thickness of 15-20 cm, located inside the wall between the frame racks. But insulation can be more serious - both in frame houses with increased energy efficiency, additionally insulated outside.

Warming of a frame house with a spraying of polyurethane foam (PPU).

Warming of a frame house with a spraying of polyurethane foam (PPU).

Such a solution also levels the bridges of the cold, which occur in the location of the frame racks. The tree, although it has a relatively low thermal conductivity, but still greater than the thermal conductivity of the insulation. The heat transfer coefficient of the outer wall of the standard frame house without an outer insulation is 2.9 m * ° C / W, the design of the "shelter-insulation-insulation" - 3.4 m * ° C / W, and at home with an outer insulation of extruded polystyrene foam 5 cm thick - 4.7 m * ° C / W. The lowest value is already complied with the standards. In addition, the variation of the parameters of the insulation allows the use of the same structures as in the southern and in the northern regions.

Myth 3. All frame houses are built on the same technology.

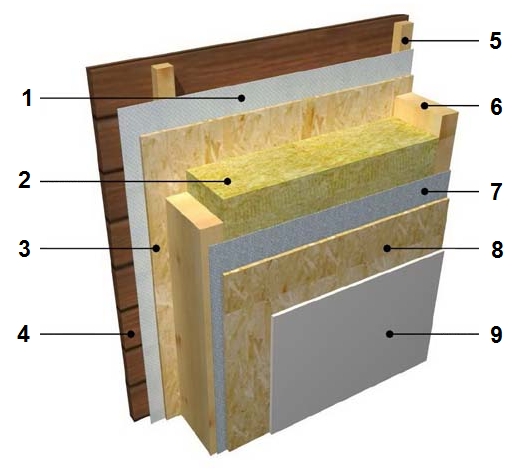

The concept of walls in all frame houses are really the same: between the frame racks there is a heater, protected from the inside of a vapor barrier film, with an outer-waterproofing superdiffuse (transmitting pairs) membrane. On both sides of the frame and the insulation are protected by a rigid trim, various sheet mothers: oriented chipboard (OSP, OSB), cement-chipstones (CSP), waterproof plywood, plasterboard sheets (GLC). Similarly, overlaps are arranged.

However, different types of buildings have significant differences in the methods of construction, materials and nuances of the structure.

Differences between frame houses consist in the features of the wall design. Materials, thicknesses and the number of layers of insulation, plating, vapor and waterproofing, the design of overlappings (on beams, farms or panels) can be different. Thus, the generalized name "Canadian houses" does not describe the entire variety of frame structures.

These types can be distinguished:

houses with wooden frame and insulation from basalt wool and a wall thickness of 18-25 cm (frame and frame-panel);

houses with metal frame , insulation from basalt wool and wall thickness 18-25 cm (frame);

frame-shield at home with insulation of polystyrene foam and wall thickness 12-25 cm;

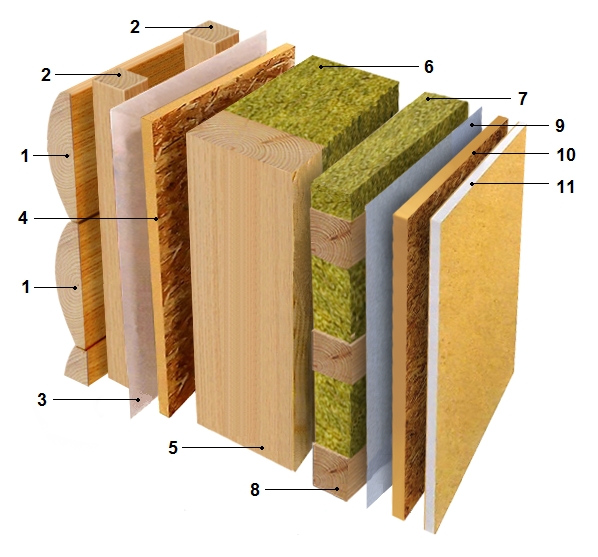

premium Houses with a frame of glued timber , several layers of insulation and wall thickness up to 35-40 cm.

Summary: Frame houses are distinguished by design, assembly technology and heat engineering properties.

Than insulated frame house?

Insulation, which are used in the walls of frame houses, must ensure thermal insulation of the house not lower than the normative layer with a layer thickness of about 15 cm (this figure is determined by the size of the frame cross section).

Mineral (basalt) wool

(sufficient thickness - 15 cm). This material also has good sound insulation qualities. The insulation plates should be rigid so that over time their shrinkage and the reduction of energy efficiency of the walls of the house occurred. Basalt Wat is the most common insulation in skewhouse houses.

Foamed polyurethane foam (PPU), sufficient thickness 10-12 cm). This is a durable, hard material. His drawback is that during the fire it highlights a poisonous smoke, so in the wall it should be insulated with a trim (which just corresponds to the design of the frame house). Polyurethane foam is used in some types of framework-shield houses of factory manufacture.

Ekwata. - Heatel from cellulose (thickness 20 cm). The material is a homogeneous mass resembling cotton. When the walls are insulation, it is covered between the trim or moisturize and apply on a warmed surface using blowing equipment. With a moist application method, the material, frozen, is tightly grasped with the structures (due to the lignin - wood glue present in it, natural binding). To reduce the flammability, the EcoWhat includes antipyrenes.

eco spraying:

alignment of laid layer

Properties of mineral wool

The effectiveness of thermal insulation material for a frame house is made up of several aspects:

thermal insulation properties, environmental and fire safety, ease of installation and durability.

These criteria correspond to plates from mineral wool - non-combustible material, which is especially important to ensure fire safety of wooden frame houses. High-quality stoves from stone wool are not burning, they do not emit smoke and flaming droplets, in addition, they serve as excellent acoustic insulation. Mineral wool is a hydrophobic (almost not absorbing moisture) and plus it does not absorb moisture from the air. The main raw materials in the process of producing this insulation are basalt and gabbro. Molten rocks at a temperature of 1400 ° C are subjected to separation on fibers, forming stone wool. Thermal insulation products from this material when right mounting and operation are capable of listening over 50 years. The insulation in the frame design should be laid tightly to the racks (the versius is installed), there should be no gaps between thermal insulating plates. Depending on the type of frame design, steam barrier and windproof may be required.

Thermal inertia frame wall

Feature frame wall - Its low thermal inertia (the ability to accumulate heat, and then gradually give it). High inertia inherent in brick, concrete, less - wood, so the cold house with stone walls heats up slowly, and when the heating is turned off, slowly cools. In a frame wall, except for wood, a significant part of the mass is a heater, which heat does not accumulate. This means that the house with frame walls is quickly heated, since it is not consumed heat for heating the wall, but also quickly cools when the heating is turned off. Low thermal inertia is not positive or negative quality, but it must be taken into account.

Walls with high thermal inertia smoothes daily fluctuations in temperatures, and in the house with frame walls they will be more pronounced. In winter, they will have to smooth out due to the dynamism of the heating system (its ability to quickly heat up when it turns on and cool when it is turned off, which is more inherent electrical systems). But from a low-cost wall will never have a cold and dampness. And if necessary, the thermal inertia of the frame house as a whole can be improved by the use of reinforced concrete foundation Plate (which is very convenient when erecting such buildings), more massive finish (for example, when used in the trim two layers of GLC).

Myth 4. The wall of the skeleton house is continuing, it can be broken and climbed into the house

This is the proportion of truth - the brick is stronger, but it's hardly a thieves to break the wall when it is much easier to climb the house through the window or the door. The design of the standard wall of the frame house is similar to the roof design and has about the same thickness. However, it's not easy to destroy it. OSP, which the house is cited outside, the stronger the wood array of similar thickness due to its multi-layer structure. Even stronger CSP. The covering along with the frame gives the wall with the necessary rigidity and stability.

Especially high strength (due to the rigid interconnection of the layers) is the wall from the factory manufacturers and walls of houses with several layers of insulation. The strength of the house itself is also sufficient. Many foreign technologies are designed for seismic sustainability up to 7 points. In addition, due to the ease of construction, frame houses without enhancing foundations can be built on soils with a small bearing ability, without fear of distortions and cracks.

Summary: Frame houses are durable and resistant to natural cataclysms, but against a person who is firmly intended to break the wall, he may not resist.

Myth 5. The frame house does not breathe, it always stuffy

In fact, in any house, a healthy microclimate provides only ventilation, regardless of the material of its walls. Myth is based on an erroneous idea that brick walls Breathing - passes through themselves excessive moisture. However, according to experts, the diffusion of steam through the vaporonic wall is insignificant compared to its accumulation in the residential premises. In old houses, including brick, ventilation provided slots in the windows and doors, underground and in the attic.

Myth 6. Frame house is not environmental

Most frame houses meet the requirements of environmental friendliness, and many of them have relevant European certificates. A tree or metal from which the framework is made belong to the most environmentally friendly of well-known materials. Stone wool, which, as a rule, is used in frame houses, is positioned as neutral, not harmful to health material (although there are different opinions on this). The polystyrene foam used in the most economical buildings at temperatures below 85 ° C is also not dangerous, in addition, in the wall it is completely isolated from indoor space trim. Inside the walls, the GLCs are crushed, the environmental friendliness of which does not cause doubts, or OSP, 95% consisting of wood (the percentage of harmful binding resins is reduced to a minimum). Insulating films in the composition of the wall are environmentally neutral. Overlapping in frame houses are performed by wooden beamsPartitions - based on wooden carcass.

Of course, if the frame house is too cheap, the likelihood of the use of poor-quality materials, dangerous for the health of materials. But such a danger may occur not only in the construction of frame houses. In any case, if you doubt as components, require environmentally friendly certificates and conclusions of the SES.

Summary: As part of the designs of a high-quality frame house there should be no materials that are harmful to health.

Housekeeping technology and environmental friendliness

To date, there are three technologies for building prefabricated frame houses: 1) frame, 2) panel and 3) frame-panel (Canadian). They differ from each other with nuances of construction. In the first case, enveloped structures and inner partitions (walls) are mounted on the erected frame. With panel house-building, the walls of the house do not need additional strengthening, as they themselves are carriers.

Myth 7. Frame house fires

In such buildings, all carrier elements of walls and roofs should have fire retardant treatment. Are also desirable to be sewn them from the effects of high temperatures leafy or plate Materials. It is precisely the trim from CSP and GLK - non-combustible materials. The casing of two layers of GLC will increase the limit of the fire resistance of the design for 30 minutes (and at the same time will improve the sound insulation of the wall). And in general, the limit of fire resistance structures of frame houses is 30-60 minutes, which meets the standards and should be reflected in the manufacturer's certificate. Also, fire safety requirements should be taken into account when placing a house on the site. Between frame buildings requires a greater fireproof distance than between stone.

Summary: The degree of fire resistance of frame houses is lower than stone, to increase their fire safety wooden designs Frames are treated with antipirens and used DM of the inner casing two layers of GLC.

Myth 8. All frame houses are built by typical projects.

Indeed, each company that builds frame houses has in its disposal in detail of the designed typical projects, the designs of which are included in the factory production programs. But if necessary, the company's project office is developing individual project Or adapts to the framework structures that already have the customer. The construction of the house in this case will cost more than a typical project for which the production of structures has already been established at the factory. In addition, more time will take place from the start of design until the end of construction.

Summary: The frame house can be built both by typical and by an individual project.

M.iF 9. Frame house is unpredictable in appearance

This cannot be agreed. The frame house is only the technology of construction. And his appearance Depends on the finishing and architectural qualities of the project. The decoration is used as for houses from stone materials: plaster, painting, ventilated facade with the use of siding, block house, etc. It is also possible to facing walls with brick, and the base of the stone (the wall is not recommended to separate the wall). In architecturally, the project of the frame house does not differ from the projects of buildings from stone materials, and almost any of them can be recycled for frame structures. Thus, the frame house may have a completely representative view.

Myth 10. All frame houses are cheape.

The cost of construction of a frame house ranges from 150 to 1200 $ / m². Such a wide range is due to various technologies and the possibility for the customer of the degree of readiness of the construction: from the acquisition of a set of the house for an independent construction before turning turnkey. Within the framework of the same technology, cost fluctuations are possible depending on the materials used. For example, a house with a frame of glued bar is more expensive than from the array. It matters material insulation and trim, etc. Houses with insulates from polystyrene foam is cheaper than from basalt wool, an insulating of an OSP is cheaper than from CSP.

With additional insulation, the cost of the house will increase. Some technologies use import energy efficient windows and doors, especially reliable membranes, which also increases the cost of construction. But in general, on consumption of material and labor intensity, frame walls are most economical. This is due to the smaller volume of the foundation and walls, as well as with a lower price of the insulation compared with massive materials.

The cost of 1 m² of a standard frame wall with a thickness of 20 cm 1.3 times cheaper than the walls from the bar, 1.7 times - from the foam concrete blocks and 2.2 times - from the brick (with the same energy-saving ability and different thickness of the walls required for it achievements). But too low price It should alert: perhaps the carcass tree will not be insufficiently dry, the casing is minimal thickness, etc. It should always be ensured as structures and materials for assembling at home. Reliable quality indicator - certificate of compliance with European standards (construction, energy-saving, environmental), as well as a guarantee provided by the company (for the highest quality frame houses, it is 30 years old). One of the advantages frame construction - Investment transparency and accuracy of estimates. The cost of the kit of the house is determined individually after the development of the project and then does not change.

Summary: The range of 1 m² of frame houses varies from the cheapest to elite.

A frame house is an opportunity not very expensive and quickly solve the housing problems of the family. Durable, practical, warm house - this is light designwhich is able to simultane more than a dozen years. At the same time, it does not require a complex heavy foundation for construction, but the complexity is skew walls. Wall structures should be properly insulated and waterproof, then your home is not afraid of any temperature differences, the microclimate will remain comfortable and the house will really gain comfort.

Inexpensive does not mean bad

The main popularity of the technology is enabled in the possibility of using inexpensive building materialsthat reduces the cost of the project price. Minimal wood use, lack brick masonryThe blocks of gas, foam concrete - this parameter greatly facilitates the total mass of the structure, and therefore it is possible to save on the arrangement of the bearing basis without losing the practical and strength characteristics of the entire house.

Another positive moment is fast installation of walls at home. Technologically, the box is raised literally for 4-6 weeks, and there is no further shrinkage, which gives savings time for construction. A simplified design and manifold of projects allow you to implement the most difficult planning without special financial investments.

Interesting! Frame walls perfectly hide communications, so during construction does not have to additionally mount the box that hide elements, which is also very convenient.

Structurally, the house consists of carrier carcass, insulation, which is laid inside, external and inner skin, supplemented by layers. The impressive list of advantages of technology can be concluded in the following: the wall of the frame house with a minimum thickness, in relation to any other type of development, retains all practical qualities, while maintaining the best relationship of building area to the useful area of \u200b\u200binterior.

Depending on the type and thickness of the insulated insulation, the wall panels possess the following power saving parameters:

- minvat thickness 150 mm \u003d R 3.2;

- minvata thickness 200 mm \u003d R 4.3;

- polystyrene foam 150 mm \u003d R 3.7;

- polystyrene foam 200 mm \u003d R 5.

Important! To ensure the conservation of all qualities, the frame house should be erected from dry lumber. The use of raw items will lead to a drying of the structure, and therefore the appearance of deformation, weakening the fasteners. Subsequently, the house will require repair and renovation. Frequently used boards have parameters 150 * 50 mm or 200 * 50 mm, the width of the elements depends on the thickness of the insulation used. Outdoor covering allows the use of OSP plates, plywood with the desired level Humidity resistance, CSP, in addition to protective functions, the casing gives the frame strength. As a heater, the usual dense mineral wool is well suited (cotton must count on the example of a vertical design, not horizontal, otherwise it will slide) or a layer of polystyrene foam materials.

The use of foam - measure is cheap, but not the most profitable. In order for the foam to hold well, you will have to close all the gaps and joints of the mounting foam. The cost of such attachment reduces the difference in price, and sometimes increases the total cost of work. In addition, the foam - the material in which the nests of rodents often arrange, and this quality is clearly negates all the advantages.

One of important elements arrangement frameless walls - Installation of vaporizolation. The materials are lined with the outside, protecting the insulation from wetting. The tightness and quality of vapor insulation materials should be very high, in addition, all the cracks are necessarily sided with a double ribbon. However, if you use polystyrene insulation, vaporizolation is not required, since the material itself perfectly removes moisture.

Important! The presence of vaporizolation creates inside the walls a closed air environment, which means that ventilation is necessary. The arrangement is thought out at the project creation stage.

Construction of a skeleton house can be produced in two options:

- the use of piece materials, the preparation of which, sawing and assembly is made at the construction site;

- the use of large-pointed dimensional elements called shields. Production making allows for industrial options, the material is delivered to the construction site in the desired configuration and only assembly and installation is made on the spot. The process is rather light and fast, however, the weight of the shield structures sometimes requires the use of special equipment.

Tip! The shield technology is available in several versions: the presence of only one-sided skin, which implies the arrangement of the plating on the other side of the shield after the construction of the box and the presence of two-sided skin. In the second case, the wall of the frame house is fully prepared and you only need to install them in place. As a rule, it is a panel sip equipped with a thick layer of polystyrene foam, which performs two functions at once: thermal insulation and vaporizolation. In this case, the panels have increased strength, in comparison with the standard framework frame.

Disadvantages of wall frame structures

One and the main minus is a cluster of moisture in the frame. This problem may arise in the thickness of the insulating material and will lead to the fact that corrosion plaques will appear, mold, dampness. Such a house will not have a short time.

Therefore, it is very important to choose the most high-quality insulation and to hydroize it as carefully. At the same time, it is necessary to ensure that the thermal insulation fell not to taste rodents, bugs, was not susceptible to rotting and deformation. As soon as this problem is solved, you can build a house that gives more than a dozen years of impeccable operation.

Frame walls: elements design

The structure of the wall of the frame house has several mandatory nodes: a rigidly connected frame element with the presence of horizontal strapping, added structures, vertical racks, an internal filler and a trim. In the context, such a "pie" looks like this (materials are given with standard construction):

- sheathing from imitation of timber;

- doom;

- membrane vaporizolation;

- wood plate (chipboard);

- wall frame design (board, timber);

- thermal insulation material;

- soundproofing;

- plywood stove;

- exterior finish.

Now consider what "cake" is especially right. The technology requires only high-quality dry wood, otherwise the drying will lead to irreversible consequences. For example, a raw width board of 150 mm in the drying process will turn into a width board 145-147 mm, which means 3-5 mm gaps that will significantly reduce the thermal qualities of the house.

Warming implies application miscellaneous material, the main thing is that it sustainably held in the vertical plane, did not roll and was not going to harmonica at Niza. It is best to use a slab material or fix the sheets of foam.

Parosolation is always shut-off, bottom up. The allen line is indicated on a roll of dotted line or a feature.

Important! The thickness of the thermal insulating layer is selected taking into account climatic features Region.

Depending on the applied wall panels, sometimes it happens that the thickness of the thermal insulation is slightly larger than the inner cavity of the wall frame. Solving the problem is the use of an additional wooden frame or a slab element mounted under the outer cladding. It doesn't matter what kind of construction option is chosen, the cake layers are hard and secured through plastic sleeves to minimize the risks of isolation deformation. The frame racks should not be located in more than 0.6 m.

The construction of houses and bathing technology includes a plurality of stages. One of the important and long-lasting is the installation of walls of a frame house. The article we will discuss how to properly perform construction work, what is the structure and device of the wall of the frame house, as well as how to avoid major errors in the construction of the structure. If you neglect the main rules and technology of work, the service life will decrease significantly, and the quality of the structure will be questionable.

Structure of wall structures and materials for construction

The frame structure is one of the varieties of wooden buildings, which is known for the speed of assembly, good thermal insulation characteristics and long service life. Such a technology for the construction of structures is distributed in many European countries, in Russia, it is also gaining popularity every year, contrary to the outdated opinion about this type of development, as an unreliable temporary dwelling.

If the frame house or the bath is built exactly with the technology and using only high-quality material, then with the appropriate finishing works, they are difficult to distinguish them from the log cabins erected from a solid bar or log. However, there is a significant advantage - for the structure under consideration it will take a much less lumber than for a fully brusade log cabin, and the construction time of such a structure will be much smaller. With competently performed works using the labor of qualified specialists, you can get absolutely ready-to-use house for three weeks (with the exception of the foundation if the tape type of base is used).

Consider the main materials and tools. For construction, you will need: Bar 100x150, 100x100, 100x80 (for ceiling beams) and 100x50. In addition, it is necessary to stock imports, nails, corners (metallic) and construction tools:

- Construction level;

- Fixtures for cutting wood (manual circular saw, ending, hacksaw);

- Drill with sweepers;

- Screwdriver, bits to it;

- Roulette.

The main material is selected for the drying in special chambers. It is important to take into account so that shrinkage processes occupy a minimum of time.

What is the wall?

The walls of the frame house can be considered one of the types of sandwich panels, including the main framework, thermal insulation and trim. Most often, the same material is used for exterior and internities, but sometimes inside it is carried out with elements with special decorative properties. Often, plasterboard sheets are used for internal work, because it is convenient to mount it, as well as plastering with further finishing works. Outside the wall of the frame house is often blocked by brick. This reduces the loss of heat and give the whole structure an interesting appearance.

The standard design of the wall of the frame house involves the presence of a lower strapping, a sidebar of thermal insulation, finishing and waterproofing material.

Assembly work

All components of the elements that will be needed with the further construction of wall structures are acquired only after the decisive structure of the structure indicating the size and layout of the house. Specialists recommend purchasing slightly more basic material due to the fact that construction workah some quantity can be spoiled, and the components break, rushing and so on.

After the accuracy of the calculations and the purchase of all the necessary can be proceeded to the main actions:

- The first thing for the foundation is laid waterproofing, most often used rubberoid or other installed materials, but solid work is possible to prevent moisture effect on wood frame, strapping and lining. When choosing belt Fundament It can be fully treated with primer;

- Next, you should make the bottom strapping. It uses the selected lumber with a cross section 100x150. As angular connection Used type "hardwood". The bars are superimposed on each other. In places of the corners, small holes are drilled (drill with an optimal drill diameter can be used for drilling). They are driven out of wood or metal. The brace must perform above the surface of about 10 centimeters. The side rack will be fixed on top. For greater strength, the location of the lumber is fixed with several nails or long-length self-stairs. To the foundation, the strapping is attached due to the anchor bolts;

- After the manufacture of the lower strapping, it is necessary to prepare fastenings of internal racks. The grooves of the desired value are cut across the entire length. The distance between them is made no more than 50 centimeters;

- For mounting racks, similar holes under the impulse are also drilled, which are slightly larger. Further, the side racks are installed on the heater and are temporarily secured by a special backup. Internal racks can be mounted using metal corners. Such corners are placed in one edge to the rack with self-draws, others - to the strapping. In addition, in some cases, a temporary backup is attached;

- The upper strapping is constructed in the same way as the bottom. However, there is one nuance here. For construction work at the height will have to resort to the use of a staircase or such a device, for example, scaffolding;

- To ensure windscreen walls of a frame house, construction is strengthened and make more rigid. Instead of the cuts set for time, hard struts are mounted. They can be both small and long. So the frame will become more resistant to wind loads;

- The next stage is the installation of floor beams and ceiling. The distance between them does not exceed 50 centimeters, the "hardwood" is connected, as well as through steel corners.

After the frame base is assembled and firmly fixed, proceed to the trim and heat-insulating work. As can be seen from the above process, the bar is required not so much, but the insulation in the rolls will need significantly more.

Work on finishing and insulation

The finish and insulation of the walls of the frame house takes place also in stages:

- The outer side of the finished frame is trimmed with a rolled insulation (the use of rolled insulation contributes to the high-quality warming of the frame house). A doomle is installed on top of it, which is further trimmed by a block house or similar finishing material;

- All space between the racks is filled with insulation from the inside of the structure in such a way that there are no cracks and lumen. It is additionally fixed to avoid inconvenience in subsequent works and operation of wall structures;

- On the interior walls The frame house is placed in hydro and vapor barrier in rolls, the drywall sheets or other sheet materials for the skin are mounted on top, the finish works are carried out after going to the house under the roof. If the internal finish is decided to use drywall, operations for its installation are also carried out after installation of rafters and roofing material.

We reviewed important momentsthat will help you independently erect frame structure. But if you don't have at least a small experience of construction work or you are not sure about your abilities, it is better for fast and well done work to seek help from specialists.

Build the walls of a frame house correctly - we get a quality result!